HD Electric VarCom 1600 Instruction Manual

VarCom®1600

VarCom

®

C mmunicati ns Ready

C A P A C I T O R C O N T R O L S

Model 1600 & 2600

Operating & Instruction Manual

VarCom®2600

1475 Lakeside Drive • Waukegan, Illinois 60085 U.S.A. • 847.473.4980

fax 847.473.4981 • website: www.HDElectricCompany.com

2

Overview ............................................................................... 3

Installation .............................................................................. 4

Current Sensor ............................................................................4

Fusing .................................................................................. 5

Manual Operation ....................................................................... 5-6

Programming for Automatic Operation....................................................... 6-15

Settings Common to All Models ............................................................ 6

Setting the Control Mode ................................................................. 7

Schedule Settings .................................................................... 7-10

Other Settings ...................................................................... 10-11

Voltage Settings ..................................................................... 10

Temperature Settings ................................................................. 10

KVAR Settings ......................................................................... 11

Reverse Power Set ................................................................... 11

System Monitoring ..................................................................... 12

Neutral Current Monitoring............................................................... 13

Clock Back-Up Battery ..................................................................... 13

LED Indicators ........................................................................... 14

LCD Display ............................................................................. 15

Specifications ......................................................................... 16-17

VarWare Programming and Data Analysis Software .............................................18-22

Software Installation .................................................................... 19

Using the Software for the First Time ........................................................ 19

Create a Control Program .............................................................. 19-20

Upload a Setup Program to a VarCom Control ................................................. 20

Use Profile Data Logging .............................................................. 20-21

View and raph Downloaded Profile Data ................................................. 21-22

Real Time Monitoring of the VarCom Capacitor Control .......................................... 22

Limitation of Warranty and Liability ........................................................... 24

WARNING: Prior to installing, operating, maintaining or testing this equipment, read and understand the

material in this manual. Failure to comply can result in death, severe injury and equipment damage. These

instructions are intended to supplement, not replace, local safety practices and procedures.

VarCom Capacitor Controls set the standard for ease of use by providing sophisticated control and

monitoring capabilities in an intuitive easy to use package. VarWare Windows™ compatible software

extends these capabilities.

Please visit our website for the latest information on these and other quality HD Electric Company products.

www.HDElectricCompany.com

VarCom

®

C mmunicati ns Ready

C A P A C I T O R C O N T R O L S

Model 1600 & 2600

3

OVERVIEW

The VarCom 1600 and 2600 Capacitor Controls utilize user selectable functions and

parameters to control switched capacitor banks. The VarCom 1600 controls with time,

temperature and voltage and the VarCom 2600 add Amps and KVAR control.

TIME - The Control will close the capacitor bank when the user selected CLOSE TIME occurs.

The Control will open the capacitor bank when the user selected OPEN TIME occurs. Both

settings are subject to the weekend settings.

OLTAGE - The Control will close the capacitor bank when the sensed line voltage drops

below the user selected CLOSE VOLTS setting. The Control will open the capacitor bank

when the sensed line voltage rises above the user selected OPEN VOLTS setting.

TIME WITH OLTAGE O ERRIDE - The Control will function according to the time mode,

except the time mode operating conditions will be overridden by voltage conditions

according to the volt mode function.

TEMPERATURE - For Summer Schedule (defined by CLOSE TEMP greater than OPEN TEMP

setting) - the Control will close the capacitor bank when the sensed ambient temperature

rises above the user selected CLOSE TEMP setting. The Control will open the capacitor bank

when the sensed ambient temperature drops below the user selected OPEN TEMP setting.

For Winter Schedule (defined by OPEN TEMP greater than CLOSE TEMP setting) - the Control

will close the capacitor bank when the sensed ambient temperature drops below the user

selected CLOSE TEMP setting. The Control will open the capacitor bank when the sensed

ambient temperature rises above the user selected OPEN TEMP setting.

TIME WITH TEMPERATURE O ERRIDE - The Control will function according to the time

mode, except the time mode operating conditions will be overridden by temperature

conditions according to the temp mode function.

TEMPERATURE WITH OLTAGE O ERRIDE - The Control will function according to the

temp mode, except the temp mode operating conditions will be overridden by voltage

conditions according to the volt mode function.

TIME WITH OLTAGE AND TEMPERATURE O ERRIDE - The Control will function according

to the time mode, except the time mode operating conditions will be overridden by

temperature conditions according to the temp mode function and/or by voltage conditions

according to the volt mode function. Voltage will override both time and temperature.

AMPS - The control will close the capacitor bank when the line amps drop below the user

selected Amps setting. The control will open the capacitor bank when the line amps rise

above the user selected Amps setting.

AMPS WITH OLTAGE O ERRIDE - The Control will function according to the Amps

settings, except the Amps setting operating conditions will be overridden by voltage

conditions according to the volt mode function.

K AR - The Control will close the capacitor bank when the line KVAR rises above the user

selected KVAR setting. The Control will open the capacitor bank when the line KVAR drops

below the user selected KVAR setting.

K AR WITH OLTAGE O ERRIDE - The Control will function according to the KVAR

settings, except the KVAR setting operating conditions will be overridden by voltage

conditions according to the volt mode function.

4

INSTALLATION

All VarCom Controls are supplied ready for 4 or 6 jaw meter socket mounting or for

mounting directly to a pole with a supplied mounting bracket.

WARNING: Before plugging the Control into a live meter socket, rotate

the main switch out of the AUTO position or remove the front panel fuse,

and observe all safety procedures for working with exposed live circuits.

Failure to comply can result in death, personal injury or equipment damage.

INSTALLING INTO A RINGED BASE

Align the terminals on the back of the Control and press firmly into the meter socket.

Use the supplied ring to complete the installation. Attach a ground wire to the external

ground lug. Seal or lock the ring only after the entire system has been verified.

INSTALLING POLE MOUNTED CONTROLS

Pole Mounted Controls are mounted with the included pole bracket and user supplied

mounting straps or lag screws. After the Control is attached to the pole, attach a ground

wire to the external ground lug.

WIRING INSTALLATION:

Use the following wiring diagram

for installing a VarCom control:

Note that the line current sensor connections

are polarity sensitive. A control indication of

reverse power flow can often be corrected by

reversing the black and white leads from the

line current sensor from those shown

in this diagram.

CURRENT SENSOR

The VarCom 2600 Control is supplied ready

to operate with Lindsey™ CVMI or Fisher

Pierce™ 1301 overhead current sensors,

which can be purchased separately. The

sensor output must be 600A: 10V. If the

current sensor is connected to a phase

different than the Control supply voltage,

refer to the software section of this

manual (beginning on pg 18)

to make phase adjustments.

Voltage sensing for the Control is pre-wired

to use the supply voltage, typically 120 or 240V.

Please consult the factory for other configurations.

Neutral

SERIES 1600 CONTROLS

Line 120V AC

Open Close

Neutral Sensor

Neutral Sensor

12

56

4

3

Neutral: Line sensor (White),

and Neutral sensor (White)

SERIES 2600 CONTROLS

Line 120V AC

Open Close

Line Sensor (Black)

Neutral Sensor (Black)

12

56

4

3

5

FUSIN

All VarCom Controls are supplied with a 15 Amp SLO-BLO® fuse, accessible from the front

panel. This fuse protects the capacitor bank switches. If it was removed before installation,

the fuse should be reinstalled after installation is complete.

An internal fuse that is not field replaceable protects the Control circuitry.

All repairs should be referred to the factory.

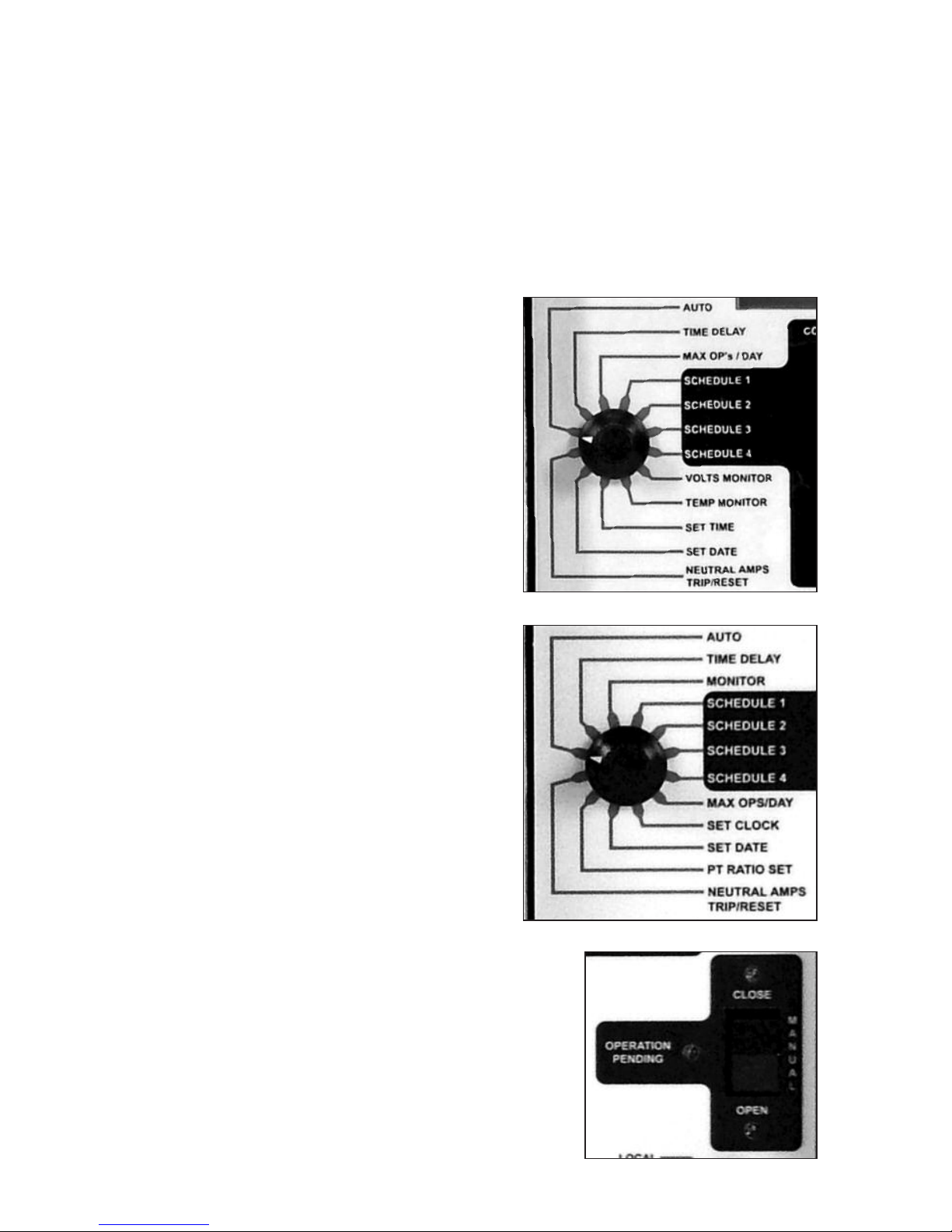

MANUAL OPERATION

All VarCom Controls can be used to operate

the connected capacitor bank switches

manually. To manually CLOSE or OPEN

the capacitor bank using the Control

front panel rocker switch:

1) Switch the Control out of the AUTO

mode, verify that the red lamp is off,

and select TIME DELAY. Using the

ADJUST knob, select the desired time

delay, in seconds, from 3 to 600. This

will delay both manual and automatic

operations by the time selected. The

OPERATION PENDIN light flashes

before every open or close operation

during the time delay period.

2) Use the MANUAL rocker switch to OPEN

or CLOSE the capacitor bank switches.

The OPERATION PENDIN light will flash

for the duration of the selected TIME

DELAY. When the output is energized, the

CLOSE or OPEN light will flash. Then, the

output will de-energize and the

light will remain on.

The capacit r bank cann t perf rm a

cl se perati n less than 5 minutes after

a trip perati n t all w time f r the

capacit rs t discharge. If a CLOSE

perati n is attempted during this

5 minute time peri d, the C ntr l will

display 5MIN DLY and the C ntr l

will n t cl se the bank.

Series 1600 Controls

Series 2600 Controls

6

NOTE: Manual operations are counted by the operations counter (close operations

only), but manual operations do not count against the preset daily limit set by MAX

OPS/DAY.

After completing the required manual operations, return the Control to AUTO

for automatic operation. The AUTO light confirms Automatic operation.

NOTE: Pending manual operations can be canceled by turning the Control to

AUTO. Similarly, pending automatic operations can be canceled by switching out

of AUTO to any other switch position.

PRO RAMMIN FOR

AUTOMATIC OPERATION

Programming and set-up information

for VarCom Controls.

Settings Common to all Models

AUTO is the normal automatic operating

mode for the Control. The display shows

the operations counter, which cannot

be reset. The operations counter counts

all CLOSE operations.

TIME DELAY sets the time delay, in seconds,

for both manual and automatic operations.

The delay can be set from 3 to 600 seconds

in 3 second increments using the ADJUST

switch. The OPERATION PENDIN light

flashes before every open or close operation

during the entire time delay period.

MAX OP’S/DAY sets the maximum number of

automatic capacitor bank CLOSE operations

per rolling 24-hour period. This can be set

from 2 to 24 operations using the ADJUST

switch. This setting overrides all other time,

temperature, current or voltage settings. If the

daily operations limit is reached, the display

will alternately show the operations counter

and OP LIMIT while the Control is in AUTO

mode. When MAX OPS is reached, the last

operation will be an OPEN. Manual

operations do not count against the

limit set by MAX OPS/DAY.

Series 1600 Controls

Series 2600 Controls

7

SETTIN THE CONTROL MODE

The Model 1600 Control can allow voltage and/or temperature to override time settings.

The Model 2600 Control can allow voltage to override temperature, time, amp and

KVAR settings. Depending on the model, the following Control Modes can be used:

C ntr l Display

M de Sh ws

Time only TIME

Time with voltage override VOLT/TIM

Voltage only VOLT

Time with temperature override TMP/TIME

Temperature only TEMP

Temperature with voltage override VOLT/TMP

Time with voltage and V/TMP/TI

temperature override

Amps LINE AMPS

Amps with voltage override LINEAMP/V

KVAR KVAR

KVAR with voltage override KVAR/VOLT

SCHEDULE SETTIN S

Four independent time schedules are available - SCHEDULE 1 through SCHEDULE 4.

Each time schedule allows one OPEN and one CLOSE operation per day. The schedules

can be used to set multiple OPEN and CLOSE operations for each day or they can be

used for seasonal changes to the schedule, e.g. different OPEN and CLOSE times for

summer and winter.

For each schedule selected, week days MON-FRI, weekend days SAT and SUN, and

HOLIDAYS can be selected to be ACTIVE or OFF. ACTIVE days will follow the TIME ON

and TIME OFF settings as well as any temperature or voltage override settings. OFF

days will cause the capacitor bank to remain open.

The six standard holidays are New Years Day, Memorial Day, July 4th, Labor Day,

Thanksgiving Day and Christmas Day. The VarCom Controls allow a maximum of ten

holidays to be programmed.

Series 2600 Controls

8

EXAMPLE 1 - SEASONAL ARIATION - Two time schedules are used for seasonal variation

in the OPEN and CLOSE times and/or override settings (if any). TIME SCHEDULE 1 is a

summer schedule with a START DATE of 4/1, a STOP DATE of 9/30, TIME ON at 07:00

and TIME OFF at 18:00 (all time settings are in 24 hour format). TIME SCHEDULE 2 is a

winter schedule with a START DATE of 10/1, a STOP DATE of 3/31, TIME ON at 08:00 and

TIME OFF at 16:00. For each time schedule, the days of the week, TIME ON, TIME OFF

and override settings (if any) can be set independently.

In this example, each schedule is ACTIVE for all days of the week and holidays and sched-

ules 3 and 4 are not used. The CONTROL MODE is set for TIME, so voltage and temperature

settings are not used.

To disable a time schedule, set the start date the same as the stop date. To make a

schedule run year round, set the start date for 01/01 and the stop date for 12/31. In

case of a conflict between time schedules, SCHEDULE 1 takes priority over SCHEDULE

2, SCHEDULE 2 over SCHEDULE 3, etc. In case of a conflict between temperature and

voltage settings, voltage takes priority. To make a time schedule active for 24 hours,

set TIME ON the same as TIME OFF.

EXAMPLE 2 - TIME WITH OLTAGE O ERRIDE - Two time schedules are used for

year-round time and voltage control. SCHEDULE 1 is a weekday schedule for time with

voltage override. Set the CONTROL MODE for VOLT/TIME (time with voltage override).

The TIME ON is 08:00 and the TIME OFF is 18:00. Set MON-FRI to ACTIVE and set SAT,

SUN and HOLIDAYS to OFF. The START DATE is 1/1 and the STOP DATE is 12/31.

The Control will anticipate voltage changes caused by opening and closing the capacitor

bank. This may cause scheduled open or close operations to be deferred or delayed.

See the Voltage Settings section (pg 10) for more information about Adaptive Trip.

SCHEDULE 1

SCHEDULE 2 Summer SCHEDULE 2

Winter Winter

JAN FEB MAR APR MAY JUN JUL AUG SEP OCT NOV DEC

12:00

10:00

08:00

06:00

20:00

18:00

16:00

14:00

SCHEDULE 1

weekdays

Sun Mon Tue Wed Thu Fri Sat

SCHEDULE 2

WEEKENDS / HOLIDAYS

SCHEDULE 2

WEEKENDS / HOLIDAYS

12:00

10:00

08:00

06:00

20:00

18:00

16:00

14:00

Example 2

Example 1

9

IMPORTANT! Time with voltage override means that voltage takes precedence. For these

SCHEDULE 1 settings, the Control will close the bank at 08:00 only if the line voltage is

below the OPEN VOLTS setting less the Adaptive Trip bias voltage. Conversely, the Control

will open the bank at 18:00 only if the line voltage is above the CLOSE VOLTS setting plus

the Adaptive Trip bias voltage. If the Control does not close the bank at the TIME ON

setting or open the bank at the TIME OFF setting due to voltage conditions, it will open or

close the bank later if the line voltage changes. The Control will also close the bank before

the scheduled time of 08:00 if the line voltage drops below the CLOSE VOLTS setting.

SCHEDULE 2 is a weekend schedule for voltage control only. Set the CONTROL MODE for

VOLT (voltage control). For 24-hour control, set the TIME ON and TIME OFF to the same

time. Set MON-FRI to OFF and SAT, SUN and HOLIDAYS to ACTIVE. Set the START DATE to

1/1 and the STOP DATE to 12/31. The Control will change from a weekday to a weekend

schedule at midnight.

If 24-hour voltage control is not desired, the TIME ON and TIME OFF settings can be set

as needed. The Control will close the bank at TIME ON only if the line voltage is below the

OPEN VOLTS setting less the Adaptive Trip bias voltage. The Control will open the bank at

TIME OFF independent of voltage.

EXAMPLE 3 - TIME WITH TEMPERATURE AND OLTAGE O ERRIDE - Two time

schedules are used for seasonal variations in temperature and voltage override settings.

SCHEDULE 1 is set for TEMP/TIME (time with temperature override) using the CONTROL

MODE setting. This is a daily summer schedule so the START DATE is 4/1 and the STOP

DATE is 9/30. The TIME ON is 08:00 and the TIME OFF is 18:00. The OPEN TEMP is 60°F

and the CLOSE TEMP is 80°F. MON-FRI SAT, SUN and HOLIDAYS are all set to ACTIVE.

IMPORTANT! Time with temperature override means that temperature takes precedence.

For these SCHEDULE 1 settings, the Control will close the bank at 08:00 only if the

temperature is above the OPEN TEMP setting of 60°F. Conversely, the Control will

open the bank at 18:00 only if the temperature is below the CLOSE TEMP setting of

80°F. If the Control does not close the bank at the TIME ON setting or open the bank

at the TIME OFF setting due to temperature conditions, it will open or close the bank

when the temperature changes. The Control will also close the bank before the

scheduled time of 08:00 if the temperature increases above the CLOSE TEMP setting.

SCHEDULE 2 SCHEDULE 1 SCHEDULE 2

Winter Summer Winter

voltage override voltage override

JAN FEB MAR APR MAY JUN JUL AUG SEP OCT NOV DEC

20:00

18:00

16:00

14:00

12:00

10:00

08:00

06:00

Example 3

10

SCHEDULE 2 is set for VOLT/TIME using the CONTROL MODE setting. This is the winter

schedule so the START DATE is 10/l and the STOP DATE is 3/31. The TIME ON is 08:00

and the TIME OFF is 18:00 MON-FRI, SAT, SUN and HOLIDAYS are all set to ACTIVE.

Voltage settings are set as needed.

OTHER SETTIN S

Besides the four independent time schedules, there are three other time settings

to be entered. DAYLIGHT SAVINGS can be set to ACTIVE or OFF. Selecting ACTIVE

automatically adjusts the internal clock and all time settings for daylight savings

time in the spring and fall. Selecting OFF causes the Control to ignore daylight

savings time changes.

SET TIME and SET DATE are used only for initial set-up of the Control, or after

the back up duration has been exceeded. The time is entered in 24 hr. format

and manually adjusted in 5-minute increments. The date is entered as mm-dd-yy.

[The first day in the year 2000 will be displayed as 1/1/00]. Reference the VarWare

software for setting the date and time.

Voltage Settings

OPEN VOLTS must be at least 3 volts above CLOSE VOLTS and cannot be set to any

voltage difference less than 3 volts. The control voltage is measured and averaged

over a 5-minute period to reject momentary spikes or sags. The Control will not

respond to short-term voltage changes such as those caused by a sudden line

voltage change or adjusting the control voltage with a variable transformer.

Voltage Controls also incorporate Adaptive Trip; the Controls are sensitive to the

voltage rise caused by closing the capacitor bank. The voltage rise caused by closing

the capacitor bank is averaged over the last 4 close operations and is used to anticipate

the voltage change for the next close or open operation. This voltage change is used

as a bias, and if the next close operation would cause the Control voltage to be above

the open voltage set-point, the close operation is not performed until the voltage

falls below the open voltage set point less the bias voltage. Similarly, if the next open

operation would cause the Control voltage to be below the close voltage set point,

the operation is not performed until the voltage rises above the close voltage set

point plus the bias voltage. The initial factory default bias setting is 2 volts.

Temperature Settings

OPEN TEMP cannot be set closer than 5°F above or below CLOSE TEMP. OPEN TEMP

can be either higher or lower than CLOSE TEMP for summer or winter peaking loads.

Temperature is measured and averaged over a 30 minute period so the Control will

better respond to temperature sensitive VAR loading. The Control will not respond

to short-term temperature changes such as those caused by spraying cold water on

the temperature sensor.

11

KVAR SETTINGS

KVAR OPEN and KVAR CLOSE determine when the capacitor bank will open and close. The

Control will display LD for leading KVAR and L for lagging KVAR. KVAR CLOSE can only be

set lagging and must be at least 20KVAR more than KVAR OPEN.

KVAR is measured and averaged over a five minute period to reject momentary transients.

The KVAR settings also incorporate Adaptive Trip; the Control is sensitive to the change in

KVAR caused by closing and opening the capacitor bank. The change in line KVAR caused

by closing the capacitor bank is averaged over the last 4 close operations and is used to

anticipate the change in KVAR caused by the next close or open operation. This change is

used as a bias. If the next close or open operation will place the Control beyond the next

KVAR set point, that operation is not performed until the line KVAR changes beyond the

KVAR setting plus the bias. The initial factory default bias setting is 20 KVAR.

NOTE: The KVAR settings and the monitored line KVAR are both single phase values.

For example, a typical 600kVAR capacitor bank will be 200KVAR/phase.

RE ERSE POWER sets the action of the Control when reverse power flow is detected.

Options are: I NORE – to do nothing and leave the capacitor bank in its present state,

VOLT – to revert to voltage control, or OPEN – to open the capacitor bank until normal

power flow is restored.

EXAMPLE – K AR WITH OLTAGE O ERRIDE – The CONTROL MODE is set to KVAR/VOLT,

for KVAR with Voltage Override. That is, the Control will follow the KVAR settings unless

the voltage is outside of the voltage set points. The KVAR settings are set as follows: KVAR

OPEN is LD 250 and KVAR CLOSE is L 300. Voltage Override settings are set to VOLTS

OPEN 128 and VOLTS CLOSE 122.0. The Control will open the bank, regardless of KVARS,

if the control voltage exceeds 128V. The Control will close the bank, regardless of KVAR,

if the control voltage falls below 122V.

IMPORTANT! The Control may not operate exactly at the above set points due to the

Adaptive Trip feature described earlier. For example, the Control may not close at the KVAR

CLOSE set point of L 300 if doing so would raise the control voltage above the VOLTS

OPEN set point of 128.5V. Similarly, the Control may not open the bank at the KVAR OPEN

set point of LD 50 if doing so would lower the control voltage below the VOLTS CLOSE set

point of 122V. Any operation that is deferred due to Adaptive Trip will take place as KVAR

or voltage conditions change.

12

SYSTEM MONITORIN

Depending on the model, the actual line voltage,

ambient temperature or current can be monitored

using the MONITOR settings. This can be helpful

for setting up and checking Control operation.

All parameters are measured and displayed

real-time without any time delay or averaging.

LINE AMPS is the total current on the line, both real and reactive. AMPS REAC is the

reactive component of the total line current. Reactive amps will be displayed along

with LD for leading, L for lagging, RV for reverse, and UN for unity power factor. Both

LINE AMPS and AMPS REAC will show LOW AMPS in the display if less than 3 amps are

measured. The AMPS REAC setting can be particularly helpful when adjusting the Amps

Reactive set points for VAR Control. The effect of the capacitor bank on feeder VARs

can also be seen by monitoring this setting while manually opening and closing the

capacitor bank. AMPS THD% is the Total Harmonic Distortion in the line current. KVA

is Kilo Volt Amperes.

KILOWATTS are the real component of the KVA. POWER FACTOR is displayed as a

percentage of unity, e.g. 90% for a 0.9 power factor. To properly display KVA, KVAR

and KW; the PT RATIO must be set. This is the ratio of the transformer supplying power

to the Control. For example, the ratio for a 7200V line to ground connected transformer

supplying 120V to the Control would be 60 (7200 / 120 = 60).

CONTROL OLTS is the voltage used to power the Control, typically 120 or 240V.

KV is the primary voltage in kilovolts and is derived from CONTROL VOLTS x PT RATIO.

KV THD% is the Total Harmonic Distortion in the line voltage. POWER FLOW DIRECTION

shows in the display as FORWARD or REVERSE. This will indicate a current sensor that

is wired backwards.

13

NEUTRAL CURRENT MONITORIN

On units equipped with optional Neutral Current monitoring, the capacitor bank neutral

line is monitored. A neutral current sensor is mounted around the capacitor bank neutral

lead and is connected to the Control. High neutral current is indicative of unbalanced VAR

loading and can be used to trip the capacitor bank off line and keep it off line until the

Control is manually reset. The neutral amps are averaged over five minutes when in AUTO

mode. This average is used for comparison to the set point.

The NEUTRAL SENSE OPTION works in the following manner:

1. In MANUAL MODE, monitoring of neutral amps is accomplished by selecting

VOLTS MONITOR, then toggling the ADJUST switch one position in either direction.

2. In AUTO MODE, monitoring of neutral amps is accomplished by toggling the

ADJUST switch slowly until the display reads iA (Instantaneous Neutral Amps),

and aA (5-minute Averaged Neutral Amps).

3. The neutral amps trip set point can be set from 3 to 100 amps. The setting below 3

amps will disable the neutral amp trip function. The display will read disabled.

4. In AUTO mode, if the neutral amps rise above the set point, the Control will open the

capacitor bank, light the neutral trip LED, and hold the bank locked out until manually

reset. Resetting the Control from neutral amp lockout is accomplished by rotating the

MODE switch to the NEUTRAL AMPS, TRIP / RESET position.

CLOCK BACK-UP

The VarCom Capacitor Control uses a capacitor back-up for maintaining the internal clock

settings when Control power is interrupted. If power is interrupted to a Control for more

than 10 days, the time settings may be lost. When this happens, the Control will alternately

display TIME ERR when in the AUTO mode.

Only the internal clock is dependent on the capacitor back up. All other previously logged

data, front panel settings and Control programming is stored in non-volatile memory,

which retains is contents indefinitely without power.

14

The following information regarding the front panel displays may prove helpful

in diagnosing a Control that appears to be functioning improperly.

LED INDICATORS

AUTO - Indicates the Control is in automatic mode. The Control will open and close the

bank only per the programmed settings and the toggle switch is disabled. The display

indicates the total number of CLOSE operations. When the LED is off, the Control is in

manual mode and the toggle switch is enabled.

NEUTRAL AMPS TRIP / RESET - (Optional) - The capacitor bank neutral current has

exceeded the preset threshold and the bank is locked OPEN. To reset this condition,

rotate the MODE switch to the AMPS TRIP/RESET position.

SCADA ACTI E - Indicates SCADA override of Control function when the control is in the

Remote mode.

COM ACTI E - Indicates communication has been received from the SCADA Master

within a 5 minute timeout period.

OPERATION PENDING - Flashes during the number of seconds selected by TIME DELAY

for every pending OPEN or CLOSE operation. CLOSE shows the bank status as closed. A

flashing LED indicates the CLOSE output is energized. OPEN shows the bank status as

open. A flashing LED indicates the OPEN output is energized.

CLOSE - Shows the bank status as closed. A flashing LED indicates the CLOSE

output is energized.

OPEN - Shows the bank status as open. A flashing LED indicates the open output is energized.

15

LCD DISPLAY

COMBUSY - The Control is communicating via the communications port.

LOW LINE - The supply voltage has dropped below its operating threshold (92V for a 120V

unit and 180V for a 240V unit). The Control will go into a standby mode until the voltage

recovers and will then perform a power up self-check.

OP LIMIT - The Control has reached its daily limit of automatic close operations as set by

MAX OPS/DAY. The Control will not CLOSE automatically again during the present 24 hour

period. Manual CLOSE and OPEN operations can still be performed.

SYS ERR - The Control has detected a memory defect. The Control will stop

operating and must be returned to the factory for repair.

TIME ERR - The Control has detected a timing error, most likely due to a discharged clock

backup capacitor. This condition can be reset by resetting the time and date via the front

panel or via the VarWare software.

OLT ERR - The voltage sensor is not operating properly or the voltage being

measured has fallen either below 100V or above 150V. If this display is due to a short-term

voltage change, the Control will reset automatically. While this condition persists, the Control

will not perform any voltage related operations but will otherwise operate normally.

AMP ERR - The current sensor is not operating properly. If this is a transient condition, the

Control will automatically reset the current sensor input and continue to operate properly.

A permanent current sensor failure can be verified with the MONITOR - LINE AMPS setting

which will show LOW AMPS. If this condition is permanent, the Control will not perform

any VAR related operations but will otherwise operate normally.

5MIN DLY - Will be displayed for 5 minutes following any OPEN operation. The Control will

not perform a CLOSE operation this period.

16

SPECIFICATIONS

Electrical

POWER REQUIREMENT: 100-140 or 200-260 VAC, 10W

MOUNTING: 4 or 6 Jaw Meter Socket or Pole Bracket with Amphenol connector.

OUTPUT CONTACTOR: 30A, 120/240 VAC. 15 second “on” duration for motor and

solenoid operated switches.

FUSE: 15A SLO-BLO®

SURGE / LIGHTNING PROTECTION: ANSI C37.90.1 1989

OPERATING FREQUENCY: 60Hz (optional 50Hz availabe)

OLTAGE ACCURACY: ±0.5 VAC, 0.1 VAC Resolution

LINE CURRENT ACCURACY: ±1% +5 counts, excludes line current sensor accuracy.

TEMPERATURE ACCURACY: ±1°F, 1°F Resolution

TIME ACCURACY: Temperature compensated oscillator, ±0.001%

CLOCK BACK-UP: Capacitor - 10 days

DISPLAY: Liquid Crystal

COMPUTER INTERFACE: USB

COMMUNICATIONS INTERFACE: Com 1: RS-232 serial interface for DNP 3.0

communication Com 2: RS-232 serial interface for local or remote PC interface

COMMUNICATIONS POWER SUPPLY: 12 VDC, 1 Amp

COMMUNICATION PROTOCOL: DNP 3.0

Mechanical

MOUNTING: 4 or 6 Jaw Meter Socket or Pole Bracket with Amphenol connector.

ENCLOSURE: NEMA 4X weather tight fiberglass; 8.75 x 10.75 x 5.5 in.

(222mm x 273mm x 140mm) Hinged left, lock hasp on right side. Weight 8.5 lbs. (3.9 kg.)

Environmental

TEMPERATURE: -22°F to +185°F (-30°C to +85°C)

HUMIDITY: 5 - 95%, non-condensing

17

Settings

USER INTERFACE: Front panel user interface with visible access to all local control settings

via rotary and rocker switches.

OLTAGE: CLOSE: 105 - 127 / 210 - 257 VAC; Max. setting = Open Volts -3 VAC.

OPEN: 108 - 130 / 213 - 260 VAC; Min. setting = Close Volts +3 VAC. 5-minute

time averaged voltage response. Setting in 0.1 volt increments.

AMPS - CLOSE: 10 - 600

AMPS - OPEN: 5 - 300, no less than 5 amps less than Close amps.

K AR - CLOSE: -10 to -2000

K AR - OPEN: -280 to 1000, no less than 20 KVAR more leading than Close KVAR

TEMPERATURE: CLOSE: 0 - 120°F;

OPEN: 0 - 120°F, no closer than 5°F to Close temperature.

TIME DELAY: 3 - 600 seconds, 3 second increments.

MAX OPERATIONS/DAY: Configurable from 2 - 24

MANUAL TRIP: Momentary Open or Close, Close and Open operations delayed

by selected Time Delay, 5-minute delay following Open before re-close.

NEUTRAL AMPS TRIP: 3 - 100 Amps, harmonic filtered, 5-minute time average response,

manual reset, 5-minute minimum tripped time

PT RATIO SET: 1 - 300

18

VarWare PRO RAMMIN AND DATA ANALYSIS SOFTWARE

Features

VarWare® software aids in programming a VarCom Capacitor Control for capacitor bank

switching and power system monitoring via a computer.

The software includes the following features:

• Design capacitor bank control strategies in the office for future uploading to the Control.

• Create and save different Control strategies for different model Controls all with the

same software.

• View and analyze data downloaded from Capacitor Controls. Examine

Control switching operations, power outages and system parameters.

• raph stored voltage, temperature and current data. Zoom in on areas of interest.

• Connect to a Control for real time monitoring of the Control parameters such

as voltage, temperature and current.

• Download stored programs to update a Control strategy or download a Control program

from a control back to a computer.

• Setup the Control for data logging. Program the Control to store control and system

parameters such as switching operations, voltage and temperature.

PRECAUTIONS

Precautions must be taken before connecting a computer to an installed capacitor

bank control.

CAUTION! Before connecting a computer to an installed capacitor bank

take the following steps:

1. Ensure the Capacitor Control is properly grounded.

2. Set the Control so it is not at AUTO or SET TIME.

Failure to follow these precautions may result in damage to the

computer, unexpected capacitor bank operation or personal injury.

19

SOFTWARE INSTALLATION

HARDWARE REQUIREMENTS: VarWare software runs on Windows™ 95 or higher. The

proper installation and use of this software requires at least 32 MB RAM and at least 20 MB

of free hard disk space. The software will communicate with the Capacitor Control through

an open USB port.

Before beginning the software installation process, close or exit all other programs.

The software is provided on CD or can be downloaded from the website. Installation

will begin automatically provided that auto-insert notification is not disabled on the

computer being used. If installation does not begin automatically, double click the CD

ROM drive in “My Computer” and run Setup.exe from the CD.

Using the Software for the First Time

Start the software via the icon or use the Windows Start button to navigate to the

folder. Before connecting the computer to a Control, verify that the computer is set up

for communications on the correct COM port. COM1 is the default port in the software.

If necessary, change the port as shown in the graphic, starting with the Communications

drop-down menu.

IMPORTANT! If the COM port is changed, the software must be restarted for the change

to take effect.

Create a Control Program

To program a Capacitor Control with a computer and software, a Control program

must be created.

Select File, then Open. If this is the first time for setting up a program, select one of the

default programs for the Control model that is to be programmed. For example, select

1600.ws for a VarCom 1600 Control. A previously created file may also be selected. All

setup files will have a .ws extension.

After the file is opened, the name of the file will be shown on the title bar of the main window.

Note that the VarCom Control front panel ADJUST switch can be disabled in the main

window by un-checking Manual setpoint adjustment enabled. This provides a level

of security and prevents unwanted changes to the control program in the field.

Select a Schedule. Each time schedule must be programmed individually. To disable

a schedule, set the start date the same as the stop date. To make a schedule active 24

hours per day for around the clock voltage control, set the start time the same as the

stop time. The schedules in black lettering are active schedules, orange lettering refers

to inactive schedules.

After entering all the desired settings, save the new file. Enter a file name and select File,

then Save. The software automatically adds the .ws extension. If an existing setup file was

modified, Save As must be selected so the original file is not overwritten.

20

To print the Active setup file, select File, then Print. To print another setup file, select File,

then Open, then Print.

Upload a Setup Program to a VarCom Control

To upload a setup program to a VarCom Control, follow the precautions shown at the

beginning of the software section of this manual (page 18) and connect a computer to

the Control. Select Communications, then Setup, then Send settings data to control

from the main menu.

Note that the name of the active setup file that will be uploaded to the VarCom Control is

shown in the upper left corner of the main title bar.

At this time, the current setup program can be downloaded from a VarCom Control

to a computer by selecting Communications, then Setup, then Read settings data

from control.

Any time communications are initiated with a VarCom Control, a warning will

appear asking the user to verify that the Control is not in Auto or Set Time. While

the setup data is being transferred, the LCD display on the VarCom Control will

display COM BUSY.

Edit Unit ID will give each Control a unique identification. The factory default ID is the

serial number of the Control. This number is used in the header of all downloaded data

and is also the default file name for the data file.

To set the clock on the Control, select Communications, then Set Unit Clock. The

clock can be set according to the clock on the computer that is connected to the

VarCom Control. Alternately, the clock can be set manually with the front panel knobs.

USE PROFILE DATA LO IN

Set up and use of the internal data logging features in a VarCom Capacitor Control and

download the stored data.

Initialize the Profile Data Collection Options

From the main menu, select Communication then Profile, then Edit profile options:

Sample Period sets the sample frequency for voltage and temperature data. All collected

data are instantaneous readings and are not averaged or delayed.

Circular overwrite enabled will overwrite the oldest data when memory is full.

Record temperature enables temperature data recording.

Record neutral current enables neutral current data recording. This option is only available

if the Control has the neutral sense feature enabled.

Select Relay operations to record data after an open or close operation. If selected, select

a Record delay frequency from the drop-down box. A time delay is recommended to allow

switching transients to settle.

This manual suits for next models

1

Table of contents

Popular Control Unit manuals by other brands

Trinamic

Trinamic TMCM-6214 Hardware manual

System Sensor

System Sensor MDL3 Series Installation and maintenance instructions

Meinberg

Meinberg IMS-VSG181 Setup guide

Honeywell

Honeywell SM150 installation instructions

GEA

GEA VARIVENT T R Series operating instructions

JBL

JBL ProFlora V002 Instructions for use

Festo

Festo NAW VDMA-02 Series Mounting instructions

Realtek

Realtek RTL8191RU user manual

RAK

RAK WisBlock RAK19012 quick start guide

SMC Networks

SMC Networks JSXH31-CP X2 Series Operation manual

SMC Networks

SMC Networks VQC2000 Installation and maintenance manual

WAREMA

WAREMA GA Kompakt Operating and installation instructions