816835_c•en•12.07.2011We reserve the right to carry out improvements1

Operating and installation instructions

GA Kompakt

Keep for future use!

Valid from 20 July 2011

General

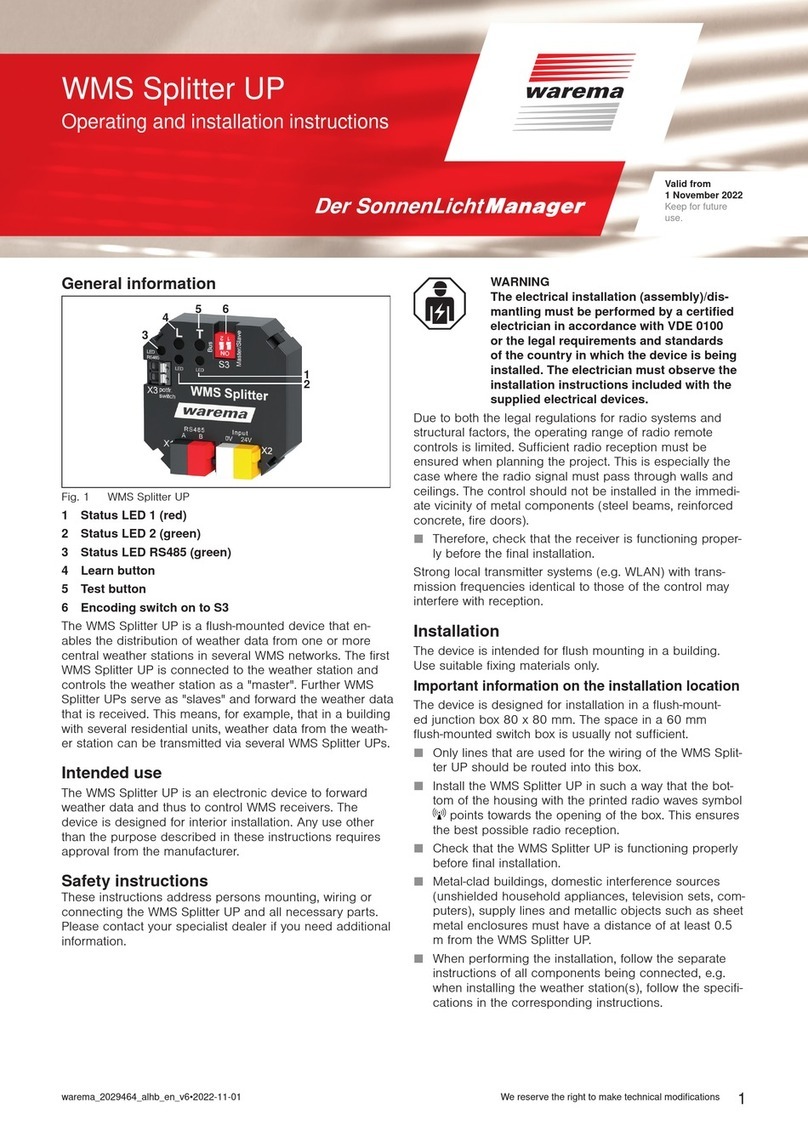

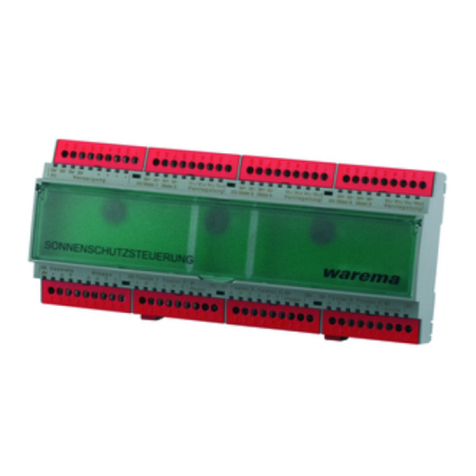

Fig. 1 GA Kompakt REG

The floor distribution control (GA) enables the central

control of the motor control units of a floor. The control

signals from the sun shading control system are forwarded

to all motor control units of a floor. The sunshade drives

of this floor can be distributed to up to four facades via

the GA and controlled separately. In addition, four facade

push buttons can be connected to the GA, which enables

the connected motor control units to be jointly operated for

each facade.

Intended use

The device was developed to control sun shading sys-

tems. The approval of the manufacturer must be obtained

for uses outside of the purposes listed in these instruc-

tions.

Safety instructions

ARNINGW

The electrical installation must be per-

formed by a certified electrician in accord-

ance with the electrical installation regula-

tions published by the Association of Ger-

man Electrical Engineers (VDE 0100) or the

standards and regulations of the country

in which the device is being installed. The

specialist must observe the installation

instructions included with the electrical

device.

ARNINGW

If hazard-free operation cannot be

assumed, the device may not be started or

must be deactivated. This assumption is

justified

If the housing or the supply lines show signs

of damage,

The device is no longer working

ARNINGW

It is important to comply with the follow-

ing instructions in the interest of personal

safety!

■ Do not allow children to play with the operating elements of the control or remote control. Store the remote controls out of range of children.■ Make sure that no persons or objects are in the range of movement of the driven parts (blinds, window, etc.).■ Disconnect the device from the supply voltage if cleaning or other maintenance work must be performed.Function

Move commands from the local facade push buttons are

forwarded to the connected motor control units via the

GA Kompakt. After the button is pressed, the sun shad-

ing system moves in the corresponding direction and

stops after two seconds. If the button is pressed for more

than two seconds, the control will stay activated automati-

cally. The button may then be released. The sun shading

system moves until the fixed run time of three minutes has

expired. In order to clear the locked state and stop the

motor, briefly press the button for the opposite direction of

movement. The move commands from a sun shading con-

trol system have priority over the move commands from

the facade push buttons and are directly forwarded to the

motor control units. Operation via the facade push button

is blocked during a central command.

Installation

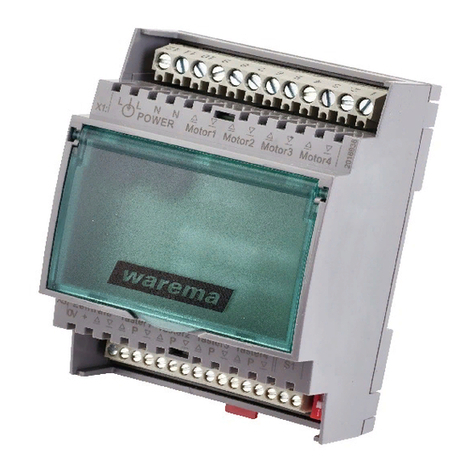

The motor control unit is, depending on the selected meth-

od of installation, designed for surface mounting (AP) or

for installation in a distributor (REG).

AP: Insert a slotted screwdriver

(recommendation: 3.0 - 4.0mm blade) into

the respective cover opening (see Fig. 4)

and carefully pry the folding cover open.

Repeat the procedure for the second

opening of the cover. The cover can be

folded up when both catches have been

released. The second cover can be opened

in the same manner. Alternatively, the

surface-mounted variant can be mounted

on a DIN rail (TH 35-15 as per EN 60715:

2001).

AP IP54: This device type is suitable for use in damp

locations. After the enclosure is mounted,

remove the two blue transport protectors

(foam inside the enclosure).