Disc-Roller 2,5 - 3,0 –3,5 - 4,0 m (1-section)

Contents

EC DECLARATION OF CONFORMITY............................................................................................................4

SAFETY INSTRUCTIONS FOR DISC-ROLLER...............................................................................................5

SAFETY AND INSTRUCTIONS ON HYDRAULICS ........................................................................................6

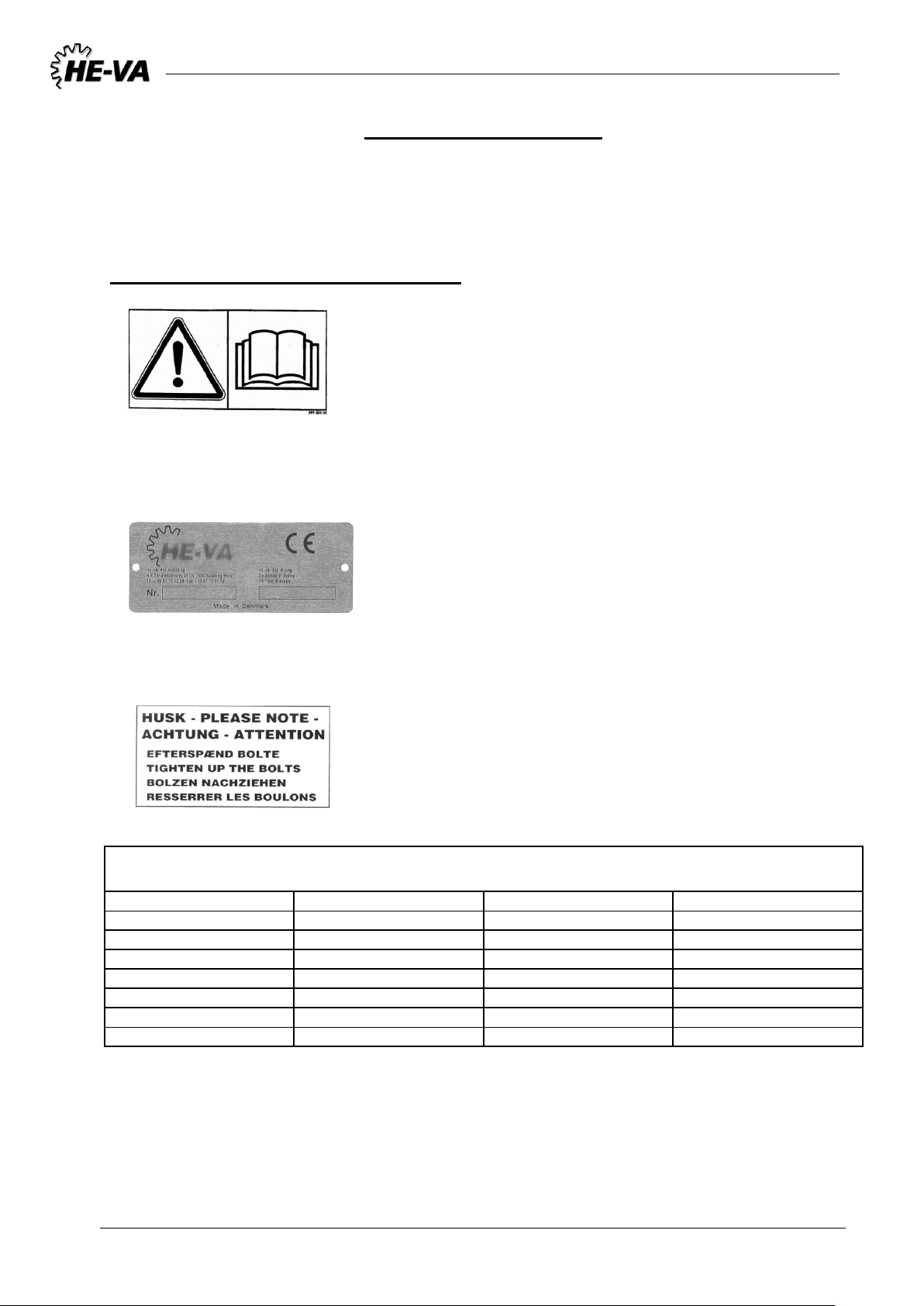

LABELS ON THE MACHINE...............................................................................................................................7

SAFETY –AND OTHER MARKINGS ON THE MACHINE...............................................................................................7

TECHNICAL SPECIFICATIONS / DATA ..........................................................................................................8

START-UP OF THE MACHINE...........................................................................................................................10

ATTACHMENT,MOUNTED MODEL.........................................................................................................................10

ATTACHMENT,TRAILED MODEL............................................................................................................................10

TRANSPORT...........................................................................................................................................................11

UNCOUPLING,MOUNTED MODEL ..........................................................................................................................11

UNCOUPLING,TRAILED MODEL.............................................................................................................................11

SETTINGS OG ADJUSTMENTS..........................................................................................................................12

DRAWBAR..............................................................................................................................................................12

DISC.......................................................................................................................................................................12

EDGE EQUIPMENT...................................................................................................................................................13

EDGE EQUIPMENT FROM MACHINE NO.341738......................................................................................................14

SCRAPER................................................................................................................................................................15

SCRAPER FROM 2009 -2013:..................................................................................................................................15

MATERIAL DAMPERGUARD ....................................................................................................................................16

TINE ERADICATOR SET (CAN ONLY BE MOUNTED ON TRAILED MODELS) ................................................................16

MAINTENANCE AND SERVICE.........................................................................................................................17

SPARE PARTS LIST ..............................................................................................................................................18

DRAWBAR (FOR TRAILED MODELS)........................................................................................................................18

WHEEL ASSEMBLY (FOR TRAILED MODELS) ...........................................................................................................22

DISC.......................................................................................................................................................................24

PACKING ROLLER...................................................................................................................................................26

SCRAPER................................................................................................................................................................28

EDGE EQUIPMENT...................................................................................................................................................30

EDGE EQUIPMENT FROM MACHINE NO.341738.......................................................................................................32

SPARE PARTS LIST - EXTRA EQUIPMENT....................................................................................................34

MATERIAL DAMPER GUARD ...................................................................................................................................34

SPRING-BOARD 2,5M +3,0M +3,5 M .....................................................................................................................36

SPRING-BOARD (LEFT)4,0M..................................................................................................................................37

EL.DEPTH STOP FOR DISC.......................................................................................................................................40

LIGHTS...................................................................................................................................................................42

HYDRAULIC BRAKES..............................................................................................................................................44

AIR BRAKES ...........................................................................................................................................................45

TINE ERADICATOR SET ...........................................................................................................................................47

SUPPORTING WHEEL (MODEL FOR SPRING-BOARD) ...............................................................................................49

SUPPORTING WHEEL (MODEL WITHOUT SPRING-BOARD).......................................................................................51

SPARE PARTS LIST - HYDRAULICS ................................................................................................................53

HYDRAULICS BETWEEN DRAWBAR AND WHEEL FRAME .........................................................................................53

HYDRAULICS FOR ADJUSTMENT OF DISC ................................................................................................................54

DIAGRAMS .............................................................................................................................................................57

EL.DEPTH STOP......................................................................................................................................................57

LIGHTS...................................................................................................................................................................58

HYDRAULICS F/DEPTH STOP ...................................................................................................................................59

HYDRAULICS F/EL.DEPTH STOP .............................................................................................................................59