Heal Force Prince 120 Body Fat User manual

Maintenance Manual for Prince 120 Body Fat Measuring Apparatus

Page 1 of 23

Prince 120 Body Fat

Measuring Apparatus

Service Manual

Version:2008.08.01

Maintenance Manual for Prince 120 Body Fat Measuring Apparatus

Page 2 of 23

COPYRIGHT

1. Without the written permission of our company, any content of the manual

should by no means be duplicated or disclosed to any other individual or

organization.

2. Individual or organization should in no way use the manual unless authorized

by our company.

3. Our company has the sole right to change or modify this manual. Any other

individual or organization thereby should in no case change or modify the

manual.

4. Without our written permission, any organization or individual should not,

by the name of sale or donation, provide the public the manual or the

duplication of the manual.

5. Anyone who violates our copyright must be pursued according to the

copyright law.

Shanghai Lishen Scientific Equipment Co., Ltd.

Maintenance Manual for Prince 120 Body Fat Measuring Apparatus

Page 3 of 23

Table of Contents

I. Panel and functions of body fat measuring apparatus ..................................................................................... 4

II. Disassembly and maintenance of mechanical parts......................................................................................... 5

III. Steps on disassembly of body fat measuring apparatus................................................................................. 5

1. Turn the body fat measuring apparatus and unscrew 4 fittings.............................................................. 5

2. Open the lower cover:.................................................................................................................................. 6

3. Open the rear cover..................................................................................................................................... 7

4. The disassembly steps to check the bottom of upper cover...................................................................... 7

5. Bottom of backplane.................................................................................................................................... 8

IV. Introduction to circuit of body fat measuring apparatus............................................................................... 9

V. Functional description on sub-circuits:........................................................................................................... 11

1. MCU control circuit: ............................................................................................................................. 11

2. Power supply circuit:............................................................................................................................. 12

3. Sine wave generation circuit:................................................................................................................ 14

4. Differential detection circuit:................................................................................................................ 15

5. Auto calibration, diode connection, tetrode connection selection circuit: ........................................ 16

6. Crystal oscillator, key and LCD display circuit:................................................................................. 17

VI. Commissioning method and common troubleshooting................................................................................ 18

1. Commissioning condition...................................................................................................................... 18

2. Commissioning equipment.................................................................................................................... 18

3. Content and step of commissioning...................................................................................................... 18

3.1 Display commissioning ..................................................................................................................... 18

3.2 Auto shutdown and shutdown commissioing .................................................................................... 19

3.3 Commissioning on functional and accuracy test ............................................................................... 20

3.4 Commissioning on logging personal data function............................................................................ 20

3.5 Alarm commissioning........................................................................................................................ 20

3.6 Withstand test..................................................................................................................................... 20

4. Project mode............................................................................................................................................... 21

4.1 PWM differential value and standard resistance value...................................................................... 21

4.2 3V voltage and 5V voltage measurements......................................................................................... 21

5. Waveform measurement ........................................................................................................................... 22

6. Troubleshooting ......................................................................................................................................... 22

6.1 No display or missing stroke in the screen ........................................................................................ 22

6.2 Measurements of body fat rate deviates beyond ±2% ....................................................................... 22

6.3 With full illumination background after startup, it works ineffectively by pressing any key and the

apparatus is able to auto shutdown in 60sec. ........................................................................................... 22

6.4 PWM differential value and standard resistance measurements beyond the specified threshold or in

unstable condition.................................................................................................................................... 22

Maintenance Manual for Prince 120 Body Fat Measuring Apparatus

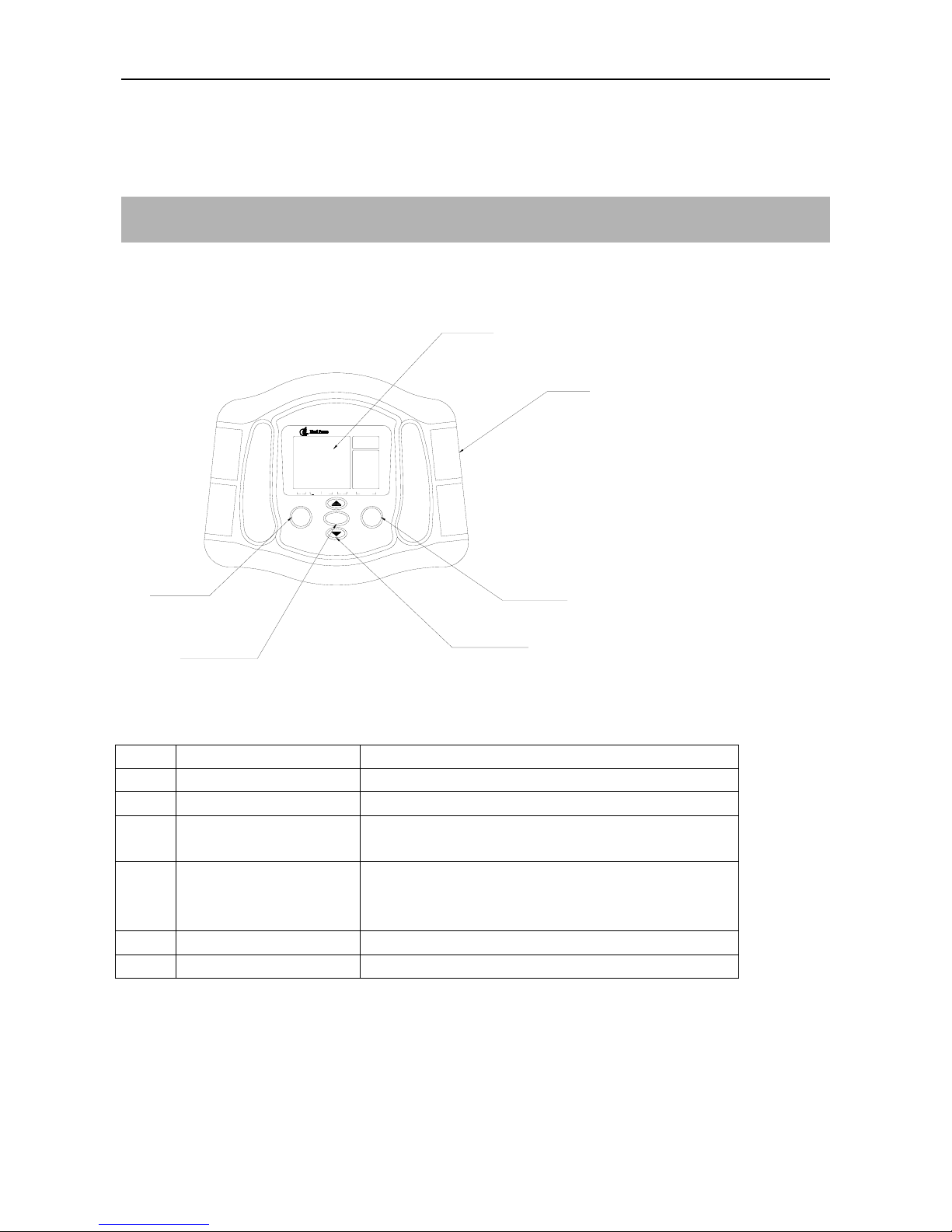

I. Panel and functions of body fat measuring apparatus

Front view of the apparatus:

6

54

3

2

1

电源

设定

测量

人体脂肪测量仪

基础

代谢

(kcal)

个人

号码

身高

体重

年龄

性别

低标准 偏高 高肥胖类型

Item Description Function

1 Electrode handle Weak detection current to be routed during test

2 Display area Display the settings and measurements

3 Test key After setting, push the key to start the test with appropriate

posture

4 Up and down keys Set the personal data (height, weight, age, sex).

Furthermore, you may select the personal code from 1 to

9.

5 Set key Set the personal code and data

6 Power key Turn on/off

Page 4 of 23

Maintenance Manual for Prince 120 Body Fat Measuring Apparatus

Page 5 of 23

II. Disassembly and maintenance of mechanical parts

Maintenance tools

Big and small Phillips

screwdriver

Nipper pliers Art knife

Big and small flat tip

screwdriver

Diagonal cutting pliers Iron, solder stick

Tweezers

Unless otherwise specified in the disassembly diagram, the installation shall be progressed in the reverse sequence

as shown in the diagram.

Components and parts shall be only replaced with those from OEM and the maintenance people must follow the

graphic directions in the manual without modification at their discretion.

Note: On reinstallation following replacement of components and parts, each screw shall be painted

with thread adhesive before being fastened.

For maintenance, the body fat measuring apparatus shall be properly placed on the robust horizontal

table.

During the assembly:

1: All components and parts shall have the surface free of score, scratch, etc.

2: During the installation, please note the assembly location and direction of each component and

part.

III. Steps on disassembly of body fat measuring apparatus

1. Turn the body fat measuring apparatus over and unscrew 4 fittings.

Table of contents

Popular Measuring Instrument manuals by other brands

Powerfix Profi

Powerfix Profi 278296 Operation and safety notes

Test Equipment Depot

Test Equipment Depot GVT-427B user manual

Fieldpiece

Fieldpiece ACH Operator's manual

FLYSURFER

FLYSURFER VIRON3 user manual

GMW

GMW TG uni 1 operating manual

Downeaster

Downeaster Wind & Weather Medallion Series instruction manual

Hanna Instruments

Hanna Instruments HI96725C instruction manual

Nokeval

Nokeval KMR260 quick guide

HOKUYO AUTOMATIC

HOKUYO AUTOMATIC UBG-05LN instruction manual

Fluke

Fluke 96000 Series Operator's manual

Test Products International

Test Products International SP565 user manual

General Sleep

General Sleep Zmachine Insight+ DT-200 Service manual