4

Vent-Free Gas Log Heater User Manual

Safety Information (cont.)

WARNING:

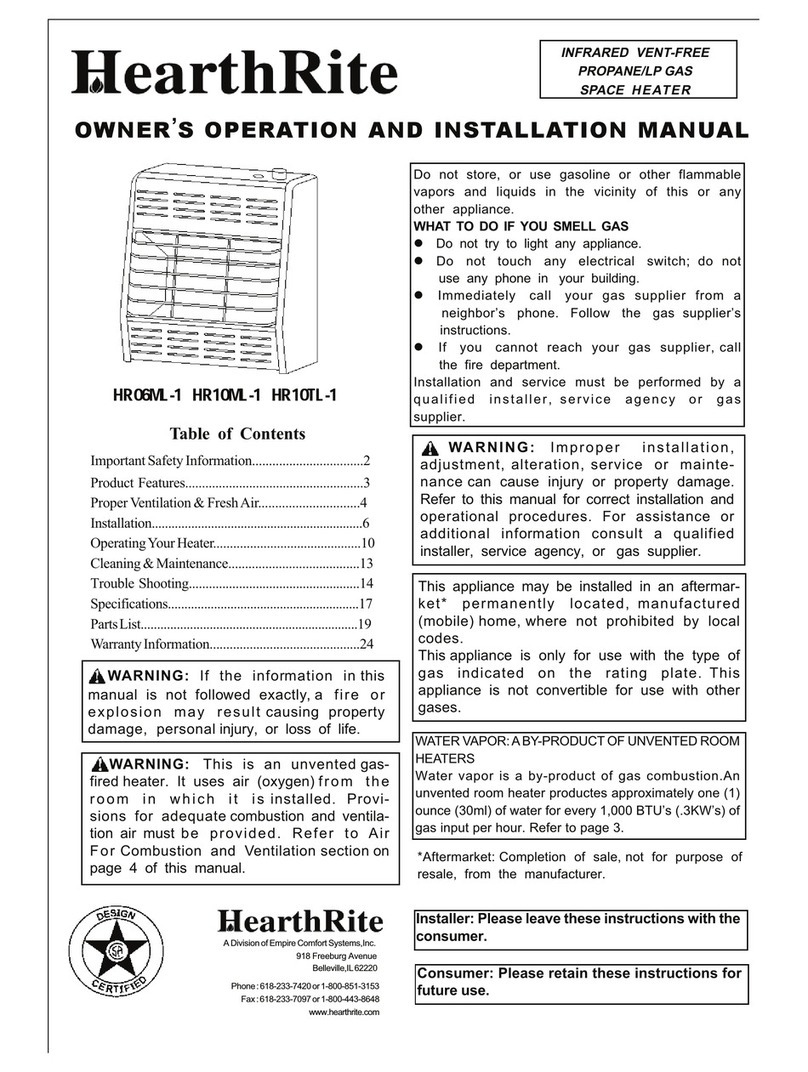

• This heater must only be used with the type of gas indicated on the rating label. This heater is not

convertible for use with other gases.

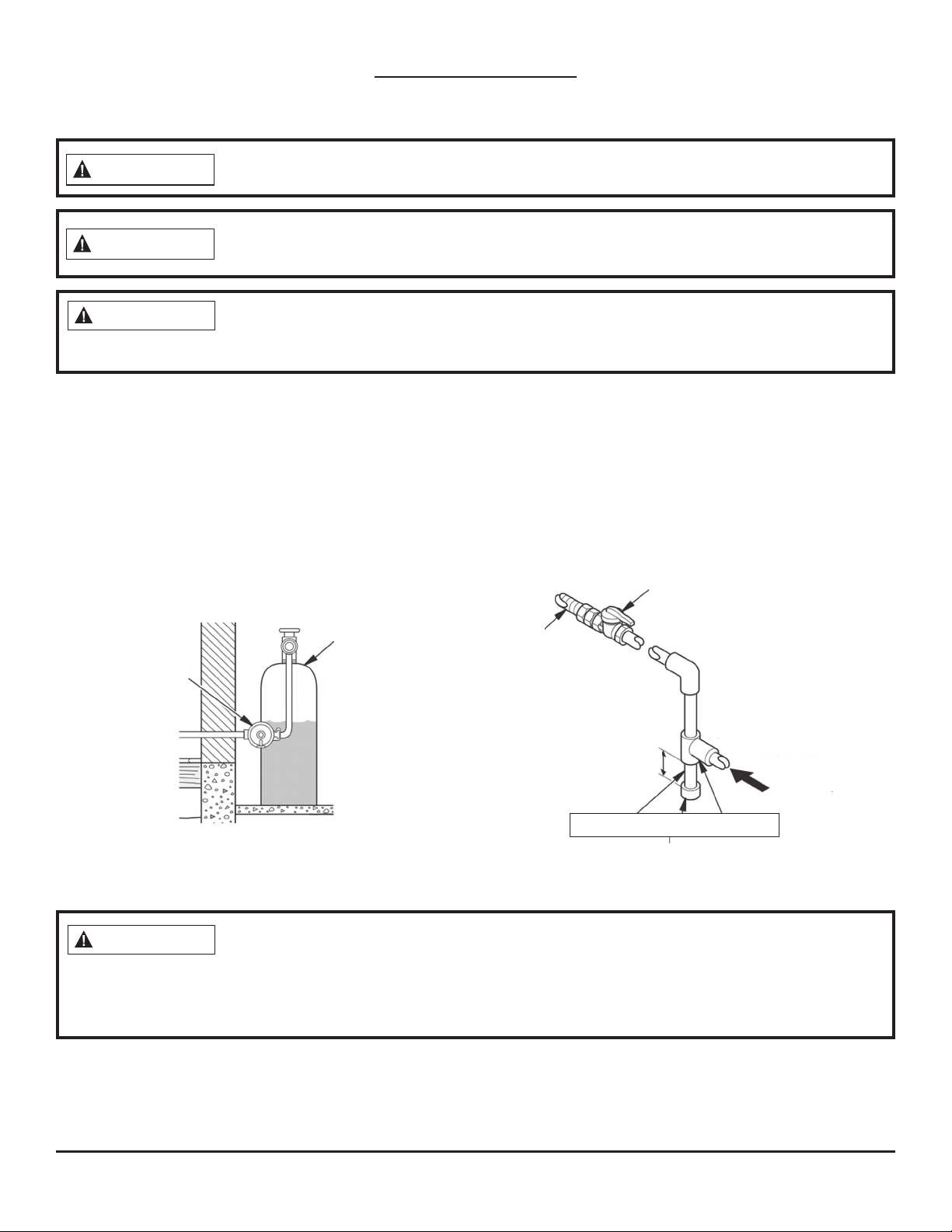

• Do not place propane supply tank(s) inside any structure. Place propane supply tank(s) outdoors.

• If you smell gas, do the following:

• Shut off the gas supply;

• Do not try to light any appliance;

• Do not touch any electrical switch, and do not use any phone in your building;

• Immediately call your gas supplier from a neighbor’s phone. Follow the gas supplier’s instructions. If

you cannot reach your gas supplier, contact the fire department.

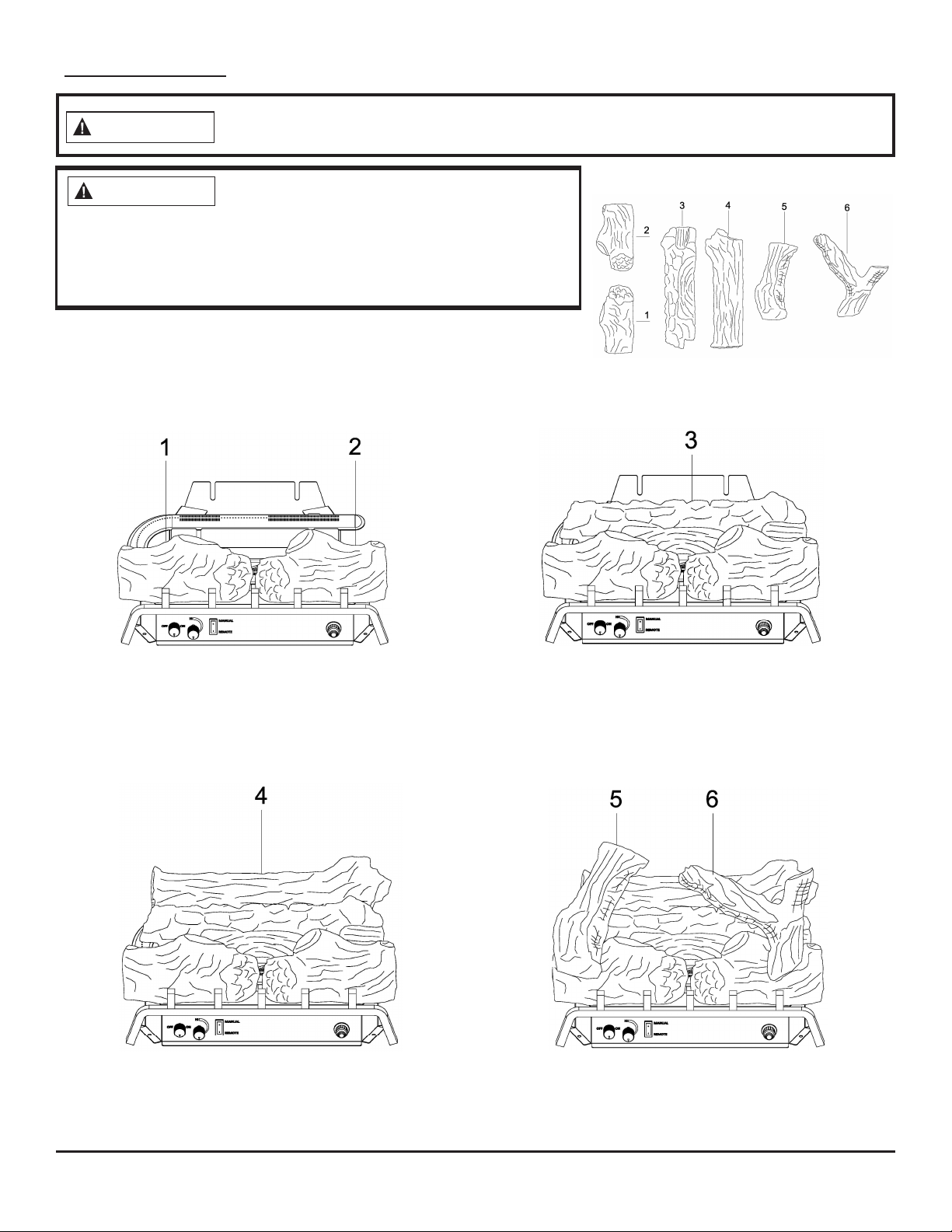

• Do not use this heater to burn real wood. Use only the logs provided with the heater.

• Do not add extra logs or ornaments such as pine cones or rock wool. These items may cause sooting.

• Never place objects in the fireplace or the logs.

• This heater is designed to be smokeless. If the logs ever appear to smoke, turn off the heater and call a

qualified service person. NOTE: When first using the heater, slight smoking may result from log curing

and manufacturing residues.

• To prevent the creation of soot, follow the instructions in CARE AND MAINTENANCE on pages 24 and 25.

•Before using furniture polish, wax, carpet cleaner, or similar products, turn the heater o. If heated, the vapors

from these products may create a white powder residue within the burner box or on adjacent walls or furniture.

• This heater must never be installed in a bedroom or bathroom.

• This heater needs fresh air ventilation to run properly and safely. This heater has an Oxygen Depletion

Sensing (ODS) safety shutoff system. The ODS shuts down the heater if not enough fresh air is available.

See AIR FOR COMBUSTION AND VENTILATION, page 7. If the heater keeps shutting o, see the

TROUBLESHOOTING GUIDE, page 26.

• Do not run the heater:

• Where flammable liquids or vapors are used or stored;

• Under dusty conditions.

• Do not use this heater to cook food or burn anything.

•Do not use the heater if any part has been under water. Before use, call a qualified service technician to

inspect the heater and replace any part of the control system and/or gas control that has been under water.

• Turn off and let the heater cool before servicing. Only a qualified service person should service and repair

the heater.

• Operating the heater above elevations of 4,500 feet may cause pilot outage.

•Do not operate the heater if a log is broken. Do not operate the heater if a log is chipped (dime-sized or larger).

• To prevent performance problems, do not use propane fuel tank of less than 100 lb. capacity.

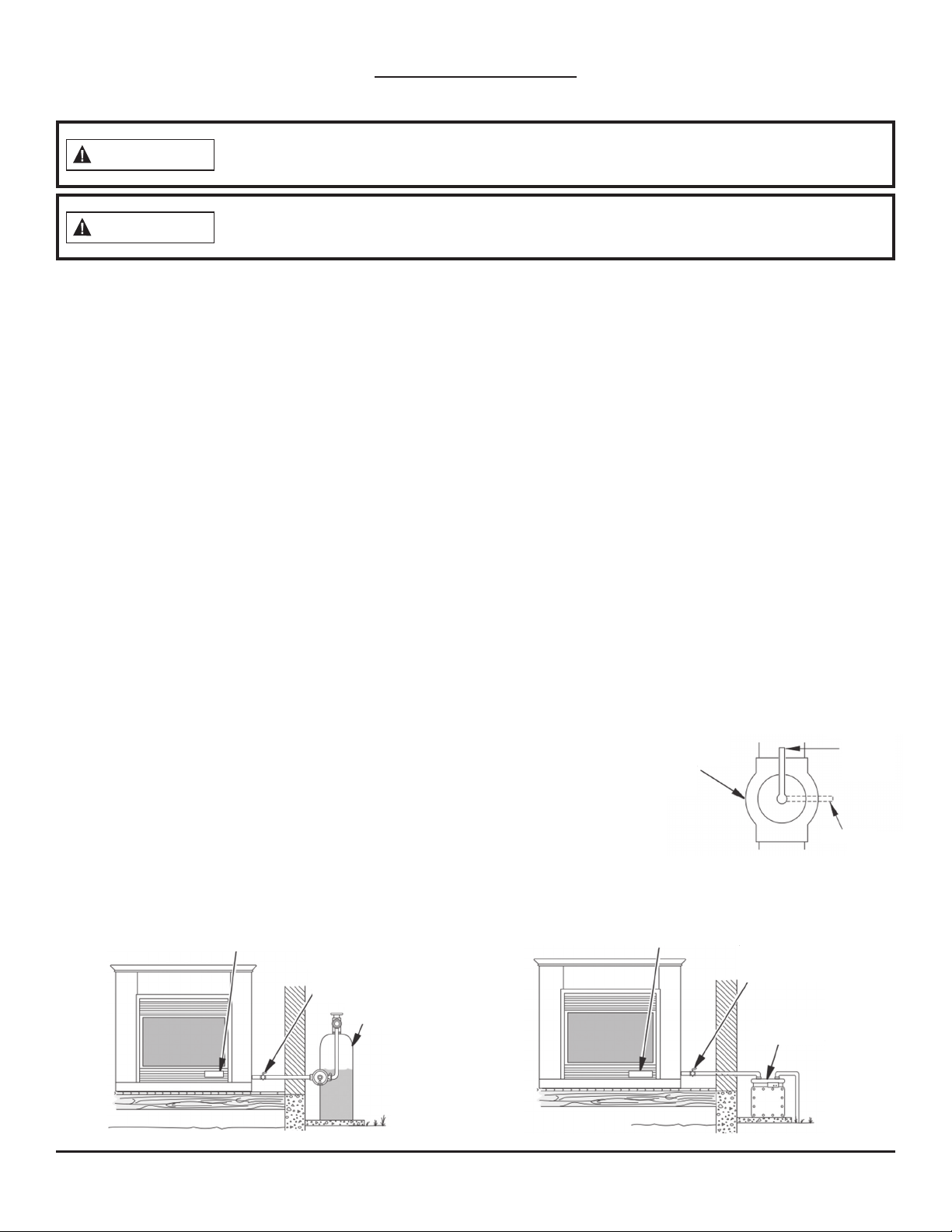

• Provide adequate clearances around air openings.

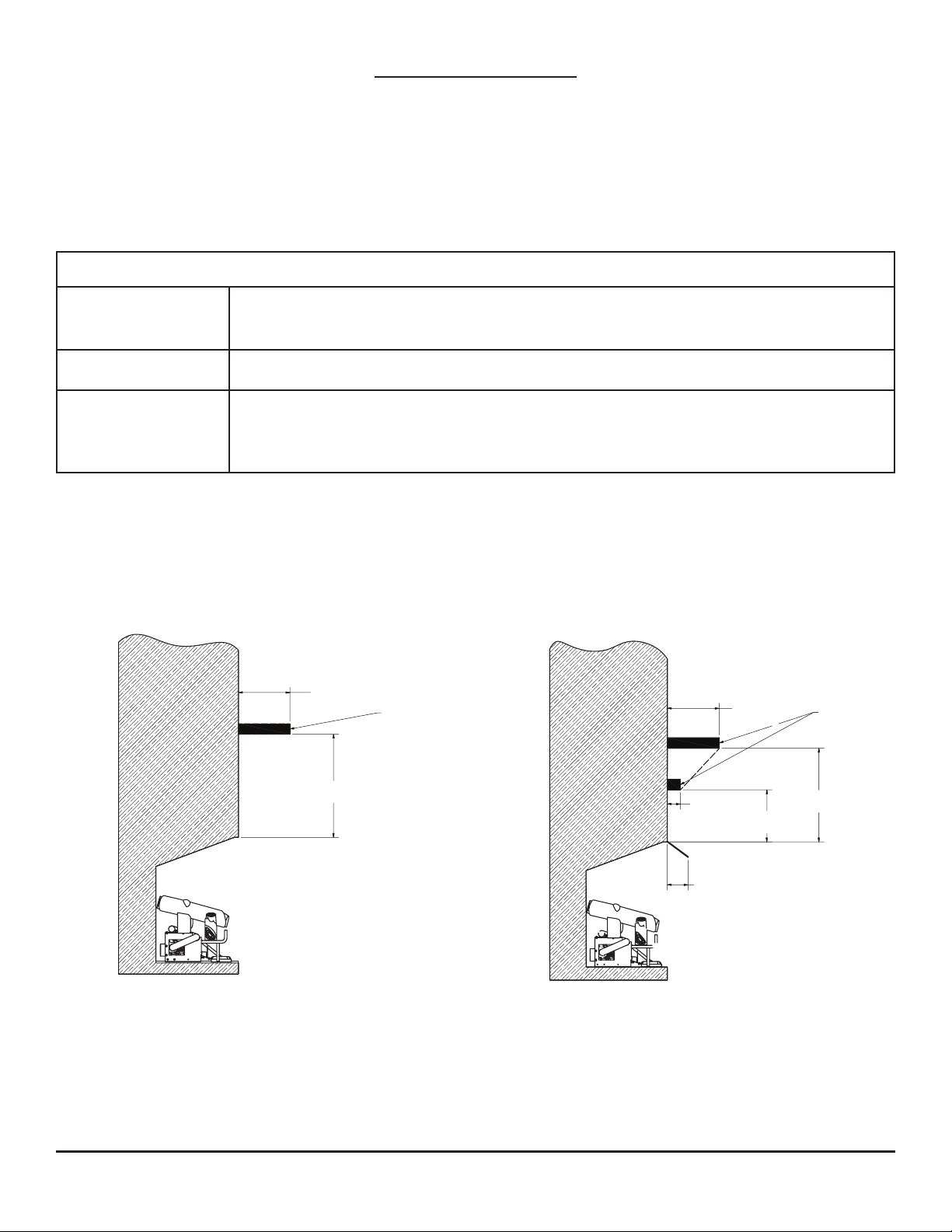

• A fireplace screen must be in place when the heater is operating. Unless other provisions for

combustion air are provided, the screen shall have an opening(s) for introduction of combustion air.

QUALIFIED INSTALLING AGENCY: Only a qualified agency should install and replace gas piping, gas

utilization equipment, or accessories, and/or repair and service such equipment. “Qualified agency” means

any entity that either in person or through a representative is engaged in and is responsible for:

• Installing, testing, or replacing gas piping; or

•Connecting, installing, testing, repairing, or servicing equipment; is experienced in such work; is familiar with

all precautions required; and has complied with all the requirements of the authority having jurisdiction.