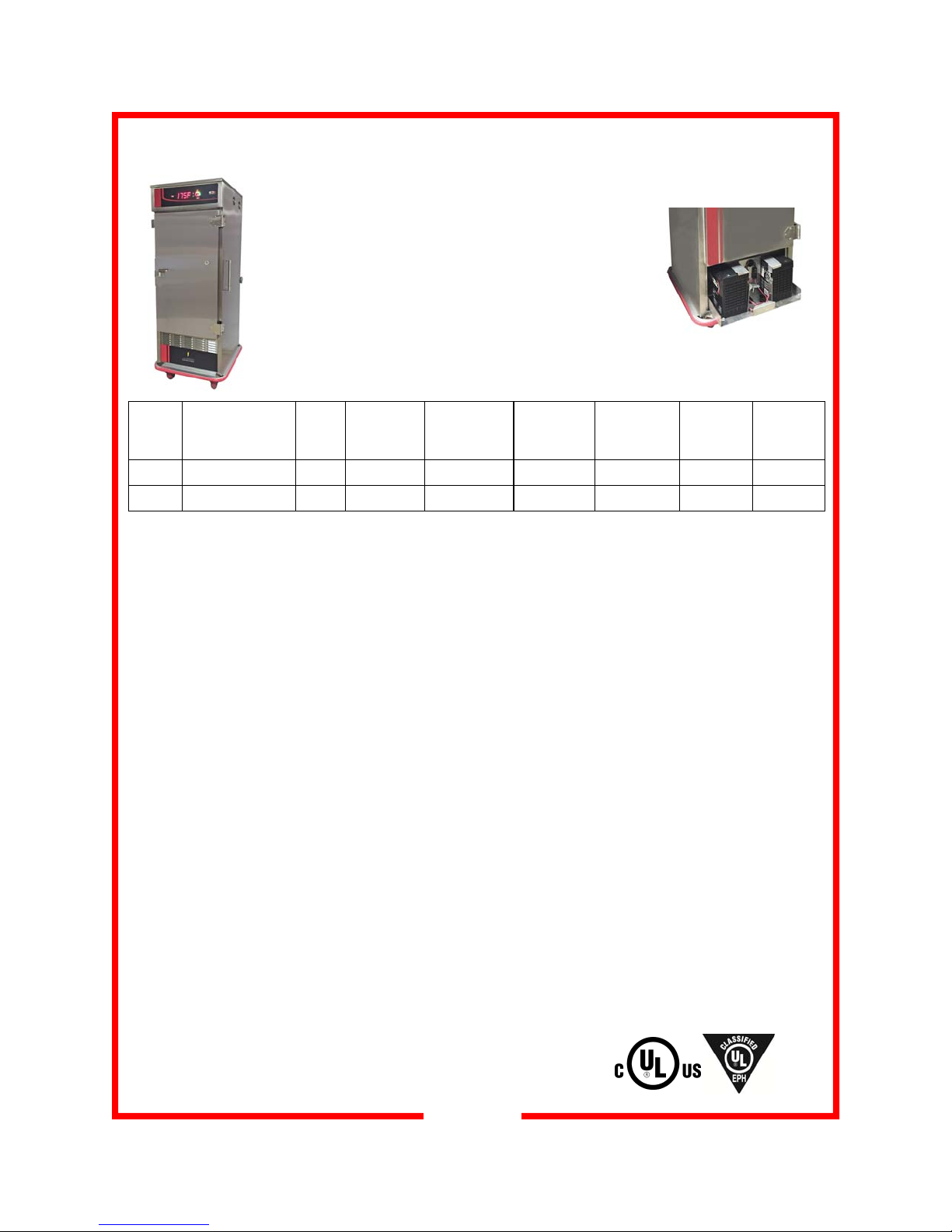

SPECIFICATIONS

The Gridless heated transport cart can operate under

both AC (wall power) or DC (battery) power. All compo-

nents, including elements, fan and controls are powered

by either source, keeping food hot and fresh during

transport. The cabinets have large, bright displays and

are easy to operate. The are all stainless steel double

wall cabinets with heavy-duty features for rugged

transport. Four to six hour run time on DC power, with a

six-hour battery charging time.

CONSTRUCTION...Completely welded

cabinet construction with outer cabinet

formed and welded to base. All seams

turned in to eliminate raw edges. All stain-

less steel; polished exterior.

BASE FRAME...12 gauge stainless steel

extended full depth bolsters.

CASTERS... 6” red balloon casters. Plate

mounted and bolted to base in offset wheel

-ahead pattern. Delrin sleeve axle bear-

ings and double ball bearing swivel. Zerk

grease fittings. Two casters fitted with

brakes.

BUMPER...Non-marking red vinyl bumper

set in heavy-duty 3/16” thick extruded

aluminum frame with reinforced corner “cut

-outs.”

INSULATION...High density fiberglass, full

2” thick continuous wrap-around type in top

and sides.

THERMOMETER...Digital type with remote

sensing bulb.

BATTERY CHARGE... Digital battery

charge level meter and % display.

DOOR...Welded double panel stainless

steel pocket door. Polished exterior. Filled

with 2” thick high density fiberglass insula-

tion. Donut bumper for protection.

HINGES...Heavy-duty strap hinges, bolted

to door and cabinet.

DOOR CLOSURE...Double wall pocket-

style door. Edge-mount lever style latch

with magnetic closure.

HANDLES...Two 1” stainless steel tubular

handles mounted to sides of cabinet. One

stainless steel handle mounted to rear, with

donut bumpers mounted to each end.

RACK ASSEMBLIES... Stainless steel

baffles with stainless steel universal tray

slides. Fully adjustable at 1-3/4” spacing.

Standard spacing at 3-1/2” centers.

HEATING SYSTEM... Top mounted blower

heater for even heat distribution. High

efficiency DC motor with cooling fans. Full

range thermostat with on/off switch and AC

or DC power indicator. Two batteries for

DC power operation and NEMA 5-20P plug

for AC power operation.

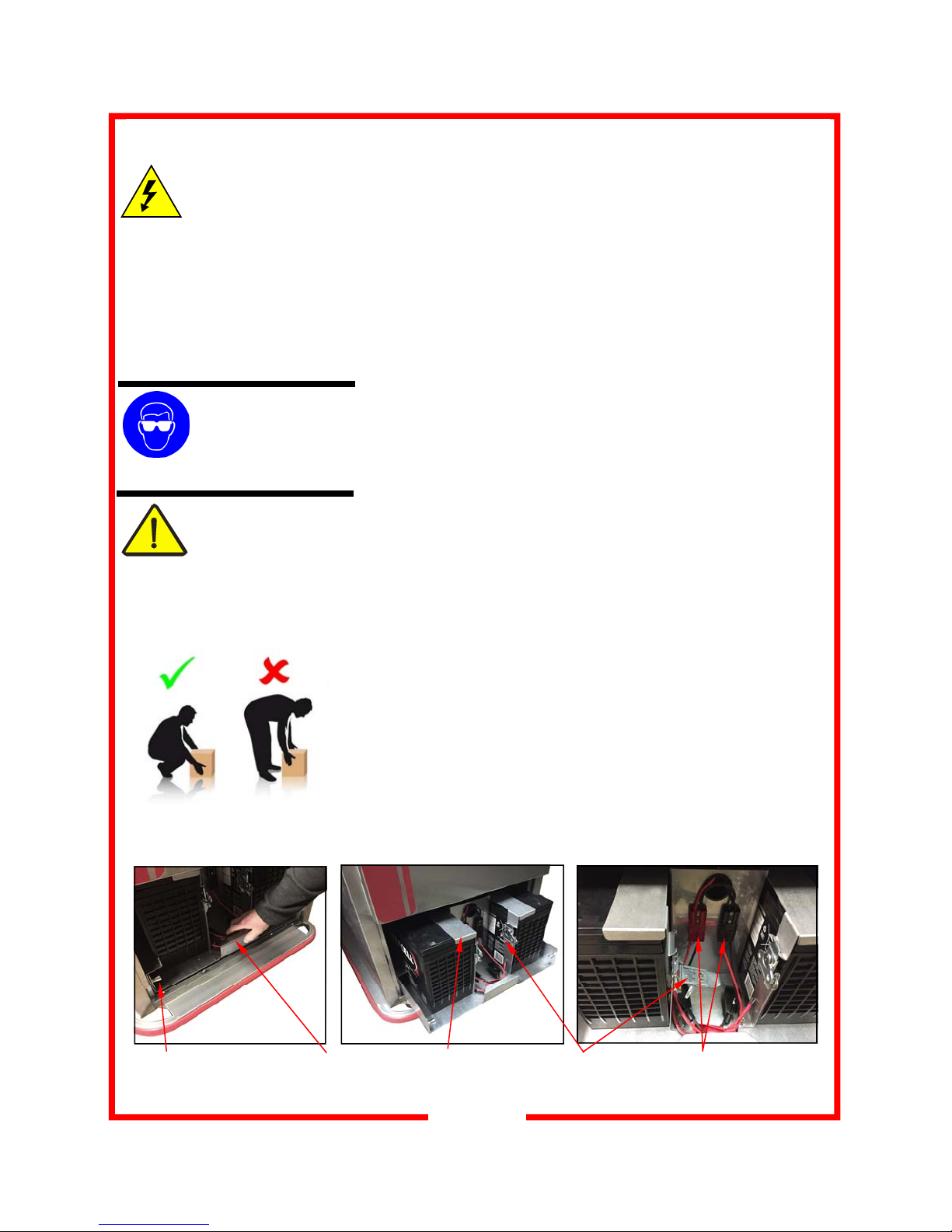

DC POWER SYSTEM... Two on board

batteries to power all electronics, including

heating elements, blower motor, cooling

fans and control board. Full battery charge

will provide 4-6 hours of operation. Robust

power converter and charge controller for

seamless transition from AC wall power

and DC battery power and vice versa. Cart

can be left to charge for as long as the user

wants and will switch to a power saving

mode when fully charged. Cart will operate

while being charged or can be charged

while the unit is cold. Battery life 3-5 years

depending on number of charge cycles.

ELECTRICAL CHARACTERISTICS...

Operates on 120 volts, 60 cycle, single

phase, 1300 watts, 10.8 amps. Ten foot 3

wire rubber cord with 3 prong grounding

plug. NEMA 5-20P. Bright LED digital

temperature and battery charge. Adjusta-

ble brightness for indoor or outdoor view-

ing.

PERFORMANCE...GTH12: preheat to

160°F (71°C) in approximately 50

minutes; 180°F in 60 minutes (82°C); 200°

F (93°C) in 80 minutes. GTH7: preheat to

160°F (71°C) in 25 minutes; 180°F (82°

C) in 40 minutes; 200°F (93°C) in 50

minutes. Temperature range of 160°F to

200°F (71°C to 93°C). Batteries can be

charged in 4 hours or less and have a 4-6

hour run time.

ACCESSORIES/OPTIONS...

Alternate caster sizes and types

Four wheel brakes

Menu card holder (5”x7” or 8.5”x11”)

6” extended width tray slides

Alternate electrical configuration

Model Capacity

12”x20” 18”x26” Slide

Pairs Inside Work-

ing Height Height

In (mm)

Depth

In (mm)

Width

In (mm)

Caster

Diameter

In (mm)

Shipping

Weight

Lbs ( kg)

GTH7 14 7 7 26-1/8 (664) 62-3/8 (1584) 37-3/8 (949) 32-5/8 (828) 6 (162) 285 (130)

GTH12 28 14 14 43-5/8 (1108) 79-1/2 (2029) 33-3/8 (949) 32-5/8 (828) 6 (162) 440 (200)

4