2

TABLE OF CONTENTS

1. TRANSPORTATION AND STORAGE OF EQUIPEMENT................................................................................................. 3

2. UNIT PACKAGE ........................................................................................................................................................... 4

3. SAFETY REQUIREMENTS............................................................................................................................................. 5

4. EU DECLARATION OF CONFORMITY........................................................................................................................... 6

5. TECHNICAL DATA ....................................................................................................................................................... 7

5.1. Product information sheet. Delegated Regulation (EU) 1254/2014............................................................. 7

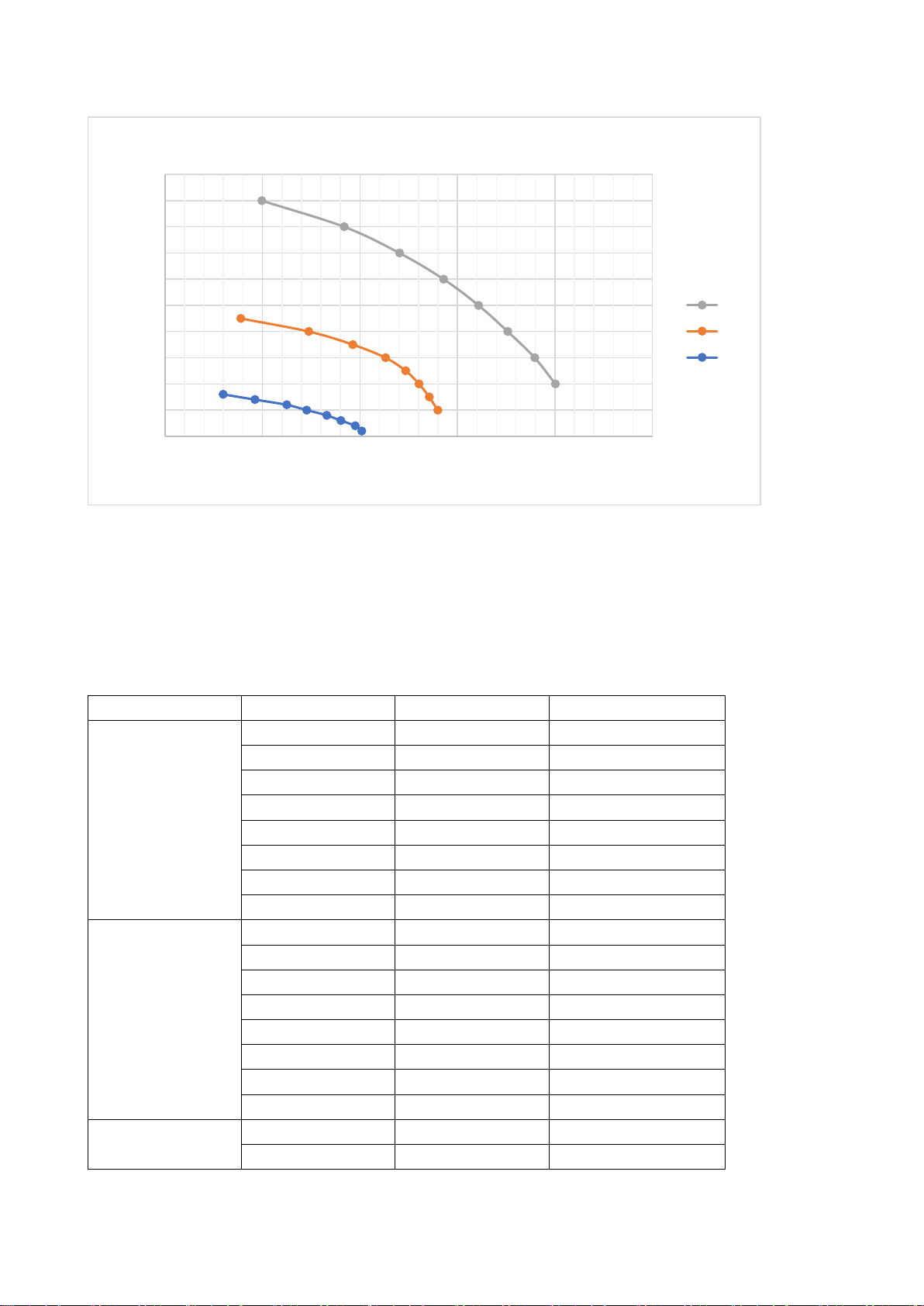

5.2. Performance curves ...................................................................................................................................... 8

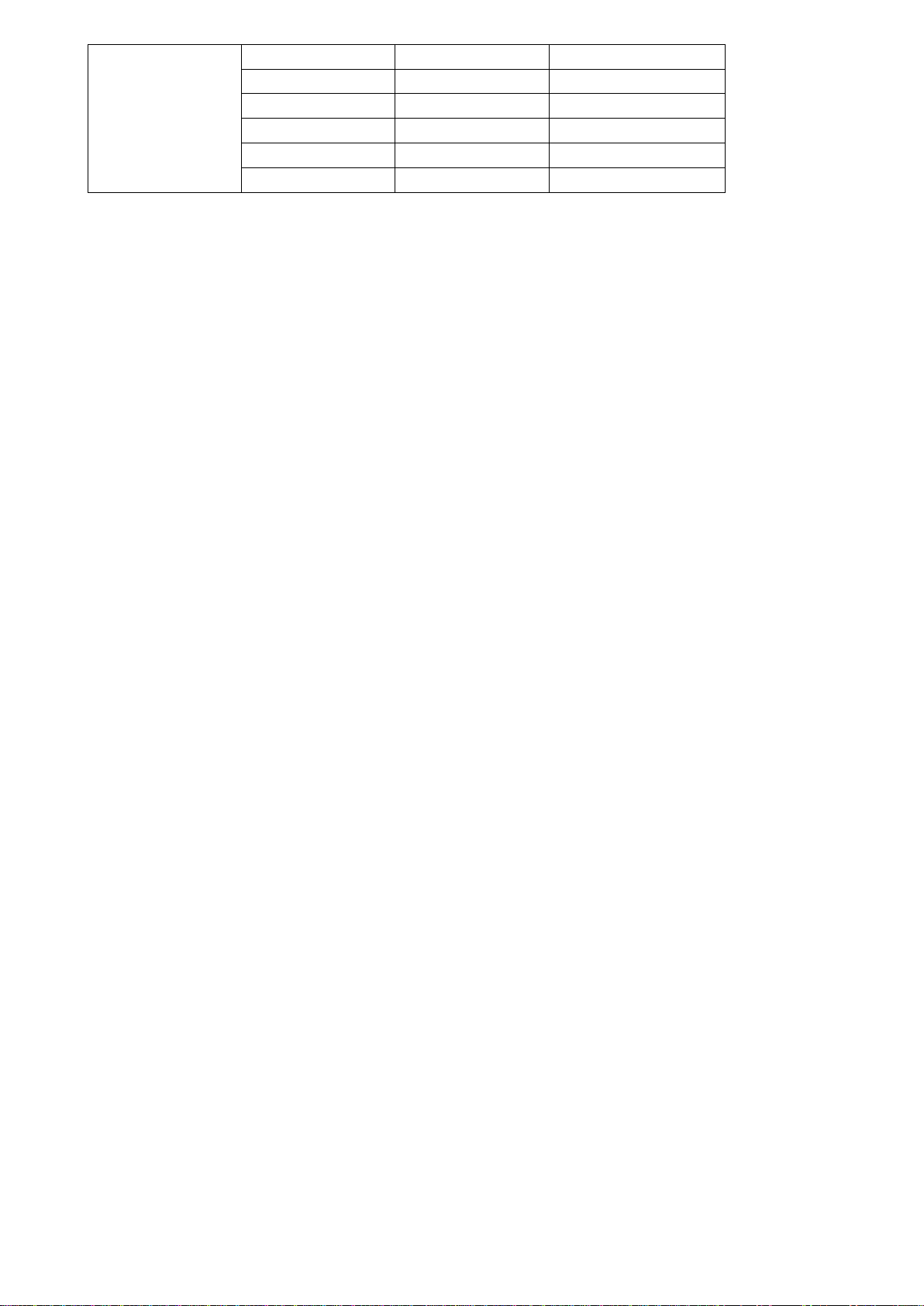

5.3. Performance and power consumption ......................................................................................................... 8

5.4. Sound characteristics.................................................................................................................................. 10

9.2. Dimensions and weight............................................................................................................................... 11

6. FUNCTIONALITY ....................................................................................................................................................... 12

7. INSTALLATION OF THE UNIT .................................................................................................................................... 13

7.1. Selecting the mounting location................................................................................................................. 13

7.2. Connecting ducts ........................................................................................................................................ 13

7.3. Maintenance space..................................................................................................................................... 14

7.4. Ventilation system balancing...................................................................................................................... 15

8. CONNECTION OF THE UNIT...................................................................................................................................... 16

8.1. Connecting electric circuit .......................................................................................................................... 17

8.2. Installation of the control panel ................................................................................................................. 17

8.3. Connector of comfort functions ................................................................................................................. 18

8.4. Control board electrical wiring diagram ..................................................................................................... 20

8.5. Description of control board contacts ........................................................................................................ 21

9. OPERATION OF THE UNIT......................................................................................................................................... 22

9.1. WiFi controller ............................................................................................................................................ 22

9.1.1. Downloading the app ............................................................................................................................. 22

9.1.2. WiFi connection set-up........................................................................................................................... 23

9.1.3. App home screen.................................................................................................................................... 25

9.1.4. Setting up weekly operation program.................................................................................................... 25

9.1.5. Ventilation boost activation ................................................................................................................... 26

9.1.6. Away....................................................................................................................................................... 26

9.1.7. Filter menu ............................................................................................................................................. 27

9.1.8. Resetting WiFi controller to factory defaults ......................................................................................... 27

9.2. Control panel with touchscreen display ..................................................................................................... 28

9.2.1. Standby mode......................................................................................................................................... 28

9.2.2. Main screen............................................................................................................................................ 29

9.2.3. Settings menu......................................................................................................................................... 30

9.2.4. Setting up weekly operation program.................................................................................................... 31

9.2.5. Failure indication .................................................................................................................................... 31

9.3. Control panel with a knob........................................................................................................................... 32

9.3.1. Operating state indicator ....................................................................................................................... 32

9.3.2. Air filter replacing / anti-frost protection indicator ............................................................................... 33

9.3.3. Failure indicator...................................................................................................................................... 33

9.3.4. RESET procedure .................................................................................................................................... 34

9.3.5. Resetting the filter lifetime meter.......................................................................................................... 34

9.3.6. Additional system settings ..................................................................................................................... 35

9.4. Replacing air filters ..................................................................................................................................... 36

10. MAINTEINANCE AND WARRANTY............................................................................................................................ 38

11. CONTACTS................................................................................................................................................................ 39