Heat-Fab Saf-T 3006 Installation and operating instructions

Saf-T Thimble

Installation & Maintenance Instructions

UL Listed Through-the-wall

Thimble Assembly

Model # 3006 adapts to 5” and 6” diameter connector pipe.

Model # 3008 adapts to 7” and 8” diameter connector pipe.

The Heat-Fab Saf-T Thimble is intended for use in conjunction

with any residential and building heating appliance burning

gas, liquid or solid fuels.

The Heat-Fab Saf-T Thimble is an engineered and Listed through-

the-wall thimble assembly that reduces the minimum 18 inch

clearance to combustibles required by NFPA 211 Standard. The

Saf-T Thimble is to be used as a thimble/wall pass thru to connect

appliances to interior or exterior masonry chimneys.

This product is Listed by UNDERWRITERS LABORATORIES, INC.

and bears the Mark: UL

WALL

ADAPTER

HOT AIR

WALL PROTECTOR AND

COVER SHIELD

HOT AIR

CONNECTING

PIPE

ROOM AIR

CHIMNEY

BACK PLATE AND INSULATED

THIMBLE ASSEMBLY

A major cause of chimney related res is failure to maintain

required clearances (air space) to combustible materials. It is of

utmost importance that the Saf-T Thimble be installed only in

accordance with these instructions.

2

Saf-T Thimble Installation & Maintenance Instructions

SAFETY FIRST

The instructions provided with the Saf-T Thimble are intended as a guide to assist

a qualied professional installer. Check your local building codes and contact local

building or re ofcials about restrictions and installation requirements in your area.

Inspect the masonry chimney for structural integrity before you install the Saf-T

Thimble. Inspect the chimney for loose or eroded mortar, cracks in the masonry,

missing bricks, internal obstructions, unused ue holes and excessive

creosote formation.

If the chimney needs to be cleaned, a professional certied chimney sweep should be

used. In the cases where the chimney system is sized incorrectly, not in compliance with

current local building codes or in poor physical condition, then a new lining system

should be installed. We recommend our Saf-T Liner designed for relining existing

masonry chimneys. Saf-T Liner satises code requirements as a substitute for 5/8”

reclay liner and is UL Listed. Go to www.selkirkcorp.com for more information

on Saf-T Liner.

The wall protector and cover shield of the Saf-T Thimble should be installed on

approved re retardant sheetrock, millboard, brick or the like.

The Saf-T Thimble must be installed so there are no obstructions below or above the

wall protector. The Saf-T Thimble should not be located directly behind a heating

appliance (i.e. straight out wall behind appliance).

The Saf-T Thimble must be properly sized for your appliance.

Appliance Flue Use Saf-T Thimble

Collar Diameter Part No.

5” #3006

6” #3006

7” #3008

8” #3008

CLEARANCE FROM COMBUSTIBLE MATERIALS

The minimum air space clearance between interior masonry chimneys (which have

any portion of the chimney located within the exterior wall of the building) and

combustible materials shall be at least 2 inches.

The minimum air space clearance between exterior masonry chimneys (which have the

chimney completely outside the exterior wall of the building, excluding the soft or

cornice area) and combustible material shall be at least 1 inch. The air space must be

left as air space and shall not be lled.

3

Saf-T Thimble Installation & Maintenance Instructions

ASSEMBLY MATERIALS

The following tools and supplies are needed to complete the installation of your Saf-T Thimble:

Hammer Screwdriver

Silicon Caulking Tape Measure

Saw Level

Masonry Drill Bit (1/4” diameter) Square

Saf-T Thimble Template

ASSEMBLY INSTRUCTIONS

1. There are 3 types of installations: (1) where a thimble hole already exists

in a properly lined chimney; (2) an installation that requires a new

thimble and (3) an installation incorporating a new Listed stainless

steel liner system. In all cases, the Saf-T Thimble template will be

used. The Template is printed on the carton in which the Saf-T Thimble

is packaged. See Fig. 1.

2. Cut the template cleanly along the perforated lines. The template will

measure 17” high by 16” wide. This template incorporates the required

clearance of 1” for the installation of the back plate. There are four ue

sizes marked in the center of the template 5”, 6”, 7”, and 8” diameter.

Cut out the required size for your installation.

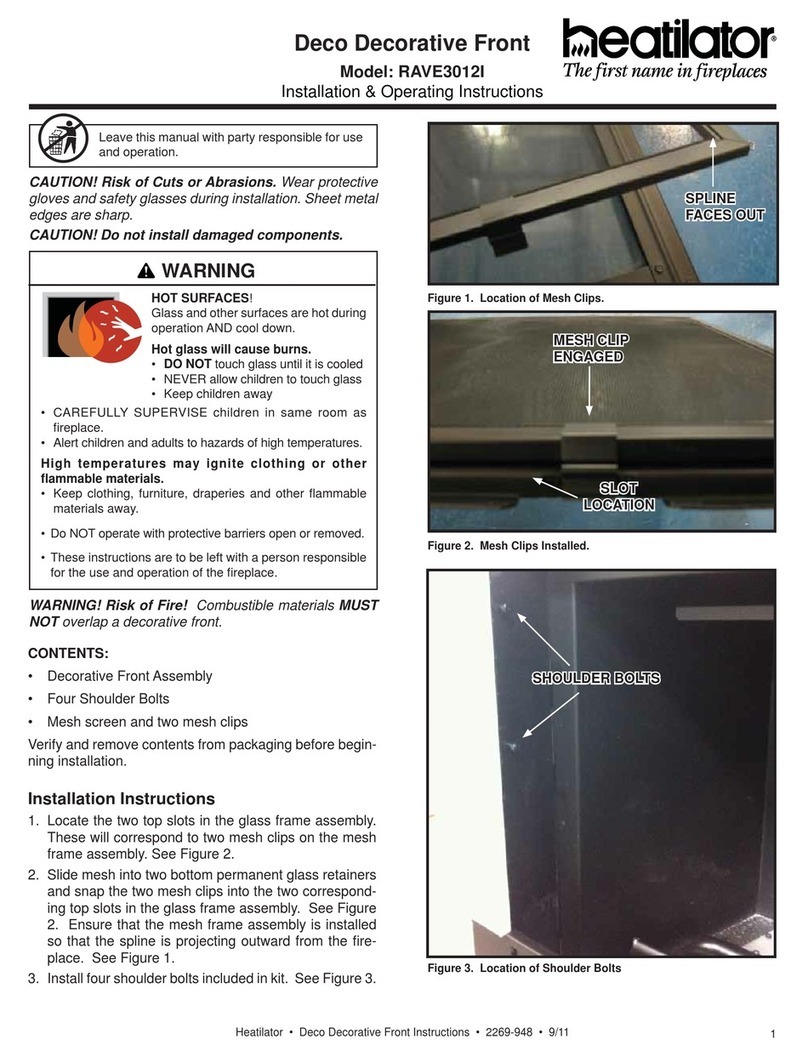

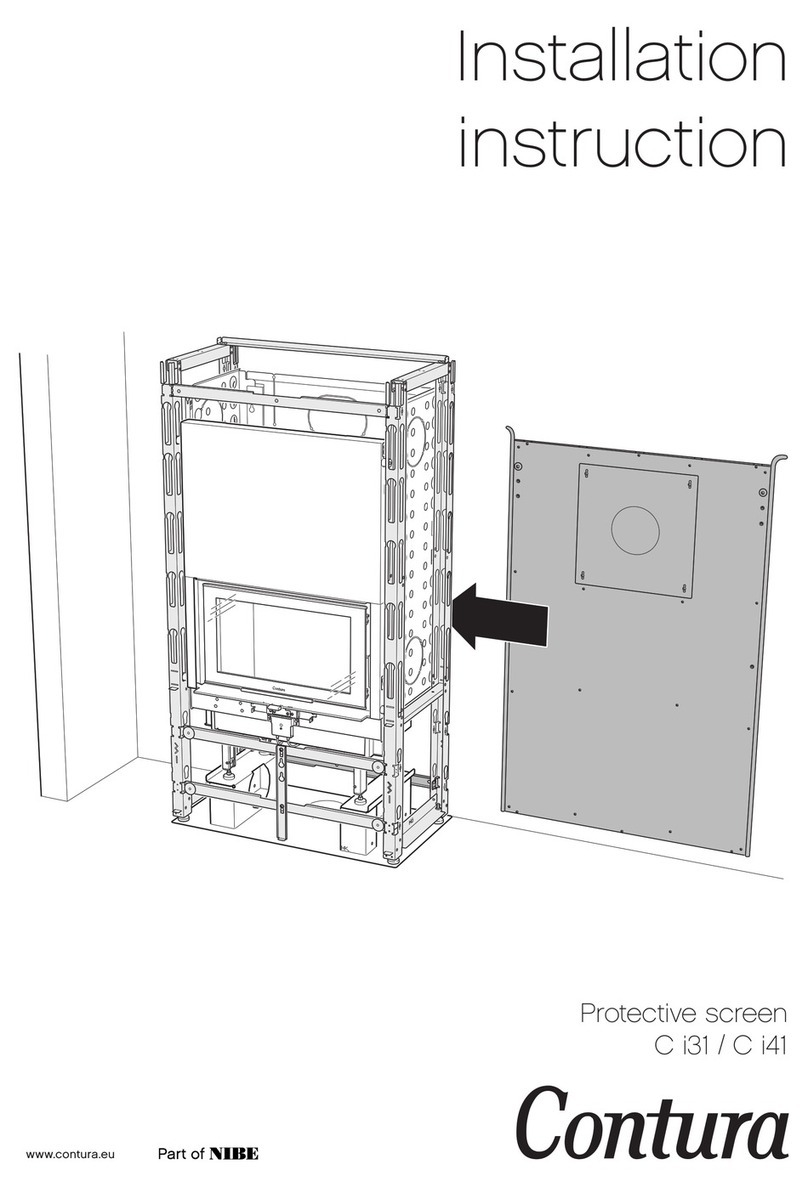

EXPLODED VIEW OF

SAF-T THIMBLE ASSEMBLY

BACK PLATE AND

INSULATED THIMBLE

ASSEMBLY

WALL ADAPTER

WALL PROTECTOR

AND COVER

SHIELD

FIG. 1

5”, 6”, 7”

AND 8”

DIAMETER

CONNECTOR

PIPE SIZES

16”

17”

4

Saf-T Thimble Installation & Maintenance Instructions

3. Position the template where the Saf-T Thimble will be located and trace around

the template carefully. You will be cutting the interior, as well as the exterior wall

so accurate measurements are necessary for a clean installation. In installations

where there is an already existing connector pipe, place the template over the

connector pipe and trace around the template keeping it level. Remove the

connector pipe and now you are ready to cut out the opening in the wall.

CAUTION: Make sure there are no electrical wires or plumbing lines within

this section of the wall and proceed to cut the opening for the back plate and

insulated thimble assembly. If a wall stud or any other combustible material is

encountered within this opening, it must be removed.

Do not frame in until step #10, Fig. 4.

4. In installations where a new ue thimble is required; again take the template with

the correct diameter hole for your connector pipe and position the template against

the chimney wall. Trace around the template the connector size for your ue

thimble installation.

NOTE: The Saf-T Thimble must be installed into a ue opening with structural

integrity. A clay thimble is recommended in the masonry chimney in conjunction

with the Saf-T Thimble for maximum safety.

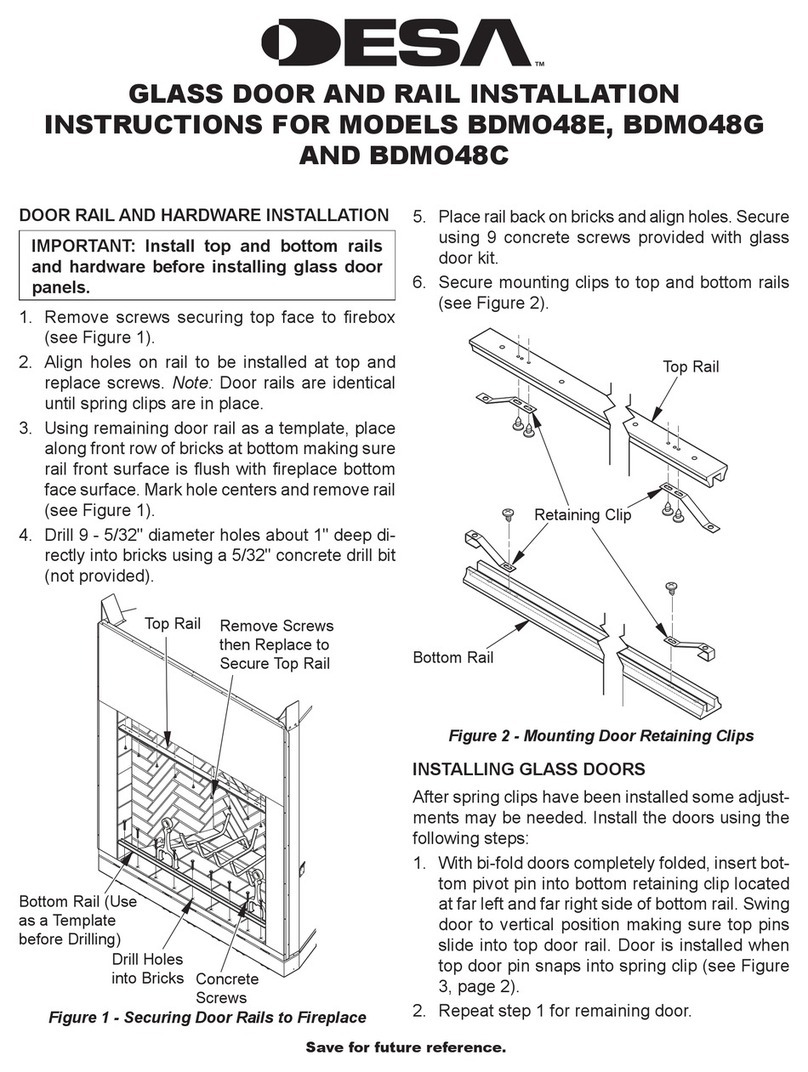

5. Using the back plate and insulated thimble assembly as a template position and

mark off the hole locations where the two support brackets on the back plate are

located. See Fig. 2.

6. Remove the back plate and using a masonry drill bit, drill the two required 1/4” x 1

1/2” deep holes in the masonry.

BOTTOM SUPPORT

BRACKET

FIG. 2

TOP SUPPORT

BRACKET

5

Saf-T Thimble Installation & Maintenance Instructions

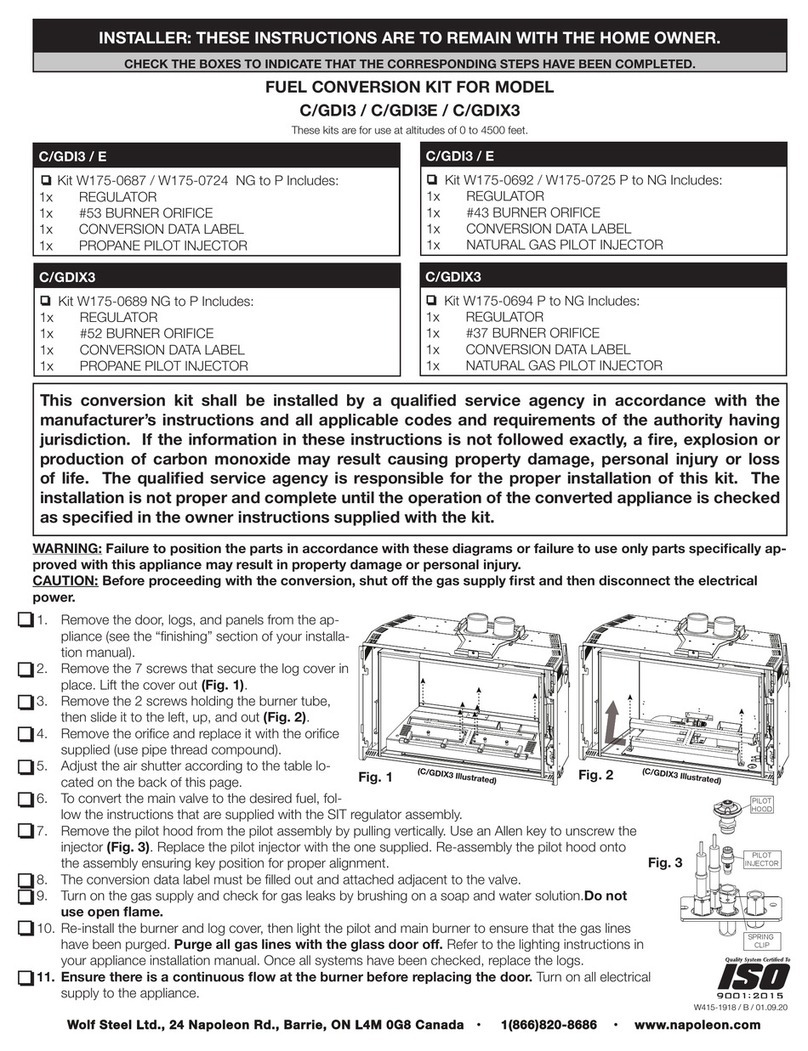

7. Apply the exterior rated silicon caulking to the back

periphery of the back plate. See Fig. 3.

8. Install the back plate and insulated thimble assembly with

the side marked top in the up position with the two

masonry bolts.

9. If the chimney is constructed with a space beyond the

exterior wall of the house, check the outside of the house

for weather tightness around the periphery of the back

plate. Do not place insulation within this area. Maintain at

least 1” air space between the masonry and any

combustible material.

10. Appropriate framing and headers must be installed to

insure a safe installation of the Saf-T Thimble. See Fig 4.

11. A one inch clearance is held around the periphery of the

back plate by the built in spacers. The framing members

abutt these spacers.

12. The Saf-T Thimble adjusts to t 4” - 8 1/2” wall structures.

See Fig. 5.

13. The inner stainless steel sleeves that make up the

insulated thimble adjust in and out. The insulated thimble

is packaged in the full extended position to accommodate

a wide wall structure. The insulated thimble must be

adjusted so it projects 2 ½ inches out from the nished

interior wall surface.

This will position the thimble ush against the back of the

wall protector. When adjusting the insulated thimble

do not remove any insulation, but lightly compress the

insulation into its adjusted position so the insulation is

evenly distributed. REMOVAL OF ANY INSULATION WILL

VOID HEATFAB’S WARRANTY.

SEAL AROUND

PERIPHERY OF

BACK PLATE

WITH EXTERIOR

RATED

CAULKING

FIG. 3

1 INCH

BRACES

FIG. 4

13”

14”

ADJUSTING

INSULATED

THIMBLE

FIG. 5

6

Saf-T Thimble Installation & Maintenance Instructions

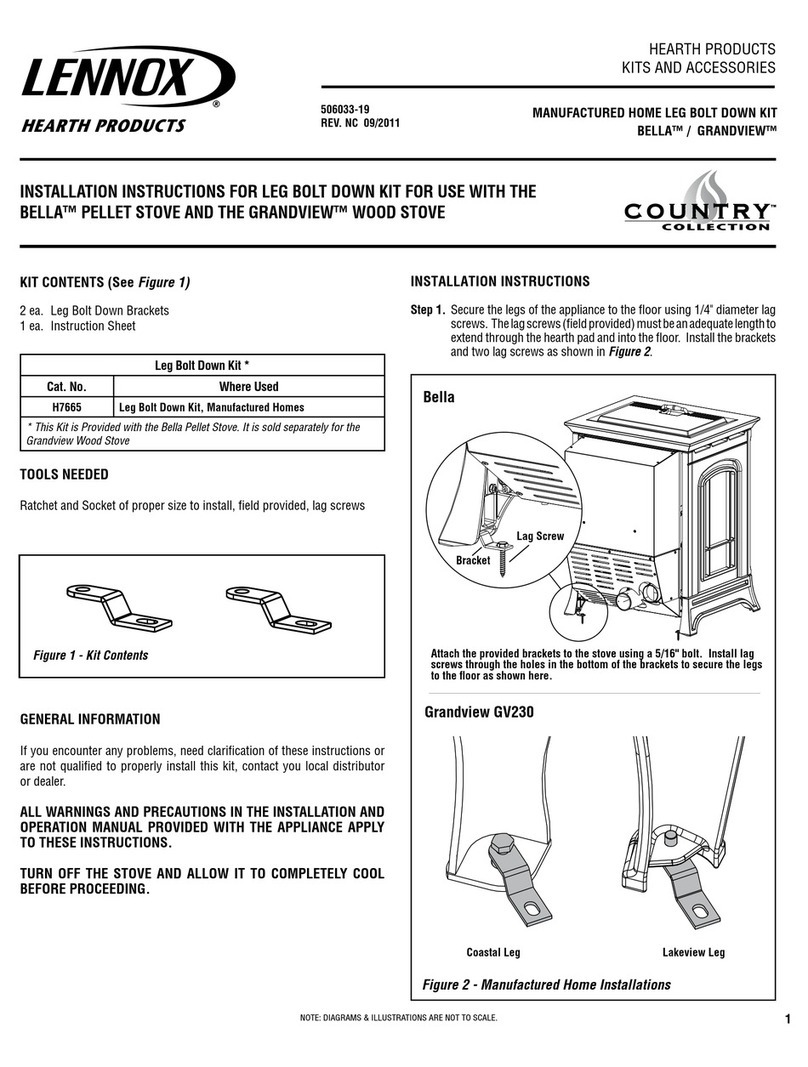

14. Take the wall adapter assembly and position it so it slides into the back plate and

insulated wall thimble assembly. The wall adapter adjusts inside the back plate for

4” thru 8 ½” wall structures and mounts ush to the framing headers. In wall

structures of 6” or more in depth, spacers are required on the framing to secure

the wall adapter. Fasten the wall adapter to the framing headers with the four

supplied #8 round head wood screws. See Fig. 6.

15. Install the correctly sized connector pipe making sure the connector pipe is of

quality construction and capable of withstanding the ue gas temperatures

produced by the appliance.

We recommend the 22 gauge Saf-T Pipe or equivalent. A minimum 24 gauge is

required by code.

16. Install the wall protector and cover shield so the rear extension of the cover shield

slides into the insulated thimble. There are 3 spacers on the rear extension of the

cover shield that t snugly into the insulated thimble to maintain the proper air

space clearance. The wall protector and cover shield should now be rmly against

the wall structure. Fasten the wall protector to the wall with the 6 supplied #8

round head wood screws. See Fig. 6.

CHIMNEY

WALL ADAPTER

BACK PLATE AND THIMBLE ASSEMBLY

FIG. 6

WALL PROTECTOR

AND COVER SHIELD CONNECTOR PIPE

(FOR ?????)

17. The Saf-T Thimble is now installed and the connector pipe can be attached to your appliance.

7

Saf-T Thimble Installation & Maintenance Instructions

CHIMNEY MAINTENANCE

The chimney connector and chimney should be checked frequently during the heating

season and cleaned by a professional certied chimney sweep if necessary.

FORMATION OF CREOSOTE AND SOOT AND THE NEED FOR REMOVAL

When wood is burned slowly, it produces tar and other organic vapors, which combine

with expelled moisture to form creosote. The creosote vapors condense in the

relatively cool ue of a slow-burning re. The resulting creosote makes for an extremely

hot re.

The chimney should be inspected at least once every two months during the heating

season to determine if a creosote or soot buildup has occurred. If creosote or soot

buildup has accumulated, it should be removed to reduce the risk of chimney re.

After cleaning or inspecting the chimney or connector system, check the Saf-T Thimble

for secureness of all parts. Make sure the chimney connector is routed to the chimney

at the required upward pitch toward the chimney.

Also available from Heat-Fab:

Saf-T Liner

Saf-T Pipe

Selkirk Corporation

5030 Corporate Exchange Blvd. SE

Grand Rapids, MI 49512

Toll Free: 1.800.433.6341

selkirkcorp.com

P/N: PI-THIM

This manual suits for next models

1

Table of contents

Popular Fireplace Accessories manuals by other brands

Superior

Superior MFS Series Operation and service manual

Modern Flames

Modern Flames DWLS-40/15 Installation

pleasant hearth

pleasant hearth LS938-96LC Assembly

PYROMANIA

PYROMANIA GWS-25R installation instructions

Valor

Valor LINEAR SERIES installation manual

Monessen Hearth

Monessen Hearth ARTISAN Series installation manual