HEATEC Firestorm Guide

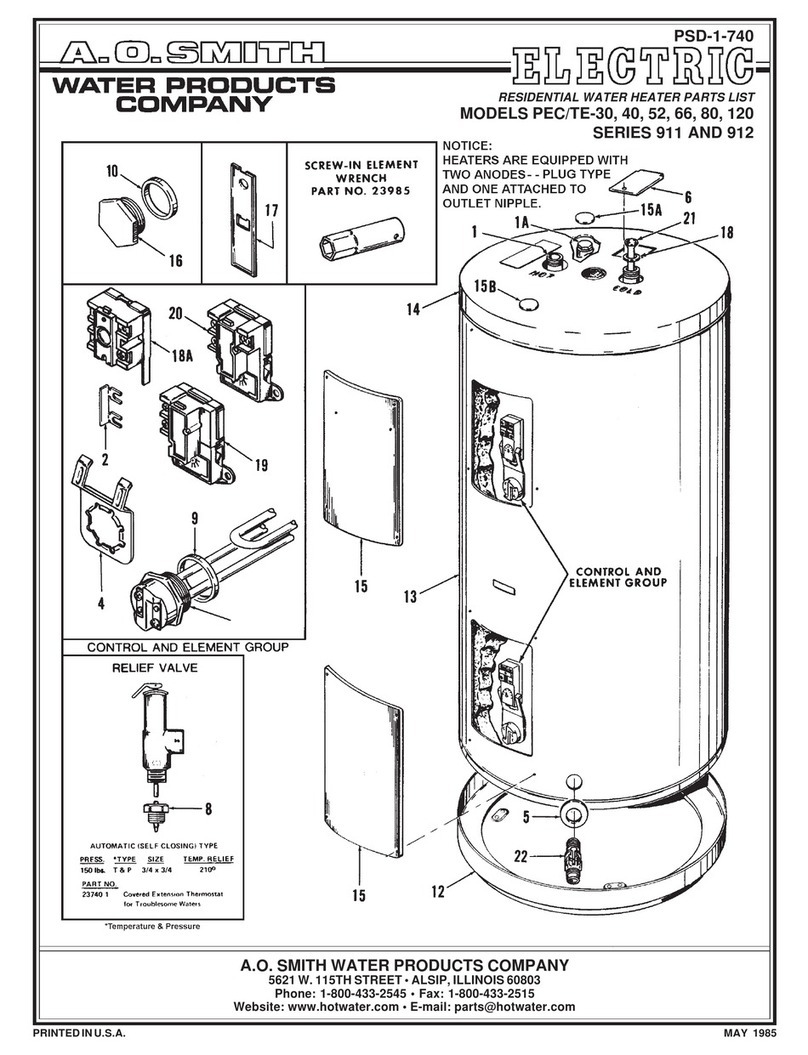

Figure 1. Heatec Firestorm heater.

MAINTENANCE

Firestorm™ water heaters

Publication 1-10-218

CONTENTS

Safety .......................................................................... 1

Scope .......................................................................... 1

Intended users ............................................................ 2

Calcium clean-out ....................................................... 2

Cleaning strainers ....................................................... 4

Freeze protection ......................................................... 4

Checking water level switches .................................... 5

Checking the flame scanner ........................................ 7

Checking pilot gas pressure regulator .........................7

Checking high fuel gas pressure switch ...................... 7

Checking low fuel gas pressure switch ....................... 8

Checking high flue gas stack temperature switch ....... 8

Checking auxiliary contacts for water pump motor ..... 9

Checking auxiliary contacts for combustion

air motor ................................................................ 9

Checking low combustion air switch ......................... 10

Maintenance schedule ............................................... 12

SAFETY

Carefully following safety instructions in this docu-

ment will help you avoid serious injury or death. Read

instructions for each topic in their entirety before actu-

ally doing the work. Pay special attention to hazard

warnings that appear herein and on the heater. These

warnings identify known hazards, their severity and

how you can avoid them.

Warnings also appear at appropriate places in the

instructions.

Please be aware that if you deviate from the instruc-

tions, you could create unforeseen safety hazards. You

should perform step-by-step instructions in the order

given.

SCOPE

This document provides instructions for maintain-

ing Firestorm water heaters (Fig. 1). It also pro-

vides instructions on how to check various devices

in case you need to make sure they are working

properly.

Failure to heed certain recommendations may re-

sult in damage to the heater and/or shorten its life.

The components covered are mainly those that can

cause heater malfunctions when they go bad, need

cleaning, or get out of adjustment.

Because of differences in heaters, some instruc-

tions may not apply to your heater.

HEATEC TEC-NOTE

INTENDED USERS

Instructions in this document are intended for use

by qualified operators and maintenance personnel.

Some procedures require setting and testing parts

inside the heater electrical control panel while it is

open and electrical power is turned on.

Qualified persons are those who fully understand

electrical shock hazards and how to avoid them.

They also know how to take necessary precautions

against being burned when working around hot

surfaces and water heated to temperatures close to

its boiling point.

CALCIUM CLEAN-OUT

Build up of calcium inside the heater can be a mat-

ter of serious concern. Excessive buildup can lead

to heater malfunctions and heater damage. The rate

of calcium buildup varies widely depending on the

amount of calcium in the water supply and operat-

ing conditions.

Frequency of checks and down-time

The heater should be checked at least once a

month while in regular use to make sure calcium

buildup has not reached a point that affects opera-

tion of the heater. If no adverse signs are found,

the checks can be made less frequently. However,

if the heater is moved to a new location or if the

water supply is changed, revert back to monthly

checks.

When excessive calcium buildup is found you need

to plan down-time for clean-out. You may need to

allow a full day for clean-out. Do not delay any

longer than absolutely necessary.

Symptoms of excessive build-up

In due time you should be able to judge when it’s

time for a clean-out by the appearance of calcium

buildup on the packing in the heater.

In order to inspect the packing, shutdown the

heater and allow it to cool. Then open the lower

access door and pull out several pieces of pack-

ing (Fig. 2) from the center of the heater. You will

need to remove packing until you are near the

bottom center of the packing column. Calcium will

build up here first.

As you continue to check packing at regular inter-

vals you should also watch for other symptoms of

calcium buildup.

One symptom is the inability to heat the water to

the desired temperature as you have in the past.

Another symptom is an abnormally high stack

temperature and excessive vapor from the stack.

Another symptom is discoloration of the outside of

the heater shell.

We strongly recommend that you do not wait until

these symptoms appear. Instead you should devel-

op your ability to judge buildup by inspecting the

packing as indicated earlier.

Figure 2. Checking packing for calcium buildup.

Cleaning methods

There are two methods for cleaning calcium from

your heater. The first method requires shutting it

down and removing all the packing. The packing

must be soaked in a chemical intended for dissolv-

ing calcium. Once the calcium has been removed

from the packing, rinse it and put it back in the

heater.

The second method is to clean the inside of the

heater and packing simultaneously. This is done

by introducing a chemical cleaner into the top of

the heater. Do this while circulating water from

the reservoir through the heater with the burner

off. This may take several hours, depending on the

amount of calcium buildup.

To circulate its water, first fill the reservoir. Then

temporarily install a pipe or hose from the water

outlet valve to the secondary water connection

Publication 1-10-218

Page 2

Figure 3. Location of components on Firestorm heater.

Publication 1-10-218

Page 3

A. Stack temperature switch

B. Inlet water pressure switch

C. Inlet water temperature

gauge

D. Low gas pressure switch

(not visible in photo)

E. Gas pressure gauge

F. Control panel

G. Overflow connection

H. Water level indicator

I. High-high water level switch

J. High water level switch

K. Low water level switch

L. Low-low water level switch

M. Drain connection

N. Thermocouple

O. Check valve

P. Outlet water Y-strainer

Q. Automatic outlet water valve

R. Outlet water temperature

gauge

S. Outlet water pressure gauge

T. Manual outlet water valve

U. Burner

A

B

C

D

E

F

G

H

I

J

K

L

M

N

OPQR

S

T

U

V

W

X

Y

Z

AA

ABAC

AD

AEAF

V. High gas pressure switch

W. Manual gas leak test valve

X. Pilot gas valve

Y. Manual gas shut off valve

Z. Inlet water Y-strainer

AA. Manual inlet water valve

AB. Automatic inlet water valve

AC. Inlet water pressure

regulator

AD. Inlet water pressure gauge

AE. Secondary water connection

AF. Exhaust stack connection

(AE, Fig. 3). Then operate the water pump to cir-

culate the water containing the cleaning chemical.

The cleaning chemical will probably work better

soon after the heater has been shut down, while it

is still warm.

The chamber that contains the floats for water level

switches (I, J, K, L, Fig. 3) should be cleaned

separately.

Chemicals

A variety of chemicals are available for remov-

ing calcium deposits. Some contain sulfamic acid.

Others contain citric acid. You may wish to use

stronger chemicals on the packing while it is out of

the heater and milder chemicals inside the heater.

Keep in mind that chemicals circulating through

the heater will contact non-stainless steel parts,

such as circulating pump, bronze valves, seals, etc.

We suggest that you contact a chemical supplier to

find out what they recommend.

Packing (removal & replacement)

Dissolving calcium from the packing may take

several hours after it is removed from the heater.

Consequently your heater will be out of service

for an extended period unless you could simply

exchange the original packing with extra packing

already cleaned. That would shorten heater down-

time and allow you to clean the coated packing as

long as necessary.

To do that you would need extra packing. It is

absolutely essential for the extra packing to be

identical to the original packing. Otherwise the

heater will not perform properly! Please contact

Heatec for information about your packing.

If you plan to use extra packing be sure to scribe

the wall of the heater to indicate the level of the

original packing. When re-filling the heater with

packing, increase its level about one inch higher

than your scribe mark to allow for settling.

CLEANING STRAINERS

All Firestorm heaters have an inlet water Y-strainer

(Z, Fig. 3). Some also have an outlet water Y-

strainer (P, Fig. 3). Clogged strainers can cause

the heater to malfunction. Symptoms of a clogged

strainer include tripping the inlet water pressure

switch and/or abnormally high flue gas tempera-

ture. You should routinely check the strainers to

make sure they are not clogged.

Cleaning inlet water Y-strainer

Manually shut off the inlet water valve (AA, Fig.

3). Remove the plug from the inlet water Y-strainer

(Z, Fig. 3). Allow the water to drain.

Only a small amount of water will drain from the

strainer, so a bucket is all you need to catch the

water. Remove the strainer basket and clean it if

it is clogged. Replace the strainer basket and the

plug.

Cleaning outlet water Y-strainer

Allow the heater and water it contains to cool

down enough to avoid being burned from contact

with the shell and the water inside.

On heaters that have an outlet water strainer (P,

Fig. 3), open the drain valve that you installed in

the drain connection at the bottom of the heater.

Or remove the plug from the drain connection (M,

Fig. 3).

Drain several gallons of water until the level

shown on the water level indicator is slightly lower

than the outlet Y-strainer. So you may want to con-

nect a hose to the drain valve so the water can be

directed to a suitable area away from the heater.

Remove the plug from the outlet water Y-strainer.

Allow the water to drain. Only a small amount of

water will drain from the strainer, so a bucket is all

you need to catch the water. Remove the strainer

basket and clean it if it is clogged. Replace the

strainer basket and plug.

Close the drain valve at the bottom of the heater or

replace the plug in the drain connection.

FREEZE PROTECTION

Be sure to protect your heater from freezing if it is

located where temperatures remain below freezing

for several hours while not running. Otherwise wa-

ter in the heater could freeze and cause extensive

damage to heater components.

Publication 1-10-218

Page 4

Figure 4. Components outside the control panel.

One way to protect it from freezing is to drain all

water from the heater shell, float chamber, piping,

pump and strainer. All of these have drain plugs

except for piping, which may require loosen-

ing connections to allow drainage where water is

trapped.

As an alternative to draining water from the pip-

ing you may want to install heat tracing around the

piping.

CHECKING WATER LEVEL SWITCHES

Check water level switches (I, J, K, L, Fig. 3) if

you encounter any of the following symptoms:

• Pump won’t run

• Tank overflows

• Outlet water valve is inoperative

• Pump cycles on/off

To check the switches proceed as follows:

1. Obtain a scrap piece of stiff wire (or a coat

hanger) about 3 feet long. Bend one end of

the wire to form a small hook.

2. Open the control panel so you can observe

the lights on the PLC (B, Fig. 5).

3. Turn on the electrical power using the main

disconnect breaker (F, Fig. 5) inside the

panel.

Note: Earlier panel marking FIREYE FLAME MONITOR is now BURNER DISPLAY

Publication 1-10-218

Page 5

Figure 6. Flame scanner.

4. Open the top of the chamber where the

switches are installed.

5. Insert the hooked end of the wire into the

channel and grab onto the float of a switch.

6. Move the float up and down while observing

the light on the PLC. The light should go on

and off in response to float movement.

7. Repeat steps 5 and 6 for each of the remain-

ing switches.

Figure 5. Components inside the control panel.

Publication 1-10-218

Page 6

A B C D E F

H

G

IJKL

M

A. Voltage label

B. PLC (Programmable Logic Controller)

C. Fireye burner management control YB110

D. Terminals and relays

E. Alarm strobe light

F. Main disconnect breaker

G. Grounding lug

H. Control transformer

I. Circuit breakers and fuse blocks

J. Blower motor controller

K. Water pump motor controller

L. Equipment grounding strip

M. Fused terminals

CHECKING THE FLAME SCANNER

1. Make sure that the BURNER switch (Fig. 4) is

set to OFF.

2. Turn on power to the control panel while the

front panel is open.

3. With no flame present, check for approxi-

mately 560 Vac between terminals S1 and

S2 using an ac voltmeter.

4. Remove the flame scanner (Fig. 6).

5. Create a flame using a cigarette lighter, a

torch or a match. Hold the flame in front of

the scanner eye. The voltage should drop to

about 340 Vac and the Fireye burner display

should show the message FALSE FLAME and

should indicate a signal number. Otherwise,

either the flame scanner or its amplifier is

defective.

CHECKING PILOT GAS PRESSURE

REGULATOR

Figure 8. Manometer connected to tee at pilot gas line.

1. Connect a manometer to the tee of the pilot

gas line where it enters the burner.

2. Open the control panel and gain access to

the Fireye burner control (C, Fig. 5).

3. Turn on power to the control panel (F, Fig.

5) while the front panel is open.

4. Set BURNER switch (Fig. 4) to ON and let the

heater start through its purge cycle.

5. Wait for the burner display (Fig. 4) to show

the words IGNITION TIMING. Quickly place

the switch marked CHECK/RUN on bottom

of Fireye burner control (C, Fig. 5) to the

position marked CHECK. This will hold the

timing sequence while you check/adjust the

regulator.

6. Check that the manometer indicates ap-

proximately 3 inches of W.C. or as specified

for your burner in the burner manual. If not,

adjust screw on the regulator to attain the

recommended setting.

7. Place switch marked CHECK/RUN on bottom

of Fireye burner control back to RUN. The

timing sequence should continue and opera-

tion should be normal.

CHECKING HIGH FUEL GAS PRESSURE

SWITCH

With the burner operating, remover the cover from

the high fuel gas pressure switch (Fig. 9). Be care-

ful not to touch the live terminals. Adjust the

switch to a lower setting that causes the switch to

open.

Figure 9. High fuel gas pressure switch.

The following reactions should occur, indicating

that the pressure switch is operating properly:

• The burner should shut down.

• The HIGH FUEL GAS PRESSURE light (Fig. 4) on

the control panel should go out. (All other

indicator lights on the panel will also go

out.)

Publication 1-10-218

Page 7

• Fireye burner display should read LOCKOUT

3-P INTLK OPEN.

Re-adjust the high pressure switch to its previous

position and reset its manual reset button. Reinstall

its cover.

CHECKING LOW FUEL GAS PRESSURE

SWITCH

Figure 10. Low fuel gas pressure switch.

Shut off the main gas manual shutoff valve (Y, Fig.

3) and set BURNER switch (Fig. 4) to ON. Remove

the plug from the tee fitting below the pressure

switch allowing gas to escape. The following reac-

tions should occur, indicating that the switch is

operating properly:

• LOW FUEL GAS PRESSURE light on control

panel (Fig. 4) should be the first light to

go out. (Subsequent indicator lights on the

panel will also go out.)

• Fireye burner display (Fig. 4) should read

LOCKOUT 3-P INTLK OPEN.

Reinstall plug in tee fitting. Slowly re-open the

main gas manual shutoff valve.

Reset the low fuel gas pressure switch (Fig. 10)

using its manual reset button. Reset the Fireye

control.

CHECKING HIGH FLUE GAS STACK

TEMPERATURE SWITCH

WARNING

Do not touch the exposed terminals (FIG. 12)

inside the stack temperature switch. Touching the

terminals could cause electrical shock causing

serious injury or death.

Figure 11. High flue gas temperature switch.

Figure 12. Inside of high flue gas temperature switch.

Publication 1-10-218

Page 8

Figure 13. Checking stack temperature at analyzer port.

With the burner operating, remove the cover from

the high flue gas temperature switch (Fig. 11).

1. Remove the plug from the analyzer port at the

base of the exhaust stack. Insert a thermom-

eter in the port and note the temperature of the

exhaust gas (Fig. 13).

2. Rotate the dial (Fig. 12) on the switch until its

setting is a lower value than the temperature of

the exhaust gas. Be careful not to slide the dial

towards the switch while rotating it. Otherwise

the dial may press on the small plunger in the

switch and prematurely trip the switch.

The following reactions should occur, indicating

that the switch is operating properly:

• The burner should shut down.

• The HIGH FLUE GAS STACK TEMPERATURE light

(Fig. 4) on control panel should be the first

light to go out.

• Burner display (Fig. 4) should read LOCKOUT

3-P INTERLOCK OPEN.

Rotate the dial to its previous setting, then reset

the manual reset button on the switch. Replace the

cover.

CHECKING AUXILIARY CONTACTS FOR

WATER PUMP MOTOR

With the burner operating, trip the breaker discon-

nect for the water pump motor (G, Fig. 15).

This should cause its auxiliary contacts (E, Fig.

15) to open. The following reactions should occur,

indicating that the contacts are operating properly:

1. The burner should shut down.

2. Fireye burner display (Fig. 4) should show

STANDBY L1-3 OPEN.

Reset the breaker disconnect for the water pump

motor.

CHECKING AUXILIARY CONTACTS FOR

COMBUSTION AIR BLOWER MOTOR

With the burner operating, trip the breaker discon-

nect for the combustion air blower motor (B, Fig.

15).

This should cause its auxiliary contacts (D Fig.

15) to open. The following reactions should occur,

indicating that the contacts are operating properly:

1. The burner should shut down.

2. The COMB. AIR MOTOR AUX. CONTACTS light

(Fig. 4) on control panel should be the first

light out.

3. Fireye burner display (Fig. 4) should read

LOCKOUT 3-P INTERLOCK OPEN.

Reset the breaker disconnect for the combustion

air blower motor.

Publication 1-10-218

Page 9

CHECKING LOW COMBUSTION AIR

SWITCH

Figure 14. Low combustion air switch.

Make sure that the BURNER switch (Fig. 4) is set to

OFF.

1. In the control panel unlatch the auxiliary

contacts (D, Fig. 15) for the combustion air

blower and physically remove it with wires

attached.

2. Pull out the blue plunger on the module and

hold it out to close its contacts.

3. Restart the burner. The COMB. AIR/ ALL LIMITS

MADE light (Fig. 4) should come on almost

immediately.

4. Trip the breaker disconnect for the combus-

tion air blower. The COMB. AIR/ ALL LIMITS

MADE light should go out within 4 to 5 sec-

onds. If not, remove cover from combustion

air switch (Fig. 14) and re-adjust it as fol-

lows: Turn the adjustment screw clockwise

to shorten the cut-off response time. Turn

it counterclockwise to lengthen the cut-off

response time.

Re-insert the auxiliary contacts module into the

breaker disconnect.

Publication 1-10-218

Page 10

Figure 15. Components of motor controllers inside the control panel.

Publication 1-10-218

Page 11

A. Breaker auxiliary contacts for combustion air blower motor

B. Breaker disconnect for combustion air blower motor

C. Contactor for combustion air blower motor

D. Auxiliary contacts for combustion air blower motor

E. Auxiliary contacts for water pump motor

F. Contactor for water pump motor

G. Breaker disconnect for water pump motor

H. Breaker auxiliary contacts for water pump motor

A

B

C

D

E

F

G

H

Heatec, Inc. 5200 Wilson Road Chattanooga, Tennessee 37410 www.heatec.com (423) 821-5200 (800) 235-5200 Fax (423) 821-7673

REQUIREMENT

WEEKLY

MONTHLY

QUARTERLY

YEARLY

Clean flame scanner. X

Check intake area of blower to make sure it is not blocked by foreign material and is

free from buildup of dirt. X

During normal operation check all pressure gauges and thermometers on heater and

record any changes from previous indications. X

Check all operating and limit controls and settings to make sure they are set properly

and are working properly. X

Check heater and piping to ensure there are no leaks. X

Check heater to ensure there is no structural damage to heater or signs of over-

heating. X

Check burner control linkage to make sure it is not binding or loose. X

Remove packing from inside heater and check to ensure that calcium buildup is not

excessive. X

Check strainers to ensure they are not clogged. X

Have exhaust stack gases analyzed and have burner tuned by a specialist X

Heatec Firestorm water heaters should be checked periodically according to the requirements below. Failure

to properly maintain your heater could result in a fire or explosion.

MAINTENANCE SCHEDULE

Firestorm™ water heaters

© 2010 Heatec, Inc.

Publication 1-10-218

Page 12

Table of contents

Popular Water Heater manuals by other brands

Bradford White

Bradford White 45837F Installation & operating instruction manual

clage

clage DBX 18 BASITRONIC Operating instructions for the user

Satchwell

Satchwell HOTFLO Instruction

WaterPORT

WaterPORT DAY TANK owner's manual

EZ TANKLESS

EZ TANKLESS EZ OUTDOOR manual

STIEBEL ELTRON

STIEBEL ELTRON DHC 3/3.5-1 Trend manual

andrews

andrews HIflo EVO HF 30/300 Installation and service manual

Thermor

Thermor VM75 instruction manual

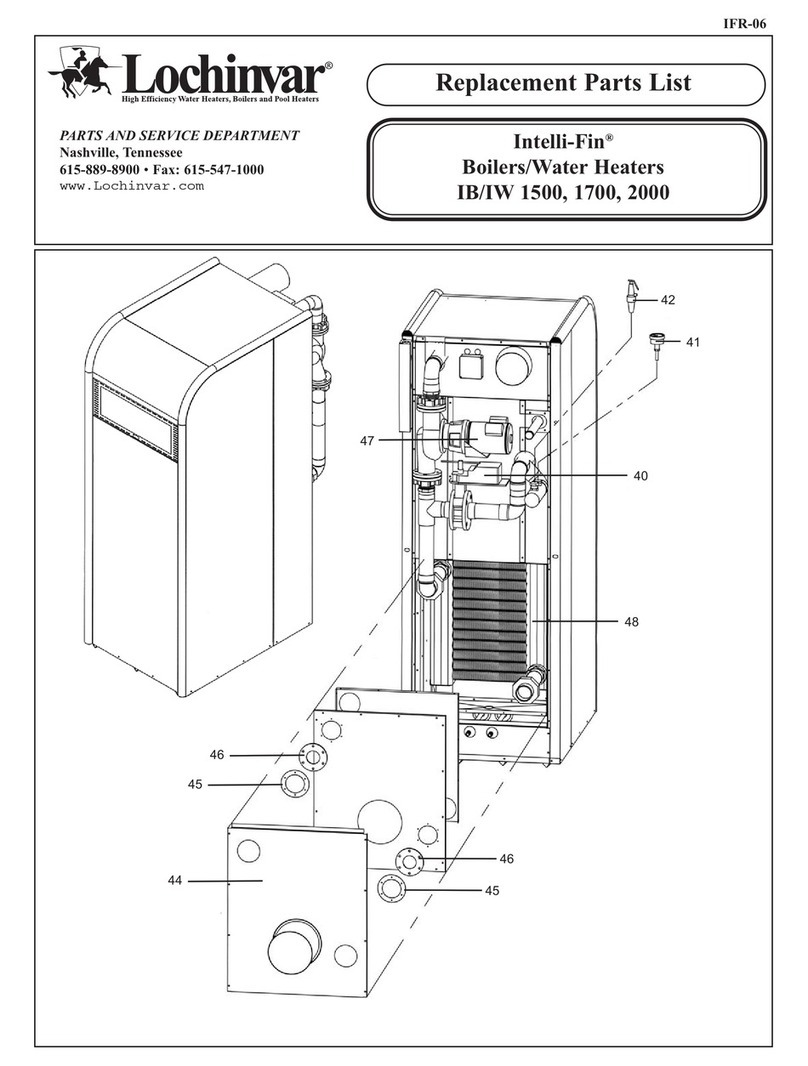

Lochinvar

Lochinvar Intelli-Fin IB 1500 Replacement parts list

Whirlpool

Whirlpool energysmart Residential Electric Water... Installation Instructions and Use & Care Guide

AER

AER INNOVATION INN600 user manual

Alfalaval

Alfalaval Micro STC Installation, service and operating instruction