Heath Company Heathkit AG-7 Guide

G. Tannenbaum

Electronic Service Data

P.O. Box 386/Ambler PA 19002

Phone 215 657 0106 Fax 215 657 0520

Web Page www.agtannenbaum.com

EA TH KIT

MODEL AG-

AUDIO GENERATOR

G A

G YO

-III!-~

Audio Generator

.. Model AG-

THE HEATH COMPANY

BENTON HARBOR, MICH.

PRICE $1.

- n

~--- -- - ---- __

d__--__- --

~------ -----

,"""""""""""""""""""""" U

"""""""""""""""" "'" ""'"

I NFORMA lrON FOR KIT

,,',,""""""""""""""""""""""""""""""""""""""""""

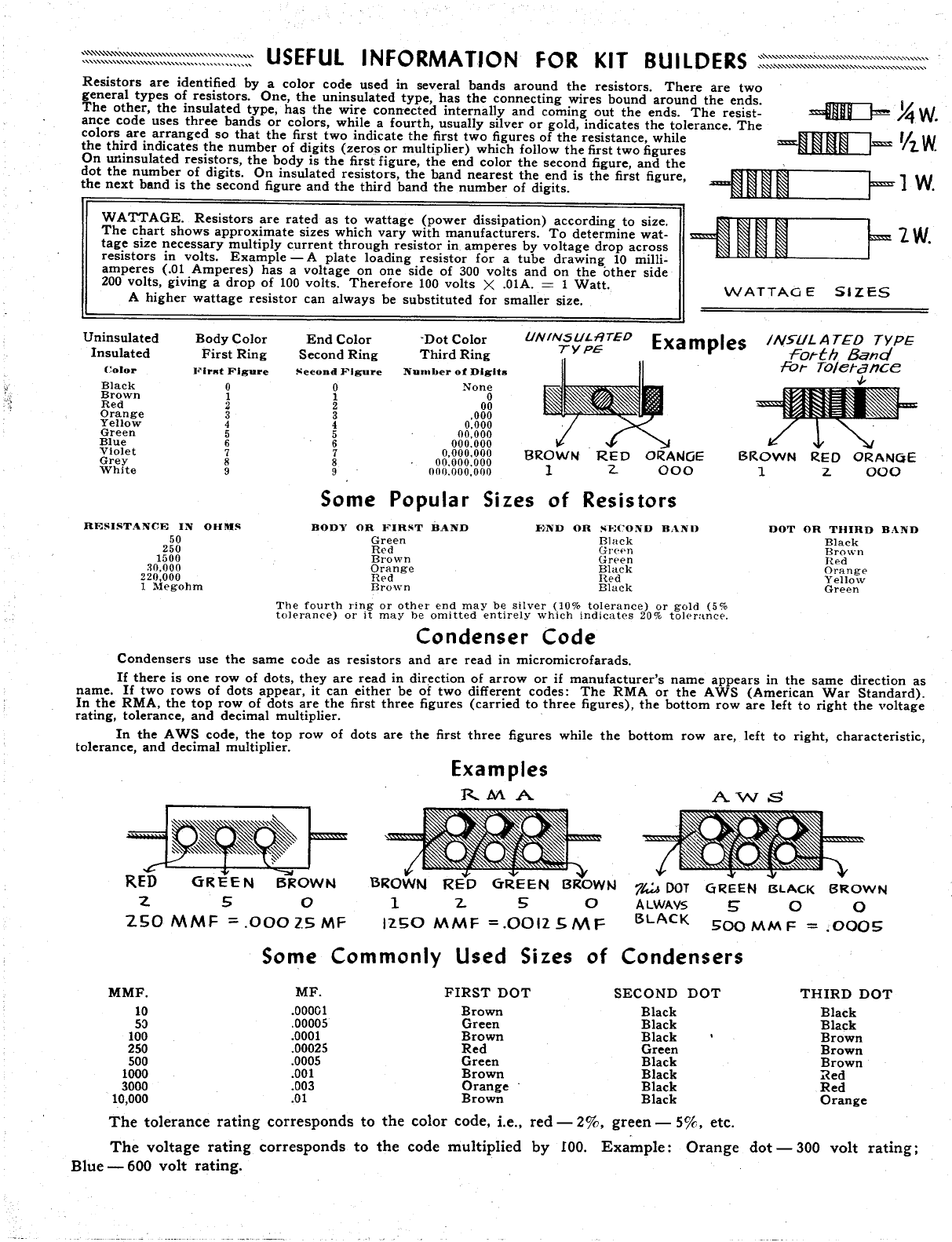

Resistors are identified by a color code used in several bands around the resistors. There are two

general types of resistors. One, the uninsulated type, has the connecting wires bound around the ends.

The other, the insulated type, has the wire connected internally and coming out the ends. The resist-

ance code uses three bands or colors, while a fourth, usually silver or gold, indicates the tolerance. The

colors are arranged so that the first two indicate the first two figures of the resistance, while

the third indicates the number of digits (zeros or multiplier) which follow the first two figures

On w1insulated resistors, the body is the first figure, the end color the second figure, and the

dot the number of digits. On insulated resistors, the band nearest the end is the first figure

the next band is the second figure and the third band the number of digits.

WATTAGE. Resistors are rated as to wattage (power dissipation) according to size.

The chart shows approximate sizes which vary with manufacturers. To determine wat-

tage size necessary multiply current through resistor in, amperes by voltage drop across

resistors in volts. Example - A plate loading resistor for a tube drawing 10 milli-

amperes (.01 Amperes) has a voltage on one side of 300 volts and on the other side

200 volts, giving a drop of 100 volts. Therefore 100 volts X .01A. = 1 Watt.

A higher wattage resistor can always be substituted for smaller size.

-fDI

=1m

~.~,

V2.W

1 W.

2W.

WATTAG E SIZES

Un insulated Body Color End Color Dot Color UNINSUL-RTED Examples INSULATED TYPE

Insulated First Ring Second Ring Third Ring TYPE; Forth. Band

-Fo,.. To/etance

Color lrKt Figure "eeond Figure Number of Digits

Black None

Brown

Red

Orange 000

Yellow 000

Green 00.000

Blue 000.000

Violet 000.000 BROWN RED ORANGE BROWN RED ORANCJE

Grey 00.000.000 000 000

White 000.000,000

Some Popular Si zes Resistors

RESISTANCE IN

250

1500

30,000

220 000

1 Megohm

OHMS BODY OR FIRST

Green

Red

Brown

Orange

Red

Brown

BANI) DOT OR THIRD

Black

Brown

Hed

Orange

Yellow

Green

BilND

BAND F)ND OR ';COND

Black

Gre.'n

Grf'en

Black

Hed

Black

The fourth ring or other end may be silver (10% tolerance) or gold (5%

tolerance) or it may be omitted entirely which indicates 20% toho rance.

Condenser Code

Condensers use the same code as resistors and are read in micromicrofarads.

If there is one row of dots, they are read in direction of arrow or if manufacturer s name appears in the same direction as

name. If two rows of dots appear, it can either be of two different codes: The RMA or the A WS (American War Standard).

In the RMA, the top row of dots are the first three figures (carried to three figures), the bottom row are left to right the voltage

rating, tolerance, and decimal multiplier.

In the A WS code, the top row of dots are the first three figures while the bottom row are, left to right, characteristic

tolerance, and decimal multiplier. Examples

RMA

=;IJft=

'BROWN RED GREEN BROWN

12~O MMF = OOI25MF

AVVS

RED GREEN BROWN

"2.

ZSO MMF

=' .

0002.5 MF

1t.:.& DOT

A LWAVS

BLACK

G~EEN BLACK BROWN

500 MM F = ,0005

Some Commonly Used Si zes of Condensers

MMF. MF. FIRST DOT

10 .00001 Brown

5:) .00005 Green

100 .0001 Brown

250 .00025 Red

500 .0005 Green

1000 .001 Brown

3000 .003 Orange

000 .01 Brown

The tolerance rating corresponds to the color code, i.e.,

The voltage rating corresponds to the code multiplied

Blue - 600 volt rating.

SECOND DOT

Black

Black

Black

Green

Black

Black

Black

Black

red - 2%, green - 5%, etc.

by 100. Example: Orange

THIRD DOT

Black

Black

Brown

Brown

Brown

Red

Red

Orange

dot - 300 volt rating;

'"'

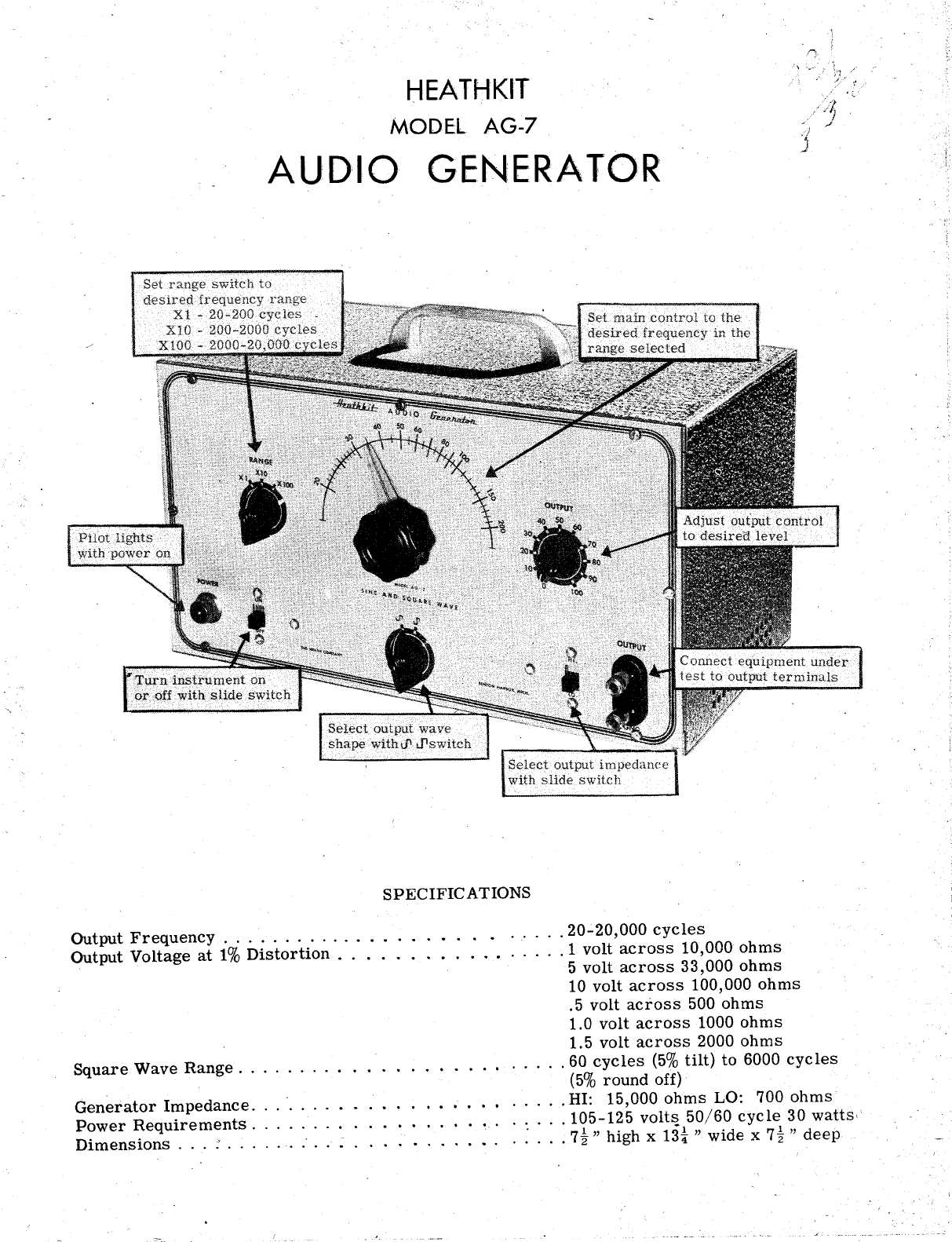

HEATHKIT

MODEL AG-

AUD;IO GENERA TOiR

SPECIFIC A TIONS

OutputFrequency..............

Output Voltage at 1% Distortion.

. . . . . . .....

20- 000 cycles

. . . . . . . .

1 volt across 10 000 ohms

5 volt across 33 000 ohms

10 volt across 100 000 ohms

5 volt across 500 ohms

1.0 volt across 1000 ohms

1.5 volt across 2000 ohms

Square Wave Range. . .

. . . . . . . . . . . . . . . . . ' . . . .

60 cycles (5% tilt) to 6000 cycles

(5% round off)

Generator Impedance. .

.. . . . . . . . . . . . . . . . .. . . .

HI: 15 000 ohms LO: 700 ohms

Power Requirements. . . . . . .

. . . . . . . . . .. . . . . .

105-125 volts 50/60 cycle 30 watts;

Dimensions..............

..... . :...

7t" highx13i" widex7t" deep

ASSEMBLY OF THE HEATHKIT

MODEL AG-

AUDIO ,GENERA TOR

The Heathkit Audia Generatar will .offer excellent .operating characteristics if praperly can-

structed. Ta insure many years .of traublefree service, the assembly and wiring sh.ould be

undertaken withaut hurrying. Take yaur time ta da a gaad jab:

This manual is intended ta facilitate pr.opercanstructi.on. THEREFORE READ THE MANUAL

COMPLETELY THROUGH BEFORE PROCEEDING WITH THE CONSTRUCTION. In this man-

ner y.ou will become familiar with the c.ontents .of the manuq.l. Then during canstructian yau can

readily refer back to specific paragraphs and pictarials.

UNPACK THE KIT CAREFULLY AND CHECK EACH PART, AGAINST THE PARTS LIST. -In

so d.omg y.ou. will became acquainted with the parts. If a sh.ortage is, found, please natify us

promptly, and attach the inspectian slip ta yaur claim. Screws, nuts and washers are caunted

mechanically, and if a few are missing, please secure them lacally. Use the charts an the inside

cavers .of this manual to identify the parts.

Read the nate an saldering an the inside .of the back caver. Make a gaod mechanical cannectian

with clean metal ta clean metal. Use .only the best quality Rasin Care Radio type salder . Paste

fluxes .or acids are difficult ta remave and even minute quantities left behind will cambine with

maisture fram the air ta farm a carrasive praduct. This carrasive praduct is generally a gaad

canductar and may cause shart circuits between switch contacts .or tube sacket lugs. Mter

weeks .or manths the carrasian may result in untimely failure .of the instrument.

NOTE: ALL GUARANTEES ARE VOIDED AND WE WILL NOT REPAffi OR SERVI9E

INSTRUMENTS IN WHICH ACID CORE SOLDER OR PASTE FLUXES ARE USED.

(When in daubt abaut s.older, it is rec.ommended that a new rall plainly marked "Rasin

Care Radia Salder" be purchased.

Resistars and cantrals generally have a talerance rating .of plus .or minus 20%, unless .otherwise

stated. Therefare a 10 000 .ohm resistar may test anywhere fram 8 000 ta 12 000 .ohms. The

talerance an candensers is generally even greater. Limits .of minus 50% and plus 100%are cam-

man for paper tubular types. This Heathkit is designed taaccommadate such variatians.

Small changes in parts may be made by the Heath Campany. All parts supplied will work just

as well as the part far which it was substituted. By reading thecalar code an resistars, for

instance, it will be readily understaad that a value .of 3.9 megahms is a substitute far the spec-

ified 3. 3 megahms, .or a resistar caded 8200 .ohms is a substitute far the s-pecified OQO .ohms

pravided the specified values are nat supplied. Such changes will .only be made if the specified

parts are unabtainable at the time, and are .only made ta insure a minimum delay in filling your

.order.

The tube socket pins are numbered fram 1 ta 8, starting at the keyway' and reading clackwise

when viewed fram the battam.

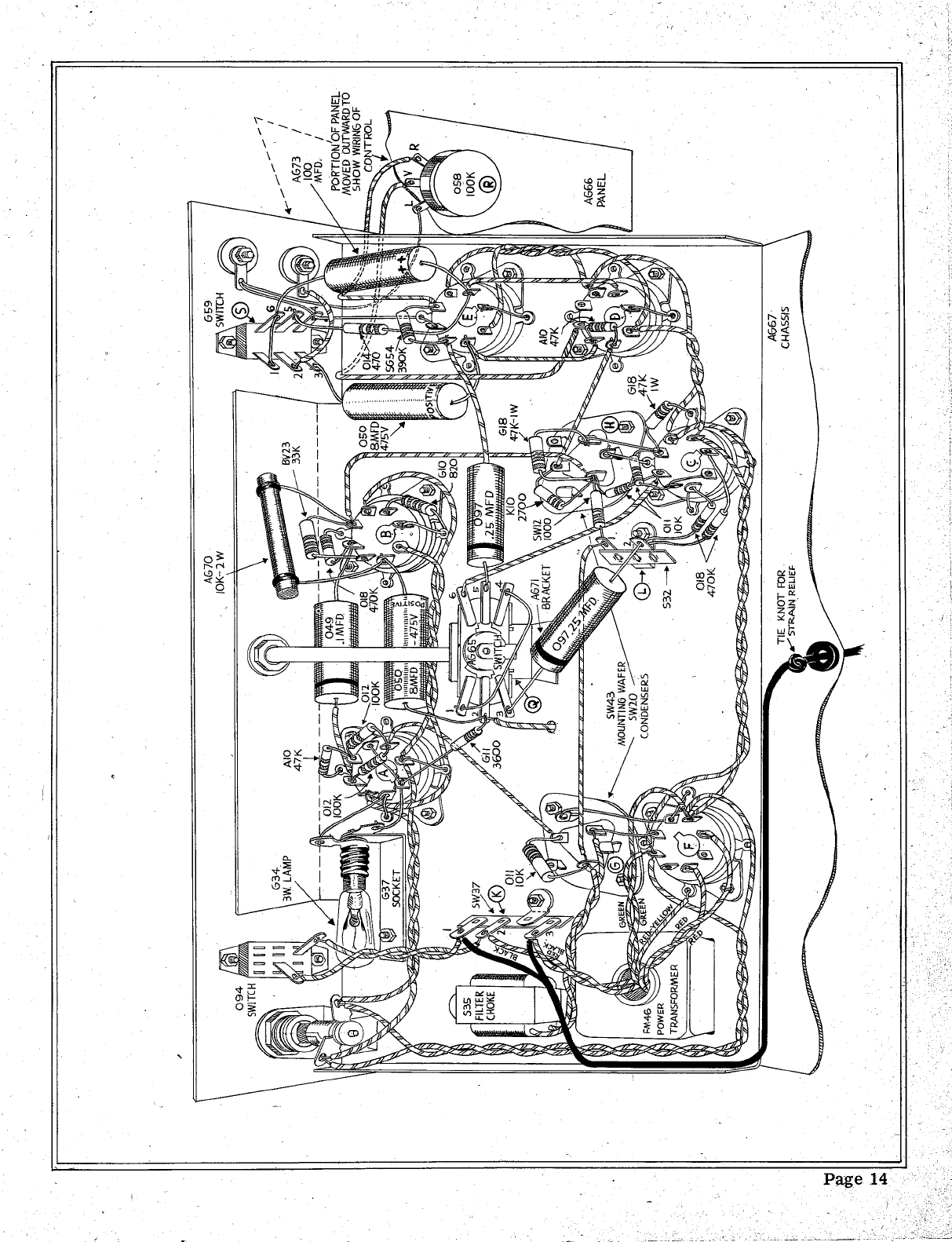

Fallaw the pictarial diagram for the best placement .of the wiring. The "lead dress" .or place-

ment .of the wires is quite impartant in this instrument as incarrect placement may result in

higher distartian leve Is.

Page 1

--~- --.._---- - ---- ---------- --,--------~ ----

STEP BY STEP ASSEMBLY

Use of bare wire where indicated will facilitate wiring, but insulated wire may be used. Use

spaghetti (insulated sleeving) over bare wires on condensers and resistors. where necessary to

prevent the leads from accidentally touching other bare wires or metal parts.

Use lockwashers under all 6-32 and 8-32 nuts and between all controls and panel.

Read each paragraph fully through before proceeding.

Check off each step in the space provided (Y) as it is completed.

(S) means solder the connection (NS) means do not solder yet

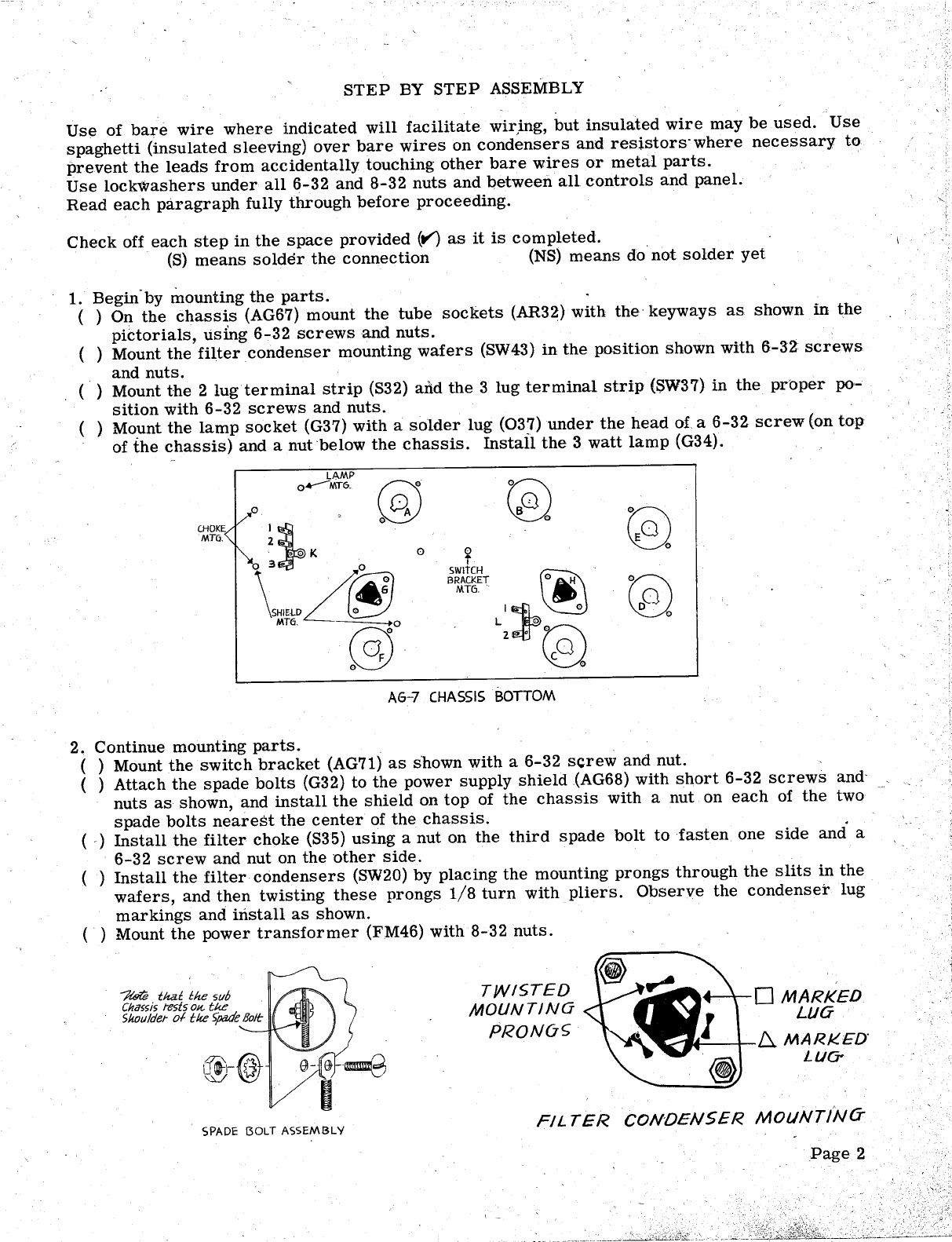

1. Begin. by mounting the parts.

( ) On the chassis (AG67) mount the tube sockets (AR32) with the' keyways as shown in the

piCtorials, using 6-32 screws and nuts.

( ) Mount the filter condenser mounting wafers (SW43) in the position shown with 6-32 screws

and nuts.

( ) Mount the 2 lug terminal strip (S32) aiid the 3 lug terminal strip ($W37) in the proper po-

sition with 6-32 screws and nuts.

( ) Mount the lamp socket (G37) with a solder lug (037) under the head of a 6-32 screw (on top

of the chassis) and a nut below the chassis. Install the 3 watt lamp (G34).

CHOKE

MTG.

LAMP

"---MT~- 0'\,

\'"

MTh

(3)

SWitCH

BRACKET

MT6. .

'1k

. \~

(E)

AG-7 CHASSIS BOTTOM

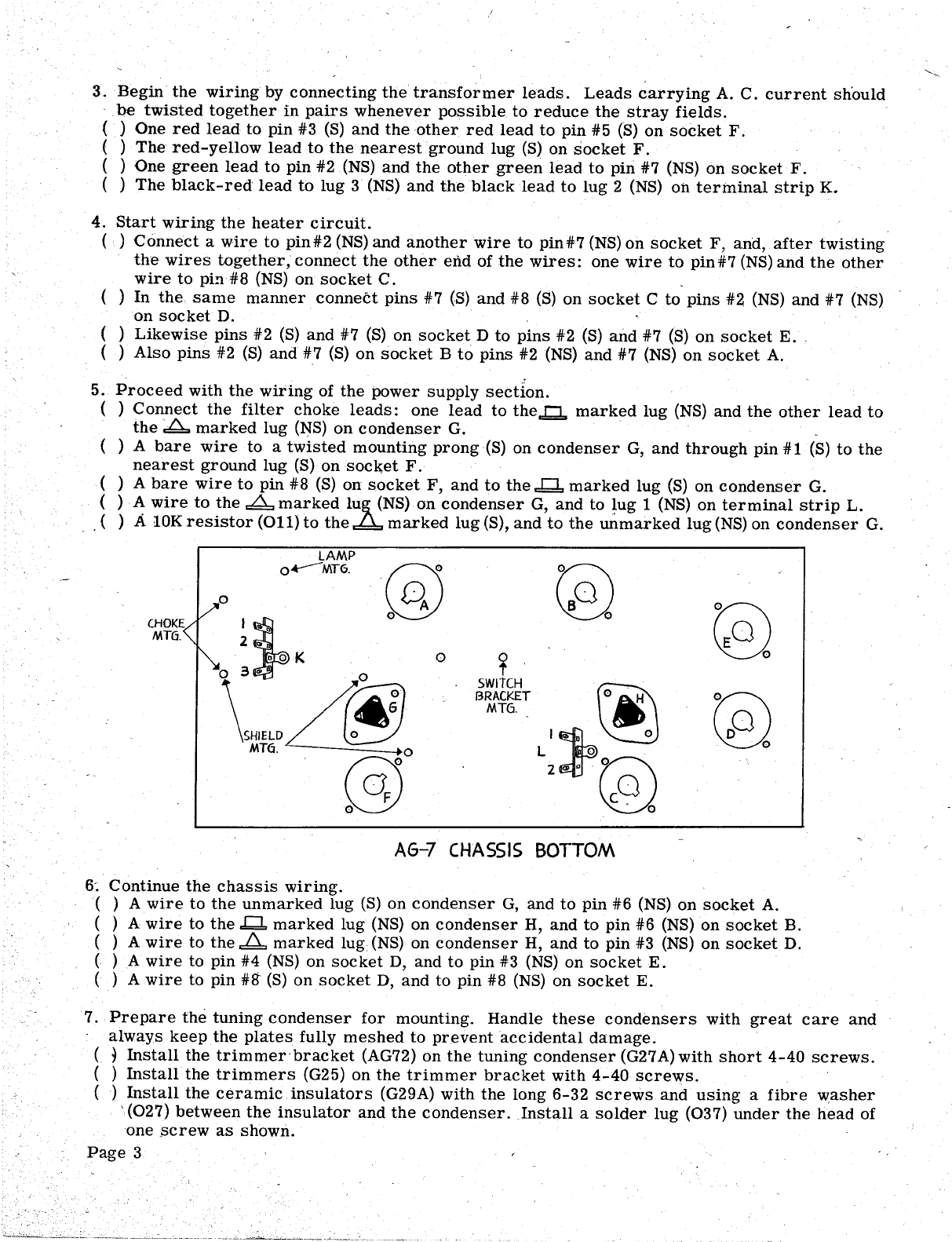

2, Continue mounting parts.

( ) Mount the switch bracket (AG71) as shown with a 6-32 screw and nut.

( ) Attach the spade bolts (G32) to the power supply shield (AG68) with short 6-32 screws and-

nuts as shown, and install the shield on top of the chassis with a nut on each of the two

spade bolts nearest the center of the chassis.

(.) Install the filter choke (S35) using a nut on the third spade bolt to fasten one side and' a

32 screw and nut on the other side.

) Install the filter condensers (SW20) by placing the mounting prongs through the slits in the

wafers, and then twisting these prongs 1/8 turn with pliers. Observe the condenser lug

markings and install as shown.

( ) Mount the power transformer (FM46) with 8-32 nuts.

/tel8 that the sub

Cha55is tests OK tke

5houldet 01 tlee ~e Bolt MARKED

LLJO

MARKED"

LUG-

TWISTED

MOUNTINO

PRONuC;

(GJ

SPADE BOLT ASSEMBLY FIL TER CONDENSER MOLlNTlNa

'--

3. Begin' the wiring by connecting the transformer leads. Leads carrying A. C. current should

be twisted together in pairs whenever possible to reduce the stray fields.

( ) One red lead to pin #3 (S) and the other red lead to pin #5 (S) on socket F.

( ) The red-yellow lead to the nearest ground lug (S) on socket F.

( ) One green lead to pin #2, (NS) and the other green lead to pin #7 (NS) on socket F.

( ) The black-red lead to lug 3 (NS) and the black lead to lug 2 (NS) Oh terminal strip K.

4. Start wiring the heater circuit.

( ) Connect a wire to pin#2 (NS) and another wire to pin#7 (NS) on socket F, and, after twisting

the wires together, connect the other end of the wires: one wire to pin #7 (NS) and the other

wire to pi!1#8 (NS) on socket C.

( ) In the same manner connect pins #7 (S) and #8 (S) on socket C to pins #2 (NS) and #7 (NS)

on socket D.

( ) Likewise pins #2 (S) and #7 (S) on socket D to pins #2 (S) and #7 (S) on socket E.

( ) Also pins #2 (S)and #7 (S) on socket B to pins #2 (NS) and #7 (NS) on socket A.

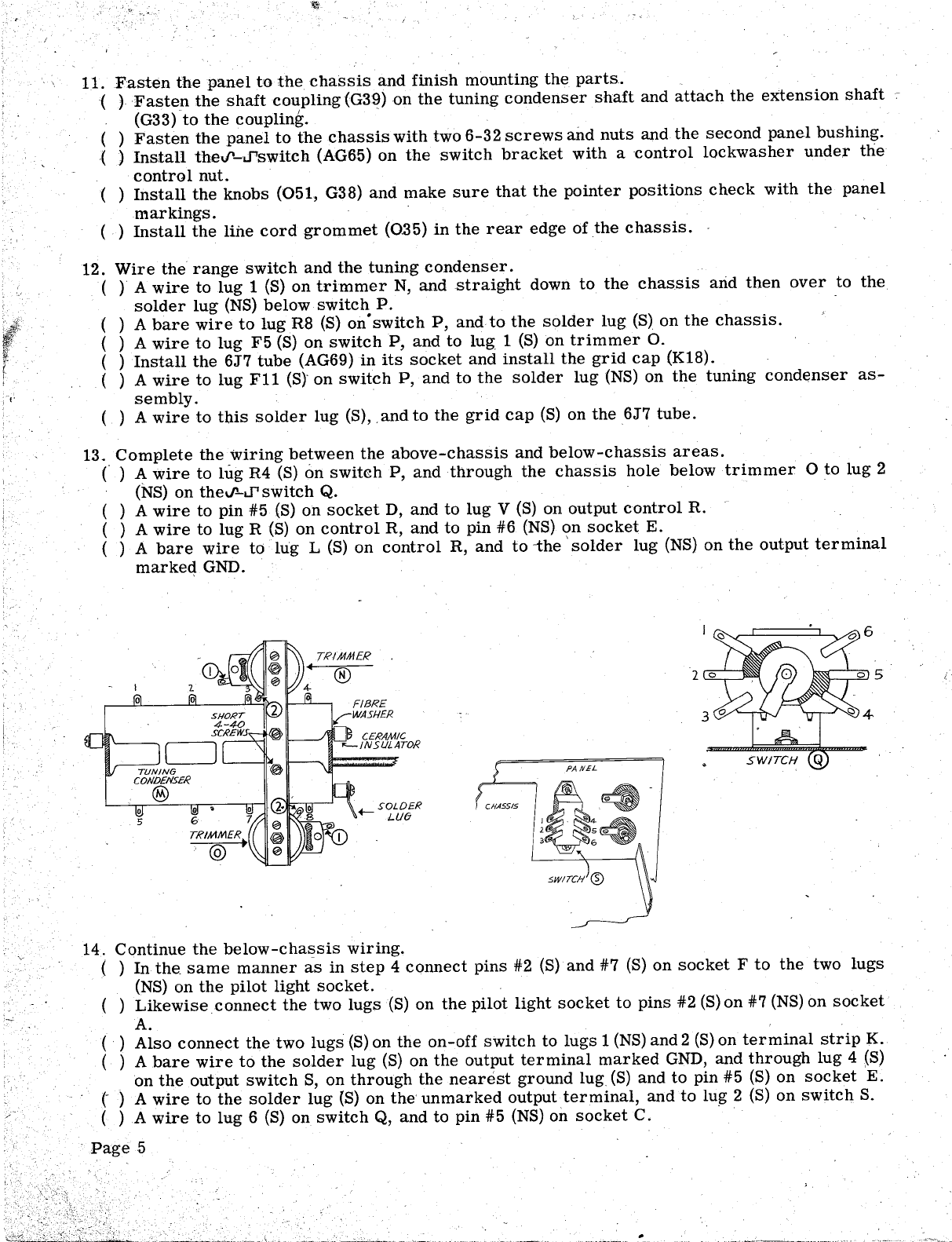

5. Proceed with the wiring of the power supply section.

( ) Connect the filter choke leads: one lead to the..!::!., marked lug (NS) and the other lead to

the marked lug (NS) on condenser G.

( ) A bare wire to a twisted mounting prong(S) on condenser G, and through pin #1 (S) to the

nearest ground lug (S) on socket F.

( ) A bare wire to pin #8 (S) on socket F, and to the..bJ. marked lug (S) on condenser G.

( ) A wire to the marked lu~ (NS) on condenser G, and to lug 1 (NS) on terminal strip L.

. . ( )

A 10K resistor (011) to the marked lug (S), and to the unmarked lug (NS) on condenser G.

LAMP

o~MT6-

CHOKE

MTG. (35

2 ..

\~f~D

swITCH

BRACKET IilIJtt.!

MT6-

G2)

. 0

AG-7 CHASSIS BOTTOM

. Continue the chassis wiring.

( ) A wire to the unmarked lug (S) on condenser G, and to pin #6 (NS) on socket A.

( ) A wire to the .bJ. marked lug (NS) on condenser H, and to pin #6 (NS) on socket B.

( ) A wire to the.ld. marked lug (NS) on condenser H, and to pin #3 (NS) on socket D.

( ) A wire to pin #4 (NS) on socket D, and to pin #3 (NS) on socket E.

( ) A wire to pin #ff (S) on socket D, and to pin #8 (NS) on socket E.

7. Prepare the tuning condenser for mounting. Handle these condensers with great care and

always keep the plates fully meshed to prevent accidental damage.

( ~ Install the trimmer-bracket (AG72) on the tuning condenser (G27 A) with short 4-40 screws.

( ) Install the trimmers (G25) on the trimmer bracket with 4- 40 screws.

( ) Install the ceramic insulators (G29A) with the long 6-32 screws and using a fibre v.zasher

(027) between the insulator and the condenser. Install a solder lug (037) under the head of

one screw as shown.

Page 3

TRIMMER

CERAMIC

"-INSULATOR

TRIMMER

(Q)

8. Wire the tuning condenser assembly and mount it on the chassis.

( ) A bare wire to lug 3 (S) on condenser M, and through lug 1 (NS) on trimmer N, to

on condenser M.

( ) A wire to lug 2 (S)on trimmer N, and to the solder lug (NS).

( ) A wire to lug 5 (S), and to lug 8 (NS) on condenser M.

( ,

) A bare wire to lug 8 (S) on condenser M, and to lug 1 (NS) on trimmer O.

( ) A bare wire to lug 2 (S) on trimmer 0, and to the solder lug (NS).

( ) Mount the assembly on the chassis with 8-32 screws.

lug 2 (S)

9. Prepare the range switch (S34) (switchP).

( ) A 10 meg precision resistor (AG63) between lug F2 (S) and lug R2 (NS).

( ) A 1 meg precision resistor (AG62) between lug F3 (S) and lug R3 (NS).

( ) A lOOK precision resistc.r (AG64) between lug F4. (S) and lug R4 (NS).

( ) A bare wire connecting lugs R2 (S), R3 (S) and R4 (NS).

( ) A 10 meg precision resistor (AG63) between lug F8 (S) and lug R8 (NS).

( ) A 1 meg precision resistor (AG62) between lug F9 (S) and lug R9 (NS).

( ) A lOOK pr~cision resistor (AG64) between lug F10 (S) and lug RI0 (NS).

( ) A bare wire connecting lugs RI0 (S), R9 (S) and R8 (NS).

R2

~::JER

TRL

'"

WR5HER

PANEL (o/!LOCK

,;;nSHER..

SWITCH P

PILOT LIGHT ASSEMBL Y

10. Install the parts on the panel.

( ) Install the first panel bushing (G30) in the center with a control lockwasher and a control

nut on the back of the panel.

( ) Mount the pilot light assembly (040, 041, 042, 052) and install the pilot lamp (039). ! ,

( ) Install the on-off slide switch (094) as shown with 6-32 screws and nuts.

( ) Install the HI- LO slide switch (G59) with 6-32 screws and nuts.

( ) Install the output terminal assembly (ffi31, ffi32, ffi33 , ffi34, IB36, ffi37 , ffi38 and 0109'). -

( ) Install the lOOK output control (058) with a controllockwasher between control and panel

and a nickel washer between the panel and the control nut.

( ) Install the range switch assembly in the same manner with the flat on the shaft towards the

. bottom edge of the panel. \ Page 4

Ii!!

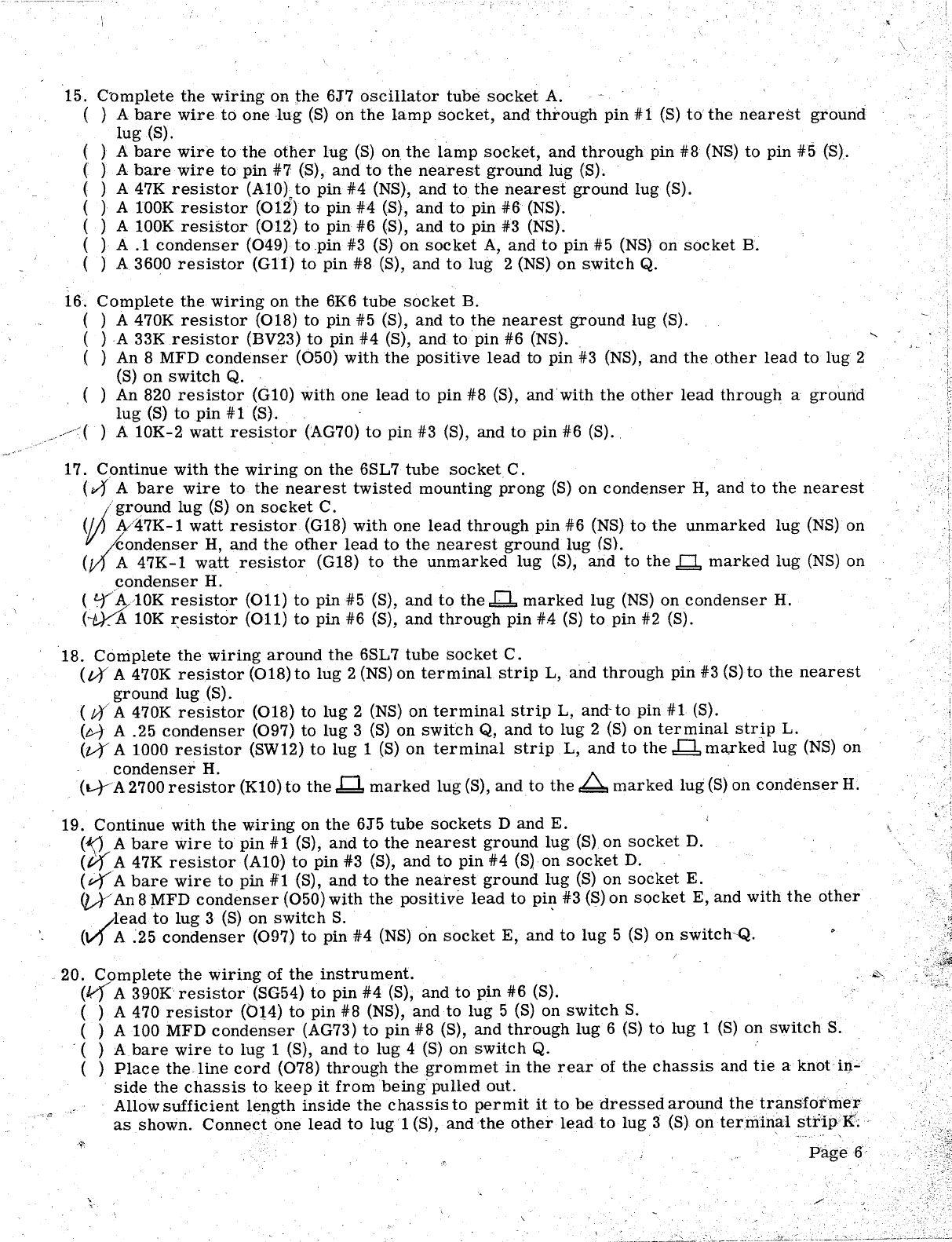

11. Fasten the panel to the chassis and finish mounting the parts.

( ) Fasten the shaft coupling (G39) on the tuning condenser shaft and attach the extension shaft

(G33) to the coupling.

( ) Fasten the panel to the chassis with two 6-32 screws and nuts and the second panel bushing.

( ) Install thed'-J'switch (AG65) on the switch bracket with a control lockwasher under the

control nut.

( ) Install the knobs (0.51, G38) and make sure that the pointer positions check with the panel

markings.

( ) Install the line cord grommet (0.35) in the rear edge of the chassis.

12. Wire the range switch and the tuning condenser.

( ) A wire to lug 1 (8) on trimmer N, and .straight down to the chassis arid then over to the

solder lug (N8) below switch P.

( ) A bare wire to lug R8 (8) on. switch P, and to the solder lug (8) on the chassis.

( ) A wire to lug F5 (8) on switch P, and to lug 1 (8) on trimmer o..

( ) Install the 6J7 tube (AG69) in its socket and install the grid cap (K18).

( ) A wire to lug F11 (8). on switch P, and to the solder lug (N8) on the tuning condenser as-

sembly.

( ) A wire to this solder lug (8), . and to the grid cap (8) on the 6J7 tube.

13. Complete the wiring between the above-chassis and below-chassis areas.

(' ) A wire to lug R4 (8) on switch P, and through the chassis hole below trimmer 0. to lug 2

(:N8) on theV'-J' switch Q.

( ) A wire to pin #5 (8) on socket D, and to lug V (8) on output control R.

( ) A wire to lug R (8) on control R, and to pin #6 (NS) on socket E.

( ) A bare wire to . lug L (S) on control R, and to -the ' solder lug (NS) on the output terminal

marked GND.

TRIMMER

(g)

PANEL

. ~

4 '"

~ 5 '"

~ 6

.-

SOLDER

Lue

14. Continue the below-chassis wiring.

( ) In the- same manner as in step 4 connect pins #2 (S) and #7 (8) on socket F to the two lugs

(NS) on the pilot light socket.

( ) Likewise . connect the two lugs(S) on the pilot light socket to pins #2 (S) on #7 (NS) on socket

( ) Also connect the two lugs (8) on the on-off switch to lugs 1 (NS) and 2 (S) on terminal strip K.

( ) A bare wire to the solder lug (S) on the output terminal marked GND, and through lug 4 (8)

. on the output switch S, on through the nearest ground lug (8) and to pin #5 (8) on socket

) A wire to the solder lug (8) on the unmarked output terminal, and to lug 2 (8) on switch S.

( ) A wire to lug 6 (8) on switch Q, and to pin #5 (N8) on socket C.

Page 5

15. Complete the wiring on the 6J7 oscHlator tube socket A.

( ) A bare wire to one lug (S) on the lamp socket, and through pin #1 (S) to the nearest ground

lugeS) .

( ) A bare wire to the other lug (S) on the lamp socket, and through pin #8 (NS) to pin #5 (S).

( ) A bare wire to pin #7 (8), and to the nearest ground lug (S).

( ) A 47K resistor (A10) to pin #4 (NS), and to the nearest ground lug (S).

( ) A lOOK resistor (012) to pin #4 (S), and to pin #6 (NS).

( ) A lOOK resistor (012) to pin #6 (S), and to pin #3 (NS).

( ) A . 1 condenser (049) to pin #3 (S) on socket A, and to pin #5 (NS) on socket B-

( ) A 3600 resistor (Gl1) to pin #8 (S), and to lug 2 (NS) on switch Q.

16. Complete the wiring on the 6K6 tube socket B.

( ) A 470K resistor (018) to pin #5 (S), and to the nearest ground lug (S).

( )A 33K resistor (BV23) to pin #4 (S), and to pin #6 (NS).

( ) An 8 MFD condenser (050) with the positive lead to pin #3 (NS), and the other lead to lug 2

(S) on switch Q.

An 820 resistor (G10) with one lead to pin #8 (S), and with the other lead through a ground

lug (S) to pin #1 (S).

A 10K-2 watt resistor (AG70) to pin #3 (S), and to pin #6 (S). ,

( )

17. Continue with the wiring on the 6SL7 tube socket C.

(vJ A bare wire to the nearest twisted mounting prong (S) on condenser H, and to the nearest

/ ground lug (S) on socket C.

Y;J 47K- 1 watt resistor (G18) with one lead through pin #6 (NS) to the unmarked lug (NS) on

'I' .kondenser H, and the other lead to the nearest ground lug (S).

(0 A 47K- 1 watt resistor (G18) to the unmarked lug (S), arid to the marked lug (NS) on

condenser H.

(:r~/10K resistor (011) to pin #5 (S), and to the marked lug (NS) on condenser

("U",A 10K r:esistor (011) to pin #6 (S), and through pin #.4 (S) to pin #2 (S).

18. Complete the wiring around the 6SL7 tube socket C.

(vY A 470K resistor (018) to lug 2 (NS) on terminal strip L, and through pin #3 (S) to the nearest

ground lug (S).

A 470K resistor (018) to lug 2 (NS) on terminal strip L, and- to pin #1 (S).

(H A .25 condenser (097) to lug 3 (S) on switch Q, and to lug 2 (S) on terminal strip L.

(0 A 1000 resistor (SW12) to lug 1 (S) on terminal strip L, and to the marked lug (NS) on

condenser H.

(L--YA 2700 resistor (K10) to the.Q. marked lug (S), and to the marked lug (S) on condenser H.

19. Continue with the wiring on the 6J5 tube sockets D and E.

(~ A bare wire to pin #1 (S), and to the nearest ground lug (S) on socket D.

(0A 47K resistor (A10) to pin #3 (S), and to pin #4 (S) on socket D.

(v-r A bare wire to pin 41'1 (S), and to the nearest ground lug (S) on socket E.

An 8 MFD condenser (050) with the positive lead to pil!- #3 (S) on socket E , and with the other

, /

lead to lug 3 (S) on switch S.

(V) A ~25 condenser (097) to pin #4 (NS) on socket E, and to lug 5 (S) on switch~Q.

20. Complete the wiring of the instrument.

(ttf A 390K resistor (SG54) to pin #4 (S), and to pin #6 (S).

( ) A 470 resistor (bH) to pin #8 (NS), and to lug 5 (S) on switch S.

( ) A 100 MFD condenser (AG73) to pin #8 (S), and through lug 6 (S) to lug 1 (S) on switch S.

( )

Abare wire to lug 1 (S), and to lug 4 (S) on switch Q.

( ) Place the line cord (078) through the gram met in the rear of the chassis and tie a knot i1).~

side the chassis to keep it from being' pulled out.

Allow sufficient length inside the chassis to permit it to be dressed around the transfor'mer,

as shown. Conned one lead to lug 1 (S), and the other lead to lug 3 (S) on terminal strip/I(;

Page 6

. "'

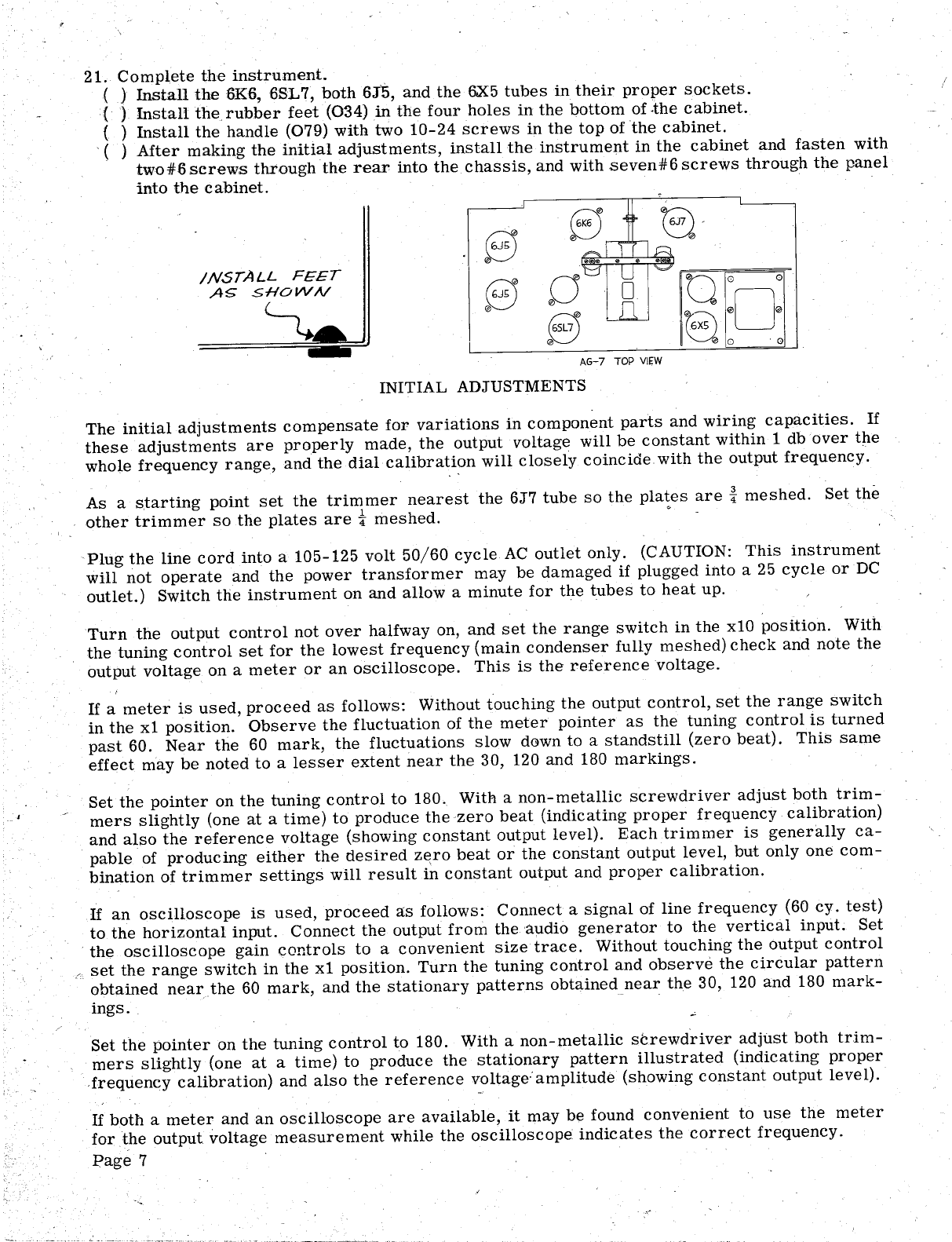

21. Complete the instrument.

( ) Install the6K6 6SL7, both 6J5, and the 6X5 tubes in their proper sockets.

( ) Install the rubber feet (034) in the four holes in the bottom of .the cabinet.

( ) Install the handle (079) with two 10- 24 screws in the top of the cabinet.

. ( ) After making the initial adjustments, install the instrument in the cabinet and fasten with

two #6 screws through the rear into the chassis, and with seven#6 screws through the panel

into the cabinet.

AG- 7 TOP VIEW

INITIAL ADJUSTMENTS

The initial adjustments compensate for variations in component parts and wiring capacities. If

these adjustments are properly made , the output voltage will be constant within 1 db over the

whole frequency range, and the dial calibration will closely coincide with the output frequency.

As a starting point set the trimmer nearest the 6J7 tube so the pla~es are ~ meshed. Set the

other trimmer so the plates are i- meshed.

Plug the line cord into a 105- 125 volt 50/60 cycle AC outlet only. (CAUTION: This instrument

will not operate and the power transformer may be damaged if plugged i11to a 25 cycle or

outlet.) Switch the instrument on and allow a minute for the tubes to heat up.

Turn the output control not over halfway on, and set the range switch in the x10 position. With

the tuning control set for the lowest frequency (main condenser fully meshed) check and note the

output voltage on a meter or an oscilloscope. This is the reference voltage.

If a meter is used, proceed as follows: Without touching the output control, set the range switch

in the xl position. Observe the fluctuation of the meter pointer as the tuning control is turned

past 60. Near the 60 mark, the fluctuations slow down to a standstill (zero beat). This same

effect may be noted to a lesser extent near the 30, 120 and 180 markings.

Set the pointer on the tuning control to 180. With a non-metallic screwdriver adjust both trim-

mers slightly (one at a time) to produce the zero beat (indicating proper frequency calibration)

and also the reference voltage (showing constant output level). Each trimmer is generally ca-

pable of producing either the desired z~ro beat or the constant output level, but only one com-

bination of trimmer settings will result in constant output and proper calibration.

If an oscilloscope is used, proceed as follows: Connect a signal of line frequency (60 cy. test)

to the horizontal input. Connect the output from the audio generator to the vertical input. Set

the oscilloscope gain controls to a convenient size trace. Without touching the output control

set the range switch in the xl position. Turn the tuning control and observe the circular pattern

obtained nearthe 60 mark, and the stationary patterns obtained near the 30 , 120 and 180 mark-

ings.

Set the pointer on the tuning control to 180. With a non-metallic screwdriver adjust both trim-

mers slightly (one at a time) to produce the stationary pattern illustrated (indicating proper

frequency calibration) and also the reference voltage: amplitude (showing constant output leve 1).

If both a meter and an oscilloscope are available, it may be found convenient to use the meter

for the output voltage measurement while the oscilloscope indicates the correct frequency.

I?age 7

The calibration may. be affected slightly when the instrument is instaHedin the cabinet. The

adjustments should therefor be rechecked and possibly readjusted to compensate for such vari-

ations.

------

t--

REFERENCE

VOLTAGE.

AMPLITUDE

-----,---

1---

The fluctuation of the meter pointer at 60 cycles is the result of pickup ' of stray electrostatic

fields '(hum pickup) by the tuning condenser and other parts in the grid circuit of the 6J7 tube.

Installation in the cabinet eliminates this effect.

IN CASE OF DIFFICULTY

If the instrument fails to perform properly, locate the trouble as outlined.

1. Check the wiring by following each wire on the pictorial and in the instrument, inspecting the

soHered connections on each end, and then checking off that wire in the pictorial with, a col-

ored pencil. This will reveal mistakes and omissions in wiring, which is the most frequent

cause of difficulties.

2. Check the voltages between tube socket pins and chassis. The readings should come reason-

ably! close to the values tabulated below, if a vacuum tube voltmeter with 11 megohm input

resistance is used. Other type meters may give considerably lower readings. .If a voltage

reading fails to check with the tabulation, investigate the portion of the circuit involved (by

checking the resistors and condensers for instance), and determine the cause.

Socket . F

Pin 6J7 6K6 6SL7 6J5 6J5 6X5

. 1 15 NEG

7 AC 110- 140

130-170 130- 170 210-250 110- 150 210-250AC

50- 140- 180 110- 140 Tie Point Tie Point .No Conn.

3 N 230-270 210-250AC

Tie Point Tie Point 120- 150 No Conn. Tie Point No Conn.

10- 280-320

*VOLTAGE BETWEEN PINS IS 5-7 VOLTS AC.

Voltage readings may be expected to fall within the ranges indIcated. Headings outside these

ranges are not necessarily indicative of faulty operation.

Page 8

3. 'If.~ part is found to be faulty, please return it promptlyfor a replacement, and attach a letter

to the package describing the nature of the fai.1lt.

4. If tl1e generator operates improperly, particularly on th~ lowest band, the feedback may re-

quire adj\,1stment. A slight adjustment in the 3600 ohm resistor (Gll) by adding 50 ohms or

more in series or 100 000 ohms or less in parallel (shunt) may correct the condition.

5. Should the procedure outlined above fail to clear up the difficulty, write to the Heath Com-

pany, describing the trouble encountered by giving all, possible details, such as voltage read-

ings. We will attempt to analyze your trouble and advise YOll accordingly.

,IN ALL CORRESPONDENCE REFER TO THIS INSTRUMENT AS THE MODEL AG'-7 AUDIO

GENERA TOR.

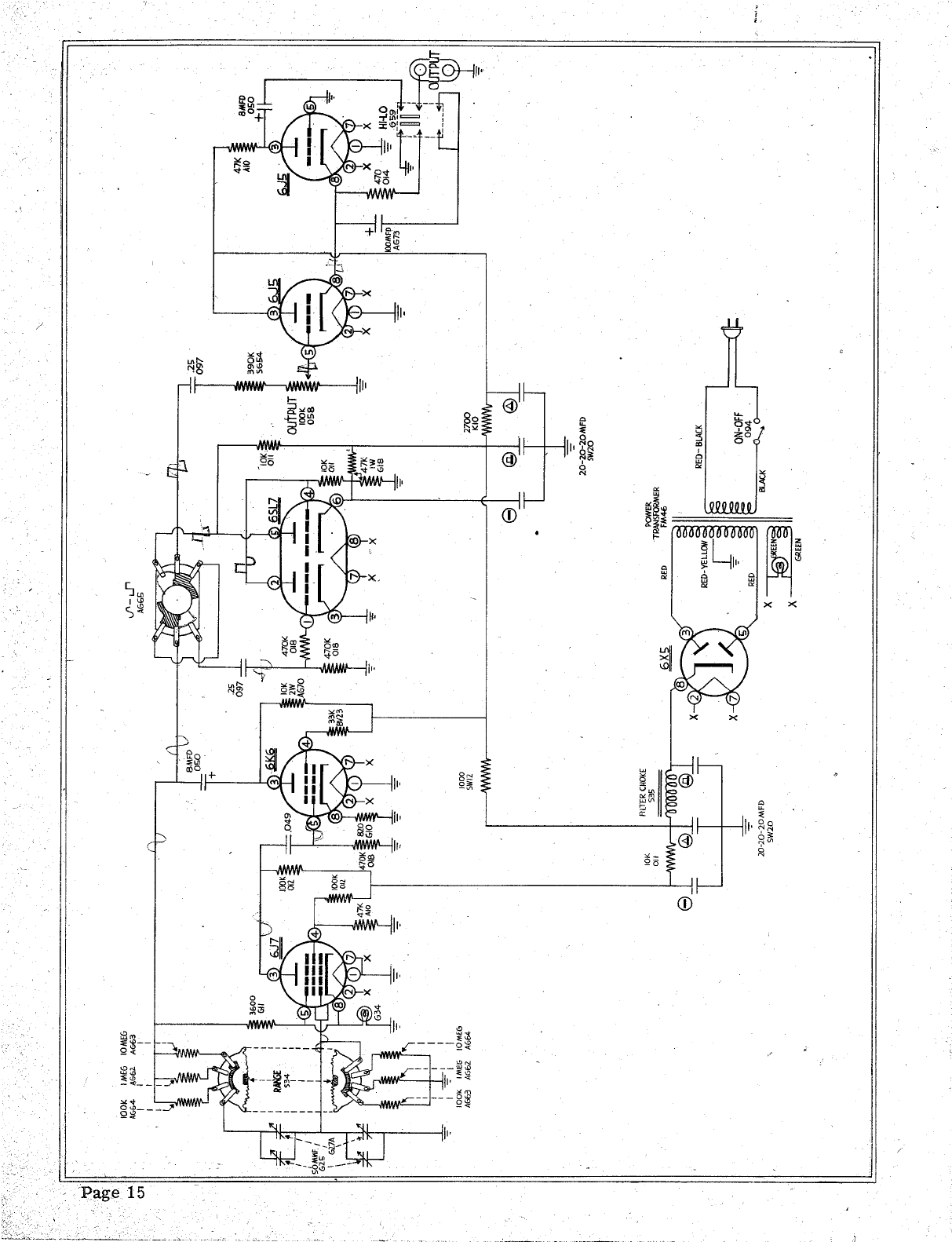

CIRCUIT DESCRIPTION

OSCILLATPR. The oscillator section is a two stage resistance coupled amplifier with both

positive and negative feedback over both stages. Positive feedback is applied through a fre-

quencyselective circuit comprising resistors and condensers. This section determines the os-

cillator frequency. The negative feedback is used to stabilize the operation of the circuit, and

is appLied through a voltage dividing n~twork. A part of this network consists of a non linear

resistor (3 watt lamp). This lamp controls the amount of feedback and thus provides stable

operating conditions.

CLIPPER. The square wave is generated by feeding the sine wave output from the oscillator

into a clipper circuit. This circuit uses a two stage direct coupled amplifier. The signal over-

/ loads the amplifiers and thus clips the peaks of the sine wave input. Thus only a square wave

remains.

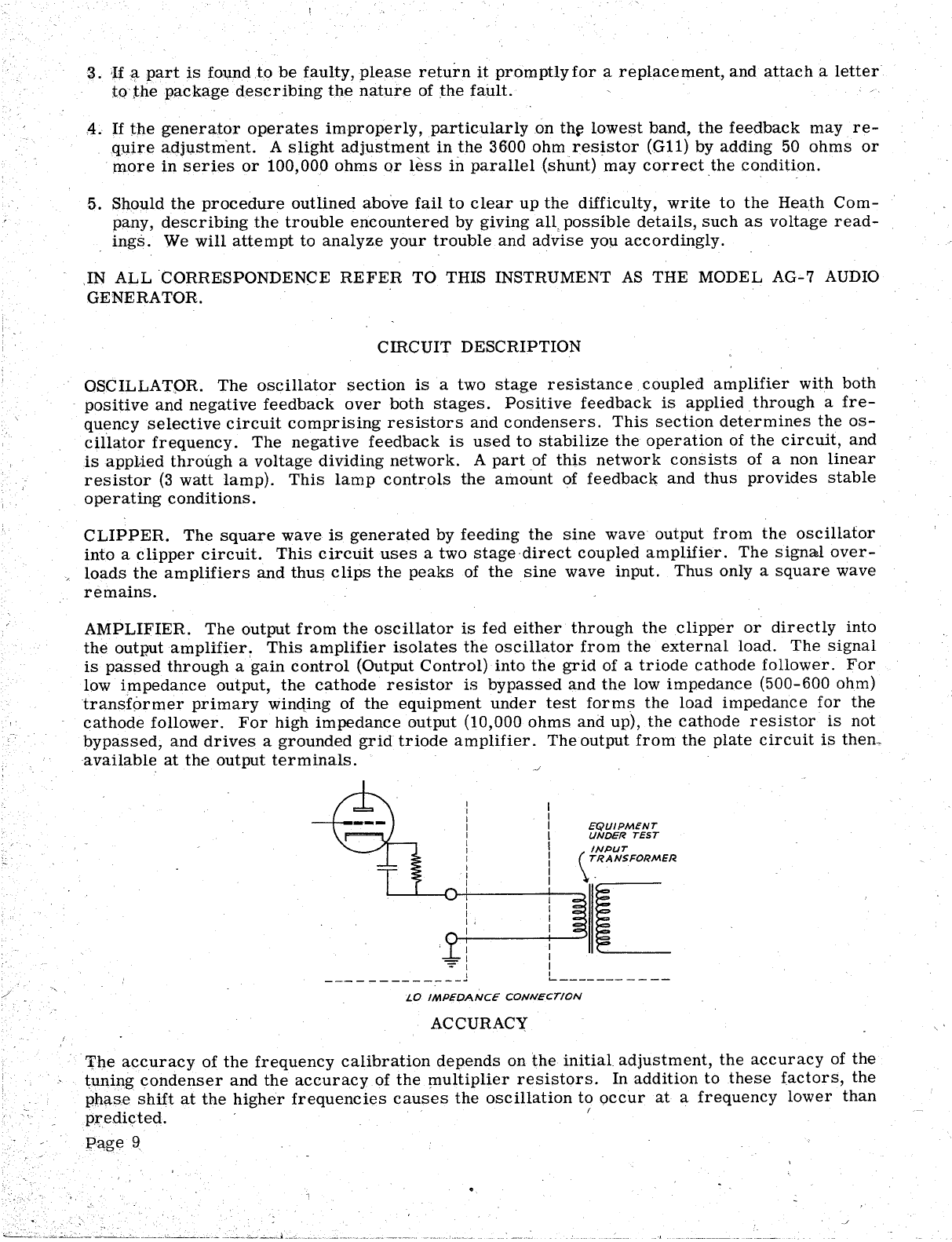

AMPLIFIER. The output from the oscillator is fed either through the clipper or directly into

the output amplifier ~ This amplifier isolates the oscillator from the external load. The signal

is passed through a gain control (Output Control) into the grid of a triode cathode follower. For

low impedance output, the cathode resistor is bypassed and the low impedance (500-600 ohm)

transformer primary winqing of the equipment under test forms the load impedance for the

cathode follower. For high impedance output (10 000 ohms and up), the cathode resistor is not

bypassed, and drives a grounded grid triode amplifier. The output from the plate circuit is then~

available at the output terminals.

-=- I

------------_

L------- -

---

LO IMPEDANCE CONNECTION

ACCURACY

'rl1e accuracy of the frequency calibration depends on the initial adjustment, the accuracy of the

tuniIlg ~ondenser and the accuracy of the l1lUltiplier resistors. In addition to these factors, the

phase shift at the higher frequencies causes the oscillation to occur at a frequency lower than

PJ'"edi~ted.

Page 9

This phase shift will vary with wiring capacity and the oscillator frequency at the high end of tQ€

highest range may fall short by as much as 10% of the calibration. On the lower ranges, the

calibration should fall within i 3%.

For precision work, the use of Lissajous figures derived from the power line frequency present

convenient calibration points on the lower frequency ranges.

APPLIC A TION

This instrument may be used as a source of sine wave audio voltage with a distortion of less

than 1% at any frequency between 20 cycles and 20 000 cycles.

The high impedance output circuit is designed to work into a high impedance load. The maximum

output voltage with 1% distortion varies with the load resistance and is approximately 1 volt at

000 ohms, 5 volts at 30 000 ohms and 10 volts .at 100 000 ohms. The source impedance of the

instrument is approximately 15 000 ohms.

The low impedance output circuit is designed to work into a low impedance transformer primary

with negligible DC resistance. The maximum output voltage with 1% distortion varies with the

transformer characteristics (and therefor the frequency) and the load resistance , and is approx-

imately 0.5 volt at 500 ohms, 1.0 volt at ~OOO ohms and 1.5 volts at 2000 ohms. The source

impedance is approximately 700 ohms. Resistance loads of 500 to 2 000 ohms may be used with a

slight decrease in maximum output voltage with 1% distortion.

The square wave output, while usable over the full frequency range covered, is substantially

square over a range of frequencies between 60 cycles (5% tilt) and 6000 cycles (5% round off).

The sine wave output is suitable for applications when a constant level low distortion source of

audio frequency signals is required, such as fidelity and distortion measurements on amplifiers

speaker testing and operation of A. F. bridges.

The square wave output is particularly useful in applications requiring rapid determination of

frequency and phase response characteristics of amplifiers and networks.

BIBLIOGRAPHY

For additional reading material about Audio Generatorsand their applications, we suggest the

many articles in the popular radio and service magazines, such as:

RADIO AND TELEVISION NEWS (RADIO NEWS)

January

September

August

November

December

January

March

June

August

September

October

November

1944

1945

1946

1946

1946

1947

1950

1950

1950

1950

1950

1950

Square 'Wave Testing of Amplifiers

Audio Oscillators and Their Applications

Audio Oscillators

Low Cost Audio Oscillator

Simple Square Wave Generator

C Audio Oscillator

Square Wave Clipper

Audio Oscillator and VTVM

100 Kc. Square Wave Generator

Wide Range R-C Oscillator

Square Wave Generator

C Beat Frequency Oscillator

ELECTRONICS

September 1948 Low Frequency Oscillator

RADIO ELECTRONICS (RADIO CRAFT)

August-September 1947

May 1948

July 1948

August 1948

October 1948

February 1949

August 1949

July 1950

July 1950

Bandspread Audio Oscillator

Laboratory Type Oscillators

Audio GeI\erator

Single Control Audio Oscillator

Calibrating Audio Oscillators

Versatile Audio Oscillator

Laboratory Square Wave Generator

Square Wave Analysis

Extended Range Oscillator

An excellent description of the principles of R-C oscillators maybe found in the "H. P. Journal

Volume 1 Nos. 3 and 4, November and December 1949, published by the Hewlett-Packard Com-

pany, Palo Alto, California, under the title of "Design Notes on the Resistance-Capacity Oscil-

hitor Circuit. " The Hewlett-Packard name has for years been synonymous with R-C oscillators

as they manufacture the greatest variety of the finest equipment of this type.

SERVICE

If correspondence fails to clear up operational difficulties of the completed instrument, the fa-

cilities of the Heath Company Service Department are available.

The Heath Company Service Department will inspect your instrument and put it into operating

condition for a service charge of $5.00 plus the cost of any new parts or extra labor required

because of damage through improper construction.

As an assurance to the customer that the Heath Company stands solidly behind all its products

and will do its utmost to insure proper operation of every kit, it is making this service available

until one year from purchase date.

After this time limit, repair work will sUll be accepted, but the cost of repairs will be deter-

mined after an examination by the Heath Company Service Department, and the customer will

be advised of the cost before work is begun

NOTE: Before returning this unit, be sure all parts are securely mounted. Attach. a tag, giving

name, address and trouble experienced, to the unit. Pack in a rugged container, preferably wood

using at least three inches of shredded newspaper or excelsior on all sides. DO NOT use folded

newspaper. DO NOT ship in original carton only. Ship by prepaid express if possible. Return

shipment will be made by express collect.

NOTE that a carrier cannot be held liable for damage in transit if packing, in HIS opinion, is in-

sufficient.

Prices subject to change without notice. The Heath Company reserves the right to change the

design without incurring liability for equ!pment previously supplied-

Page 11

.---... .. /. ..'

WARRANTY

The Heath Company limits its warranty on any part supplied with any Heathkit (except tubes

meters, and rectifiers, where the original manufacturer s guarantee only applies) to the re-

placement within three (3) months of said part which, when returned with prior p~rmission, post...,

paid, was, in the judgment of the Heath Company, defective at the time of sale.

..

The assembler is urged to follow the instructions exactly as provided. The Heath Company as-

sumes no responsibility or liability for any damages or injuries sustained in the assembly of the

device or in the operation of the completed instrument.

HEA TH COMPANY

Benton Harbor, Michigan

Page 12

, "-.

Part Parts

No. P€r

Kit

Resistors

014

G10

SW12

K10

G11

011

AG70

BV23

A10

G18

:()12

SG54

018

AG64

AG62

AG63

Cqndensers

049

097

050

AG73

SW20

G25

G27A

Description

470 ohms

820 ohms

1000 ohms

2700 ohms

3600 ohms

10 K ohms

- 10 K ohms 2 watt

33 K ohms

47 K ohms

47K ohms 1 watt

100 K ohms

390 K ohms

470 K ohms

100 K ohms, precision

1 Meg ohm, precision

10 Meg ohm, precision

1 MFD

25 MFD

8 MFD-475 V

100 MFD-15 V

20-20-20 MF'D- 300 V

50 MMF Trimmer

4 section Tuning

Control- -Switches

058 100 K ohm Control

S34 3 pas. Rotary Switch

AG65 2 pas. Rotary Switch

G59 DPDT Slide Switch

094 SPST Slide Switch

Sockets--Terminal Strips--Knobs

AR32 Octal Tube Sockets

G37 Candelabra Lamp Socket

S32 2 lug Terminal Strip

SW37 3 lug Terminal Strip

051 Pointer Knobs

G38 Indicator Knob

Tubes- -Lamps

AG69

G43

G42

A48

V30

G34

039

6J7 (GT) Tube

6K6GT Tube

6SL7GT Tube

6J5 (GT) Tubes

6X5 (GT) Tube

3 watt Lamp

#47 Pilot Lamp.

Pilot Light Assembly

040 Nut

041 Bushing

042 , Jewel

052 Socket

Page 13

AG7 PARTS LfST

Part

No. Parts

Per Kit Description

Insulators - - Wafers- -Grommet

G29A Ceramic Insulators

IB31 Binding Post Insulator

SW43 Condenser Mounting Wafers

035 i 3/8" Grommet

Screws --Nuts- -Washers

AG74 . 4-40x3/16 Screws

G31 6 4-40 x 3/8 Screws

K16 3 6-32 x 3/16 Screws

031 27 6-32 x 3/8 Screws

G53 3 6-32 x 1- Screws

G52 3 8-32 x 3/8 Screws

030 2 10-24 Handle Screws

0102 #6 Sheet Metal Screws

. S22 33 6-32 Nuts

TP16 2 8-32 Nuts

033 Control Nuts

TS72 33 #6 Lockwashers

BR36 #8 Lockwashers

0101 Control Lockwashers

028 Nickel Washers

027 Fibre Flat Washers

037 Solder Lugs

G32 Spade Bolts

Bushings - -Shaft --C oupling

G30 Panel Bushings

G33 Shaft

G39 Shaft Coupling

Terminal Hardware

IB32 Binding Post Bases

IB33 Thumbscrews

IB34 10-32 Nuts

IB36 #10 Lockwashers

IB37 no Fibre Washers

IB38 #10 Nickel Washers

0109 #10 Solder Lugs

Sheet Metal Parts

AG67 Chassis

AG66 Panel

AG71 Switch Bracket

AG68 Power Supply Shield

AG72 Trimmer Mtg. Bracket

PS10 Cabinet

079 Handle

Miscellaneous

FM46

S35

K18

034

078

077

081

Power Transformer

Filter Choke

Grid Cap

Rubber feet

Line Cord

Length Hookup Wire

Length Spaghetti

L- "' . -c,

" ~'--"-.-

018

470K

TIE KNOT FOR

.....-STRAIN RELIEF

A667

CHASSIS

I-""

C)1 oJ' - ...r

A6G!;

20-20~20MFD

5'1120

20-20-20MFD

SW20

094 .

0..,.,.

BLACK

cJI:

RED

EEN

GREEN

Table of contents

Popular Inverter manuals by other brands

SolarMax

SolarMax S series instruction manual

Sunways

Sunways STT-29.9KTL user manual

FRONIUS

FRONIUS Symo GEN24 6.0.Plus operating instructions

Heavy Duty Power Systems

Heavy Duty Power Systems HDI 7000RWB owner's manual

Sofar solar

Sofar solar SOFAR 7.5KTLM user manual

FRONIUS

FRONIUS Fronius Agilo 360.0-3 TL operating instructions