9910045 RevF October 2020

Introduction

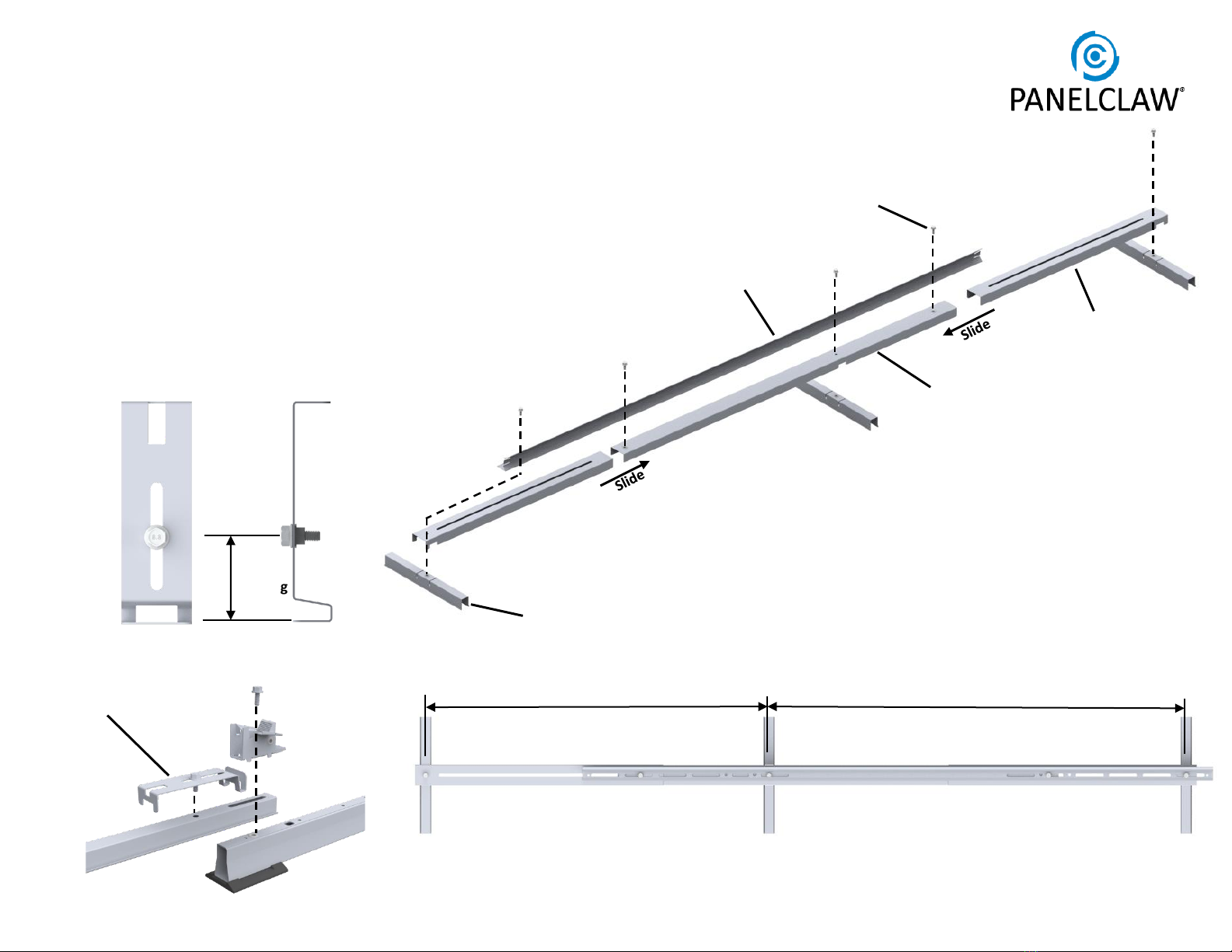

The clawFR 10 Degree flat roof mounting system is

comprised of four major components that intuitively

assemble into a support structure for photovoltaic (PV)

modules.

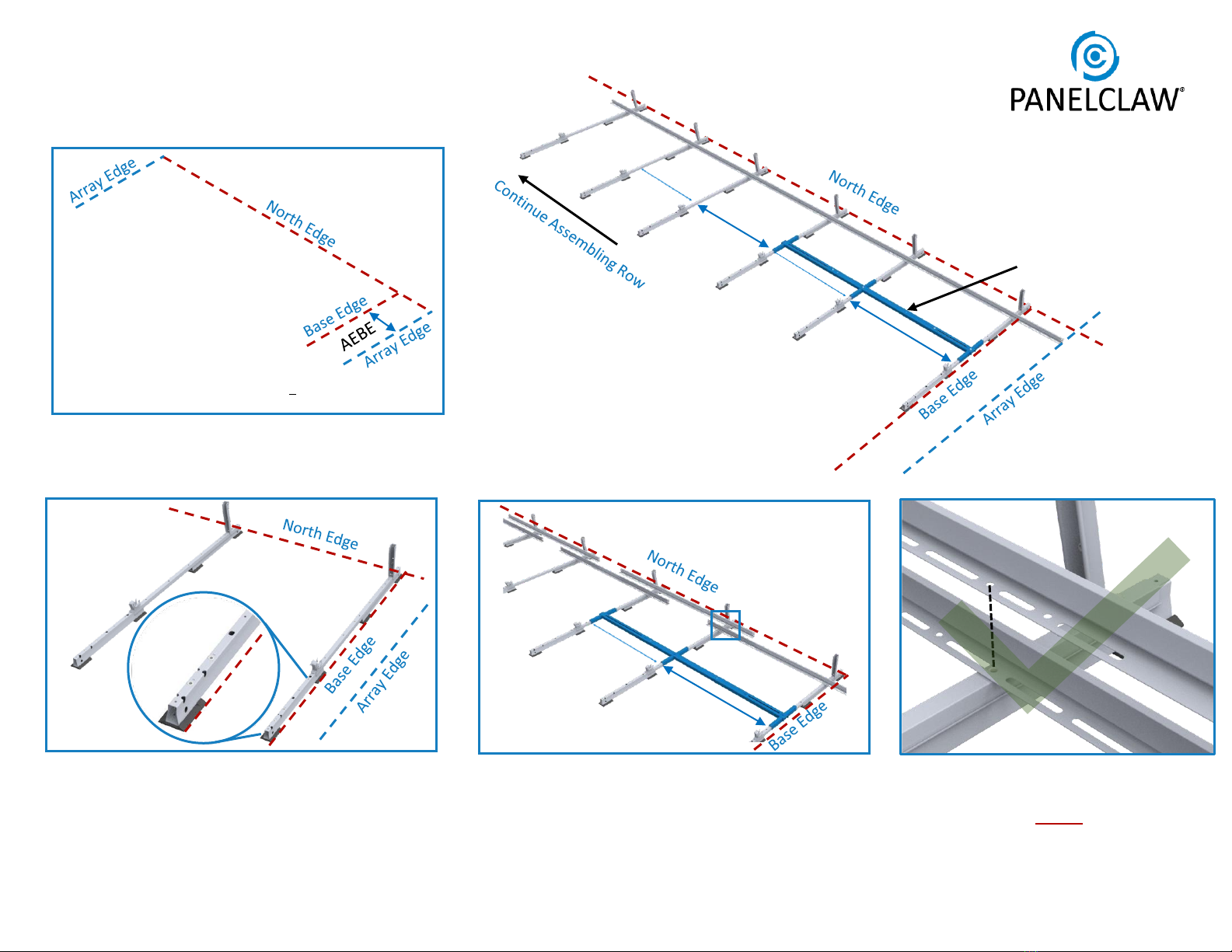

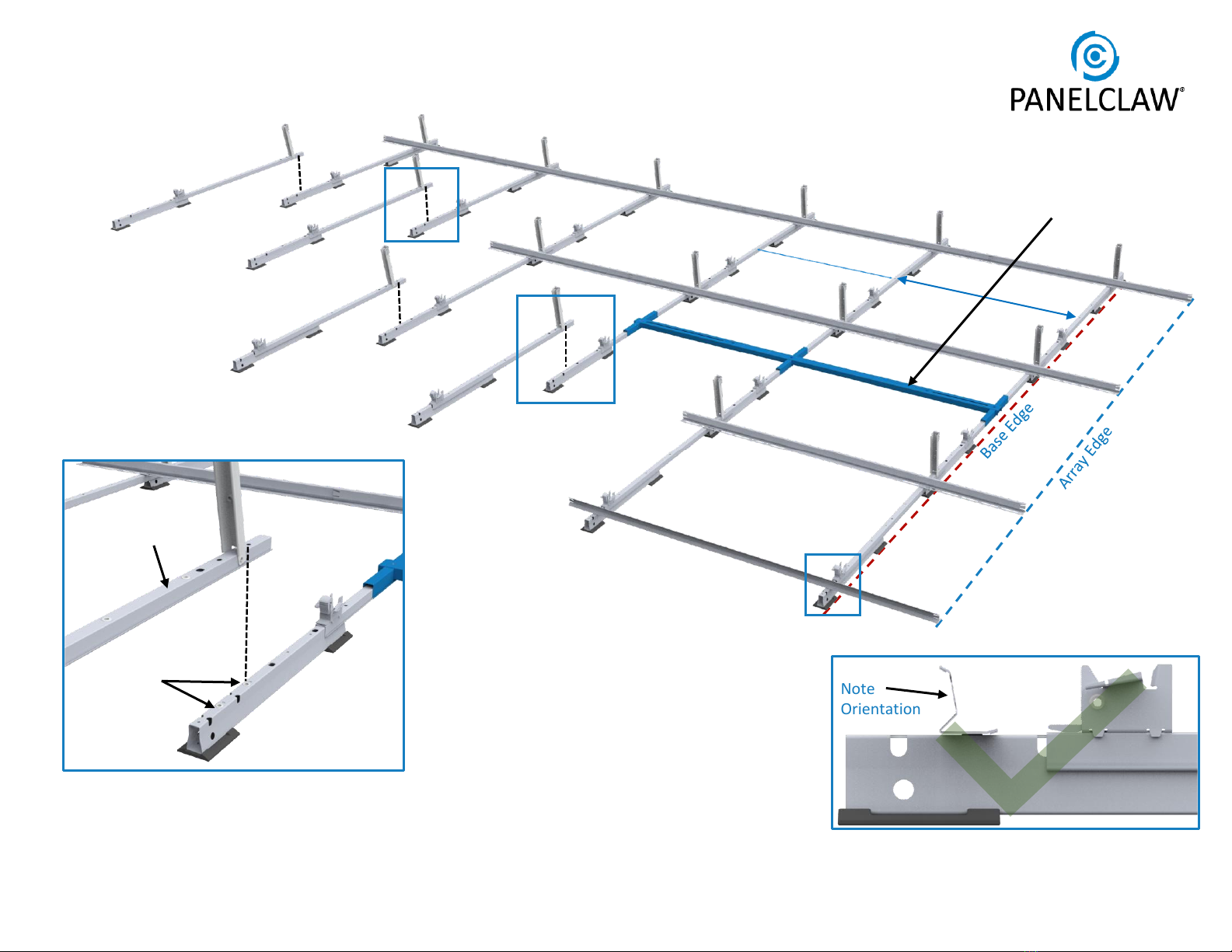

This installation manual explains how to build a PV array

using clawFR 10 Degree.

PAGE 2

PRIOR TO INSTALLATION, READ THE SAFETY PROVISIONS

ATTACHED IN Appendix A: Safety AND REVIEW THIS INSTALLATION

MANUAL IN ITS ENTIRETY.

A CORROSION INSPECTION ONE YEAR AFTER INSTALLATION AND

ONCE EVERY THREE YEARS THEREAFTER IS REQUIRED TO MAINTAIN

THE PRODUCT WARRANTY. VISIBLE SURFACE RED RUST ON ZAM®

COATED STEEL COMPONENTS MUST BE LOCALLY COATED WITH A

COMMERCIALLY AVAILABLE GALVANIZED PAINT OR COATING TO

MAINTAIN PRODUCT WARRANTY.

Mechanical Attachments

THIS INSTALLATION MANUAL DOES NOT COVER THE

SELECTION OR INSTALLATION OF MECHANICAL

ATTACHMENTS INCLUDING MATERIALS AND FASTENERS

USED TO SECURE AND/OR SEAL MECHANICAL

ATTACHMENTS TO THE ROOF. PLEASE SEE OEM

PROVIDER INSTALLATION MANUALS AND RELATED

LITERATURE. A LIST OF OEM PROVIDERS IS SHOWN

BELOW.

OEM MECHANICAL ATTACHMENT PROVIDERS:

•Anchor Products: www.anchorp.com

•OMG Roofing Products: www.omgroofing.com

•Facet: www.sustainabletechnologiesllc.com

Safety Overview

Safety is an essential part of every PV installation and every construction

site. It is imperative to plan ahead for any safety concerns and hazards to

promote safe work practices during installation. This section does not claim

to address or support all safety concerns that may arise during the

installation of PanelClaw mounting systems or any other aspect of the work

being performed. Before beginning work, installers should refer to all local

and federal safety, health, and regulatory requirements to assure

compliance. Refer to OSHA Part 1926 and its related Subparts for federal

construction related regulations and standards.

Appendix A: Safety outlines some of the major hazards to be aware of during

the installation of PanelClaw products.

EXCEPT FOR DEFLECTORS, ALL RACKING COMPONENTS IN EACH SUBARRAY AND THEIR CONNECTIONS, BALLAST, AND MECHANICAL

ATTACHMENTS (IF ANY IN DESIGN) MUST BE INSTALLED BEFORE MOUNTING MODULES. WHEN FORECASTED WIND GUSTS EXCEED

25% OF THE WIND SPEED LISTED IN THE SITE CRITERIA TABLE OF THE RACKING CONSTRUCTION SET, DEFLECTORS MUST BE INSTALLED

ON ALL MOUNTED MODULES TO AVOID POSSIBLE SYSTEM DAMAGE.