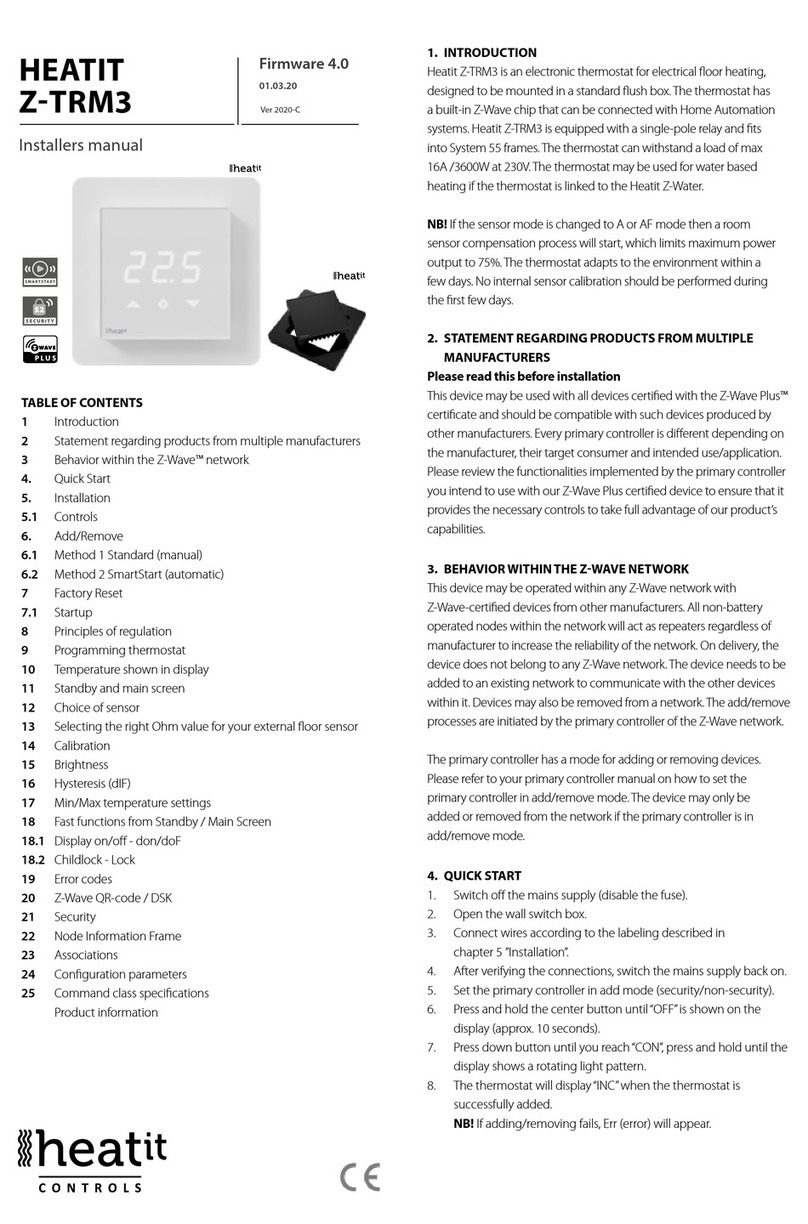

Heatit Controls Z-TRM6 User manual

1. INTRODUCTION

Heatit Z-TRM6 is an electronic thermostat designed for

electrical heating. The thermostat can be controlled through

your Z-Wave™ network or via the buttons on the front. The

thermostat has a user friendly interface.

Heatit Z-TRM6 has 3 modes; Heat - Cool and Eco.

The thermostat fits in standard European junction boxes and

may be used with most System 55 frames. It has a sturdy metal

frame for secure fastening on the junction box. The thermostat

has one built-in room temperature sensor. Two additional

external temperature sensors may also be connected.

Heatit Z-TRM6 has active power metering and it gives you

real time information about your power consumption. It also

allows you to set the power metering value manually in case

of connection with a contactor.

The device has implemented ZeroX technology. This

technology makes sure the relay switches at 0V when turning

on and o. With this technology the thermostat will have a

much longer lifetime.

The thermostat can be set up with multiple associations and

can be used as a master thermostat. It can control up to 10

thermostats and 10 external relays E.g wall plugs.

The thermostat can withstand a load of max 16A/3600W at

230VAC. We recommend a contactor for loads above 13A.

2. STATEMENT REGARDING PRODUCTS FROM MULTIPLE

MANUFACTURERS

Please read this before installation

This device may be used with all devices certified with the

Z-Wave Plus™ certificate and should be compatible with

such devices produced by any manufacturer. Every primary

controller is dierent depending on the manufacturer, their

target audience and intended use/application. Please review

the functionalities implemented by the primary controller you

intend to use with our Z-Wave Plus certified device to ensure

that it provides the necessary controls to take full advantage of

our product’s capabilities.

3. BEHAVIOR WITHIN THE Z-WAVE NETWORK

This device may be operated within any Z-Wave™ network

with Z-Wave-certified devices from other manufacturers. All

non-battery-operated nodes within the network will act as

repeaters regardless of manufacturer to increase the reliability

of the network. On delivery, the device does not belong to any

Z-Wave network. The device needs to be added to an existing

network to communicate with the other devices within it.

Devices may also be removed from a network. The add/

remove processes are initiated by the primary controller of the

Z-Wave network.

PRODUCT

DOCUMENTS

HEATIT

Z-TRM6

Installers manual

Firmware version Document version

FW 1.0 2023-B

Article no. Document date

54 305 66

54 305 67

54 305 68

01.09.2023

Org. doc. date 01.07.2023

White RAL 9003 White RAL 9010

54 305 66 54 305 67

TABLE OF CONTENTS

1. Introduction

2. Statement regarding

products from multiple

manufacturers

3. Behavior within the

Z-Wave network

4. Quick Start

5. Installation

6. Connections

7. Add/Remove

8. Factory reset

9. Startup

10. Principles of regulation

11. Local settings menu

12. Display menu structure

13. Temperature shown in

display

14. Standby and main screen

15. KWh value in menu

16. Size of load

17. Choice of sensor

18. Selecting sensor value

19. Calibration

20. Brightness

21. Display on/o

22. Display icons

23. Child lock

24. Open window detection

25. Error codes

26. Safety features

27. QR-Code placement (DSK)

28. Security

29. Node Information Frame

30. Associations

31. Association Groups

32. Configuration Parameters

33. Command Classes

34. Supported Command

Classes

35. Controlled Command

Classes

36. Thermostat dimensions

37. Chart - Display menu

structure

Product info

Black matt

54 305 68

4. QUICK START

1. Switch o the mains voltage (disable the fuse).

2. Open the junction box.

3. Connect the wires according to the description in

Chapter 6; ”Connections”. Optional: Connect external wired

sensors.

4. After verifying the connections, switch on the mains voltage.

5. Set the primary controller in add mode (security/non-

security).

6. Hold the Center button until “OFF” is shown in the display

(approx. 5 seconds).

7. Press the ”+” button once to reach “CON”, and hold until the

display shows a rotating light pattern.

8. The thermostat will display “INCL” when the thermostat is

successfully added. NB! If adding/removing fails, Err (error)

will appear.

5. INSTALLATION

Installation must be done by a qualified electrician in

accordance with national building codes. Before installation,

disconnect the power to the device from the mains. During

installation of the device, power to the device must be

disconnected AT ALL TIMES!

The product allows for wiring of cables with a cross section of

up to 1x2.5mm.

6. CONNECTIONS

Max tightening torque for terminal screws: 2Nm.

If the cable used has multiple strands using a end sleeve is

advised.

To access the terminal screws, hold the sides of the display

and gently pull outwards to detach the front piece.

Floor sensor NTC type 6.8, 10, 12, 15, 22, 33, 47 or 100kΩ.

Default 10kΩ.

External sensor NTC type 6.8, 10, 12, 15, 22, 33, 47 or 100kΩ.

Default 10kΩ.

NPower connection (Neutral) 230VAC.

Heating N Heating cable N connection.

LPower connection (Live) 230VAC.

Heating L Heating cable L connection.

Next, position the thermostat and mount it into the junction

box using 2 screws. Position the thermostat front over the part

mounted in the junction box, then carefully press the front

until it clicks into place. In order to get power metering values,

the load needs to be connected to both heating L + N.

7. ADD/REMOVE

Please read this before installation

The primary controller/gateway has a mode for adding or

removing devices. Please refer to your primary controller

manual on how to set the primary controller in add/remove

mode. The device may only be added or removed from the

network if the primary controller is in add/remove mode.

When the device is removed from the network, it will NOT

revert to factory settings.

An always listening node must be powered continuously

and reside in a fixed position in the installation to secure the

routing table. Adding the device within a 2 meter range from

the gateway can minimize faults during the Interview process.

There are two ways to add the device to a Z-Wave network.

7.1 Method 1: Standard (Manual)

Add/remove mode is indicated on the device by rotating

LED segments on the display. It indicates this for 90 seconds

until a timeout occurs, or until the device has been added to/

removed from the network. Configuration mode can also be

cancelled by performing the same procedure used for starting

Configuration mode.

1. Hold the Center button for 5 seconds.

The display will show “OFF”.

2. Press the ”+” button once to see “CON” in the display.

3. Start the add/remove device process in your primary

controller.

4. Start the configuration mode on the thermostat by holding

the Center button for approximately 2 seconds.

The device is now ready for use with default settings.

NB! When the device is removed from the gateway, the

parameters are not reset. To reset the parameters, see Chapter

”Factory reset”.

If inclusion fails, please perform a ”remove device” process and

try again. If inclusion fails again, please see “Factory reset”.

7.2 Method 2: SmartStart (Automatic)

SmartStart enabled products may be added to a Z-Wave

network by scanning the Z-Wave QR-Code on the product

if your primary controller supports SmartStart inclusion. No

further action is required and the SmartStart product will be

added automatically after being powered on within range of

the primary controller.

8. FACTORY RESET

Enter the menu by holding the Center button for about 5

seconds, navigate in the menu with the ”+” button til you see

FACT. Press the Center button until you see “-- --” blinking in

the display, then hold for about 5 seconds to perform a reset.

You may also initiate a reset by holding the Right and Center

buttons for 60 seconds.

When either of these procedures has been performed, the

thermostat will perform a complete factory reset. The device

will display “RES” for 5 seconds while performing a factory

reset. When “RES” is no longer displayed, the thermostat has

been reset.

Please use this procedure only when the primary controller is

missing or otherwise inoperable.

By pressing any button once, you will see the measured

temperature. By pressing the Left or Right button multiple

times, you will change the setpoint.

15. KWH VALUE IN MENU

The device supports power metering to give insight into the

power consumption of the heating. The total consumption of

the device can be seen in the system from the “kWh” menu

option. The total consumption data can be reset by holding

the Center button while in the kWh menu.

16. SIZE OF LOAD

In the “load” menu or from Parameter 29 (size of load), the

load value can be set manually if the load is not directly

connected to the thermostat. The size of load can be adjusted

in 100W increments up to 9900W.

17. CHOICE OF SENSOR

The thermostat has multiple sensors and sensor modes. This

lets you configure the thermostat to work correctly in most

installations. The sensors and modes may be selected from

either the local settings menu or via Parameter 2; ”Sensor

mode (“OPER”)”.

Available sensor modes:

FFloor sensor

AInternal room sensor

AF Internal room sensor + Floor sensor

A2 External room sensor

A2F External room sensor + Floor sensor

PWER Power regulator mode (no sensor used)

NOTE: Some types of floor require that a floor sensor

is connected in order to limit the floor temperature to

a maximum of 27°C (check the manual from the floor

manufacturer). When the thermostat is used in (AF or A2F) the

floor limiter FHI is automatically set to 27°C. When using any

other sensor type (A, F or A2) the minimum and maximum

limits are 5°C and 40°C respectively.

18. SELECTING SENSOR VALUE

The thermostat allows the selection of multiple dierent

resistance values of an NTC sensor and can be selected using

either the local settings menu or via Parameter 3: ”Sensor value

“SEN”. The supported sensor values are as follows:

6.8, 10, 12, 15, 22, 33, 47 or 100KΩ.

The factory default value is 10kΩ. When connecting both the

floor sensor and the external sensor, make sure to use sensors

with the same Ohm value.

19. CALIBRATION

If the temperature sensor readout is not correct, you can make

minor changes to the temperature readout. The temperature

readings can be calibrated by ±6°C using Parameter 10, 11

and 12. The calibration can also be performed from the menu

using CAR, CAE and CAF. The adjusted value will be displayed

in the controller/gateway indicating what the thermostat uses

for regulation.

9. STARTUP

After powering up the device for the first time, all parameters

will have default settings and the thermostat will start by asking

which sensor mode should be used.

10.PRINCIPLES OF REGULATION

The thermostat uses temperature readings retrieved from the

internal sensor and/or from external wired sensors to regulate

the temperature. The thermostat will regulate the temperature

using hysteresis or PWM, based on the setpoint temperature.

To select either “HYST” or “PWM” you can find the “REG” menu

option or use Parameter 13 “Regulation mode (“OPER”)”.

10.1 Hysteresis

Hysteresis will turn on and o the load based on the hysteresis

value in comparison to the setpoint. You can make changes

to the thermostat hysteresis. You may choose hysteresis

values between 0.3°C and 3.0°C using Parameter 14. The

default setting is 0.5°C. When using waterbased heating we

recommend a hysteresis of 1.0°C.

You may also change the hysteresis by entering the local

settings menu and holding the Center button for 2 seconds

when “REG” is displayed. Here you can choose values

between 0.3 and 3.0.

10.2 Pulse-width modulation PWM

With PWM regulation enabled, the thermostat will regulate

based on duty cycles. The thermostat is turned on and o in

percentage intervals of the cycle. The amount of time the relay

will be on is based on how far the measured temperature is

from the setpoint.

11. LOCAL SETTINGS MENU

To enter the settings menu, hold the Center button for 5

seconds. The display will display “OFF”. You are now in the

settings menu. While in the settings menu, “SET” will be

displayed in the bottom right of the display. You can now scroll

up and down using the Left and Right buttons. Some options

have submenus. To navigate the submenus, press the Center

button once to enter or exit the submenu. Press the Left and

Right buttons to find your desired value and hold the Center

button for 2 seconds to confirm your selection. “STOR” will

appear to indicate settings are stored.

12. DISPLAY MENU STRUCTURE

See flowchart at the end of this manual.

13. TEMPERATURE SHOWN IN DISPLAY

By default, the temperature shown on the display while

in standby state is the setpoint. This may be altered with

Parameter 15:”Temperature display”. It may also be changed

by entering the local settings menu and holding the Center

button for 2 seconds when “MODE” is displayed. You can

choose between “SETT” and “RELT”. “SETT” is the Setpoint

temperature and “RELT” is the real-time temperature.

14.STANDBY AND MAIN SCREEN

When the thermostat remains untouched for a while, it will

automatically go to the standby screen. The standby will by

default show the setpoint temperature.

SENSOR TYPE IN MENU STRUCTURE PARAMETER

Internal sensor CAR 10

External sensor CAE 11

Floor sensor CAF 12

20.BRIGHTNESS

Using the menu choices “BR1” and “BR2”, the brightness

of the display in Active and Standby state can be changed

respectively. “BR1” and “BR2” are also included in the device as

Parameter 16 (BR1) and Parameter 17 (BR2).

21. DISPLAY ON/OFF (DON/DOFF)

The thermostat has a display ON/OFF function which decides

whether the display should turn completely o when in

Standby. To enable/disable this function, hold the Left and

Center buttons for 10 seconds. The display will show “DOFF”

when the function is activated and “DON” when the function is

disabled. When operating any button, the display will light up.

22.DISPLAY ICONS

ICON DESCRIPTION

This icon will be displayed while the relay is on and the

thermostat is in either Heating or Eco mode.

This icon will be displayed while the relay is on and the

thermostat is in Cooling mode.

This icon shows the current signal strength.

23. CHILD LOCK

Child lock is a function for disabling the buttons from the

display locally. It will show “LOCK” when attempting to

operate it while the function is enabled. To enable or disable

the function, hold the Left and Right buttons for 10 seconds.

Enabling the function will show “LOCK” in the display, disabling

the function will show “OPEN”.

24.OPEN WINDOW DETECTION OWD

Open Window Detection (OWD) is a function which will

reduce the thermostat setpoint on detection of an open

window. This happens when the temperature sensor registers

a rapid temperature drop.

When OWD is active, the setpoint is reduced to 5°C in order

not to waste energy. OWD will automatically be cancelled

if OWD has been active for more than 1 hour, or if the

temperature increases by 3°C. OWD can also be cancelled

manually by increasing/decreasing the setpoint with the Left

and Right buttons.

By default, OWD is not enabled. The feature may be enabled

by selecting “OWD” from the menu. Choose between options

“OFF” and “ON”. It can also be enabled by setting parameter 26

(open window detection) to 1.

25. ERROR CODES

Err Adding fail. See Chapter 7 “Add/remove”.

Err1 Internal error. Most probably a faulty unit. Replace unit.

Err2 Z-Wave error. Most probably a faulty unit. Replace unit.

Err3 Internal error. Most probably a faulty unit. Replace unit.

Err4 Floor sensor error. You have chosen F, AF or A2F sensor

mode without having a floor sensor connected, or the

sensor may be damaged.

Err5 External sensor error. You have chosen A2 or A2F sensor

mode without having an external sensor connected, or

the sensor may be damaged.

Err6 Overheating. Contact your electrician.

Err7 Overload. Contact your electrician.

26.SAFETY FEATURES

The device has safety features to ensure safe operation and

warn the user of any faults/unexpected behavior. The device

has an Overheat and Overload function. If the thermostat

registers an Overheat or Overload incident, the thermostat will

switch o and an error will appear in the display.

26.1 Overheating

The device features internal temperature sensors that

detect overheating. It warns the user and turns o the relay to

prevent any damage.

When overheating is detected, the device will:

• Turn o the relay.

• Display Err6 in the display.

• Send a notification to the gateway.

26.2 Overload

The device features a 16A overload protection. The overload is

triggered if there is a current draw of more than 16A.

When overload is detected, the device will:

• Turn o the relay.

• Display Err7 in the display.

• Send a notification to the gateway.

26.3 Sensor failure

The device has the ability to detect when there is no sensor

connected or the sensor is broken or otherwise defective,

causing an open circuit.

When the device detects the sensor error, the device will:

• Turn o the relay.

• Display an error in the display, changes based on which

sensor is not connected/faulty.

To clear the “Sensor not connected” error the device has to

be disconnected from the mains, and the wiring and sensor(s)

need to be checked. When the fault is resolved the mains can

be reconnected and the device will function normally again.

27. QR-CODE PLACEMENT (DSK)

The QR-Code is needed when including a device using S2

security or SmartStart. The DSK can be found in the QR-Code

and is located;

• On the product.

• In the Quick Guide.

• On the packaging box/gift box.

28.SECURITY

S2 security enhances Z-Wave Plus with an additional layer of

AES 128-bit encryption of the wireless Z-Wave communication

to prevent hacking and man-in-middle attacks on the home

network.

This device supports S2 and has a Z-Wave DSK QR-Code label

that may be used when the device is added to the Z-Wave

home network. The primary controller will ask for a 5-digit

code. They are the first underlined 5 digits located on the

QR code sticker. The primary controller will then ask you to

confirm the rest of the code that is contained in the QR-Code.

29.NODE INFORMATION FRAME

The node information frame is the ”business card” of a Z-Wave

device. It contains information about the device type and

its technical features. The add and remove procedure of

the device is confirmed by sending out a node information

frame. Besides this, it may be necessary for certain network

operations to send out a node information frame.

30.ASSOCIATIONS

Z-Wave devices interact with other Z-Wave devices. The

relationship between one device controlling another device is

called an association. In order to control a subordinate device,

the controlling device needs to maintain a list of devices that

will receive controlling commands. These lists are called

”Association Groups”. They are always related to the specific

event triggered (e.g., sensor reports). In case the event is

triggered, all devices stored in the respective association group

will receive a joint wireless command.

30.1 Setting and Removing Associations

Associations may be assigned and removed via Z-Wave

commands. Please refer to your primary controller/Z-Wave

gateway for more information.

30.2 Multi Channel support

Heatit Z-TRM6 has support for the Multi Channel Command

Class. This allows the thermostat to be perceived as multiple

devices by the primary controller, which enables the reporting

of multiple temperature sensors and the ability to distinguish

between the reports coming from the device.

30.3 No Multi Channel support

If the primary controller or the Z-Wave devices to be

associated with Heatit Z-TRM6 do not support the Multi

Channel Association Command Class (Multi Channel

encapsulation), only the association groups in the root device

are accessible. This device contains 3 association groups in

addition to the Lifeline Group.

31. ASSOCIATION GROUPS

Without Multi Channel support:

MULTI LEVEL SWITCH DEVICE DESCRIPTION

Group 1

Lifeline.

Lifeline Group to be used by primary controller, sends:

-Thermostat Mode Report

-Thermostat Setpoint Report

-Thermostat Operating State Report

-Protection Report

-Notification Report

-Meter Report

-Sensor Multilevel Report

-Device Reset Locally Notification

-Indicator Report

-Configuration Report

Max nodes in group: 1

Group 2

Binary Switch Set.

Send Binary Switch set commands based on the internal relay state, sends:

-Binary Switch Set

Max nodes in group: 10

MULTI LEVEL SWITCH DEVICE DESCRIPTION

Group 3

Thermostat Setpoint set.

Sends Thermostat Setpoint set commands based on own setpoint to allow for

use as master thermostat, sends:

-Thermostat Setpoint Set

Max nodes in group: 10

Group 4

Thermostat Mode set.

Sends Thermostat Mode set commands based on own mode to allow for use as

master thermostat, sends:

-Thermostat Mode Set

Max nodes in group: 10

With Multi Channel support:

1: THERMOSTAT DEVICE THE MAIN THERMOSTAT DEVICE

Group 1

Lifeline.

Lifeline Group to be used by primary controller, sends:

-Thermostat Mode Report

-Thermostat Setpoint Report

-Thermostat Operating State Report

-Protection Report

-Notification Report

-Meter Report

-Sensor Multilevel Report

-Device Reset Locally Notification

-Indicator Report

-Configuration Report

Max nodes in group: 1

Group 2

Binary Switch Set

Send Binary Switch set commands based on the internal relay state, sends:

-Binary Switch Set

Max. nodes in group: 10

Group 3

Thermostat Setpoint Set

Sends Thermostat Setpoint set commands based on own setpoint to allow for

use as master thermostat, sends:

-Thermostat Setpoint Set

Max. nodes in group: 10

Group 4

Thermostat Mode Set.

Sends Thermostat Mode set commands based on own mode to allow for use as

master thermostat, sends:

-Thermostat Mode Set

Max. nodes in group: 10

2: MULTILEVEL SENSOR DEVICE INTERNAL SENSOR

Group 1

Lifeline.

Lifeline Group for internal sensor, sends:

-Sensor Multilevel Report

Max. nodes in group: 0

3: MULTILEVEL SENSOR DEVICE EXTERNAL SENSOR

Group 1

Lifeline.

Lifeline Group for external sensor, sends:

-Sensor Multilevel Report

Max. nodes in group: 0

4: MULTILEVEL SENSOR DEVICE FLOOR SENSOR

Group 1

Lifeline.

Lifeline Group for floor sensor, sends:

-Sensor Multilevel Report

Max. nodes in group: 0

32. CONFIGURATION PARAMETERS

Z-Wave products are supposed to work out of the box after

inclusion. Some device configuration may, however, alter

the functionality to better serve user needs or unlock further

enhanced features. All the parameters below do not feature

altering capabilities, advanced or read only flags.

PARA NO#

PARA SIZE

(BYTE)

NAME

SHORT

DESCRIPTION / COMMENT

MIN

MAX

DEFAULT

DESCRIPTION

OF VALUE

1 1 Disable

buttons

Disable buttons, must be en-

abled through the parameter,

or turned back on locally by

holding the center and right

button for 30 seconds until the

display shows “UNLK”.

0

0

Enabled, buttons on the

front of the device work.

(Default)

1

Disabled, buttons on the

front of the device are

disabled.

2 1

Sensor

mode

(OPER)

Choose which sensors the

thermostat should use for

regulation.

0

1

F, Floor sensor

1 A, Internal sensor (Default)

2AF, Internal sensor with

floor sensor limitations

3 A2, External sensor

4A2F, External sensor with

floor sensor limitations

5PWER, Power regulator

mode

PARA NO#

PARA SIZE

(BYTE)

NAME

SHORT

DESCRIPTION / COMMENT

MIN

MAX

DEFAULT

DESCRIPTION

OF VALUE

3 1 Sensor

value (SEN)

Select the resistance value of

the connected NTC.

0

0

10KΩ(Default)

1 12KΩ

2 15KΩ

3 22KΩ

4 33KΩ

5 47KΩ

6 6.8KΩ

7 100KΩ

4 2

Internal

sensor min

temp limit

Decides the lowest tempera-

ture allowed by the thermostat

when using sensor mode A.

50 400 50 5°C to 40°C (Default is 5°C)

5 2

Floor

sensor min

temp limit

Devices the lowest tempera-

ture allowed by the thermostat

when using sensor mode

AF, F, A2F.

50 400 50 5°C to 40°C (Default is 5°C)

6 2

External

sensor min

temp limit

Decides the lowest tempera-

ture allowed by the thermostat

when using sensor mode

A2, A2F.

50 400 50 5°C to 40°C (Default is 5°C)

7 2

Internal

sensor max

temp limit

Decide the highest tempera-

ture allowed by the thermostat

when using sensor mode A.

50 400 400 5°C to 40°C

(Default is 40°C)

8 2

Floor

sensor max

temp limit

Decide the highest tempera-

ture allowed by the thermostat

when using sensor mode

AF, F, A2F.

50 400 400 5°C to 40°C

(Default is 40°C)

9 2

External

sensor max

temp limit

Decide the highest tempera-

ture allowed by the thermostat

when using sensor mode

A2, A2F.

50 400 400 5°C to 40°C

(Default is 40°C)

10 1

Internal

sensor

calibration

(CAR)

Manually calibrate sensor

A ±6°C. -60 60 0

-6.0°C to 6.0°C

Calibrates the sensor by

±6°C. (Default is 0°C)

NB! To set a negative value,

use 256 and subtract the

desired value.

11 1

Floor

sensor

calibration

(CAF)

Manually calibrate sensor

F ±6°C. -60 60 0

-6.0°C to 6.0°C

Calibrates the sensor by

±6°C. (Default is 0°C)

NB! To set a negative value,

use 256 and subtract the

desired value.

12 1

External

sensor

calibration

(CAE)

Manually calibrate sensor

A2 ±6°C. -60 60 0

-6.0°C to 6.0°C.

Calibrates the sensor by

±6°C. (Default is 0°C)

NB! To set a negative value,

use 256 and subtract the

desired value.

13 1

Regulation

mode

(REG)

Choose between regulation

modes PWM and Hysteresis.

0

0

Hysteresis

1 PWM regulation

14 1

Tempera-

ture control

hysteresis

(HYST)

Choose the hysteresis used

when regulation mode is set

to HYST.

3 30 5 0.3°C to 3.0°C.

Default is 5 (0.5°C)

15 1 Tempera-

ture display

Select what is shown on the

display during Standby state.

0

0

Display setpoint tempera-

ture. (Default)

1Display measured

temperature.

16 1

Active

display

brightness

(BR1)

Configure the brightness of the

display during active state. 1 10 10 10 to 100% (Default 100%)

17 1

Standby

display

brightness

(BR2)

Configure the brightness of the

display during standby state. 1 10 5 10 to 100% (Default 50%)

18 2

Tempera-

ture report

interval

Set the time interval between

consecutive temperature

reports.

30 65535 840 30 to 65535 seconds.

840s (14 min) (Default)

19 1

Tempera-

ture report

hysteresis

Set the change in temperature

required to send a temperature

report based on change.

1 100 10 0.1°C to 10°C

10 (1°C) (Default)

20 2

Meter

report

interval

Set the time interval between

consecutive meter reports. 30 65535 840 30 to 65535 seconds.

840s (14 min) (Default)

21 2 Action after

error

Decide how the device should

react when the overload /

overheating features has

turned OFF relay.

0

0

0, device will turn o

and show an error in the

display. (Default)

10 65535

10 to 65535 seconds, de-

vice will attempt to turn on

again after an error based

on the delay specified.

22 2 Heating

setpoint Set setpoint for Heating mode. 50 400 210 5°C to 40°C.

21°C (Default)

23 2 Cooling

setpoint Set setpoint for Cooling mode. 50 400 180 5°C to 40°C.

18°C (Default)

24 2ECO

setpoint Set setpoint for ECO mode. 50 400 180 5°C to 40°C.

18°C (Default)

25 1

Power

regulator

active time

Set the % of time the relay

should be active when using

PWER mode. (30-minute

duty cycle).

1 10 2

1 - 10

10 to 100%.

20% (Default)

PARA NO#

PARA SIZE

(BYTE)

NAME

SHORT

DESCRIPTION / COMMENT

MIN

MAX

DEFAULT

DESCRIPTION

OF VALUE

26 2

Thermostat

state

update

interval

Set the time interval of how

often the device updates

Thermostat Setpoint set, Ther-

mostat Mode set and Binary set

to associated devices.

0

43200

Sends only when changed.

30 65535

30 to 65535 seconds.

43200 seconds + when

changed. (Default)

27 1

Operating

Mode

(MODE)

Set the thermostat mode.

0

1

OFF

Thermostat will not operate

1 Heating mode (Default)

2 Cooling mode

3 ECO mode

28 1

Open

window

detection

Choose to enable or disable

the Open windows detection.

0

0

Open window detection

disabled. (Default)

1Open windows detection

enabled.

29 2 Size of load

Allows the user to decide

the power consumption of

the connected load in 100W

increments.

0Uses power metering

values. (Default)

1 99

1-99 = 100-9900 Watt

Allows the user to set the

size of the load, used when

connected to a contactor.

33. COMMAND CLASSES

Additional information regarding Command Classes and their

functionality:

33.1 Basic Command Class

A Basic command to the device will change the thermostat

mode. Uses the following values:

0x00 = OFF (0x00)

0xFF = HEAT (0x01)

If the thermostat is in ECO or COOL mode, 0x00 will still

change the mode to OFF. ECO or COOL cannot be enabled

with a Basic Set command.

33.2 Meter Command Class

The device supports Meter Command Class Get, and the

thermostat will only respond on supported electric meter

scales: kWh (accumulated) and Watt (instant).

The device will report when asked:

Rate type: Import (0x01)

Meter type: Electric meter (0x01)

TYPE SCALE VALUE SIZE PRECISION REPORT HYSTERESIS

Electric kWh 0x01 4 1 840s, configurable

Electric W 0x01 4 1 75W (not configurable),

840s, configurable

33.3 Protection Command Class

Protection Command Class allows you to disable local control

of the thermostat, this is separately from the Child Lock

function.

To enable the Protection Command Class, either set

Parameter 1 (disable buttons) to value 1, enabling Local

Protection State 0x02, or send a Protection Set with Local

Protection State 0x01 or 0x02.

During Protection State 0x01, the device is protected by a

button sequence and allows for no local operation until it is

unlocked. To unlock the thermostat while in Protection state

0x01, first press twice on the Left button, then press twice on

the Right button and then finally twice on the Center button.

This will unlock the thermostat until it goes back to standby,

requiring you to unlock it again.

Protection State to 0x02 means that no operation is possible

and the thermostat can only be unlocked by setting Parameter

1 to 0, or by holding the Center and Right buttons for 30

seconds.

33.4 Thermostat Setpoint Command Class

Thermostat Setpoint is implemented with 3 setpoints, Heating,

Cooling and ECO. Supported setpoints are from 5°C - 40°C

with 0.5°C increments.

33.5 Thermostat Mode Command Class

It is possible to change the operating mode of the thermostat

by sending a Thermostat Mode set command. The accessible

operating modes are:

0x00: OFF (Thermostat regulation and display are

deactivated).

0x01: Heating Mode (Thermostat regulation is active).

0x02: Cooling Mode (Thermostat regulation is inverted).

0x0B: ECO Mode (Thermostat regulation is active with a

separate setpoint from Heating Mode).

33.6 Thermostat Operating State Command Class

The thermostat reports the operating state of the interal relay

using this Command Class.

0x00 = Idle

0x01 = Heating (used for Heating and ECO mode)

0x02 = Cooling

33.7 Indicator Command Class

The device supports the Indicator Command Class. The

indicator Command Class will flash the display.

33.8 Notification Command Class

The product features security features that announce any

action using the Notification Command Class.

The following commands are implemented:

NAME VALUE

EVEN/

STAT

STATE

VARIABLE

STATE

VARIABLE

AFTER

NOTIFICATION

NAME VALUE

Heat alarm 0x04 State Heat sensor status Idle Overheating

detected 0x02

Power

management 0x08 State Overload status Idle Overload

detected 0x08

33.9 Binary Switch Command Class

Binary Switch commands are used to control external relays

associated with group 2.

Uses the following values:

0x00 = OFF

0xFF = ON

This Command Class is based on the operating state of the

thermostat (relay on or o).

34.SUPPORTED COMMAND CLASSES

The following table lists all Command Classes supported by

the Z-Wave device. The device supports S0, S2 Authenticated

security and S2 Unauthenticated security.

ASSOCIATION VERSION INSECURE ON

SECURE INCLUSION

SECURE ON

SECURE INCLUSION

Association v2 Yes

Association Group Information v3 Yes

Device Reset Locally Notification v1 Yes

Firmware Update MD v5 Yes

Indicator v3 Yes

Manufacturer Specific v2 Yes

Multi channel Association v3 Yes

Multi channel v4 Yes

Power level v1 Yes

Security v1 Yes

Security v2 v1 Yes

Supervision v1 Yes

Transport Service v2 Yes

Version v3 Yes

Z-Wave Plus Information v2 Yes

Configuration v4 Yes

Basic v2 Yes

Notification v11 Yes

Meter v5 Yes

Sensor Multilevel v11 Yes

Protection v1 Yes

Thermostat Mode v3 Yes

Thermostat Operating State v1 Yes

Thermostat Setpoint v3 Yes

35. CONTROLLED COMMAND CLASSES

ASSOCIATION VERSION INSECURE ON

SECURE INCLUSION

SECURE ON

SECURE INCLUSION

Binary Switch 2 Yes

36.THERMOSTAT DIMENSIONS

37. THERMOSTAT CONTROLS

ICON DESCRIPTION

Previous.

Decrease set temperature.

Menu confirm.

Menu enable.

Next.

Increase set temperature.

45.5mm

22mm 23.5mm

84mm

50mm

50mm

38.CHART - DISPLAY MENU STRUCTURE

Hold the middle button for 5 seconds to enter menu.

Fail

Success

Hold button

for 2 seconds

TDS: Temperature displayed

in standby mode

SETT: Setpoint temperature

RELT: Real time temperature

Only shows

available options

Only shows

available options

Short hold to

change the mode

Hold the middle button to

set HYST value, from 0.3-3.0

Default

Default

Hold to reset the Kwh.

Only shows

available options

Load value from 100-9900W,

by increments of 100.

Heatit Controls AB · Läkarvägen 4, 454 31 BRASTAD, SWEDEN

PRODUCT INFO

38.1 Error messages in display

38.2 General display messages

PRODUCT INFO Heatit Z-TRM6

FEATURES

• Z-Wave thermostat

• Internal room sensor

• External room sensor (wired)

• Floor sensor

• Power regulator

• Temperature limiter

• 3 modes; Heat, Cool og Eco

• SmartStart

• Temperature shown in

gateway

• Weekly schedule in gateway

• Firmware update (OTA)

• Active power metering

• Hysteresis/PWM

• Relay status icon

• Adjustable display

brightness

• Single pole switch

• Lock mode/child lock

• Temperature calibration

• Open window detection

• ZeroX detection

• Supports encryption mode: S0, S2 Authenticated Class,

S2 Unauthenticated Class

The product must be used with a security-enabled Z-Wave

controller in order to fully utilize security/encryption.

TECHNICAL DATA

Protocol Z-Wave, 868.4MHz

Chip Z-Wave 800 chip

Rated voltage 230VAC 50Hz

Max load 3600W (resistive load)

Contactor recommended for

loads above 13A

Max current 16A

Power consumption <2W

Power regulator Time cycle 0 to 30 min.

Ambient temperature 5°C to 40°C

Temperature range 5°C to 40°C

Storage temperature -30°C to 70°C

Hysteresis 0.3°C to 3.0°C (default 0.5°C)

Humidity 10% to 85% RH

Compatible with NTC-

sensor with values 6.8, 10, 12, 15, 22, 33, 47 or

100kΩ@ 25°C

Range RF Min. 40 meter

Screw terminals Max. 2.5mm 2Nm

IP Code IP21

Size (LxWxH) 84 x 84 x 45mm

Approvals Z-Wave Plus v2, CE, Nemko

MAINTENANCE

The device is maintenance-free. Indoor use only.

Failed to include

Internal error:

MCU and Z-Wave chip

communication failed

Z-Wave error

Internal sensor error

Floor sensor error

External sensor error

Overheat

Overload

Childlock activated

Childlock disabled

Backlight on when

device in standby

Backlight o when

device in standby

Open window detected

Settings stored

We have designed this product in accordance with our strict quality requirements (ISO 9001) and

environmental requirements (ISO 14001). All electrical installations must be carried out by an authorized

electrical installer. The product must be installed in accordance with our installers manual and national

building codes. Any wrongful installation, misuse or damage to the product is not covered under warranty.

Heatit Controls AB can not be held liable for any type of errors or omittances in our product information.

Product specifications may change without further notice.

DISPOSAL GUIDELINES

Do not dispose of electrical appliances as unsorted municipal waste, use separate collection

facilities. Contact your local government for information regarding the collection systems

available. If electrical appliances are disposed of in landfills or dumps, hazardous substances

can leak into the groundwater and get into the food chain, damaging health and well-being.

This manual suits for next models

3

Table of contents

Other Heatit Controls Thermostat manuals

Popular Thermostat manuals by other brands

Micropelt

Micropelt MVA008 User manual and device specification

Braeburn

Braeburn Economy Series user manual

MyPlace

MyPlace ADVANTAGE AIR user manual

Computime

Computime Salus Controls iT500 Full user manual

Theben

Theben RAM 785 operating instructions

Honeywell Home

Honeywell Home PRO 1000 Series operating manual

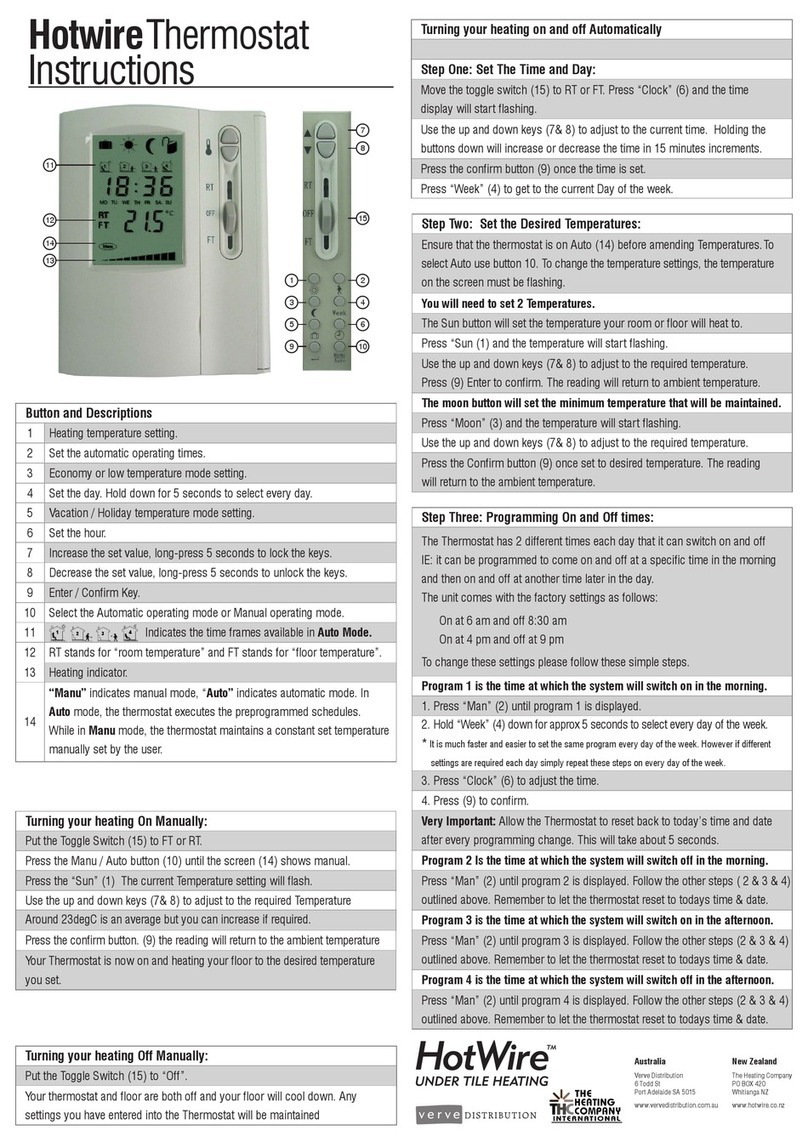

HotWire

HotWire T888 instructions

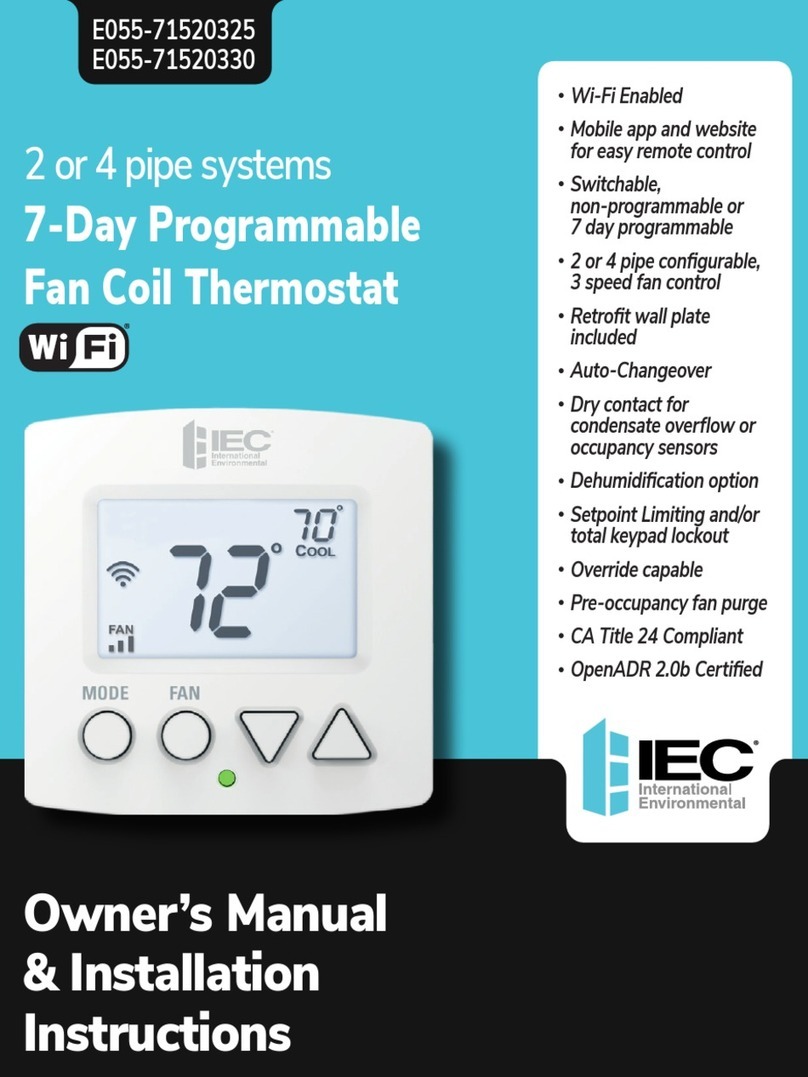

IEC

IEC E055-71520325 Owner's Manual & Installation Instructions

Viessmann

Viessmann VITOTROL 100 installation instructions

White Rodgers

White Rodgers 1F92-71 Operation guide

Elnur Gabarron

Elnur Gabarron CTM21 Installation and use manual

RS PRO

RS PRO 124-1054 instruction manual