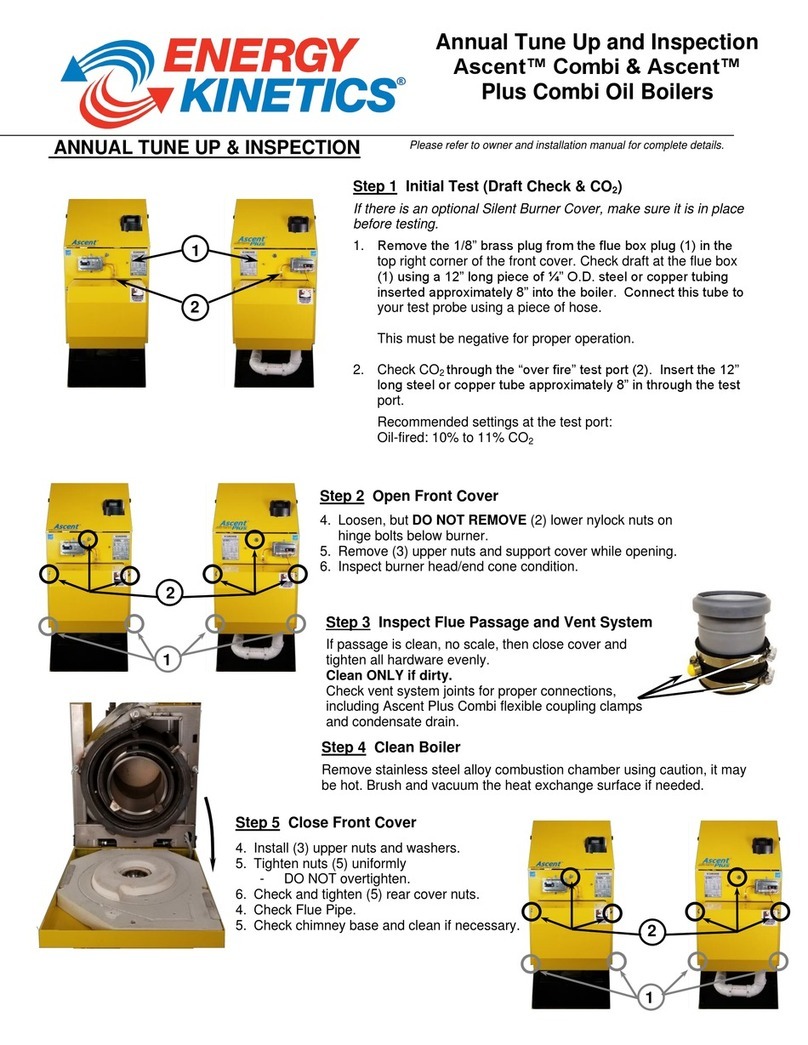

ENERGY KINETICS Ascent Combi Installation instructions

Other ENERGY KINETICS Boiler manuals

ENERGY KINETICS

ENERGY KINETICS EK2C Supplement

ENERGY KINETICS

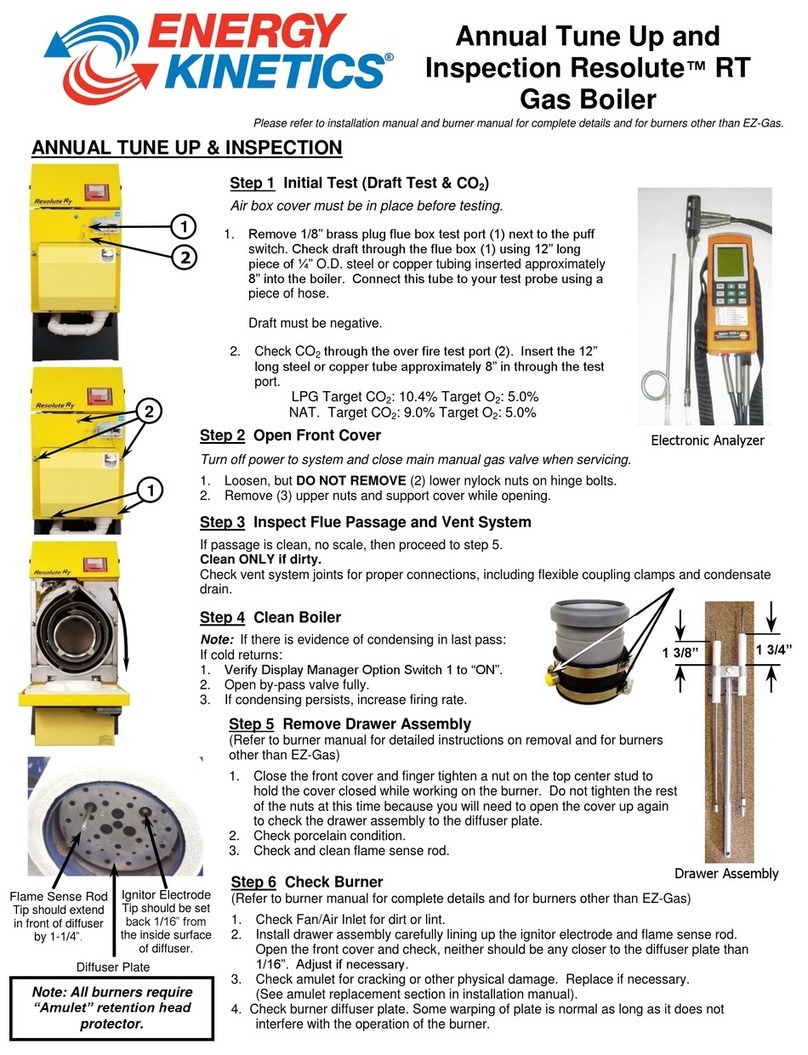

ENERGY KINETICS 90+RESOLUTE BOILER Service manual

ENERGY KINETICS

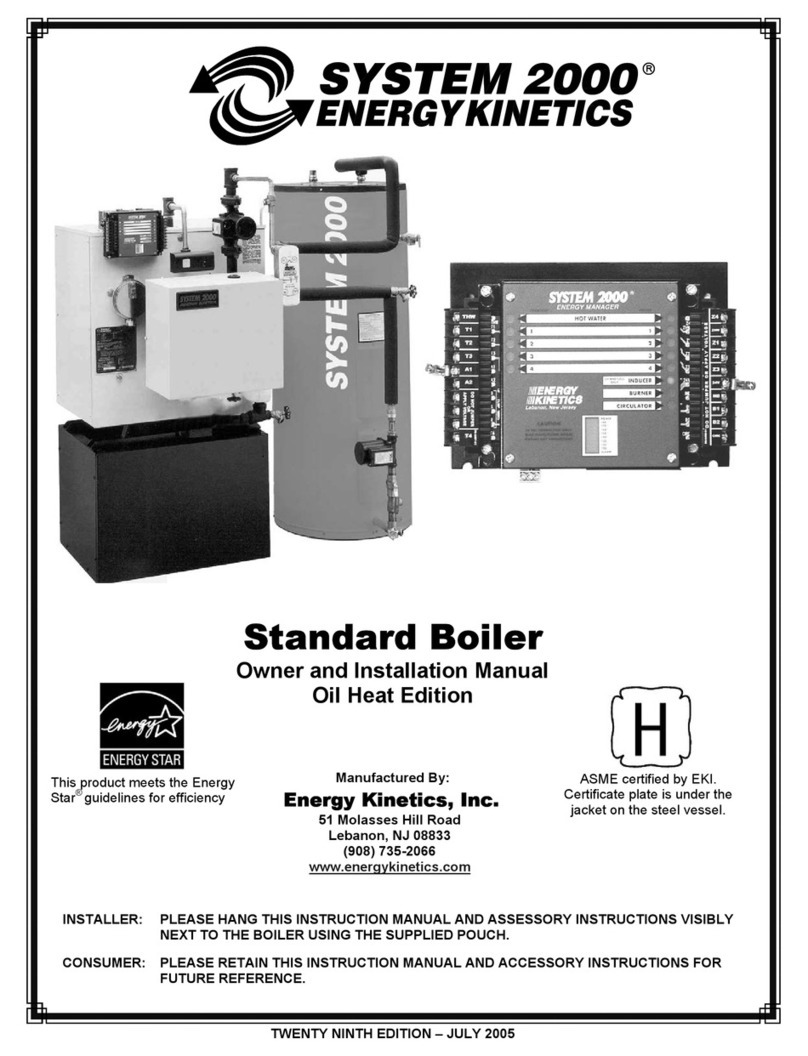

ENERGY KINETICS System 2000 EK1 Frontier Service manual

ENERGY KINETICS

ENERGY KINETICS System 2000 Supplement

ENERGY KINETICS

ENERGY KINETICS Resolute RT Installation instructions

ENERGY KINETICS

ENERGY KINETICS 90+RESOLUTE BOILER User manual

ENERGY KINETICS

ENERGY KINETICS EK3 Frontier Quick start guide

ENERGY KINETICS

ENERGY KINETICS EK1 Frontier User manual

ENERGY KINETICS

ENERGY KINETICS SYSTEM 2000 Ascent Combi Service manual

ENERGY KINETICS

ENERGY KINETICS Ascent Combi Service manual

ENERGY KINETICS

ENERGY KINETICS System 2000 Guide

ENERGY KINETICS

ENERGY KINETICS Ascent Combi Installation instructions

ENERGY KINETICS

ENERGY KINETICS System 2000 Frontier User manual

ENERGY KINETICS

ENERGY KINETICS Resolute Boiler Supplement

ENERGY KINETICS

ENERGY KINETICS Ascent Combi Boilers Guide

ENERGY KINETICS

ENERGY KINETICS EK1 Frontier Service manual

ENERGY KINETICS

ENERGY KINETICS RESOLUTE RT Service manual

ENERGY KINETICS

ENERGY KINETICS SYSTEM 2000 Accel CS Installation instructions

ENERGY KINETICS

ENERGY KINETICS 90+RESOLUTE BOILER Installation instructions

ENERGY KINETICS

ENERGY KINETICS Accel CS User manual

Popular Boiler manuals by other brands

UTICA BOILERS

UTICA BOILERS UB95M-200 Installation, operation & maintenance manual

Lennox

Lennox GWB8-262E-2 installation instructions

Ritek

Ritek UNIVERSAL RG Series operating manual

Atag

Atag Q-Solar Operating instruction

Crown Boiler

Crown Boiler FWZ060 installation instructions

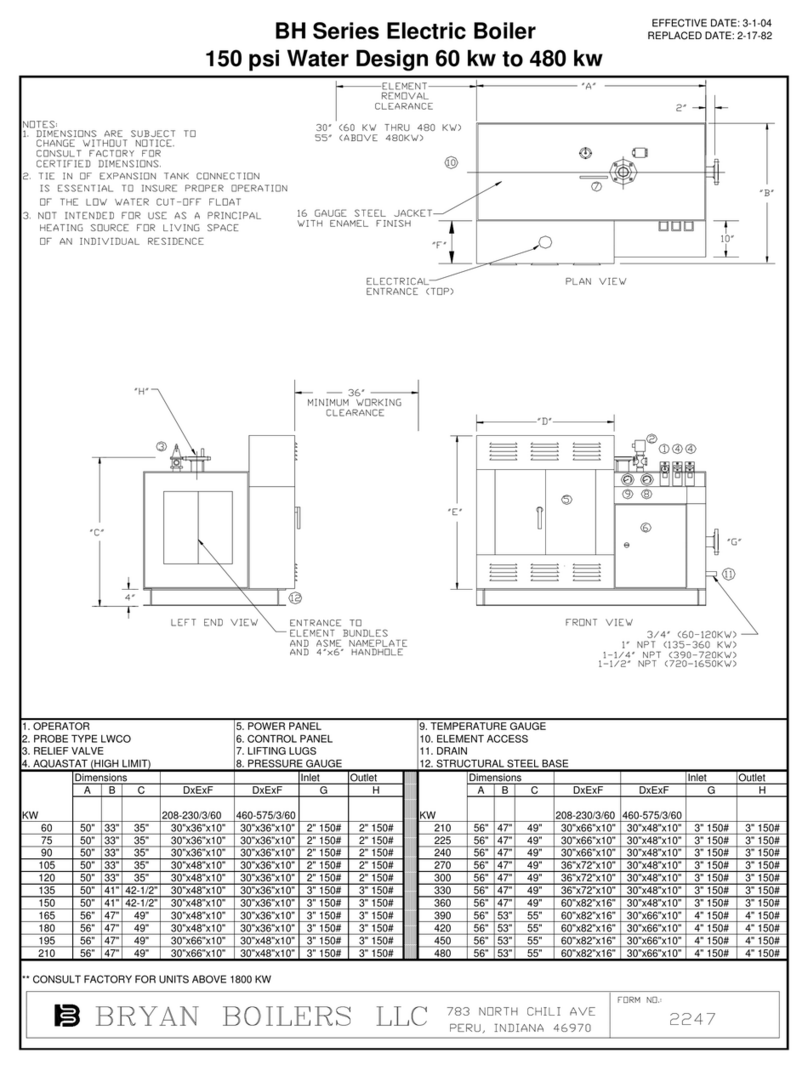

Bryan Boilers

Bryan Boilers BH Series parts list

KERR

KERR Highlander TW-2000 owner's manual

Potterton

Potterton Ultra 2 Installation & service instructions

Sime

Sime ESTELLE HE 3 ErP Original instructions

Immergas

Immergas Hercules Condensing 26 3 ErP Instruction and recommendation booklet

Cecilware

Cecilware CS113 instruction manual

Fondital

Fondital ANTEA Monothermal CTFS 40 Installation - use - maintenance

Alpha

Alpha 47 532 69 Installation and servicing instruction

IDEAL

IDEAL IMAX XTRA EL Installation and servicing

Potterton

Potterton Eden Two Series Maintenance instructions

Sussman

Sussman EW Series Installation, operation & maintenance manual

Potterton

Potterton Profile Installation and servicing instructions

Watts

Watts AERCO KC Series user manual