HeatStar JET20 Assembly instructions

WARNING: Improper installation, adjustment, alteration, service or maintenance can cause

property damage, injury, or death. Read the installation, operating and maintenance instructions

thoroughly before installing or servicing this equipment.

— WHATTODOIFYOUSMELLGAS

• OpenWindows

• DO NOTtrytolightanyappliance.

• DO NOTuseelectricalswitches.

• DO NOTtouchanyelectricalswitch;donotuseanyphoneinyourbuilding.

• Immediatelycallyourlocalgassupplier;followthegassupplier’sinstructions.

(Installationandservicemustbeperformedbyaqualifiedinstaller,serviceagencyorthegassupplier.)

• Ifyoucannotreachyourgassupplier,calltheFireDepartment.

FOR YOUR SAFETY:

-This heater is intended to be used as a gas fired radiant heater for the heating of poultry and swine

confinement buildings. If you are considering using this product for any application other than its

intended use, then please contact Heatstar, Inc

- Donotstoreorusegasolineorotherflammablevaporsandliquidsinthevicinityofthisoranyotherappliance.

WARNING: Iftheinformationintheseinstructionsisnotfollowedexactly,afireorexplosionmayresultcausing

propertydamage,personalinjuryorlossoflife.

18683

Heatstar,IncGroup,Inc.,4560W.160THST.,CLEVELAND,OHIO44135•866-447-2194

OPERATING INSTRUCTIONS

AND OWNER’S MANUAL

READ INSTRUCTIONS CAREFULLY: Read and follow all instructions.

Place instructions in a safe place for future reference. Do not allow any-

one who has not read these instructions to assemble, light, adjust or operate the heater.

Model#

by ENERCO

LANGUAGES INCLUDED

JET SERIES

Poultry & Swine Confinement Buildings

Agricultural Buildings

•ENGLISH

•SPANISH

JET20

JET25

2

Enerco | Heatstar AG Series Heater Operating Instructions and Owner’s Manual

WARNING:

FIRE,BURN,INHALATION,ANDEXPLOSIONHAZARD.

KEEPSOLIDCOMBUSTIBLESSUCHASBUILDING

MATERIALS,PAPERORCARDBOARDASAFEDISTANCE

AWAYFROMTHEHEATERASRECOMMENDEDBYTHE

INSTRUCTIONS.NEVERUSETHEHEATERINSPACES

WHICHDOORMAYCONTAINVOLATILEORAIRBORNE

COMBUSTIBLES,ORPRODUCTSSUCHASGASOLINE,

SOLVENTS,PAINTTHINNER,DUSTPARTICLESOR

UNKNOWNCHEMICALS.

GENERAL HAZARD WARNING:

FAILURETOCOMPLYWITHTHEPRECAUTIONSAND

INSTRUCTIONSPROVIDEDWITHTHISHEATERCAN

RESULTINDEATH,SERIOUSBODILYINJURYAND

PROPERTYLOSSORDAMAGEFROMHAZARDSOF

FIRE,EXPLOSION,BURN,ASPHYXIATION,CARBON

MONOXIDEPOISONING,AND/ORELECTRICALSHOCK.

ONLYPERSONSWHOCANUNDERSTANDAND

FOLLOWTHEINSTRUCTIONSSHOULDUSEORSERVICE

THISHEATER.

IFYOUNEEDASSISTANCEORHEATERINFORMATION

SUCHASANINSTRUCTIONSMANUAL,LABELS,ETC.,

CONTACTTHEMANUFACTURER.

WARNING:

YOURSAFETYISIMPORTANTTOYOUANDTO

OTHERS,SOPLEASEREADTHESEINSTRUCTIONS

BEFOREYOUOPERATETHISHEATER.

CONTENTS

SECTION1INTRODUCTION...................................2

SECTION2PLANNING...........................................3

SECTION3INSTALLATION&ASSEMBLY.................5

SECTION4ENGINEERINGSPECIFICATIONS............9

SECTION5AIRINTAKE/VENTING........................9

SECTION6GASPIPING........................................ 11

SECTION7WIRING.............................................. 11

SECTION8OPERATIONMAINTENANCE............... 13

SECTION9TROUBLESHOOTING........................... 13

ACCESSORYPARTS.............................................. 14

SECTION10REPLACEMENTPARTS....................... 15

WARRANTYINFORMATION.................................20

WARNING:

THIS PRODUCT CAN EXPOSE YOU TO CHEMICALS

INCLUDING LEAD AND LEAD COMPOUNDS,

WHICH ARE KNOWN TO THE STATE OF CALIFORNIA

TO CAUSE CANCER AND BIRTH DEFECTS OR OTHER

REPRODUCTIVE HARM. FOR MORE INFORMATION

VISIT WWW.P65WARNINGS.CA.GOV

SECTION 1:Introduction

JETmodelsarelow-cost,fieldassembledinfraredheatersthatare

easytoinstallandrequireonlyminimalmaintenance.Theyare

designedtoprovideyearsofeconomicaloperationandtrouble-

freeservice.

Checking Shipment

ChecktheshipmentagainsttheBillofLadingforshortages.

Also,checkforexternaldamagetocartons.Noteanyshortages,

and/orexternaldamagetocartonsontheBillofLadingin

thepresenceofthedeliverytrucker.Thedeliverytrucker

shouldacknowledgeanyshortagesordamagebyinitializing

this“noted”BillofLading.Immediatelyreportanyclaimsfor

damagedmaterial,orshortagesthatwerenotevidentatthe

timeofshipment,tothecarrierandyourHeatstar,IncFactory

Representative.

Installer Responsibility

Allheatersandassociatedgaspipingshouldbeinstalledin

accordancewithapplicablespecificationsandthisinstallation

madeonlybyfirms(orindividuals)wellqualifiedinthistypeof

work.Consultlocalbuildinginspectors,FireMarshalsoryour

localHeatstar,IncFactoryRepresentativeforguidance.

JETheatersareinstalledonthebasisofinformationgivenin

alayoutdrawing,whichtogetherwiththecitedcodesand

regulations,comprisethebasicinformationneededtocomplete

theinstallation.Theinstallermustfurnishallneededmaterialthat

isnotfurnishedasstandardequipment,anditishisresponsibility

toseethatsuchmaterials,aswellastheinstallationmethodshe

usesresultinajobthatisworkmanlikeandincompliancewithall

applicablecodes.

Heatstar,IncFactoryRepresentativeshavehadtrainingand

experienceintheapplicationofthisequipmentandcanbecalled

onforsuggestionsaboutinstallationwhichcansavematerialand

cost.

3Operating Instructions and Owner’s ManualEnerco | Heatstar AG Series Heater

SECTION 2: Planning

Thefollowingcodesandinstructionsshouldbefollowedwhen

planningtheinstallationofthisJETheater.Inadditiontothese

instructions,thewarningsmustbecarefullyadheredtosince

improperinstallationmayleadtopropertydamage,injury,or

death.

National Standards and Applicable

Codes

Gas Codes:

•Thetypeofgasappearingonthenameplatemustbethe

typeofgasused.Installationmustcomplywithlocalcodes

andrecommendationsofthelocalgascompany,andthe

NationalFuelGasCode,ANSIZ223.1–latestrevision,(same

asNFPABulletin54)(theNaturalGasandPropaneInstallation

Code,CSAB149.1)Canadaonly.

•Clearancebetweentheheateranditsventandadjacent

combustiblematerial(whichispartofthebuildingorits

contents)shallbemaintainedtoconformwiththeStandard

forInstallationofGasAppliancesandGasPiping,NFPA-54

/ANSIZ223.1–latestrevision,NationalFuelGasCode(the

NaturalGasandPropaneInstallationCode,CSAB149.1)

Canadaonly.

Hazardous Locations:

Wherethereisthepossibilityofexposuretocombustible

airbornematerialorvapor,consultthelocalFireMarshal,

thefireinsurancecarrierorotherauthoritiesforapprovalof

theproposedinstallation.

Critical Considerations

ThisJETmodelisasuspendedheater.Therefore,itsstability,

flexibility,andsafetyareveryimportant.Beforestarting

installation,besurethesystemcanmeetthefollowing

requirements.

•Maintainspecifiedclearancestocombustibles,andsafe

distancefromtheheat-sensitivematerial,equipmentand

workstations.

•Thestatedclearancestocombustiblesrepresentasurface

temperatureof90°F(30°C)aboveroomtemperature.

Buildingmaterialswithlowheattolerance(suchasplastic,

vinylsiding,canvas,etc.)maybesubjecttodegradationat

lowertemperatures.Itistheinstallersresponsibilitytoassure

thatadjacentmaterialsareprotectedfromdegradation.

•Provideaccesstoburnersforservicing,preferableonboth

sides,aboveandbehindtheburnerforremoval.

•Alwaysobserveminimumclearancestocombustibleslocated

onpage4.

•Planlocationsupports(seeFigure2A-Bstartingonpage6).

•Theinstallationmustconformwithlocalbuildingcodesor

intheabsenceoflocalcodes,withtheNationalFuelGas

Code,ANSIZ223.1/NFPA54(theNaturalGasandPropane

InstallationCode,CSAB149.1)Canadaonly.

•Ifanexternalelectricalsourceisutilized,theheater,when

installed,mustbeelectricallygroundedinaccordancewith

theNationalElectricalCode,ANSI/NFPA70orcurrent

CanadianElectricalCode,CSAC22.1.

Installation Procedure

Takemaximumadvantageofthebuildingupperstructure,

beams,joists,purlins,etc.,fromwhichtosuspendtheheater.

Thereisnouniquesequenceforinstallationofthetubing.On-

siteobservationwillusuallyrevealalogicalsequence.Beginthe

installationatthemostcriticaldimension.Reflectorsandtubing

canbeinstalledasyoumovealong.Carefullyadjustsystempitch

ateachpositiontoleveltheheater.Pitchdownone-halfinchin

20feet(awayfromburner).

DON’TPressuretestthegaslineusinghighpressure(greater

than½PSIG)withoutclosingthehigh-pressureshutoff

cocks.Failuretodosowillresultindamagetothe

burners.

DO Familiarizeyourselfwithlocalandnationalcodes.

Developaplannedprocedurewhichwillconserve

materialandlaboronthejob.

Checktoseethatallmaterialandequipmentisonthe

jobbeforestartinginstallation.

Allowforthermalexpansionofthetubes.

Installthegasconnectoronlyasshownininstructions

(seeFigure14&15onpage11).

Useselftappingscrewswherereflectorsoverlapto

assurethattheydon'tcomeapart.

Attachreflectorretentionwiretoburnerboxorchain

suspendingburnerbox.Thewirecomesattachedtoone

ofthereflectors.Seeintructionsintubesetfordetails.

Provide1sq.inchoffreeairopeningtoeach1,000BTU/

hr.ofheaterinput(butnotlessthan100sq.inches)in

enclosedspaces.Oneopeningshouldbewithin12inches

ofthetopandonewithin12inchesofthebottomofthe

enclosure.

4

Enerco | Heatstar AG Series Heater Operating Instructions and Owner’s Manual

Clearances To Combustibles

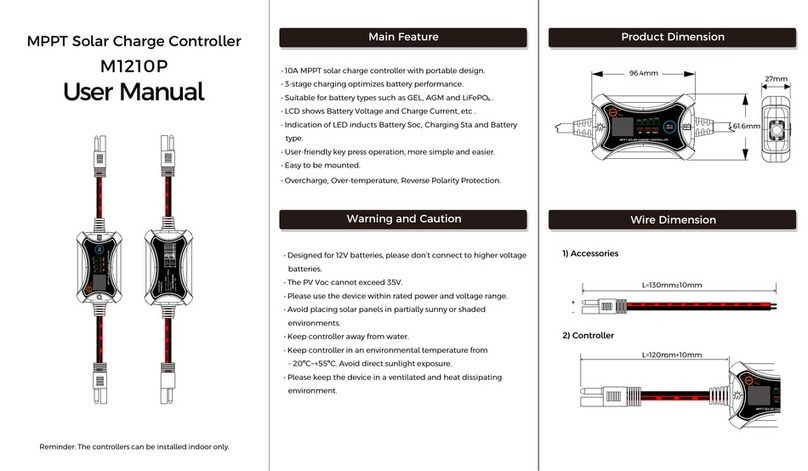

Figure 1: (RefertoTABLE1)

STANDARD REFLECTOR

D

A

C

E

B

TO VENT CAP

TO BACK OF HEATER

WARNING:

FIRE OR EXPLOSION HAZARD

CAN CAUSE PROPERTY DAMAGE, SEVERE INJURY OR DEATH.

Inallsituations,clearancestocombustiblesmustbemaintained.Failuretoobserveclearancestocombustiblesmayresultinproperty

damage,severeinjury,ordeath.

Cautionshouldbeusedwhenrunningthesystemnearcombustiblematerialssuchaswood,paper,rubber,etc.Considerationshouldbe

giventopartitions,storageracks,hoists,buildingconstruction,etc.

TABLE1givesminimumacceptableclearancestocombustibles.

Clearances To Combustibles

TABLE 1:MinimumClearancestoCombustibles(UseFigure1asGuide)

ReflectorType Position HSJET20 HSJET25

Standard

Reflector

(Horizontal)

A12 " 12 "

B36" 36"

C55" 74 "

D36" 36"

E72" 72"

5Operating Instructions and Owner’s ManualEnerco | Heatstar AG Series Heater

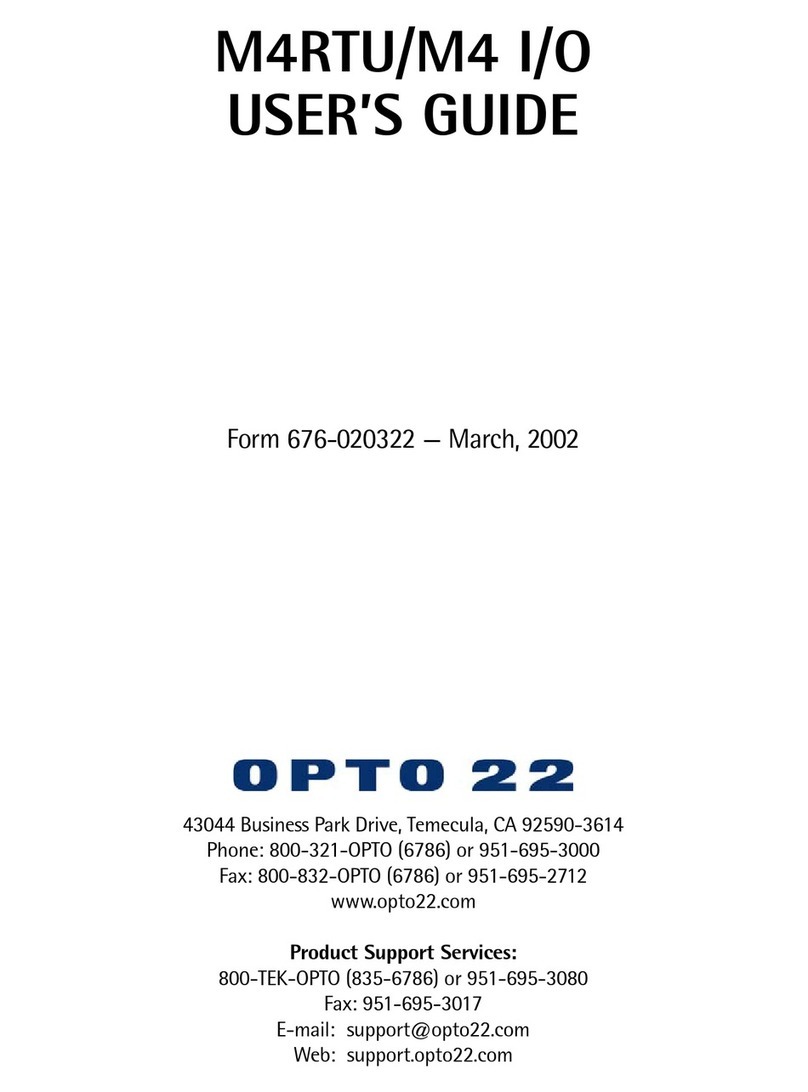

SECTION 3: Installation & Assembly

TUBECOUPLING(14612)

*USEDONJET25*

KEYFORTUBECOUPLING

(14616)*USEDONJET25*

TUBEHANGER

-3"Tube=14572

-3.5"Tube=14573

-4"Tube=14585P

JET20

•10'-3"ODAluminized(06454)

•10'-3.5ODSteel(06457)

JET20-TURBULATORBAFFLE7'(03444)

JET25-TURBULATORBAFFLE10'(03445)

REFLECTOR

-5'=00417A*JET25ONLY*

-10'=00418A

-10'w/Wire=00422

BURNERBOX

JET25

•10'-3.5"ODAluminized(06455)

•10'-4"ODSteel(06456)

•5'-4"ODSteel(06453)*NOFLANGE*

HEATEXCHANGERTUBE

VENTCAP(19041)

VENTADAPTER(14582)

6

Enerco | Heatstar AG Series Heater Operating Instructions and Owner’s Manual

Assembly Overview

20 ft. Exchanger length. 21 ft. - 4 in. Total Heater length. Six suspension points as indicated.

HANGER HANGER HANGER HANGER

10’ 2-1/2”

Reflector

HRS TUBE 3.5”

2-1/2”

OVERLAY TYP

(1) 7’ Turbulator Section

Located at the End of Tube Set

ALUMINIZED TUBE 3” Vent CapFlange

10’ 2-1/2”

Reflector

Arrow Indicates Suspension Point

Assembly Overview

25 ft. Exchanger length. 26 ft. - 4 in. Total Heater length. Seven suspension points as indicated

10’ 2-1/2”

Reflector

(1) 10’ Turbulator Section

Located at End of Tube

HANGER HANGER HANGER HANGER

ALUMINIZED TUBE 3.5” HRS TUBE 4”

Flange

HRS TUBE 4”

HANGER

Vent Cap

Coupler

10’ 2-1/2”

Reflector

5’ 2”

Reflector

Arrow Indicates Suspension Point

Burner Housing

Mustalwaysbe

installedhorizontally.

Turbulator Assembly

HeatstarAGJetheatersshipwithturbulatorslooseinbox.Turbulatoristo

beplacedintoendoftubeaftertubeassembly.

Reflectors

Alternateoverlapasshownon

overview.Lengthofreflector

andamountofoverlapis

indicated.Reflectorwith

retentionwiretobeused

closesttoburnerbox.See

instructionsincludedwith

tubeset

10'2-1/2"

Tube Coupling Assembly

Couplingshouldbeorientedwith

slidebarontop.

(OnlyusedonJET25)

AssembletheheatercomponentsasshowninFigures2A,2B.Installappropriatedsuspensionhardware,beamclamps,chainorrodat

predeterminedlocations.Adjustmentofchainlengthwillprovideuniformpitch.

Tube and Reflector Hanger

2hangersrequiredforeachtube,

differentsizedhangersfordifferent

sizedtubes.

ALUMINIZED(ONLYfirst10ft.)andHOTROLLEDSTEEL

Heat Exchanger Tubes

Suppliedin10ft.lengths(5'includedwithJet25)

Whenhangingthetubesyouwillnoticeaweldseamdown

thelengthofthetube.Whenassemblythetubestogetherisis

importanttonothavethisweldseamfacedirectlyupordown,this

willincreasethelongevityofyourheatexchangers.

Figure 2: Heatstar JET Parts Overview

*JET25ONLY*

Figure 2A JET20

Figure 2B JET25

7Operating Instructions and Owner’s ManualEnerco | Heatstar AG Series Heater

FIGURE 4: 4" Tube Sleeve Connection (JET25 Only)

The2ndsteeltubeandtheadditional5'tubesectionareconnected

byawrap-aroundcouplingwhichclampsbymeansofatapered,

hammer-drivenlockmember.Thestartingendsofthecouplingand

lockmemberareidentifiedby1/4”holeswhichareputtogether

whenstartingassembly.Besurethetubeendsareinlineandtube

endsbuttagainststoppin(s)insidecoupling.Theslidebaristobe

hammer-driventoapointofsecuringthecouplingfirmlytothe

tubes.Over-drivingwillresultindistortionofthecouplingorslidebar

liptoapointdecreasingtheholdingthecapabilityofthecoupling.

FLANGE - COUPLING - REFLECTOR ASSEMBLY DETAILS

Plain Coupling - 14612

Key for Coupling - 14616

Tighten

Loosen

Hole 1

Coupling

Assembly

Impact

Block

Hole 2

Whenassemblingcouplingnote

thelocationofHole1andHole2

Orientcouplingsothat

theimpactblockisabove

tubecenterline.

TUBECOUPLING

KEYforCOUPLING

FIGURE 3: Tube Flange Connection

Alignthegasketboltholesbetweenthealuminizedtube

flangeholesandthesteeltubeflangeboltholes.The

aluminizedtubewillslideintothesteeltube,oncethe

flangesandgasketarealignedusethe4boltsandtighten

togetherwiththeattached4nuts.Asnotedabove,theweld

seamsonthetubeshouldnotbefacingdirectlyupordown.

Chainkit-Stk.#17362

Onechainkitwillsuspendone10ft.sectionoftubeandone10ft.

sectionofreflector.

FIGURE 7: Typical Suspension Details

Locknut

Washer

WoodBeam

Washer

ScrewHook

min.3/8"(10mm)

I-Beam

Beam

Clamp

AsReq'd

S-Hook

BarJoist

Clip

Truss

Concrete

Beam

Anchor

horizontal reflector position (standard)

radiant tube

horizontal

hanger

reflector

top

side

below

FIGURE 6: Tube and Reflector Hanger

BesuretonotethateachJetheaterusestwodifferentsizehangers

forthedifferentsizedtubes.Forabalancedreflector,makesurethe

45°looppointedoutintheaboveimageisonthesamesideforall

thereflectors.

FIGURE 5: Reflector End Cap Installation

Thereflectorendcapshouldbeattachedtothereflectorateachend

ofthetubesystemusingtheselftappingscrewsprovidedasshown

intheimagebelow.

8

Enerco | Heatstar AG Series Heater Operating Instructions and Owner’s Manual

VENTCAPREDUCERTUBE EXHAUSTCLAMP

VENT CAP & TUBE CLAMP INSTALLATION

FIGURE 9

CLAMP ASSEMBLY(ShowninFIGURE10)

1.Makesuretohaveallhardwarepartsforassembly:

(1Base,2SupportBracket,2Bolts(9/16")and2nuts)

2.NOTE:ThecurvedsideoftheBaseshouldbefacingupandflat

sideisonthebottom.

3.AligntheSupportBracketsothecurvedsideisfacinginwardstoward

theclampwiththeholeopeningthenslidethe(9/16")Boltthrough

toattachtheotherSupportBracket,usethenuttotighten.Repeatfor

otherboltandnut.

ATTACH TUBE TO BURNER BOX(ShowninFIGURE11)

1.SlideTubeoveruntilflushwithburnerboxflange.NOTE

assembledclampshouldbelooselyfittingonburnerboxflange.

2.AligntheClampsoeachboltandnutareoneithersideofthe

seaminwhichthetubeandburnerboxflangemeet.

3.TightentheClampusinga9/16"wrench.

FIGURE 10

FIGURE 11

BASE

SUPPORTBRACKET

9/16BOLTS

CLAMP

SUPPORTBRACKET

NUTS

CLAMP

TUBE

JET20 Vent Cap Installation(ShowninFIGURE9)

1.Ventcapreducerslidesover3.5"tube.

2.Exhaustclampusedtocoverhalfoftubeandhalfofventreducer.

3.Exhaustclampfastenedtightwith9/16"wrench.

JET25 Vent Cap Installation

1.Ventcapbuttsupagainst4"tube.

2.Ventadapterusedtocoverhalfoftubeandhalfof4"ventcap.

3.VentadapterfastenedwithPhillipsscrewdriver.

9Operating Instructions and Owner’s ManualEnerco | Heatstar AG Series Heater

SECTION 4

Engineering Specifications

A. Burner & Burner Controls

1.Burnersshallbecapableoffiringwithoneofthefueloptionsas

specifiedontheratingtag:NaturalGasorLP.

2.Burnersshallbesuppliedtofireatanyoneoftheinputratesas

specified.

JET20 80,000BTU/Hr.

JET25 100,000BTU/Hr.

3.Burnershallbeequippedwithadirectsparkignitioncontrol

systemwith100%shut-offignitiondevice.Powersuppliedtoeach

heatershallbe120V,60Hz,singlephase.Burnersshallberatedfor

1.0Amp(run)and5.0Amp(start.)

4.Burnershallbeequippedwiththermaloverloadmotorprotection

andacombustionairprovingsafetypressureswitch.

5.Whenspecified,incontaminatedenvironments,theburner

shallbecapableofsupplyingoutsideairtoeachburnerforthe

supportofcombustion.

6.Allburnersshallbepre-wiredwithagroundedelectrical

cordandplug.

7.Atcustomer’schoice,burnersmaybecontrolledwitheither

anoptionallinevoltagethermostatorbyoptionallowvoltage

thermostatswithanappropriatelowvoltagetransformerrelay.

8.Gassupplytotheburnersshallconformtothefollowing:

Gas pressure at MANIFOLD:

Natural Gas: 3.5” W.C.

LP Gas: 10.5” W.C.

1/2”NPTGasConnectorSize

Gas INLET pressure:

Natural Gas: 4.6” W.C. Min

14.0” W.C. Max

LP Gas: 11.0” W.C. Min

14.0” W.C. Max

1/2”NPTGasConnectorSize

B. Heat Exchanger

1.Radianttubingshallbe:

-JET20shippedwith3"diameteraluminizedsteeltubeand3.5”

diameterhotrolledsteeltube.

-JET25shippedwith3.5"diameteraluminizedsteeltubeand4”

diameterhotrolledsteeltube.

2.Reflectortobeofaluminummaterialanddesignedtodirectall

radiantoutputbelowhorizontalcenterlineofradianttube.

Electrical Rating:(AllModels)

120V-60Hz

1.0AMP(Run)5.0AMP(Start)

Dimensions:

Flue Connection Size…………………3.5"(JET20) or 4”(JET25)

Outside Air Connection Size………4”

SECTION 5

AIR INTAKE / VENTING

WARNING

Failuretoprovideafreshairinletinpoultryfarmscanleadto:

-Sootingcausingdamage

-Highcarbonmonoxidelevels,causingseriousinjuryordeathto

livestockandhumans

-Highertemperaturedifferencesoverthelengthofthetubes,

causingproblemsintemperaturecontrolandbirdperformance.

Outside Combustion Air Supply

TheHeatstarAGheaterisapprovedforinstallationwithanoutside

airsupplysystemthatrequiresfreshairatnormalatmospheric

pressure.Somecompoundssuchashalogenatedhydrocarbonsor

othercorrosivechemicalsintheaircanbedrawnintotheequipment

andcauseanacceleratedrateofcorrosionofsomeoftheheater

components.Theuseofsuchchemicalcompoundsnearthe

enclosureshouldbeavoided.

Itisrecommendedthatinletairbedrawninfromtheatticbutyou

mayalsodrawinletairfromthesidewallforhouseswithoutanattic

(Seefigures13Aand13B). Airinletterminationsshallnotbeaffected

bybuildingventilationfans.Airintakekit,F111756,isavailablefor

purchasetocompletetheinstallationwhendrawingairthroughthe

attic.Whendrawingairthroughthesidewallsupplieswillhavetobe

obtainedthroughanoutsidesource.

IMPORTANT:

•DO NOT draw inlet air from inside the poultry confinement

area.

•If the attic has a slight negative pressure or contaminants

are present in the air, an outside combustion air supply to the

heaters is strongly recommended.

•The pressure switch will not close causing the heater not to

operate if the intake is blocked by insulation in the attic. We

recommend double checking that the intake isn't blocked after

initial installation as well as in betweeen flocks when it is

known that the attic has blown in and loose insulation.

•Always attach your air inlet system to the burner box with

a flexible section. This piece should be free of kinks and as

straight as possible, no more than one 90° bend.

Ventilation

Ventilationequalto4CFMper1,000BTU/HRfiringratemustbe

providedinunventedheaterinstallations.

10

Enerco | Heatstar AG Series Heater Operating Instructions and Owner’s Manual

CEILING

Burner Box

Rear View

12” (31 cm) MIN. FROM

INSIDE OF ROOF

INLET TUBE MUST BE 12” (31cm)

MIN. ABOVE INSULATION

Cut 4 1/4” in./10.8 cm

hole in through support board

and ceiling adjacent to joist.

Spread insulation away and

fasten cieling flange to board/joist.

RO

O

F

MAKE SURE INLET CAP IS NOT

BLOCKED BY INSULATION

Flex tube section used to

attach burner box to hard

pipe going through ceiling.

Cut to necessary length to

avoid sagging or kinks.

Hard pipe, flange, flex pipe

and two clamps all included

in Air Intake Kit, F111756.

SUPPORT BOARD

FLANGE

FIGURE 13A: Drawing Inlet Air From Attic

FIGURE 13B: Drawing Inlet Air From Side Wall

Burner Box

Back View

4” ID PVC

Always use a section of 4” ex to connect the burner box

to the PVC/Sewer pipe used to go through the sidewall.

Keep this section at a minimal length and free from kinks.

DO NOT connect hard rigid pipe directly to burner box.

For horizontal runs longer than 25’ it

is recomended to use 6”ID PVC in order

to ensure adequate supply air to heater.

Provide adequate weight-bearing

supports to hang the hard pipe from

the ceiling.

11 Operating Instructions and Owner’s ManualEnerco | Heatstar AG Series Heater

FIGURE 15: Gas Line Connection with Stainless Steel Flex Gas

Connector

Nipple

Shuto Valve

Nipple

Tee

Nipple

Cap

Burner Box

Stainless Steel Flex Gas Connector

Nipple

2”

12”

Included in Install Kit

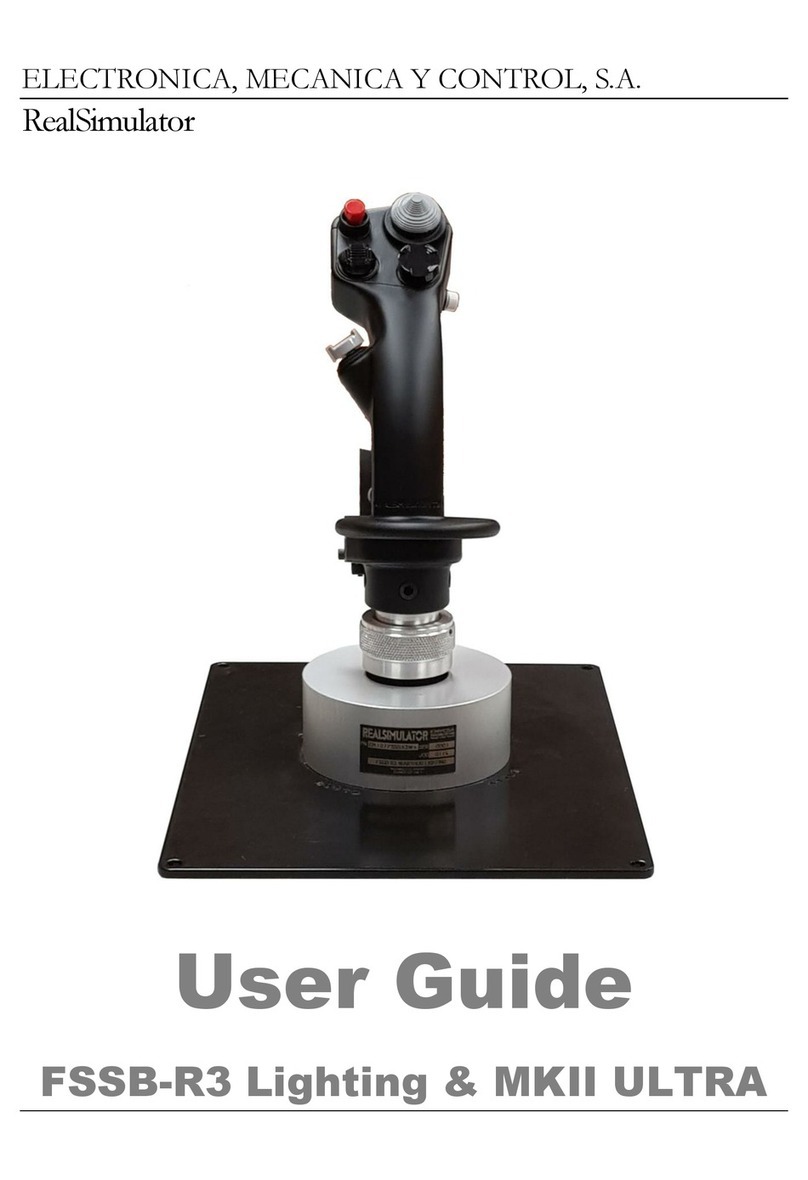

SECTION 7 - WIRING

Heatersarenormallycontrolledbythermostats.Linevoltagethermostatsarewireddirectly(seeFigure16),24Vthermostatsarewireddirectlyusing

theterminalsonburnerbox(seeFigure18).HeatersmustbegroundedinaccordancewiththeNationalElectricCodeANSI/NFPA-70orcurrent

CanadianElectricalCode,CSAC22.1.Heatersmayalsobecontrolledwithamanuallinevoltageswitchortimerswitchinplaceofthethermostat.

T

H

N

120v – 60 Hz

White

White

Green

Green

Supply Circuit

120v – 60 Hz

Supply Circuit

Burners

(Maximum – 2 per Thermostat)

Burners

(Maximum – 1 per Thermostat)

Black

Black

H

N

T

T

H

N

120v – 60 Hz

White

White

Green

Green

Supply Circuit

120v – 60 Hz

Supply Circuit

Burners

(Maximum – 2 per Thermostat)

Burners

(Maximum – 1 per Thermostat)

Black

Black

H

N

T

FIGURE 16: Line Voltage Thermostat Wiring FIGURE 17: Low Voltage Thermostat Wiring

SECTION 6 - GAS PIPING

Readapplicablewarningsonpage1&2beforeproceedingwithGasPipeinstallation.Improperinstallationmayresultinpropertydamage,

severeinjury,ordeath.

Meterandservicemustbelargeenoughtohandlealltheburnersbeinginstalledplusanyotherconnectedload.Thegaslinewhichfeedsthe

systemmustbelargeenoughtosupplytherequiredgaswithamaximumpressuredropof1/2”watercolumn.Localgassupplierwillusually

helpinplanningthecorrectgaspipingsize.

A1/2”pipeateachburnerlocationmustbelocatedandorientedasshownin(Figure14).Tochecksystempressure,putaplugged1/8”NPTtapinthe

gaslineattheconnectiontotheburnerfarthestfromthesupply.Beforeconnectingtheburnerstothesupplysystem,verifythatallhighpressuretesting

ofthegaspipinghasbeencompleted.Donothighpressuretestthegaspipingwiththeburnersconnected.

Followtheseinstructionstoensureaprofessionalgassupplyinstallation:

• Supportallgaspipingwithsuitablepipehangingmaterials.

• Usewroughtironorwroughtsteelpipeandmalleableironfitting.Allpipefittingsshouldbenewandfreefromdefects.

• UseL.P.gas-resistantjointcompoundonallpipethreads.

• Checkthepipeandtubingendsforleaksbeforeplacingheatingequipmentintoservice.Whencheckingforgasleaks,usesoap

andwatersolution:NEVER USE AN OPEN FLAME.

Installtheflexgasconnectorasshown.Theflexgasconnectoraccommodatesexpansionoftheheatingsystemandallowsforeasyinstallation

andserviceoftheburner.Theshut-offvalvemustbeparalleltoburnergasinlet.The2"displacementshownisforthecoldcondition.This

displacementmayreducewhenthesystemisfired.

Heater Movement

Heater Movement

Heater Movement

Heater Movement

FIGURE 14: Incorrect Gas Line Connection with Stainless Steel

Flex Gas Connector

• NOTE: Jet heaters come with the thermostat connection jumped out with a piggyback connector inside the burner box to pro-

vide a constant call for heat. If the themostat junction needs utilized, you will need to open up the box and attach these wires

to the bushing on the back of the burner box.

12

Enerco | Heatstar AG Series Heater Operating Instructions and Owner’s Manual

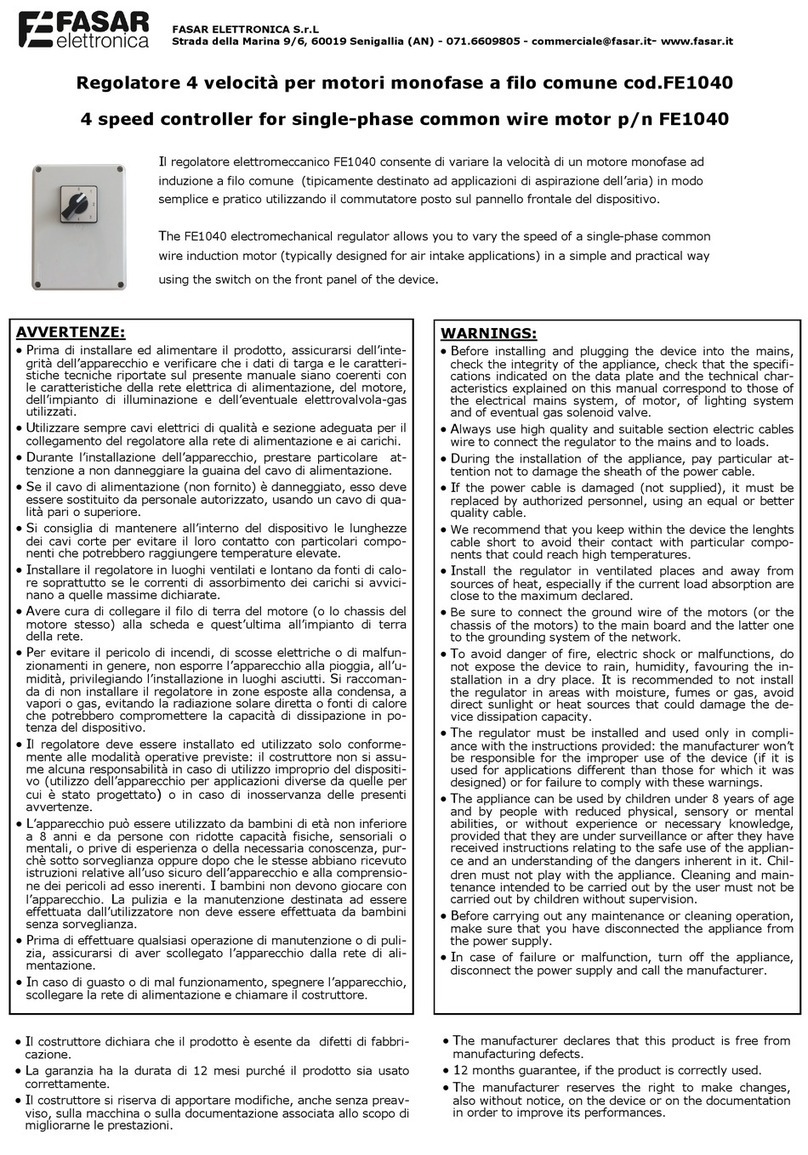

LADDER DIAGRAM

SECONDARY - 24V

T1

PRIMARY - 120V

L1

N

PCB

PCB

L1

IND

M

120V

LED

PCB

IGN

IGNITER/FLAME SENSOR

BURNER

PCB

PSW

PCB

TH

T'STAT (Optional)

JUMPER (Optional)

24 VAC

PCB

PRESSURE SWITCH

GV

PCBPCB

V1 V2

GND

Earth &

Chassis Ground

24V

LED

V2

GND

24 VAC

L1

IND

NC

V1

PSW

TH

IGN

FC-

FC+

LED

L1

T1

Primary

Secondary

120V

LED

M

24V

LED

GAS VALVE

N

Earth Ground

Pressure Switch

To Thermostat

(Optional)

W

24V

BURNER

IGNITER / FLAME SENSOR

CONTROL BOARD

Chassis Wiring Is 18 AWG / 105 Degrees C / @ 600 Volts

Igniter Wire Is 16 AWG / 25 KVDC / 10 KVDC

Crimp Caps Are # CE5 / 105 Degrees C

Replace Any Wiring With Same Ratings

All Quick Connects Are Fully Insulated (Except Igniter)

WHITE WHITE

WHITE

WHITE

GREEN

GREEN

GREEN

GREEN

GREEN

GREEN

BLACK

BLACK BLACK

BLACK

YELLOW

RED

BLUE

BLACK

GREEN

RED

BLACK

YELLOW

YELLOW

ORANGE

RED

RED

CONNECTION DIAGRAM

Earth &

Chassis Ground

FIGURE 18: Heatstar JET SERIES Burner Internal Wiring

• Ifanyoftheoriginalwireassuppliedwiththeappliancemustbereplaced,itmustbereplacewithwiringmaterialhavingatemperature

ratingofatleast105°Cand600volts.

• Eachburnermustbeelectricallygroundedinaccordancewiththe

NationalElectricCodeANSI/NFPA-70orcurrentCanadianElectrical-

Code,CSAC22.1.

13 Operating Instructions and Owner’s ManualEnerco | Heatstar AG Series Heater

WHAT TO DO IF:

Blower Motor 1.Isthethermostatcallingforheat?Isthere

Fails to Run: 120Vatthemotorterminals?

2.Checkblowerforobstructions.Replace

blowerifnecessary.

1.Checkigniterfordamageorexcesscarbon.

Replaceifnecessary.

2.Checkforobstructionstotheairinletand

outlet.

3.Checkwiringandhoseconnectionstothe

airswitch.Replaceifnecessary.

4.Checkvoltagesattransformerprimaryand

secondary.Replacetransformerormoduleif

necessary.

Valve Does Not Gaspressuredownstreamofgascontrolcan

Open: bemeasuredbyusingamanometerand

connectingtopressuretaponvalve.

1.ChecktoseeifgasvalveswitchheaterisON.

2.Supplygaspressurecanbecheckedat1/8”

NPTpressuretaponheaterexternalmanual

valve.

3.Checktoseeifgascontrolisopening:no

manifoldpressureindicatesvalveisclosed.

Ifthevalveisclosed,eitherthegasvalveorthe

ignitionmoduleisfaulty.

WARNING:Donotdisconnectgroundleads

insideheater.Donotinterchangegrounded

andungroundedleadsontransformeror

ignitionmodule.

SECTION 8

Operation & Maintenance

Sequence of Operation

1. Turnthethermostatup.Whenthethermostatcallsforheat,

blowermotorwillenergize.

2. WhenthemotorapproachesnominalrunningRPM,theair

provingswitchclosesandactivatestheignitionmodule.

3. Oncetheignitersparks,thegasvalveisenergized.

4. Ifaflameisdetected,thegasvalveremainsopen.Whenthecallfor

heatissatisfied,andthesystemcontrolmechanismde-energizesthe

burnerlinevoltagesupply,thegasvalvesareturnedoff.

5. Ifnoflameisdetected,thegasvalveisclosed,andapurge

periodbegins.Afterthepurge,themoduleactstopowerthe

igniterforasecondwarm-upperiod,andasecondtrialfor

ignitionperiod.Ifflameisstillnotestablished,athirdandfinal

purge,warm-up,andtrialcyclebegins.Afterthreetrials,the

modulewilllockoutuntilreset.Resetisaccomplishedbyremoving

powerfromthemoduleforatleastfive(5)seconds(thermostat

cyclerequired.)

6. Ifflameisestablishedandlostonthefirstorsecondtrial,the

gasvalveisturnedoff,apurge,warm-up,andtrialforignition

willoccuronathree-trialmodule,onlythreetrialsforignition

areallowedperthermostatcycle.

Maintenance

Forbestperformance,thefollowingmaintenanceproceduresshould

beperformedbeforeeachheatingseason:

1. Besuregasandelectricalsupplytoheaterareoffbefore

performinganyserviceormaintenance.

2. Checkconditionofblowerscrollandmotor.Dirtanddustmay

beblownoutwithcompressedair,oravacuumcleanermay

beused.Whenusingcompressedairdonotexceed30psi.

3. Checkconditionofburner.Carefullyremoveanydustor

debrisfrominsidetheburnerboxandthefaceoftheburner

venturi.

4. Inspecttheigniter.Replaceigniterifthereisexcessivecarbon

residue,erosion,breakageorotherdefects.

5. Checktheinsideofthefiringtubewithaflashlight.Ifcarbon

orscalearepresent,scrapeoutthedepositswithawire

brushorrod,ormetalplateattachedtoawoodenpole.

•Tubesandreflectorscanbepowerwashedbut*DO NOT*

powerwashtheburnerbox.

6. Checktheventcapforsootordirt.Aftercleaningas

necessary,re-attachtheflapperorventcaptotheheater.

7. Checktheairintakesystem,besurethatthetopisnot

blockedintheattic.Also,emptycontentsofairintake

systemwhetheryour'reusingtraporflexpipetotheattic.

8. Checktomakesurethe4boltsconnectingthetubesto

eachotheraretight,re-tightenifneeded.

9. Checkthatthefirstreflectorstillhasthesteelretentionwire

connectedtotheburnerbox.

10. Checkventcapandfreshairinlettoseethattheyhavenotbeen

blockedduringthenon-heatingseason.Ifeitherpipeisrestricted,the

airswitchwon’tclose,resultinginano-heatsituation.

Aqualifiedserviceagencyshouldbecontactedforservice

otherthanroutinemaintenance.

SECTION 9

Troubleshooting

WARNING

•Donotattempttoservicethisheaterunlessyouhavebeen

properlytrained.

•Troubleshootingthissystemmayrequireoperatingtheunit

withlinevoltagepresentandgason.Useextremecautionwhen

workingonthisheater.

•Failuretofollowthiswarningmayresultinpropertydamage,

personalinjuryordeath.

Theaccessdoormaybeopenwhentroubleshootingbyopening

thetwolatcheslocatedontopoftheunit.Withtheaccessdoor

openyouwillhaveaccesstothepressureswitch,ignitionmodule,

transformer,andgasvalve.Ifyouneedtoaccesstheburner,igniter,

ormotoryouwillneedtotakeoffthecoverbyunscrewingthe

phillipsheadscrews.

CAUTION:

BeforeopeningtheJetcoverforanytypeofservicebesurethegas

supplyhasbeenshutoffattheheaterandtheelectricalcordfrom

theburnerboxhasbeenunplugged.

14

Enerco | Heatstar AG Series Heater Operating Instructions and Owner’s Manual

DIAGNOSTIC

LED

DIANGNOSTICINDICATORFLASHES:

TheLEDwillflashonfor1/4second,thenofffor1/4secondduring

afaultcondition.Thepausebetweenfaultcodesis3seconds.

SteadyON ControlFault

(1)FLASHES-AirFlowFault

(2)FLASHES-Flamenocallforheat

(3)FLASHES-Ignitionlockout

STEADYON:

InternalcontrolFailure.

AIRFLOWFAULT:

Combustionairflowiscontinuallymonitoredduringanignition

sequencebytheairflowswitch(PSW).Ifduringtheinitialcallfor

heatthepressurecontactsareintheclosedpositionfor30seconds

withoutanoutputtotheCombustionBlower,anairflowfault

willbedeclaredandthecontrolwillremaininthismodewiththe

combustionbloweroff.

FLAMEFAULT:

Ifatanytimethemainvalvefailstoclosecompletelyandmaintains

aflame,thefulltimeflamesensecircuitwilldetectitandenergize

thecombustionblower.Shouldthemainvalvelaterclose

completelyremovingtheflamesignal,thecombustionblowerwill

powerofffollowingtheoptionalpostpurgeperiod.

IGNITIONLOCKOUT:

Shouldthemainburnerfailtolight,orflameisnotdetectedduring

thetrialforignitionperiod,thecontrolwillgointolockout.The

valvewillbeturnedoffimmediately,andthecombustionblowerwill

beturnedofffollowingtheoptionalpostpurgeperiod.

ACCESSORY PARTS

STOCKNUMBERDESCRIPTION:

10371....................................Thermostat24volt

10392...................................Thermostat110Volt

17362...................................ChainKit

F111756……………………………AirIntakeKit(Flextube)

AirIntakeKitincludes:

Mini-ventcap,verticalsupportpipe,flexventandtwo-4"

wormgearclamps

CONVERSION KITS

Model STOCK

NUMBER DESCRIPTION STOCK

NUMBER DESCRIPTION

JET20 117 7 3 LPTONG 117 7 2 NGTOLP

JET25 117 7 5 LPTONG 117 74 NGTOLP

FIGURE 19

Burner Does Not1.Checktoseeifgaslineswereproperly

Light: purgedofair.

2.Checkinletandoutletgaspressureduring

ignitionperiod.

•Naturalinletpressureshouldbe4.6”

•Naturalmanifoldpressureshouldbe3.5”

•LPinletpressureshouldbe11.0”

•LPmanifoldpressureshouldbe10.5”

3.Checkforproperorifice.

Burner Does Not 1.Checkgroundwirecontinuity.

Stay Lit: 2.Checkburnerinternalwiringforreversed

leads.

3.Checkinsulationontheigniterleads.

4.Replacemoduleifnecessary.

15 Operating Instructions and Owner’s ManualEnerco | Heatstar AG Series Heater

Parts List for JET Tube Heaters

Item Stock # Description QTY

1F102090 JET25BurnerBox-NG 1

F102095 JET25BurnerBox-LP

202976 3.5"TubeCoupler 1

306455 3.5"AluminizedTubew/Flange 1

412396 TubeFlangeGasket 1

598 014 3/8"-16Bolts 4

606456 4"HRSTubew/Flange 1

714 612 4"TubeConnectionCoupler 1

814 616 4"TubeCouplerKey 1

9 06453 5'Long4"HRSTube 1

Item Stock # Description QTY

1F102080 JET20BurnerBox-NG 1

F102085 JET20BurnerBox-LP

202975 3"TubeCoupler 1

306454 3"AluminizedTube 1

412394 TubeFlangeGasket 1

598 014 3/8"-16Bolts 4

606457 3.5"HotRolledSteelTube 1

702976 3.5"TubeCoupler 1

8145 82 3.5"-4."VentCapReducer 1

Item Stock # Description QTY

10 19021 4"VentAdapter 1

11 19 0 41 4"VentCap 1

12 0 0 419 ReflectorEndCaps 2

13 00422 10'ReflectorwithSteelWire 1

14 00418A Standard10'Reflector 1

15 0 0 417 A Standard5'Reflector 1

16 14585P 4"TubeHanger 3

17 14573 3.5"TubeHanger 2

18 19 012 SteelReflectorRetentionWire

(Includedwithitem13)

1

19 03345 10'Turbulator(Insideendof

tube)

1

JET25

JET20

Item Stock # Description QTY

919 0 41 4"VentCap 1

10 00422 10'ReflectorwithSteelWire 1

11 00418A Standard10'Reflector 1

12 0 0 419 ReflectorEndCaps 2

13 19 012 SteelReflectorRetentionWire

(Includedwithitem10)

1

14 14572 3"TubeHangers 2

15 14573 3.5"TubeHangers 2

16 03444 7'Turbulator(Insideendof

tube)

1

1

3

6

4

5

2

7

8

9

10

11

12

13

14

15

12

16

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

12

16

17

18

18

16

Enerco | Heatstar AG Series Heater Operating Instructions and Owner’s Manual

ITEM# EGI# DESCRIPTION QTY

102999 ENCLOSURE,AG,TUBE,BOXBURNER 1

202963 COVER,AG,TUBE,BOXBURNER 1

300055 GASVALVENG 1

4 00056 GASVALVELP 1

507376 MOTOR 1

602968 VENTADAPTER 1

702964 POWERCORD 1

860889 POWERCORDSTRAINRELIEF 1

902721 THERMOSTATBUSHING 1

10 08364A TRANSFORMER 1

11 02970 IGNITIONMODULE 1

12 02973 BURNERASSEMBLY 1

13 60729 IGNITER/FLAMESENSORELECTRODE 1

14A 02969 JET25PRESSURESWITCH

1

14B 02979 JET20PRESSURESWITCH

15 12397 TUBEFLANGEGASKET 1

ITEM# EGI# DESCRIPTION QTY

16A 02967 JET253.5"TUBEFLANGE

1

16B 02966 JET203"TUBEFLANGE

17 02720 ORIFICEHOLDERFITTING 1

18A 05712 JET25NGORIFICE

1

18B 05718 JET20NGORIFICE

19A 05733 JET25LPORIFICE

19B 05737 JET20LPORIFICE

20 9 8 012 BOLT5/16"-18x1" 4

21 98902 SCREW#8-32x3/8" 10

22 98907 SCREW#8-32x1" 2

23 989 01 SCREW#8-32x1/4" 4

24 98692 NUT#8-32 9

NS 60845 120V"POWERON"LEDLIGHT 1

NS 60846 24V"GASVALVEON"LEDLIGHT 1

NS 02987 PRESSURESWITCHTUBE-LONG10" 1

NS 02933 PRESSURESWITCHTUBE-SHORT5" 1

JET 20/25 PARTS LIST

17 Operating Instructions and Owner’s ManualEnerco | Heatstar AG Series Heater

WARNING:

USEONLYMANUFACTURER’SREPLACEMENTPARTS.USEOFANYOTHERPARTS

COULDCAUSEINJURYORDEATH.REPLACEMENTPARTSAREONLYAVAILABLE

DIRECTFROMTHEFACTORYANDMUSTBEINSTALLEDBYAQUALIFIEDSERVICE

AGENCY.

FOR INFORMATION REGARDING SERVICE OR PARTS:

Contactyourlocalheatingservicetechnicianordealer.

FOR ADDITIONAL INFORMATION:

PleasecallToll-Free866-447-2194—www.heatstarbyenerco.com

Ourofficehoursare8:00AM—5:00PM,EST,MondaythroughFriday.

Pleasehavethemodelnumber,serialnumberanddateofpurchaseready.

LIMITED WARRANTY

Thecompanywarrantsthisproducttobefreefromimperfectionsinmaterialor

workmanship,undernormalandproperuseinaccordancewithinstructionsofThe

Company,foraperiodof1yearontheboxand2yearsonthetubesfromthedate

ofdeliverytothebuyers.

TheCompany,atitsoption,willrepairorreplaceproductsreturnedbythebuyertothe

factory,transportationprepaidwithinsaidwarrantyperiodandfoundbytheCompanyto

haveimperfectionsinmaterialorworkmanship.

Ifapartisdamagedormissing,callourCustomerServiceDepartmentat866-447-2194.

AddressanyWarrantyClaimstotheCustomerServiceDepartment,Heatstar,Inc,4560W.

160THST.,CLEVELAND,OHIO44135.Includeyourname,addressandtelephonenumberand

includedetailsconcerningtheclaim.Also,supplyuswiththepurchasedateandthename

andaddressofthedealerfromwhomyoupurchasedourproduct.

TheforegoingisthefullextentoftheresponsibilityoftheCompany.Therearenoother

warranties,expressorimplied.Specificallythereisnowarrantyoffitnessforaparticular

purposeandthereisnowarrantyofmerchantability.InnoeventshalltheCompanybeliable

fordelaycausedbyimperfections,forconsequentialdamages,orforanychargesofthe

expenseofanynatureincurredwithoutitswrittenconsent.Thecostofrepairorreplacement

shallbetheexclusiveremedyforanybreachofwarranty.Thereisnowarrantyagainst

infringementofthelikeandnoimpliedwarrantyarisingfromcourseofdealingorusageof

trade.Thiswarrantywillnotapplytoanyproductwhichhasbeenrepairedoralteredoutside

ofthefactoryinanyrespectwhichinourjudgmentaffectsitsconditionoroperation.

Somestatesdonotallowtheexclusionorlimitationofincidentalorconsequentialdamages,

sotheabovelimitationorexclusionmaynotapplytoyou.ThisWarrantygivesyouspecific

legalrights,andyoumayhaveotherrightswhichvaryfromstatetostate.

Heatstar,Inc,4560W.160THST.,CLEVELAND,OHIO44135•866-447-2194

©2019,Heatstar,IncAllrightsreserved

Heatstar,Increservestherighttomakechangesatanytime,withoutnoticeor

obligation,incolors,specifications,accessories,materialsandmodels.

OPERATING INSTRUCTIONS AND OWNER’S MANUAL

120VMODELS

by ENERCO

JET20

JET25

18

Enerco | Heatstar AG Series Heater Operating Instructions and Owner’s Manual

ADVERTENCIA: La instalación, ajuste, alteración, reparación o mantenimiento inadecuados

puede causar daños materiales, lesiones o la muerte. Lea completamente las instrucciones de

instalación, operación y mantenimiento antes de instalar o reparar este equipo.

— QUÉHACERSIDETECTAOLORAGAS

• Abralasventanas.

• NOintenteencenderningúnartefacto.

• NOuseinterruptoreseléctricos.

• NOtoqueningúninterruptoreléctrico;nouseningúnteléfonoeneledificio.

• Llameinmediatamentealacompañíalocaldegasysigalasinstruccionesquerecibadeella.

(Lainstalaciónylareparacióndebenserrealizadasporuninstaladorcalificado,agenciadereparacionesola

compañíadegas).

• Sinosepuedecomunicarconlacompañíadegas,llamealosbomberos.

POR SU SEGURIDAD:

-Este calefactor está diseñado como un calefactor radiante de gas para el calentamiento de edificios

de confinamiento de aves y cerdos. Si está considerando usar este producto para cualquier aplicación

distinta a su uso previsto, comuníquese con Heatstar, Inc.

-Noalmaceneniutilicegasolinaniningúnotrovapornilíquidoinflamablecercadeestenideningúnotroartefacto.

ADVERTENCIA: Sinosesiguenestasinstruccionesalpiedelaletra,podríaproducirseunincendioounaexplosión

queprovocaríadañosmateriales,lesionespersonalesomuertes.

18683

Heatstar,IncGroup,Inc.,4560W.160THST.,CLEVELAND,OHIO44135•866-447-2194

INSTRUCCIONES DE OPERACIÓN

Y MANUAL DEL USUARIO

LEA CUIDADOSAMENTE LAS INSTRUCCIONES:Leaysigatodaslasinstrucciones.Conserveestas

instruccionesenunlugarseguroparafuturareferencia.Nopermitaquenadiequenohayaleídoestas

instruccionesarme,encienda,ajusteouseelcalefactor.

Modelo#

by ENERCO

IDIOMAS INCLUIDOS

SERIE JET

Edificios de confinamiento de aves y cerdos

Edificios agrícolas

•INGLÉS

•ESPAÑO

JET20

JET25

19 Operating Instructions and Owner’s ManualEnerco | Heatstar AG Series Heater

ADVERTENCIA:

PELIGRODEINCENDIO,QUEMADURAS,INHALACIÓN

YEXPLOSIÓN.MANTENGALOSCOMBUSTIBLES

SÓLIDOSCOMOMATERIALESDECONSTRUCCIÓN,

PAPELOCARTÓNAUNADISTANCIASEGURADEL

CALEFACTORTALCOMOLORECOMIENDANLAS

INSTRUCCIONES.NUNCAUSEELCALEFACTOREN

ESPACIOSQUECONTIENENOPODRÍANCONTENER

COMBUSTIBLESVOLÁTILESOPRODUCTOSCOMO

GASOLINA,SOLVENTES,DILUYENTEDEPINTURAO

PRODUCTOSQUÍMICOSDESCONOCIDOS.

ADVERTENCIA GENERAL DE PELIGRO:

ELNOCUMPLIRCONLASPRECAUCIONESE

INSTRUCCIONESQUEVIENENCONESTECALEFACTOR

PUEDECAUSARLAMUERTE,LESIONESGRAVESY

PÉRDIDASYDAÑOSMATERIALESDERIVADOSDEL

PELIGRODEINCENDIO,EXPLOSIÓN,QUEMADURAS,

ASFIXIA,ENVENENAMIENTOCONMONÓXIDODE

CARBONO,Y/ODESCARGASELÉCTRICAS.

SOLOLASPERSONASQUEENTIENDANYPUEDAN

SEGUIRLASINSTRUCCIONESDEBENUSARO

MANTENERESTECALEFACTOR.

SINECESITAAYUDAOINFORMACIÓNACERCA

DELCALENTADOR,COMOUNMANUALDE

INSTRUCCIONES,ETIQUETAS,ETC.,PÓNGASEEN

CONTACTOCONELFABRICANTE.

ADVERTENCIA:

SUSEGURIDADESIMPORTANTEPARAUSTEDY

PARALOSDEMÁS,ASÍQUEPORFAVORLEAESTAS

INSTRUCCIONESANTESDEUTILIZARELCALEFACTOR.

CONTENIDO

SECCIÓN1INTRODUCCIÓN...................................2

SECCIÓN2PLANIFICACIÓN...................................3

SECCIÓN3INSTALACIÓNYARMADO...................5

SECCIÓN4ESPECIFICACIONESDEINGENIERÍA......9

SECCIÓN5TOMADEAIRE/VENTILACIÓN.............9

SECCIÓN6TUBERÍADEGAS............................... 11

SECCIÓN7CABLEADO........................................ 11

SECCIÓN8OPERACIÓNYMANTENIMIENTO...... 13

SECCIÓN9RESOLUCIÓNDEPROBLEMAS........... 13

PARTESACCESORIAS........................................... 14

SECCIÓN10PARTESDEREPUESTO..................... 15

INFORMACIÓNDELAGARANTÍA........................20

ADVERTENCIA:

ESTE PRODUCTO PUEDE EXPONERLO A PRODUCTOS

QUÍMICOS, INCLUYENDO PLOMO Y COMPUESTOS

DE PLOMO, QUE DE ACUERDO CON EL ESTADO DE

CALIFORNIA PRODUCEN CÁNCER Y DEFECTOS DE

NACIMIENTO U OTROS DAÑOS REPRODUCTIVOS.

POR MAYOR INFORMACIÓN, VISITE

WWW.P65WARNINGS.CA.GOV

SECCIÓN 1: Introducción

LosmodelosJETsoncalefactoresinfrarrojoseconómicos,de

armadoenellugar,quesonfácilesdeinstalaryquerequieren

muypocomantenimiento.Estándiseñadosparabrindarañosde

funcionamientoeconómicosinproblemas.

Verificación del envío

Compareelenvíocontralalistadeenvíoparaverificarque

nolefaltenada.Además,reviselascajasparaverificarqueno

tengandañosexternos.Anotecualquiercosaquefaltey/olos

dañosexternosalascajasenlalistadeenvíoantelapresencia

delcamioneroquerealizalaentrega.Elcamionerodeberá

reconocercualquierfaltanteodañocolocandosusinicialesen

lalistadeenvíoconloscomentarios.Realiceinmediatamente

elreclamopormaterialesdañadosofaltantesquenohaya

notadoalmomentoderecibirlos,alaempresadetransporteyal

representantedelafábricaHeatstar,Inc.

Responsabilidad del instalador

Todosloscalefactoresylastuberíasdegasasociadasdebenser

instaladasdeacuerdoconlasespecificacionescorrespondientes

ylainstalacióndebeserrealizadaúnicamenteporempresas(o

personas)correctamentecalificadasparaestetipodetrabajo.

Consulteconinspectoreslocalesdeedificios,losbomberososu

representantelocaldelafábricaHeatstarporrecomendaciones.

LainstalacióndeloscalefactoresJETsebasaenlainformación

suministradaenundiagramadedistribución,quejuntocon

lasnormasyreglamentacionesmencionadasanteriormente

constituyenlainformaciónbásicanecesariaparacompletarla

instalación.Elinstaladordeberáproporcionartodoelmaterial

necesarioquenoseincluyecomoequipoestándar,yessu

responsabilidadverificarquedichomaterialylosmétodos

deinstalaciónqueutiliceconstituyanuntrabajodecalidad

profesionalydeacuerdocontodaslasnormascorrespondientes.

LosrepresentantesdelafábricaHeatstar,Inc.cuentancon

entrenamientoyexperienciaenesteequipoylospuedellamar

porsugerenciasacercadelainstalación,loquepuedeahorrarle

materialycostos.

20

Enerco | Heatstar AG Series Heater Operating Instructions and Owner’s Manual

SECCIÓN 2: Planificación

Debenrespetarselassiguientesnormaseinstruccionesalplanificar

lainstalacióndeestecalefactorJET.Ademásdeestasinstrucciones,

hayquerespetarcuidadosamentelasadvertencias,yaqueuna

instalacióninadecuadapodríacausardañosmateriales,lesionesola

muerte.

Normas nacionales y reglamentaciones

correspondientes

Normas de gas:

•Sedebeutilizareltipodegasqueseindicaenlaplacade

identificación.Lainstalacióndebecumplirconlasnormas

locales,conlasrecomendacionesdelacompañíalocaldegas

yconelCódigonacionaldelgascombustible,ANSIZ223.1–

últimaversión,(igualqueconelBoletínNFPA54)(Códigode

instalacióndegasnaturalypropano,CSAB149.1)paraCanadá

únicamente.

•Debemantenerselaseparaciónentreelcalefactorysu

ventilaciónyelmaterialcombustibleadyacente(yaseaparte

deledificioosucontenido)paracumplirconlanormade

instalacióndeartefactosagasytuberíasdegas,NFPA-54/ANSI

Z223.1–últimaversión,elCódigonacionaldelgascombustible

(Códigodeinstalacióndegasnaturalypropano,CSAB149.1)

paraCanadáúnicamente.

Lugares peligrosos:

Cuandoexistalaposibilidaddeexposiciónamaterial

combustiblesuspendidoenelaireoenformadevapor,

consulteconlosbomberoslocales,lacompañíadeseguros

contraincendiouotrasautoridadesparaqueapruebenla

instalaciónpropuesta.

Consideraciones críticas

EstemodeloJETesuncalefactorsuspendido.Porlotanto,su

estabilidad,flexibilidadyseguridadsonmuyimportantes.Antesde

comenzarconlainstalación,verifiquequeelsistemapuedacumplir

conlossiguientesrequisitos.

•Mantenerlasdistanciasespecificadasacombustiblesyuna

distanciaseguraamateriales,equiposyestacionesdetrabajo

sensiblesalcalor.

•Lasdistanciasacombustiblesindicadasrepresentanuna

temperaturasuperficialde90°F(30°C)porencimadela

temperaturaambiente.Losmaterialesdeconstrucciónconbaja

toleranciaalatemperatura(comoelplástico,revestimiento

vinílico,lona,etc.)podríandegradarseatemperaturasmenores.

Esresponsabilidaddelinstaladorelasegurarsedequelos

materialesadyacentesesténprotegidoscontraladegradación.

•Brindaraccesoalosquemadoresparareparaciones,

preferentementedeamboslados,porencimaypordebajodel

quemadorparapoderremoverlo.

•Respetarsiemprelasdistanciasmínimasamateriales

combustiblesindicadasenlapágina4.

•Planificarlossoportesparaellugar(verlaFigura2A-B

comenzandoenlapágina6).

•Lainstalacióndebecumplirconlasnormaslocalesde

construcción,ysinoexistennormaslocales,conelCódigo

nacionaldelgascombustible,ANSIZ223.1/NFPA54(Códigode

instalacióndegasnaturalypropano,CSAB149.1)paraCanadá

únicamente.

•Siseutilizaunafuentedeenergíaeléctricaexterna,el

calefactor,alinstalarlo,deberáestarconectadoeléctricamente

atierradeacuerdoconlaNormaeléctricanacional,ANSI/NFPA

70oconlaNormadeElectricidadCanadiense,CSAC22.1.

Procedimiento de instalación

Aprovechealmáximolaestructurasuperiordeledificio,vigas,

viguetas,largueros,etc.dedondepuedacolgarelcalefactor.

Noexisteunaúnicasecuenciadeinstalaciónparalatubería.

Laobservacióndellugarusualmentelerevelaráunasecuencia

lógica.Comiencelainstalaciónenellugarcondimensionesmás

críticas.Losdeflectoresylastuberíassepuedenirinstalandoa

medidaquevaavanzando.Ajustecuidadosamentelainclinación

delsistemaencadaposiciónparanivelarelcalefactor.Use

unainclinaciónhaciaabajodemediapulgadaporcada20pies

(alejándosedelquemador).

LO QUE NO DEBE HACER

Probarlatuberíadegasconaltapresión(másde1/2

PSIG)sincerrarlallavedecortedealtapresión.Elno

hacerlodañaríalosquemadores.

LO QUE DEBE HACER

Familiaríceseconlasnormaslocalesynacionales.

Desarrolleunprocedimientoplanificado,paraahorrar

materialytrabajodurantelainstalación.

Verifiquequetengatodoelmaterialylosequiposenel

lugarantesdecomenzarconlainstalación.

Permitalaexpansióntérmicadelastuberías.

Instaleelconectordegassolamentecomosemuestraen

lasinstrucciones(verlaFigura14y15delapágina11).

Usetornillosautorroscantesdondelosreflectoresse

superponganparaasegurarsedequenoseseparen.

Fijeelcablederetencióndelreflectoralacajadel

quemadoroalacadenaquesuspendelacajadel

quemador.Elcablevieneunidoaunodelosreflectores.

Consultelasinstruccionesenconjuntodetubopormás

detalles.

Brindeunaaberturade1pulgada2deairelibreporcada

1.000BTU/hdeentradadelcalefactor(peronomenos

de100pulgadas2)enespacioscerrados.Unaabertura

debeestardentrodelas12"deltechoylaotradentrode

las12"delpisodelrecinto.

Other manuals for JET20

1

This manual suits for next models

1

Table of contents

Languages:

Popular Controllers manuals by other brands

Moeller

Moeller Xcomfort CAAE-01/01 Assembly instructions

SMC Networks

SMC Networks E-MY2B Series Operation manual

FASAR ELETTRONICA

FASAR ELETTRONICA FE1040 manual

nekos

nekos SKYRO 850 instruction manual

Hanna Instruments

Hanna Instruments EC Series instruction manual

Franke

Franke AQUA802 Installation and operating instructions

AUMA

AUMA SA 07.1 - SA 30.1 Operation instructions

Rockwell Automation

Rockwell Automation Allen-Bradley MicroLogix 1400 user manual

Mold-Masters

Mold-Masters TempMaster M2 Plus Series user manual

Toshiba

Toshiba TCR15AG Series reference guide

Festo

Festo SPC200 Series Electronic manual

VNC Automotive

VNC Automotive Cobalt Cube Getting started guide