nekos SKYRO 850 User manual

4420148 - Rev 1 del 03/2021

SKYRO 850

INSTRUCTION MANUAL -

TRANSLATION OF ORIGINAL INSTRUCTIONS

RACK ACTUATOR

Force 850N – Strokes 350, 550, 750, 1000 mm

Electrical feeding 110-230V~ 50/60Hz and 24V

NEKOS S.r.l. - Via Capitoni, 7/5 - 36064 Colceresa – VI – ITALY

EN

2

USER INSTRUCTIONS

CAUTION. Carefully observe all the following installation

instructions to ensure personal safety.

The device is not intended for use by persons (including children)

with reduced physical, sensory or mental capabilities, or lacking

experience and knowledge. Do not allow children to play with the

fixed controls and keep any remote-control units out of their reach.

Have installation checks performed periodically by qualified

personnel from a service centre authorised by the manufacturer. Do

not use if repair or adjustment is required.

CAUTION: if the power cable is damaged, it must be replaced by

qualified personnel from a service centre authorised by the

manufacturer.

CAUTION. Disconnect the power supply during cleaning or

maintenance operations. Do not use solvents or jets of water to

wash the appliance; the appliance should not be submerged in

water.

In the event of fault or malfunction, switch off the device at the main

switch. All repairs and adjustments (e.g. setting the stroke) must

only be performed by qualified personnel from a service centre

authorised by the manufacturer.

Always request exclusive use of original spare parts. Failure to

respect this condition could compromise safety and invalidate the

benefits contained in the warranty for the appliance. In the event of

any problems or queries, consult your agent or contact the

manufacturer directly.

The A-weighted sound pressure level is less than 70dB(A).

Carefully preserve these instructions after installation.

INSTALLER INSTRUCTIONS

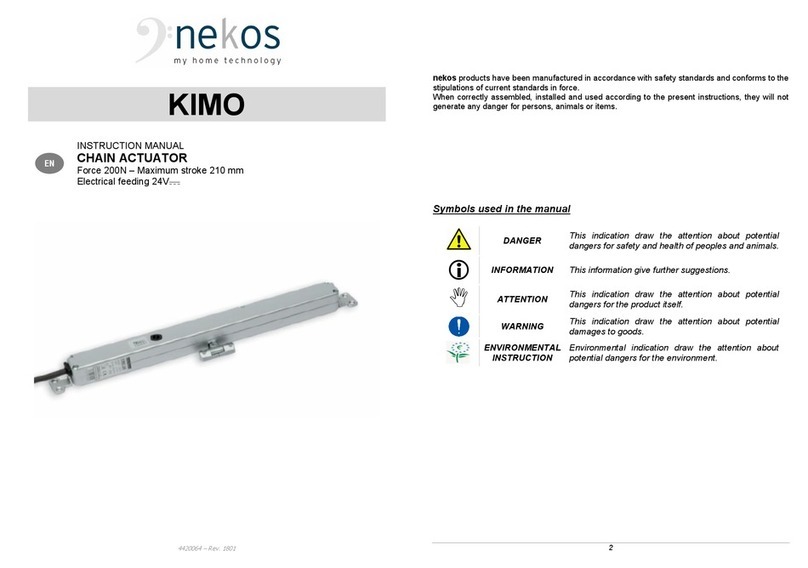

nekos

products have been manufactured in accordance with safety standards and conforms to the

stipulations of current standards in force.

When correctly assembled, installed and used according to the present instructions, they will not

generate any danger for persons, animals or items.

Symbols used in the manual

DANGER

This indication draw the attention about potential dangers for

health of peoples and animals.

Contents

1. SECURITY RULES

................................

2.

FORMULAS AND RECOMME

2.1.

Calculation of opening / closure force

2.2.

Maximum opening in accordance with sash height

3.

TECHNICAL INFORMATIO

4.

CONSTRUCTION AND REG

5.

USE OF ACTUATOR IN SYNCRO³ VERSION

5.1. Recognition

................................

5.2. Use of a Syncro³-

version actuator

6. ID PLATE AND MARKING

DATA

7. TECHNICAL DATA

................................

8.

ACTUATOR DIMENSIONS

9.

ELECTRICAL POWER SUP

9.1.

Selection of power cable section

10.

INSTRUCTIONS FOR ASS

10.1.

Preparation of actuator for assembly

10.2.

Calculation of the number of push / retention points

10.3.

Assembly with outward opening window

10.4.

Installation on domed rooflights, dormers or industrial skylights

10.5.

Assembly with opening

10.6.

Installing the actuator and rod (or transmission) with connection bar

11.

ELECTRICAL CONNECTIO

11.1. Connections of

SKYRO 850

11.2. Connections of

SKYRO 850 SYNCRO³

12.

PROGRAMMING THE ACTU

12.1. RESET Procedure

................................

12.2. Closing stroke-end

................................

12.3. Overlap acquisition

................................

12.4. LED Light signals

................................

13.

CHECKING FOR CORRECT

14.

EMERGENCY MANOEUVRES

15. TROUBLESHOOTING

................................

16.

ENVIRONMENTAL PROTEC

17.

CERTIFICATE OF GUARANTEE

18.

DECLARATION OF INCORPORATION (FOR A PARTLY COMPLETED MACHINE)

AND

EC DECLARATION OF CONFORMITY

3

INSTALLER INSTRUCTIONS

products have been manufactured in accordance with safety standards and conforms to the

stipulations of current standards in force.

When correctly assembled, installed and used according to the present instructions, they will not

generate any danger for persons, animals or items.

Symbols used in the manual

This indication draw the attention about potential dangers for

health of peoples and animals.

................................

................................

................................

FORMULAS AND RECOMME

NDATIONS FOR INSTALLATION

................................

Calculation of opening / closure force

................................

................................

Maximum opening in accordance with sash height

................................

TECHNICAL INFORMATIO

N ABOUT FUNCTION

................................

CONSTRUCTION AND REG

ULATORY REFERENCES

................................

USE OF ACTUATOR IN SYNCRO³ VERSION

................................

................................

................................

................................

version actuator

................................

................................

DATA

................................

................................

................................

................................

................................

ACTUATOR DIMENSIONS

................................

................................

ELECTRICAL POWER SUP

PLY ................................

................................

Selection of power cable section

................................

................................

INSTRUCTIONS FOR ASS

EMBLY ................................

................................

Preparation of actuator for assembly

................................

................................

Calculation of the number of push / retention points

................................

Assembly with outward opening window

................................

Installation on domed rooflights, dormers or industrial skylights

Assembly with opening

inwards ................................

................................

Installing the actuator and rod (or transmission) with connection bar

ELECTRICAL CONNECTIO

NS ................................

................................

SKYRO 850

................................

................................

SKYRO 850 SYNCRO³

................................

PROGRAMMING THE ACTU

ATOR ................................

................................

................................

................................

................................

................................

................................

................................

................................

................................

..............................

CHECKING FOR CORRECT

ASSEMBLY ................................

................................

EMERGENCY MANOEUVRES

, MAINTENANCE OR CLEANING

...............................

................................

................................

................................

ENVIRONMENTAL PROTEC

TION ................................

................................

CERTIFICATE OF GUARANTEE

................................

................................

DECLARATION OF INCORPORATION (FOR A PARTLY COMPLETED MACHINE)

EC DECLARATION OF CONFORMITY

................................

..............................

INSTALLER INSTRUCTIONS

products have been manufactured in accordance with safety standards and conforms to the

When correctly assembled, installed and used according to the present instructions, they will not

This indication draw the attention about potential dangers for

safety and

................................

....... 4

................................

.. 5

................................

....... 5

................................

................... 5

................................

........................ 5

................................

............... 6

................................

.............................. 7

................................

........... 7

................................

......... 7

................................

.................. 7

................................

....... 8

................................

........................... 9

................................

................... 9

................................

......... 10

................................

............. 10

................................

. 10

................................

.......... 11

................................

............................ 11

Installation on domed rooflights, dormers or industrial skylights

............................. 12

................................

........ 12

Installing the actuator and rod (or transmission) with connection bar

...................... 13

................................

................... 14

................................

.............. 15

................................

............................. 15

................................

............ 16

................................

............................ 16

................................

............................ 17

................................

........................... 17

..............................

18

................................

.. 19

...............................

20

................................

20

................................

............. 20

................................

................ 21

DECLARATION OF INCORPORATION (FOR A PARTLY COMPLETED MACHINE)

..............................

22

1. SECURITY RULES

C

AREFULLY OBSERVE ALL

PERSONAL SAFETY

.

I

MPROPER INSTALLATION

MANDATORY RISK ANALY

The Nekos electrical actuators comply with the Machinery Directive (2006/42/EC), Standard

IEC 60335-2-

103 (Particular requirements for drives for gates, doors and windows) and other

directives and regulations indicated in the attached Declarations of Incor

Conformity (at the end of the manual). According to the Machinery Directive, actuators are

“partly completed machinery” intended for incorporation into doors and windows. The

manufacturer/supplier of the window is required, with exclusive r

compliance of the entire system with the applicable standards and to issue CE certification.

We strongly discourage any use of the actuators other than that specified and therefore, in

any case, the supplier of the complete sys

For systems installed at a height of less than 2.5 m above floor level or other levels

accessible to users, the manufacturer/supplier of the window must conduct

regarding potential harm (violent blows, crushing, w

or possible malfunction or accidental breakage of the automated windows, and to implement

suitable protective measures

in view of these. Such measures include those recommended

by the specified standard:

- controlling th

e actuators via a “deadman’s button” placed near the system and within the

operator’s field of view, to ensure that people are out of the way during operation. The

button must be placed at a height of 1,5 m and operated by key if accessible to the

public; or:

-

use of contact safety systems (also included in the actuators) that ensure a maximum

closing force of 400/150/25 N, measured in accordance with paragraph BB.20.107.2 of

IEC 60335-2-103; or:

- use of non-

contact safety systems (lasers, light grids); or:

-

use of fixed safety barriers that prevent access to moving parts.

Automated windows are deemed adequately protected if they:

-

are installed at a height of >2.5 m; or:

- have a leading-

edge opening of <200 mm and a closing speed of <15 mm/s; or:

- are part of a

smoke and heat evacuation system for emergency use only.

In any case, moving parts of windows that could fall below 2.5 m following breakage of a

system component need to be fixed or secured in order to prevent them from suddenly

falling or collapsing: e.

g. the use of safety arms on bottom

The device is not intended for use by persons (including children) with reduced

physical, sensory or mental capabilities, or lacking experience and knowledge. Do

not allow children to play with the fixed

out of their reach.

The actuator is destined exclusively for installation indoors. For any special

application we recommend you consult the manufacturer beforehand.

After removing packaging, check for any damage

Always request exclusive use of original spare parts. Failure to respect this condition

could compromise safety and invalidate the benefits contained in the warranty for the

appliance.

In the event of any problems or queries, consult your

manufacturer directly.

4

AREFULLY OBSERVE ALL

THE FOLLOWING INSTAL

LATION INSTRUCTIONS

MPROPER INSTALLATION

CAN SERIOUSLY ENDANG

MANDATORY RISK ANALY

SIS AND PROTECTION MEASURES

.

The Nekos electrical actuators comply with the Machinery Directive (2006/42/EC), Standard

103 (Particular requirements for drives for gates, doors and windows) and other

directives and regulations indicated in the attached Declarations of Incor

Conformity (at the end of the manual). According to the Machinery Directive, actuators are

“partly completed machinery” intended for incorporation into doors and windows. The

manufacturer/supplier of the window is required, with exclusive r

esponsibility, to ensure the

compliance of the entire system with the applicable standards and to issue CE certification.

We strongly discourage any use of the actuators other than that specified and therefore, in

any case, the supplier of the complete sys

tem retains full liability.

For systems installed at a height of less than 2.5 m above floor level or other levels

accessible to users, the manufacturer/supplier of the window must conduct

regarding potential harm (violent blows, crushing, w

ounds) caused to people by normal use

or possible malfunction or accidental breakage of the automated windows, and to implement

in view of these. Such measures include those recommended

e actuators via a “deadman’s button” placed near the system and within the

operator’s field of view, to ensure that people are out of the way during operation. The

button must be placed at a height of 1,5 m and operated by key if accessible to the

use of contact safety systems (also included in the actuators) that ensure a maximum

closing force of 400/150/25 N, measured in accordance with paragraph BB.20.107.2 of

contact safety systems (lasers, light grids); or:

use of fixed safety barriers that prevent access to moving parts.

Automated windows are deemed adequately protected if they:

are installed at a height of >2.5 m; or:

edge opening of <200 mm and a closing speed of <15 mm/s; or:

smoke and heat evacuation system for emergency use only.

In any case, moving parts of windows that could fall below 2.5 m following breakage of a

system component need to be fixed or secured in order to prevent them from suddenly

g. the use of safety arms on bottom

-

hung windows.

The device is not intended for use by persons (including children) with reduced

physical, sensory or mental capabilities, or lacking experience and knowledge. Do

not allow children to play with the fixed

controls and keep any remote

The actuator is destined exclusively for installation indoors. For any special

application we recommend you consult the manufacturer beforehand.

After removing packaging, check for any damage

on the appliance.

Always request exclusive use of original spare parts. Failure to respect this condition

could compromise safety and invalidate the benefits contained in the warranty for the

In the event of any problems or queries, consult your

LATION INSTRUCTIONS

TO ENSURE

CAN SERIOUSLY ENDANG

ER SAFETY

.

The Nekos electrical actuators comply with the Machinery Directive (2006/42/EC), Standard

103 (Particular requirements for drives for gates, doors and windows) and other

directives and regulations indicated in the attached Declarations of Incor

poration and CE

Conformity (at the end of the manual). According to the Machinery Directive, actuators are

“partly completed machinery” intended for incorporation into doors and windows. The

esponsibility, to ensure the

compliance of the entire system with the applicable standards and to issue CE certification.

We strongly discourage any use of the actuators other than that specified and therefore, in

For systems installed at a height of less than 2.5 m above floor level or other levels

accessible to users, the manufacturer/supplier of the window must conduct

risk analysis

ounds) caused to people by normal use

or possible malfunction or accidental breakage of the automated windows, and to implement

in view of these. Such measures include those recommended

e actuators via a “deadman’s button” placed near the system and within the

operator’s field of view, to ensure that people are out of the way during operation. The

button must be placed at a height of 1,5 m and operated by key if accessible to the

use of contact safety systems (also included in the actuators) that ensure a maximum

closing force of 400/150/25 N, measured in accordance with paragraph BB.20.107.2 of

edge opening of <200 mm and a closing speed of <15 mm/s; or:

smoke and heat evacuation system for emergency use only.

In any case, moving parts of windows that could fall below 2.5 m following breakage of a

system component need to be fixed or secured in order to prevent them from suddenly

hung windows.

The device is not intended for use by persons (including children) with reduced

physical, sensory or mental capabilities, or lacking experience and knowledge. Do

controls and keep any remote

-control units

The actuator is destined exclusively for installation indoors. For any special

application we recommend you consult the manufacturer beforehand.

on the appliance.

Always request exclusive use of original spare parts. Failure to respect this condition

could compromise safety and invalidate the benefits contained in the warranty for the

agent or contact the

2.

FORMULAS AND RECOMMENDATIONS FOR INSTALLATION

2.1.

Calculation of opening / closure force

Using the formulas on this page, approximate calculations can be made for the force

required to open or close the window cons

calculation.

Symbols used for the calculation

F (Kg) =

Force for opening or closing

C (cm) =

Opening stroke (actuator stroke)

For horizontal light domes or

skylights

F = 0,54 x P

(Eventual weight of snow or wind on the

cupola should be calculated separately.)

2.2.

Maximum opening according to height of sash

The actuator can be recessed mounted in the frame as well as outside on the frame or on

the sash. In any case the actuator

its application. Check that

the actuator

that there are no obstacles for the opening or it does not exert force on the window frame.

A

TTENTION

. For

safety reasons the actuator should not be assembled if

dimensions are inferior to those indicated in the table below. In the event that

the height of the sash should be lower, call on the manufacturer to check the

appliance.

3.

GENERAL INFORMATION ABOUT THE

The SKYRO 850 actuator moves the window by means of a

device. The rack

is moved by a

powered and controlled by an electronic card. The opening and closing movement

determined by the polarity of

carried out

(see wiring diagrams on page 15).

5

FORMULAS AND RECOMMENDATIONS FOR INSTALLATION

Calculation of opening / closure force

Using the formulas on this page, approximate calculations can be made for the force

required to open or close the window cons

idering all the factors that determine the

Symbols used for the calculation

Force for opening or closing

P (Kg) =

Weight of the window (mobile sash only)

Opening stroke (actuator stroke)

H (cm) =

Height of the mobile sash

For horizontal light domes or

F = 0,54 x P

(Eventual weight of snow or wind on the

cupola should be calculated separately.)

For vertical windows

TOP HUNG WINDOWS

,

OUTWARD OPENING

BOTTOM HUNG WINDOWS

F = 0,54 x P x C : H

(Eventual

load of favourable or

unfavourable wind on the sash should be

calculated separately.)

Maximum opening according to height of sash

The actuator can be recessed mounted in the frame as well as outside on the frame or on

the sash. In any case the actuator

stroke is in accordance with the height of the sash and

the actuator

stroke

does not touch the profile of the sash and

that there are no obstacles for the opening or it does not exert force on the window frame.

safety reasons the actuator should not be assembled if

dimensions are inferior to those indicated in the table below. In the event that

the height of the sash should be lower, call on the manufacturer to check the

GENERAL INFORMATION ABOUT THE

ACTUATOR

The SKYRO 850 actuator moves the window by means of a

rack

is moved by a

gear motor

driven by an electric motor, which in turn is

powered and controlled by an electronic card. The opening and closing movement

determined by the polarity of

the power supply wires depending on how the wiring is

(see wiring diagrams on page 15).

FORMULAS AND RECOMMENDATIONS FOR INSTALLATION

Using the formulas on this page, approximate calculations can be made for the force

idering all the factors that determine the

Weight of the window (mobile sash only)

Height of the mobile sash

For vertical windows

OUTWARD OPENING

(A)

BOTTOM HUNG WINDOWS

(B)

F = 0,54 x P x C : H

load of favourable or

unfavourable wind on the sash should be

The actuator can be recessed mounted in the frame as well as outside on the frame or on

stroke is in accordance with the height of the sash and

does not touch the profile of the sash and

that there are no obstacles for the opening or it does not exert force on the window frame.

safety reasons the actuator should not be assembled if

dimensions are inferior to those indicated in the table below. In the event that

the height of the sash should be lower, call on the manufacturer to check the

rack

that runs inside the

driven by an electric motor, which in turn is

powered and controlled by an electronic card. The opening and closing movement

is

the power supply wires depending on how the wiring is

The opening and closing stroke

through power absorption when the rac

internal stop in the rack or complete opening/closure of the window); therefore, no

adjustments are required and the end position depends on the length of the rod connected

to the gear reducer or the stro

ke set during production.

During initial operation, the actuator memorises the stroke end position; during subsequent

operation, it maintains the memorised stroke end positions and also adjusts the start and

stop ramp.

4.

CONSTRUCTION AND REGULATORY

INTENDED USE.

The SKYRO 850 rack actuator is designed and built to move

awning windows, bottom

dormer windows and skylights. Its use is specifically intended for ventilation and

natural air

conditioning of rooms; any other use is strongly discouraged, with the

supplier of the entire system in any case retaining sole liability.

The actuator is manufactured in accordance with the Directives and following

Regulations listed in the attached Declaration of Incorporation and Conformity

Electrical connections must conform to regulations in force for the de

up of electrical equipment.

To ensure efficient separation from the grid, an approved type of bipolar “dead

switch should be used. An omnipolar general power switch with minimum distance of

3 mm between contacts should be installed upstre

Application is performed using the brackets provided and any other type of

assembly should be checked with the manufacturer, who will not accept any

responsibility for incorrect or malfunctioning assembly.

The SKYRO 850 actuator is

individually packaged in a cardboard container and each pack

contains:

• 1

actuator with 2 metre (±5%) lead,

• 1

standard support bracket with respective grips and fixing screws,

• 1

bracket for fixing to the frame,

• Small parts packaging,

• Instruction manual

IMPORTANT: The Syncro³ version of the actuator comes individually

packaged in a cardboard box and is factory tested as an individual machine

When installing a system that requires the use of several Syncro³ actuators

or a K-

LOCK electro

§ 12.1).

6

The opening and closing stroke

-

end stop occurs with an automatic positioning process

through power absorption when the rac

k encounters an obstacle that stops its stroke (the

internal stop in the rack or complete opening/closure of the window); therefore, no

adjustments are required and the end position depends on the length of the rod connected

ke set during production.

During initial operation, the actuator memorises the stroke end position; during subsequent

operation, it maintains the memorised stroke end positions and also adjusts the start and

CONSTRUCTION AND REGULATORY

REFERENCES

The SKYRO 850 rack actuator is designed and built to move

awning windows, bottom

-hung windows, parallel-

opening windows, light domes,

dormer windows and skylights. Its use is specifically intended for ventilation and

conditioning of rooms; any other use is strongly discouraged, with the

supplier of the entire system in any case retaining sole liability.

The actuator is manufactured in accordance with the Directives and following

Regulations listed in the attached Declaration of Incorporation and Conformity

Electrical connections must conform to regulations in force for the de

up of electrical equipment.

To ensure efficient separation from the grid, an approved type of bipolar “dead

switch should be used. An omnipolar general power switch with minimum distance of

3 mm between contacts should be installed upstre

am of the control line.

Application is performed using the brackets provided and any other type of

assembly should be checked with the manufacturer, who will not accept any

responsibility for incorrect or malfunctioning assembly.

individually packaged in a cardboard container and each pack

actuator with 2 metre (±5%) lead,

standard support bracket with respective grips and fixing screws,

bracket for fixing to the frame,

IMPORTANT: The Syncro³ version of the actuator comes individually

packaged in a cardboard box and is factory tested as an individual machine

When installing a system that requires the use of several Syncro³ actuators

LOCK electro

-lock, a new RESET

procedure must be performed.

end stop occurs with an automatic positioning process

k encounters an obstacle that stops its stroke (the

internal stop in the rack or complete opening/closure of the window); therefore, no

adjustments are required and the end position depends on the length of the rod connected

During initial operation, the actuator memorises the stroke end position; during subsequent

operation, it maintains the memorised stroke end positions and also adjusts the start and

The SKYRO 850 rack actuator is designed and built to move

opening windows, light domes,

dormer windows and skylights. Its use is specifically intended for ventilation and

conditioning of rooms; any other use is strongly discouraged, with the

supplier of the entire system in any case retaining sole liability.

The actuator is manufactured in accordance with the Directives and following

Regulations listed in the attached Declaration of Incorporation and Conformity

.

Electrical connections must conform to regulations in force for the de

sign and set

To ensure efficient separation from the grid, an approved type of bipolar “dead

-man”

switch should be used. An omnipolar general power switch with minimum distance of

am of the control line.

Application is performed using the brackets provided and any other type of

assembly should be checked with the manufacturer, who will not accept any

individually packaged in a cardboard container and each pack

standard support bracket with respective grips and fixing screws,

IMPORTANT: The Syncro³ version of the actuator comes individually

packaged in a cardboard box and is factory tested as an individual machine

.

When installing a system that requires the use of several Syncro³ actuators

procedure must be performed.

(see

5.

USE OF ACTUATOR IN SYNCRO³ VERSION

In the

SYNCRO

³

version the actuator has been equipped with the new system patented by

NEKOS for coordinated synchronisation of a group of actuators (up to eight at the same

time). Electronic control of speed is completely automatic device inside the actuator and

does no

t require any external control station: just connect the feeder cable communication

wires to each other (see

diagram on page 15)

5.1. Recognition

Three elements differentiate the SYNCRO

The technical data label with the “..…

The SYNCRO label to one side of the technical data label on the

actuator.

In the 230V ~ version, the power cord has 4 wires

5.2.

Use of a Syncro³

The Syncro³ version of the actuator is used when the window is particularly heavy or wide

(more than approximately 1,2 m wide)

of the window, especially in the corners, therefore making it necessary to h

retention points.

When a group of Syncro³ actuators is used, the movement of the window sashes occurs in

a synchronized manner, i.e., uniformly without interruptions and/or variations in the speeds

of the actuators. If one of the actuators

electronic problem, the other actuators stop as well, thereby guaranteeing the integrity of

the window.

Recall that the force exerted by a group of actuators installed on the same

window sash is equivalent to the

assembling two actuators doubles the force exerted on the window.

IMPORTANT: when calculating the dimensions of a system with multiple

Syncro³ actuators, it is advisable to consider the force of each

90% of that stated on the plate.

6.

ID PLATE AND MARKING DATA

The actuators have

marking and comply with the Standards listed in the Declaration of

Conformity. They also come with a Declaration of Incorporation, due

by the Machinery Directive as “partly completed machines”. Both declarations are included

in the final pages of this manual.

The plate data is displayed on an adhesive label placed on the outside of the casing, which

must remain int

act and visible.

The main information it displays includes: manufacturer's address, product name

number, technical characteristics, production date and serial number

7

USE OF ACTUATOR IN SYNCRO³ VERSION

version the actuator has been equipped with the new system patented by

NEKOS for coordinated synchronisation of a group of actuators (up to eight at the same

time). Electronic control of speed is completely automatic device inside the actuator and

t require any external control station: just connect the feeder cable communication

diagram on page 15)

and carry out

R

ESET

procedure.

Three elements differentiate the SYNCRO

3

version of the actuator:

The technical data label with the “..…

SYNCRO

3

” label.

The SYNCRO label to one side of the technical data label on the

In the 230V ~ version, the power cord has 4 wires

(3 power +1 signal

Use of a Syncro³

-version actuator

The Syncro³ version of the actuator is used when the window is particularly heavy or wide

(more than approximately 1,2 m wide)

and a single actuator doesn't allow complete closure

of the window, especially in the corners, therefore making it necessary to h

When a group of Syncro³ actuators is used, the movement of the window sashes occurs in

a synchronized manner, i.e., uniformly without interruptions and/or variations in the speeds

of the actuators. If one of the actuators

stops, due to mechanical obstruction or an

electronic problem, the other actuators stop as well, thereby guaranteeing the integrity of

Recall that the force exerted by a group of actuators installed on the same

window sash is equivalent to the

sum of the forces exerted by each actuator; so

assembling two actuators doubles the force exerted on the window.

IMPORTANT: when calculating the dimensions of a system with multiple

Syncro³ actuators, it is advisable to consider the force of each

90% of that stated on the plate.

ID PLATE AND MARKING DATA

marking and comply with the Standards listed in the Declaration of

Conformity. They also come with a Declaration of Incorporation, due

by the Machinery Directive as “partly completed machines”. Both declarations are included

in the final pages of this manual.

The plate data is displayed on an adhesive label placed on the outside of the casing, which

act and visible.

The main information it displays includes: manufacturer's address, product name

number, technical characteristics, production date and serial number

version the actuator has been equipped with the new system patented by

NEKOS for coordinated synchronisation of a group of actuators (up to eight at the same

time). Electronic control of speed is completely automatic device inside the actuator and

t require any external control station: just connect the feeder cable communication

procedure.

The SYNCRO label to one side of the technical data label on the

(3 power +1 signal

).

The Syncro³ version of the actuator is used when the window is particularly heavy or wide

and a single actuator doesn't allow complete closure

of the window, especially in the corners, therefore making it necessary to h

ave two or more

When a group of Syncro³ actuators is used, the movement of the window sashes occurs in

a synchronized manner, i.e., uniformly without interruptions and/or variations in the speeds

stops, due to mechanical obstruction or an

electronic problem, the other actuators stop as well, thereby guaranteeing the integrity of

Recall that the force exerted by a group of actuators installed on the same

sum of the forces exerted by each actuator; so

IMPORTANT: when calculating the dimensions of a system with multiple

Syncro³ actuators, it is advisable to consider the force of each

actuator as

marking and comply with the Standards listed in the Declaration of

Conformity. They also come with a Declaration of Incorporation, due

to their classification

by the Machinery Directive as “partly completed machines”. Both declarations are included

The plate data is displayed on an adhesive label placed on the outside of the casing, which

The main information it displays includes: manufacturer's address, product name

- model

number, technical characteristics, production date and serial number

.

8

In the event of a complaint, please indicate the serial number (SN) displayed on the label.

An explanation of the symbols used on the label to abbreviate the technical characteristics

is given in the table in the chapter on “TECHNICAL DATA”.

7. TECHNICAL DATA

Model SKYRO 850 230V 24V

SOLO SYNCRO³ SYNCRO³ RWA

Thrust and traction force (FN) 850 N

Course lengths (SV) 350, 550, 750, 1000 mm

Input voltage (UN) 110-230V~ 50/60 Hz 24V

Current absorption at nominal load

(IN)

0,37A (110V) - 0,18A

(230V) 1,0 A 2,0 A

Power absorption at nominal load

(PN)

28W (110V) - 24W

(230V) 24 W 48 W

No load speed (Open / Close) 5 mm/s 7 mm/s ↑ 10 mm/s

↓ 7 mm/s

Duration of no load stroke In relation to the stroke Stroke 550

< 60 s

Electrical insulation Class II Class III (Selv)

Type of service (DR) 2 cycles 5 cycles

Operating temperature (- 20°C) (+ 70 ºC)

Protection index for electrical devices IP65

Soft-stop function Yes

Relax function Yes

Adjustment of connection to window

frame Position self-determining

Parallel powering of two or more motors Yes (max 20)

Synchronised function No Yes - max

4 Yes max 8

Holding nominal force 3000 N

Stroke-end at opening Electronic with encoder (once the end position is

acquired)

Stroke-end at closing At absorption of power

Protection against overload At absorption of power

Noise level 55 dB(A)

Type and length of power cable H05VV-F - 2m S-FG4GA/2 - 2m

Dimensions 44,6x113x(stroke + 163) mm

Weight 2,0 / 2,34 / 2,69 / 3,11

Kg

1,95 / 2,29 / 2,64 / 3,07

Kg

Information presented in these illustrations is not binding and is also subject to variation without prior notice

9

8. ACTUATOR DIMENSIONS

The main overall dimensions of the actuator are shown in the figure below.

9. ELECTRICAL POWER SUPPLY

The actuator is commercially available in four versions identified according to electrical

specifications:

1. SKYRO 850 230V: runs on grid tension of 110-230V~ 50/60Hz, with a three wire

cable (LIGHT BLUE, common neutral; BLACK, phase open; BROWN, phase closed).

2. SKYRO 850 230V SYNCRO3: is powered by 110-230V~ 50/60Hz mains voltage, with a

four-wire power cord (BLUE, common neutral; BLACK, open live; BROWN, close live),

and a GREEN fourth wire for electronic synchronisation with other similar (NEKOS

patent) actuators.

3. SKYRO 850 24V SYNCRO3: is powered by 24V voltage with a three-wire power cable:

BLACK connected to + (positive) open, RED connected to + (positive) close. The GREEN

“3” third wire is used both for synchronisation with other similar actuators and for

connection to the K-Lock electromechanical lock.

4. SKYRO 850 24V RWA SYNCRO3; this version is destined for the smoke and heat

extraction: is powered by 24V voltage with a three-wire power cable: BLACK

connected to + (positive) open, RED connected to + (positive) close. The GREEN “3” third

wire is used both for synchronisation with other similar actuators and for connection to the

K-Lock electromechanical lock.

Low tension actuators 24V can be powered using a specific RWA station with

emergency battery or a security feeder with an output tension of 24V 24V (min. 20.4V,

max. 28.8V).

IMPORTANT FOR PRODUCT SAFETY: The Syncro³ version actuators in 24V

, wire GREEN if not used, must be insulated.

9.1.

Selection of power cable section

The following table indicates maximum cable lengths for connection to a single motors.

CABLE SECTION

0,50 mm²

0,75 mm²

1,00 mm²

1,50 mm²

2,50 mm²

4,00 mm²

6,00 mm²

10.

INSTRUCTIONS FOR ASSEMBLY

These indications are for specialised technical personnel and basic work and

techniques are not indicated.

All preparatory, assembly and electrical connection operations must be performed by

specialised technical personnel to guarantee optimal function and service of the actuator.

Check that the following fundamental condit

Before installing the actuator, check that the moving parts of the window on which

it is to be installed are in perfect working condition and that they open and close

properly and are well balanced (where applicable).

Actuator specifications must be sufficient for movement of the window without

encountering any

obstacle. The limits indicated in the technical data table must

not be superseded

(page 8)

Calculations should be checked using the formula indicated on page 5.

Attention.

Check that the electrical supply used corresponds to the indications on

the technical data plate on the machine and tha

is compatible with the installation site

Ensure that the actuator has not been damaged during transport.

Check

, once the actuator is installed, that the window is fully closed

For bottom hung window frames injury could be caused by accidental falls of the

window.

An appropriately sized flexible link arm or fall prevention safety system

designed to resist a force equal to at least three times the total weight of the

window MUST b

e installed.

10.1.

Preparation of actuator for assembly

Before starting assembly of the actuator, prepare the following material for completion,

equipments and tools.

For fixing onto metal window frames

headed metric screws

(6 pieces)

For fixing onto wooden window frames

For fixing onto PVC window frames

Equipment and tools

: measuring tape,

metal, insert for screwing in, electricians pliers, screwdrivers.

10

Selection of power cable section

The following table indicates maximum cable lengths for connection to a single motors.

Actuator fed at

24V 110V~

~20 m ~300 m

~30 m ~450 m

~40 m ~600 m

~60 m ~900 m

~100 m ~1500 m

~160 m ~2500 m

~240m ~3700 m

INSTRUCTIONS FOR ASSEMBLY

These indications are for specialised technical personnel and basic work and

techniques are not indicated.

All preparatory, assembly and electrical connection operations must be performed by

specialised technical personnel to guarantee optimal function and service of the actuator.

Check that the following fundamental condit

ions have been met:

Before installing the actuator, check that the moving parts of the window on which

it is to be installed are in perfect working condition and that they open and close

properly and are well balanced (where applicable).

Actuator specifications must be sufficient for movement of the window without

obstacle. The limits indicated in the technical data table must

(page 8)

and the most appropriate stroke should be selected.

Calculations should be checked using the formula indicated on page 5.

Check that the electrical supply used corresponds to the indications on

the technical data plate on the machine and tha

t the indicated temperature range

is compatible with the installation site

.

Ensure that the actuator has not been damaged during transport.

, once the actuator is installed, that the window is fully closed

For bottom hung window frames injury could be caused by accidental falls of the

An appropriately sized flexible link arm or fall prevention safety system

designed to resist a force equal to at least three times the total weight of the

e installed.

Preparation of actuator for assembly

Before starting assembly of the actuator, prepare the following material for completion,

For fixing onto metal window frames

: M5 threaded inserts

(6 pieces)

.

For fixing onto wooden window frames

: self threading screws for wood Ø4.5

For fixing onto PVC window frames

: self threading screws for metal Ø4.8

: measuring tape,

pencil, drill/screwdriver, set of drill heads for

metal, insert for screwing in, electricians pliers, screwdrivers.

The following table indicates maximum cable lengths for connection to a single motors.

230V~

~1400 m

~2100 m

~2800 m

~4000 m

~6800 m

~11000 m

~15000 m

These indications are for specialised technical personnel and basic work and

safety

All preparatory, assembly and electrical connection operations must be performed by

specialised technical personnel to guarantee optimal function and service of the actuator.

Before installing the actuator, check that the moving parts of the window on which

it is to be installed are in perfect working condition and that they open and close

Actuator specifications must be sufficient for movement of the window without

obstacle. The limits indicated in the technical data table must

and the most appropriate stroke should be selected.

Calculations should be checked using the formula indicated on page 5.

Check that the electrical supply used corresponds to the indications on

t the indicated temperature range

Ensure that the actuator has not been damaged during transport.

, once the actuator is installed, that the window is fully closed

.

For bottom hung window frames injury could be caused by accidental falls of the

An appropriately sized flexible link arm or fall prevention safety system

designed to resist a force equal to at least three times the total weight of the

Before starting assembly of the actuator, prepare the following material for completion,

: M5 threaded inserts

(6 pieces), M5x12 flat

: self threading screws for wood Ø4.5

(6 pieces).

: self threading screws for metal Ø4.8

(6 pieces).

pencil, drill/screwdriver, set of drill heads for

11

10.2. Calculation of the number of push / retention points

If the window has a width exceeding 120 cm, it is advisable to use several push / retention

points by assembling several actuators. The simple formula below allows you to calculate

the position of these points.

Formula:

The two side dimensions - LA : (PA x 2) = QL

The central dimensions - QL x 2

Legend:

LA = Window Sash Width (hinges side)

PA = Actuator Attachment Points

QL = Side Dimensions

Fig. 1 Fig. 2 Fig. 3 Fig. 3 bis

Fig. 4 Fig. 5 Fig. 5 bis Fig. 6

10.3. Assembly with outward opening window

A. Mark the centre line of the frame in pencil on both moveable and fixed parts (Fig. 1).

When more than one actuator is installed on the same window, mark as indicated in §

10.2 above.

B. Place the motor support bracket along the edge of the fixed part of the frame in line

with the centre line marked out previously and mark the positions for the four holes

for the fixing screws (Fig. 2).

C. Drill holes into the frame and screw in the motor support bracket, making sure that all

screws are fitted tightly (Fig. 3 and Fig. 3bis).

D. Line up the front bracket along the centre line on the moveable part of the frame and

mark out the holes required for the screws (Fig. 4).

E. Drill the holes and screw in the front bracket, making sure that all screws are fitted

tightly (Fig.5 and Fig. 5bis).

F. Take the clamp screws and connect them to the motor support bracket. Leave them

slack by at least two turns.

G. Insert the dove-tailed section of the actuator into the clamp screws. Make sure the

shaped part of the base fits neatly into the slot to ensure the actuator runs smoothly

along its axis (Fig. 6).

H. Now position the actuator so the eyebolt head is inserted into the front bracket

support. Insert the M6x25 screw into the bracket and into the eyebolt and tighten the

self-locking bolt with two 10 spanners.

12

I. Manually move the actuator along its axis to close the frame and make it weather

tight. Tighten the clamp screws previously only placed and set the actuator in line

with the frame. Suggested tightening torque is 4-5 Nm.

J. Plug the actuator in and carry out a test to check opening and closure of the frame.

Make sure the frame closes fully and is weather tight.

K. The limit switch for the actuator is automatic on re-entry. The equipment will exert a

pressure to guarantee even the largest of frames is completely weather tight.

10.4. Installation on domed rooflights, dormers or industrial skylights

To install the actuator on these types of windows, follow the instructions for “Installation on

awning windows” given in § 10.3 above.

10.5. Assembly with opening inwards

A. Mark the centre line of the frame in pencil on both moveable and fixed parts (Fig.1).

When more than one actuator is installed on the same window, mark as indicated in § 10.2

above.

B. Place the motor support bracket along the edge of the moveable part of the frame in

line with the centre line marked out previously and mark the positions for the four

holes for the fixing screws (Fig. 2).

C. Drill holes into the frame and screw in the motor support bracket, making sure that

all screws are fitted tightly (Fig. 3 and Fig. 3bis).

D. Line up the front bracket along the centre line on the fixed part of the frame and

mark out the holes required for the screws (Fig. 4).

E. Drill the holes and screw in the front bracket, making sure that all screws are fitted

tightly (Fig. 5 and Fig. 5bis).

F. Take the clamp screws and connect them to the motor support bracket. Leave them

slack by at least two turns.

G. Insert the dove-tailed section of the actuator into the clamp screws. Make sure the

shaped part of the base fits neatly into the slot to ensure the actuator runs smoothly

along its axis (Fig. 6).

H. Now position the actuator so the eyebolt head is inserted into the front bracket

support. Insert the M6x25 screw into the bracket and into the eyebolt and tighten the

self-locking bolt with two 10 spanners.

I. Manually move the actuator along its axis to close the frame and make it weather

tight. Tighten the clamp screws previously only placed and set the actuator in line

with the frame. Suggested tightening torque is 4-5 Nm.

J. Perform a complete opening and closing test on the window. When the closing

operation is completed, ensure that the window is properly closed by checking the

compression of the seals.

K. The stroke-end of the actuator during return is automatic. The device exerts traction to

ensure perfect compression of the seals.

13

10.6. Installing the actuator and rod (or transmission) with a connection bar

Skyro 850 actuators can be connected in tandem using a rod without a motor, by

means of a mechanical connection bar. The movement of one actuator is mechanically

linked to the rod in order to transmit motion in a uniform manner and at the same

speed.

Two or more actuators can be installed on the window frame, with one or more Syncro³

version motors, depending on the force requirements.

Assemble as follows:

A. Mark the assembly distance between centres for the two actuators out onto the

frame in accordance with the measurements in the above table.

B. Place the support brackets of the actuator into position, mark

out the holes for drilling, drill the frame and mount the brackets

(see “Assembly for outward opening windows” for details).

C. Place the front brackets into position, mark out the holes for

drilling, drill the frame and mount the front brackets (see

“Assembly for outward opening windows” for details).

D.

Mount the actuators

E. Mount the connection bar as follows:

Insert the connection bar first into one of the actuators, and then into the second

actuator. Make sure the bar protrudes at least 2 mm from each actuator

(Fig. 7).

Mount and screw the M8x14 mm flat headed screw

(provided with connection bar), into the two ends of the bar

to prevent the bar from slipping out.

DISTANCE BETWEEN THE CENTRES OF THE CONNECTION BARS

Code

Description

Length of bar

(mm)

“D”

distance between

centres

4010009 Connection bar 1000 mm length 1.035 1.000

4010010 Connection bar 1500 mm length 1.535 1.500

4010011 Connection bar 2000 mm length 2.035 2.000

4010011 Connection bar 2500 mm length 2.535 2.500

For special measurements, consult the manufacturer

The drawing below shows an installation example with various push point solutions, with

actuators and rods on a large window or on “strip” windows. It should be noted that up to a

maximum of 8 Syncro actuators (4 for 230V) can be fitted, with various rod solutions for

additional push points.

Fig. 7

Two or more Syncro³ version

motors in tandem

11.

ELECTRICAL CONNECTIONS

Appliances are equipped with cable manufactured in accordance with safety standards and

protection

against radio disturbances.

E

ACH ACTUATOR MODEL M

UST USE ITS OWN SPEC

Before performing the electrical connection consult the table below and check

correspondence between the feeder cable and the tension data on the actuator label.

Tension

Cable length

110-230V~ 50/60Hz

2 m

110-230V~ 50/60Hz

Syncro3

2,5 m

24V Syncro³

24V RWA

2 m

If feeder

cables require extending to the control button for low voltage actuators (24V

cable sections should be selected accordingly. Conductor sections are indicated in the

table on page 10 (

Selection of cable section)

IMPORTANT FOR PRODUCT SAFETY:

in 24V

actuators, wire Green if not used must be insulated.

14

Two or more Syncro³ version

Two or more Syncro³

version motors + 1 rod

with a connection bar in

tandem

One motor + 1 rod +

connection bar in tandem

ELECTRICAL CONNECTIONS

Appliances are equipped with cable manufactured in accordance with safety standards and

against radio disturbances.

UST USE ITS OWN SPEC

IFIC CABLE

.

Before performing the electrical connection consult the table below and check

correspondence between the feeder cable and the tension data on the actuator label.

Cable length

Number of

wires Wire colours

2 m

3

L

IGHT

B

LUE

B

LACK

B

ROWN

2,5 m

4

L

IGHT

B

LUE

B

LACK

B

ROWN

2 m

3 R

ED

B

LACK

cables require extending to the control button for low voltage actuators (24V

cable sections should be selected accordingly. Conductor sections are indicated in the

Selection of cable section)

.

IMPORTANT FOR PRODUCT SAFETY:

actuators, wire Green if not used must be insulated.

One motor + 1 rod +

connection bar in tandem

Appliances are equipped with cable manufactured in accordance with safety standards and

Before performing the electrical connection consult the table below and check

correspondence between the feeder cable and the tension data on the actuator label.

Colour of wires used

for notification

-

G

REEN

G

REEN

cables require extending to the control button for low voltage actuators (24V

),

cable sections should be selected accordingly. Conductor sections are indicated in the

actuators, wire Green if not used must be insulated.

15

11.1. Connections of SKYRO 850

For cabling, follow the diagrams below.

3

1 2 3

FN

100-230V~ 50/60Hz

1 2

110/230V ~

-+

24V

3

1

2

1 2 3

24V

11.2. Connections of SKYRO 850 Syncro³

Cable supplied together with the SYNCRO3 actuator is 2,5 m long for 230V~ Syncro³ version

and 2 m long for 24V Syncro³ version; it’s calculated in accordance with safety rules.

Electrical connection of the communication wires should be performed using a simple

appropriately sized bell clamp (supplied with the appliance). Secure connections with good

electrical contact (copper to copper) are vital to avoid communication disturbs.

Maximum length of feeding cables can be 10 m.

For cabling, follow the diagrams below.

3

4

1 2 3 4

FN

100-230V~ 50/60Hz

1 2

110/230V ~

SYNCRO

-+

24V

3

1

2

1 2 3

24V

SYNCRO

WARNING: after every limit switch or electronic protection device function the rack

will back track for around 1-2 mm in the opposite direction. This is quite normal, and

has been designed to release tension on mechanical parts and allow complete

weather proofing to enhance durability of mechanical parts.

12.

PROGRAMMING THE ACTUATOR

Once all electrical connections are completed, before putting the actuator into operational

use, the procedure for acquiring the operating parameters must first be performed; this

operation is known as R

ESET

.

The actuator has been individually tested in th

comes already programmed for the maximum opening stroke.

R

ESETTING

, or if the actuator loses its basic settings, the internal memory automatically

recognises and saves the install

between sash and frame.

The difference in height between the protruding part of the sash and the frame is known as

“overlay” (See § 12.3)

and in the acquisition phase it allows the actuator to acquire the

closing stroke-

end parameter.

or following a R

ESET

operation, and it

On the left side of

the gear reducer there is a screw cap that must be removed in order to

access the dip-

switch. Beside it there is also an LED indicator used to define errors and the

identifiers

of the various machines

Programming is quick and simple and can be done at an

With the dip-

switch set to

implemented and the stroke is memorised

With the dip-

switch set to

installation procedure and implements the operating parameters and stroke end

position.

IMPORTANT: If the K

-

actuator, a new R

ESET

Before starting the

R

connection with the K

-

12.1. R

ESET

procedure

The procedure is valid for configuring a single actuator, a Syncro³ array or when a K

LOCK electromechanical lock is installed

IMPORTANT

:

The dip

-

switch

after each change it is necessary to wait a few seconds (~ 5 sec) before restoring the

power to the actuators in order for the change to become effective

Set the dip-switch to OFF

. For configuration with multiple devices (or when a K

electric lock is installed) in which the

needs to be set for one actuator,

The actuator will start at

once (or after about 8 seconds if there is an electro

perform a full closing manoeuvre (

manoeuvre of about 5 cm.

the movement of the rack

to complete the procedure

.

When the operation is finished, each connected device gives a flashing orange signal to

indicate completion of the RESET procedure. Each device will give a different

flashes to indicate that the access code is received (actuator 1

flash

→ pause; actuator 2 → 2 flashes → pause → 2 flashes → pause, etc.)

16

PROGRAMMING THE ACTUATOR

Once all electrical connections are completed, before putting the actuator into operational

use, the procedure for acquiring the operating parameters must first be performed; this

The actuator has been individually tested in th

e factory, its operation is guaranteed and it

comes already programmed for the maximum opening stroke.

During initial installation or

, or if the actuator loses its basic settings, the internal memory automatically

recognises and saves the install

ation and operating parameters, including the distance

The difference in height between the protruding part of the sash and the frame is known as

and in the acquisition phase it allows the actuator to acquire the

end parameter.

This is seen the first time the device fully closes the window,

operation, and it

is saved as an operating parameter

the gear reducer there is a screw cap that must be removed in order to

switch. Beside it there is also an LED indicator used to define errors and the

of the various machines

.

Programming is quick and simple and can be done at an

y time.

switch set to

ON

, the actuator is operational, the parameters are

implemented and the stroke is memorised

.

switch set to

OFF

(1), the actuator performs the

installation procedure and implements the operating parameters and stroke end

-

Lock electro-

mechanical lock is fitted, even to only one

procedure must be performed.

R

ESET

procedure, it is advisable to check the electrical

-

LOCK.

The procedure is valid for configuring a single actuator, a Syncro³ array or when a K

LOCK electromechanical lock is installed

.

switch

settings should be changed to non

after each change it is necessary to wait a few seconds (~ 5 sec) before restoring the

power to the actuators in order for the change to become effective

. For configuration with multiple devices (or when a K

electric lock is installed) in which the

G

REEN

wires are connected, the dip

needs to be set for one actuator,

the other devices will link to it automatically

once (or after about 8 seconds if there is an electro

perform a full closing manoeuvre (

rack

completely retracted) and then an opening

manoeuvre of about 5 cm.

During this phase, ensure that there are no obstructions to

the movement of the rack

and, when using Syncro actuators, wait for all the machines

.

When the operation is finished, each connected device gives a flashing orange signal to

indicate completion of the RESET procedure. Each device will give a different

flashes to indicate that the access code is received (actuator 1

→ 1 flash → pause → 1

→ pause; actuator 2 → 2 flashes → pause → 2 flashes → pause, etc.)

Once all electrical connections are completed, before putting the actuator into operational

use, the procedure for acquiring the operating parameters must first be performed; this

e factory, its operation is guaranteed and it

During initial installation or

, or if the actuator loses its basic settings, the internal memory automatically

ation and operating parameters, including the distance

The difference in height between the protruding part of the sash and the frame is known as

and in the acquisition phase it allows the actuator to acquire the

This is seen the first time the device fully closes the window,

is saved as an operating parameter

.

the gear reducer there is a screw cap that must be removed in order to

switch. Beside it there is also an LED indicator used to define errors and the

, the actuator is operational, the parameters are

(1), the actuator performs the

R

ESET

or initial

installation procedure and implements the operating parameters and stroke end

mechanical lock is fitted, even to only one

procedure, it is advisable to check the electrical

The procedure is valid for configuring a single actuator, a Syncro³ array or when a K

-

settings should be changed to non

-

powered actuators;

after each change it is necessary to wait a few seconds (~ 5 sec) before restoring the

power to the actuators in order for the change to become effective

.

. For configuration with multiple devices (or when a K

-LOCK

wires are connected, the dip

-switch only

the other devices will link to it automatically

once (or after about 8 seconds if there is an electro

-lock) and

completely retracted) and then an opening

During this phase, ensure that there are no obstructions to

and, when using Syncro actuators, wait for all the machines

When the operation is finished, each connected device gives a flashing orange signal to

indicate completion of the RESET procedure. Each device will give a different

number of

→ 1 flash → pause → 1

→ pause; actuator 2 → 2 flashes → pause → 2 flashes → pause, etc.)

.

The power supply to the devices can now be switched off.

The opening stroke

(outward

stroke)

or can be customised as required; this is decided at this stage

Command the actuator to

desired position (stroke customisation). The point at which the command is stopped will

be the outward stroke-

end position.

as the

O

PENING

stroke end

the same point.

If the window does not open to the desired position, repeat the

If the K-LOCK electro-

lock is present, refer to the respective user and installation

manual.

12.2. Closing stroke-

end

There are two options for the opening stroke end

stroke

(factory default)

, which depends on the length of the rod, or

programming the desired stroke

The closing stroke end

(rack return travel)

stops due to the power absorption it encounters when the rack reaches complete closure

of the window, with the seals fully compressed, or when the power absorbed exceeds a

threshold set i

n the microprocessor

CAUTION:

After each closure or activation of the electronic protection, the rack

moves slightly in the opposite direction, to allow the right compression of the seals

and/or to relax the internal mechanical components of the actuato

After programming the stroke end positions, it is recommended to check the opening and

closing of the window a few times. In the case of error, the programming can be repeated

to achieve the desired stroke. If you need to perform the

instructions given above.

12.3.

Overlap acquisition

The operation that must be carried out to acquire the overlap (after the

has already been executed) is described below:

-

The steps for installing the actuator/s on the window and the electrical connections

have already been explained (see § 10 and

-

Use the controls to open the window a few centimetres

-

Use the controls to close the window up to the stroke end

- When the w

indow is completely closed, if acquisition of the overlap is successful, the

actuator will display an orange flashing light for 3 seconds

IMPORTANT:

If, for any reason, the actuator fails to complete the closure of

the window correctly, stopping before finishing the stroke, the

overlap acquisition operation will have to be repeated in that order, until the

procedure is completed correctly

17

The power supply to the devices can now be switched off.

(outward

rack movement)

may be left as set in the factory

or can be customised as required; this is decided at this stage

Command the actuator to

O

PEN

,

without interrupting the command

desired position (stroke customisation). The point at which the command is stopped will

end position.

This outward distance will be saved and used

stroke end

. With Syncro³ actuators, they will move in sync a

If the window does not open to the desired position, repeat the

R

lock is present, refer to the respective user and installation

end

There are two options for the opening stroke end

(outward rack travel)

, which depends on the length of the rod, or

programming the desired stroke

(see §12.1).

(rack return travel)

is automatic and not programmable. The actuator

stops due to the power absorption it encounters when the rack reaches complete closure

of the window, with the seals fully compressed, or when the power absorbed exceeds a

n the microprocessor

.

After each closure or activation of the electronic protection, the rack

moves slightly in the opposite direction, to allow the right compression of the seals

and/or to relax the internal mechanical components of the actuato

After programming the stroke end positions, it is recommended to check the opening and

closing of the window a few times. In the case of error, the programming can be repeated

to achieve the desired stroke. If you need to perform the

R

ESET

Overlap acquisition

The operation that must be carried out to acquire the overlap (after the

has already been executed) is described below:

The steps for installing the actuator/s on the window and the electrical connections

have already been explained (see § 10 and

11).

Use the controls to open the window a few centimetres

.

Use the controls to close the window up to the stroke end

.

indow is completely closed, if acquisition of the overlap is successful, the

actuator will display an orange flashing light for 3 seconds

.

If, for any reason, the actuator fails to complete the closure of

the window correctly, stopping before finishing the stroke, the

overlap acquisition operation will have to be repeated in that order, until the

procedure is completed correctly

may be left as set in the factory

(maximum

or can be customised as required; this is decided at this stage

.

without interrupting the command

, up to the

desired position (stroke customisation). The point at which the command is stopped will

This outward distance will be saved and used

. With Syncro³ actuators, they will move in sync a

nd stop at

R

ESET

procedure.

lock is present, refer to the respective user and installation

(outward rack travel)

of the actuator: full

, which depends on the length of the rod, or

R

ESETTING

and

is automatic and not programmable. The actuator

stops due to the power absorption it encounters when the rack reaches complete closure

of the window, with the seals fully compressed, or when the power absorbed exceeds a

After each closure or activation of the electronic protection, the rack

moves slightly in the opposite direction, to allow the right compression of the seals

and/or to relax the internal mechanical components of the actuato

r.

After programming the stroke end positions, it is recommended to check the opening and

closing of the window a few times. In the case of error, the programming can be repeated

ESET

procedure, see the

The operation that must be carried out to acquire the overlap (after the

RESET procedure

The steps for installing the actuator/s on the window and the electrical connections

indow is completely closed, if acquisition of the overlap is successful, the

If, for any reason, the actuator fails to complete the closure of

the window correctly, stopping before finishing the stroke, the

RESET and

overlap acquisition operation will have to be repeated in that order, until the

12.4. LED Light signals

If there are any problems during installation or operation of the machines, consult the

possible causes listed below:

The LED can be seen on the cap that conceals the dip

positioned to the left of the gear reducer, and has three

R

ED

,

indicates an error or malfunction;

G

REEN

,

operation is OK

O

RANGE

,

wait: functions in progress

Number

of

Flashes

Type of Error

1 Current error:

The actuator has detected an

overcurrent in the motor.

2

Communication error:

Communication between the devices

is interrupted, or the devices being

used have undergone the

procedure separately

3 Electro-lock error

4

Discordant internal setting:

The internal setting of the actuators

is discordant.

5

RESET Procedure error:

The R

ESET

procedure was not

completed successfully or was

interrupted.

6

Wiring error:

The power supply cables of the

devices configured in Syncro³ are

inverted.

7

Encoder error:

The internal encoder had a

counting error

8

Electric power supply error:

The power supply voltage is outside

the permitted range or is unstable.

9

Alignment error:

The rack position displacement of

the actuators connected in Syncro

is beyond the permitted maximum.

10 Memory error:

The internal

memory write

process failed.

11

Connection error:

A RESET procedure is being

started with actuators different than

Syncro³

18

If there are any problems during installation or operation of the machines, consult the

The LED can be seen on the cap that conceals the dip

-switch,

positioned to the left of the gear reducer, and has three

colours:

indicates an error or malfunction;

operation is OK

;

wait: functions in progress

.

WITH RED LED

Type of Error

Possible Solution

The actuator has detected an

overcurrent in the motor.

Check

that there are no obstacles preventing

the actuator from completing its stroke. Check

that the actuator is installed correctly.

Communication error:

Communication between the devices

is interrupted, or the devices being

used have undergone the

R

ESET

procedure separately

Check the condition of the connection cables,

and repeat the R

ESET

procedure if necessary.

Check the electro-

lock.

manual

Discordant internal setting:

The internal setting of the actuators

Repeat the

R

ESET

procedure

RESET Procedure error:

procedure was not

completed successfully or was

Repeat the

R

ESET

procedure

The power supply cables of the

devices configured in Syncro³ are

Check and correct the wiring.

The internal encoder had a

Repeat the

R

ESET

procedure

Electric power supply error:

The power supply voltage is outside

the permitted range or is unstable.

Check the electrical contacts at

actuator cable and ensure that the power

supply is correct.

The rack position displacement of

the actuators connected in Syncro

is beyond the permitted maximum.

Repeat the

R

ESET

procedure

memory write

Repeat the

R

ESET

procedure

A RESET procedure is being

started with actuators different than