Heatwagon VF400 Manual

Installation and Maintenance Manual

Please retain this manual for future reference.

342 N. Co. Rd. 400 East

Valparaiso, IN 46383

888-432-8924 • Fax 219-462-7985

www.heatwagon.com

Revision 12-16

CAUTION: Do not use this heater in a

space where gasoline or other liquids

having lammable vapors are stored.

Construction

Heater

VF400

C US

Dept. of Buildings

29-05-E

I PORTANT INFOR ATION! READ FIRST

The heater is designed for use as a construction heater under CSA-B140.8-1967 (General

Requirements For Oil Burning Equipment) and UL-733 (Oil Fired Heaters and Direct Fired

Heaters). Heater is not intended for use in pest remediation. The primary purpose of construc-

tion heaters is to provide temporary heating of buildings under construction, alteration, or repair

and to provide emergency heat. Properly used, the heater provides safe, economical heating.

Products of combustion are vented outside the area being heated.

Use of the heater must be in accordance with this Standard and in compliance with all governing

state and local codes.

We cannot anticipate every use which may be made for our heaters. CHECK WITH YOUR

LOCAL FIRE SAFETY AUTHORITY IF YOU HAVE QUESTIONS ABOUT LOCAL REGULATIONS.

Other standards govern the use of fuel gases and heat producing products in specific applica-

tions. Your local authority can advise you about these.

FOR YOUR SAFETY

DO NOT USE THIS HEATER IN A SPACE WHERE GASOLINE OR OTHER LIQ-

UIDS HAVING FLA ABLE VAPORS ARE STORED OR USED.

CONSTRUCTION HEATER GENERAL HAZARD WARNING:

Failure to comply with the precautions and instructions provided with this heater, can

result in death, serious bodily injury and property loss or damage from hazards of

fire, explosion, burn, asphyxiation, carbon monoxide poisoning, and/or electrical

shock.

Only persons who can understand and follow the instructions should use or service

this heater.

If you need assistance or heater information such as an instruction manual, labels,

etc., contact your local Heat Wagon dealer or the manufacturer.

W A R N I N G

Fire, burn, inhalation, and explosion hazard. Keep solid combustibles, such as build-

ing materials, paper or cardboard, a safe distance away from the heater as recom-

mended by the instructions. Never use the heater in spaces which do or may contain

volatile or airborne combustibles, or products such as gasoline, solvents, paint thin-

ner, dust particles or unknown chemicals.

Not for home or recreational vehicle use!

If you have read this entire manual and you still have ques-

tions, please call us at 219-464-8818

Table of Contents:

Page

Safety & Caution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Operating nstructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

llustrated Parts Breakdown . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Wiring Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Exhaust Flue Pipe Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Installation and Maintenance Manual

Model VF400

Construction Heater

342 N. Co. Rd. 400 East • Val araiso, IN 46383

219-464-8818 • 888-432-8924 • Fax 800-255-7985

www.heatwagon.com

WARRANTY

All new Heat Wagon and Sure Flame heaters and fans are guaranteed against defective materials and workman-

ship for one (1) year from Heat Wagon invoice date.

Warranty repairs may be made only by an authorized, trained and certified Heat Wagon dealer. Warranty repairs

by other entities will not be considered. Warranty claims must include model number and serial number.

Components are guaranteed to the extent of the components manufacturer’s warranty.

LI ITATIONS

Warranty claims for service parts (wear parts) such as spark plugs, igniters, filters, nozzles, and flame rods will not

be allowed. Diagnostic parts such as voltage meters and pressure gauges are not warrantable. Evidence of improp-

er fuel usage, fuel pressures outside of manufacturer’s specification, poor fuel quality, and improper electric power,

misapplication or evidence of abuse may be cause for rejection of warranty claims.

Labor, travel time, mileage and shipping charges will not be allowed. Minor adjustments of heaters are dealers’

responsibility. Defective parts must be tagged and held for possible return to the factory for 60 days from date of

repair. The factory will provide a return goods authorization, (RGA) for defective parts to be returned. No war-

ranty will be allowed for parts not purchased from Heat Wagon.

SAFETY & CAUTION

• nstructions given in this manual and the applicable regulation of the local authorities

must be followed.

• The unit may be operated only by those persons who have been instructed in it’s use.

• The unit is to be installed and operated in such a way as to ensure safety of employees and

surroundings.

• Never cover the unit’s air openings.

• Always secure an adequate fresh air supply to the unit.

• Never stand in front of the discharge end of the heater.

• Do not introduce foreign objects into the unit.

• Do not expose the unit to direct water jets.

• All electric cables outside the unit are to be protected against damage.

• Always disconnect the unit from power supply when maintenance or service is being

performed.

• IF NOT OPERATED WITHIN GUIDELINES OF THESE OPERATING INSTRUCTIONS

ANUFACTURER WILL NOT BE HELD RESPONSIBLE AND WARRANTY

WILL BECO E VOID.

4

SPECIFICATIONS

odel No. VF400

Fuels: #1 or #2 Kerosene, Diesel, Heating Fuel

Capacity: 400,000 BTU/HR

Blower: 2,100 CFM 1/2” SP

Electrical Rating: 120 Volts, 10 Amps

Fuel Consumption: 3 GPH Max

Remote Thermostat: On/Off

Max. Discharge Temp.: 200ºF @ 0ºF Ambient

Duct Size: 12” Dia., 50 ft. max (straight), temp rating 300ºF min.

Weight (approximate): 400 lbs.

Fuel Supply: anifold Pressure (Fuel Pump) Burner Nozzle

110 psi 3 GPH x 80A

OPERATING INSTRUCTIONS

INSTALLATION

• When transporting, use both lifting eyes located on sides of heater.

• Place the unit on a level and non-combustible surface.

• Minimum clearances from combustible materials for indoor or outdoor installation on

combustible flooring:

- outlet, minimum 10 feet

- sides, minimum 3 feet

- top, minimum 3 feet

- flue pipe exhaust, gas discharge minimum 2 feet

• Manufacturer recommends a free zone of 5 feet around the unit and a minimum distance of 10

feet at the unit’s flue gas openings are to be maintained.

• f the unit is placed indoors, secure an adequate fresh air opening for the burner combustion air.

• The unit may not be installed and operated in premises where explosive or combustible fumes

or dust are present. Check the regulation of local authorities, when necessary.

• Make sure that neither the air inlet nor the air outlet is obstructed.

FUEL SUPPLY

• This heater will burn kerosene (#1 or #2), diesel fuel (#1 or #2), and heating fuel (#1 or #2). t is

highly recommended to use winterized fuel with ambient temperatures less than 20ºF and to

also install optional circulation or fuel tank heaters.

• The installation of this heater must comply with all applicable local codes.

• Check and clean fuel filter (if necessary) on a weekly schedule.

ELECTRICAL

• Electric cable extensions must be connected based on the unit capacity and cable length.

• Connect unit to a power supply with a suitable appliance receptacle (15 Amp).

• Confirm voltage at heater connection (105V min.) to ensure proper operation.

EXHAUST FLUE PIPE

• The unit is to be connected to a flue pipe with adequate draft, to ensure the proper start and

operation of the unit. Refer to page 16.

• The flue pipe is to be made of non-combustible material and clearances from combustible

materials must be a minimum 8 inches (temperature of flue gases is approximately 410º F).

• The flue pipe and its installation must comply with the regulations and instructions given by

the local authorities.

5

START UP

• Only people who are trained in the operation and supervision of this heater should operate

and maintain the unit.

• Check the unit to make sure that there are no visible defects on the control and safety devices

and that the unit has been installed correctly.

1. Check that the control switch on the control box is in position “0” (STOP).

2. Pre-select desired room temperature on the room thermostat. The temperature must be set

higher than the ambient temperature.

3. Turn the control switch in control box to position “1” (HEAT NG).

4. When the ambient temperature level is low, the burner switches on automatically. The fan

does not switch on until the set temperature (104ºF) of the heat-exchanger has been

reached (will take approximately 1-5 minutes).

• After starting, the unit runs fully automatically with the pre-selected room temperature

thermostat and it is controlled by its own control devices and safety limit controls.

• The room thermostat (TSTAT) and burner sensor control the running sequences of the

burner and the fan sensor controls the fan function.

• Overheat limit reset (STB) controls and shuts off the heater (burner) in the case of overheating.

• The unit can also be used for ventilation purposes only, if needed.

1. Turn the control switch on the control box to position “2” (VENT LAT ON).

2. The unit is now in the continuous ventilating mode.

3. Heating is not possible in this mode.

DUCTING (Warm Air)

• Clearness from combustible materials have to be a minimum of 4 inches.

• Use steel ducting or fabric ducting capable of withstanding a minimum temperature of 300ºF.

• Maximum length of duct: 50’ (straight).

• Duct diameter: 12”.

• Make sure that the duct is safely and properly fastened to the outlet.

• Avoid sharp bends and corners to ensure maximum air flow and avoid back pressure/heat

accumulation in heater.

• FA LURE TO COMPLY W TH THESE RECOMMENDAT ONS COULD RESULT N SHUTDOWN

OF THE HEATER.

SHUT DOWN

• Turn control switch to position “0” (STOP).

WARNING!

UNIT AY BE UNPLUGGED IN E ERGENCY SITUATIONS ONLY. OTHERWISE, DO NOT

STOP THE UNIT BY UNPLUGGING IT. UNIT NEEDS TO COOL DOWN USING ITS OWN

FAN. FAILURE TO CO PLY WITH PROPER SHUT-DOWN PROCEDURES CAN CAUSE

DA AGE TO THE CO BUSTION CHA BER, HEAT EXCHANGER, SAFETY FEATURES AND

ALSO VOID WARRANTY.

6

mportant!

The air supply fan continues running

to cool down the combustion

chamber/heat exchanger and then

stops later. The fan can restart for

several times before finally switching off!

AINTENANCE

Prior to starting any maintenance work, wait until unit cools down fully and fan shuts off

before unplugging unit and beginning any maintenance work.

(Shut Down Procedures page 6)

To ensure the proper function of the unit, it must be serviced on regular basis. Maintenance can

be performed, (excluding the control devices and safety limit controls), by an authorized trained &

certified Heat Wagon dealer. The control devices and safety limit controls do not need routine

maintenance. f these items fail they must be replaced.

- Do not use any aggressive cleaning agents (which are harmful or environmentally

unfriendly), when cleaning the unit.

- Do not use water jet when cleaning the unit.

- Pressurized air may be used for maintenance. Be careful not to damage the fan blower wheel

with too much pressure.

- Check whether the unit is free from mechanical damage. Replace faulty parts as necessary.

- Check fan blower wheel at regular intervals and clean it when needed.

- Check functionality of control and safety devices regularly.

- Have the flue gas values of the burner checked regularly by authorized agents.

- Be sure to store the unit in a dust free and dry place when it is not used for a long period of

time. Cover the exhaust flue to prevent entry of foreign objects.

SERVICE

• The complete unit, including heat exchanger, combustion chamber and burner should be

cleaned from dust and dirt after every heating period, at a minimum of once per year.

-Removal of combustion chamber/heat exchanger:

For proper cleaning of the unit, manufacturer recommends removal of the complete

combustion chamber with heat exchanger. Clean combustion chamber and heat exchanger tube

with a brush. Vacuum all loose ash and soot. Close all cleaning flanges carefully to avoid damage

to gasket material.

-Disassembling of burner:

1. Disassemble four tightening bolts on the combustion chamber flange and remove burner’s

mounting flange. Take care not to damage the flange seal.

2. Pull out the burner. Take care not to damage the burner head and power cable. Clean blower

wheel, ignitor electrodes, and photocell. Replace fuel nozzle and fuel filter.

Refer to seperate burner manual for adjustment of burner.

7

1. Turn the

heater to

position #1

and nothing

happens.

2. The heater

runs for a little

while, but

shuts down. It

won’t come on

again until the

limit switch is

reset.

• ower supply cord

• Burner reset button on the burner flame

safeguard control box is tripped

• Overheat limit switch is tripped

• Burner sensor

• Heater control unit (HCU)

• Burner nozzle is improperly sized

• Incorrect burner fuel pump pressure

• Restricted airflow

• Overheat limit switch

• Test for 120 volts between L1 and L2 on the main terminal block.

• Reset the button on the flame safeguard control.

• Reset the switch, which is on the side of the heater near the warm air outlet.

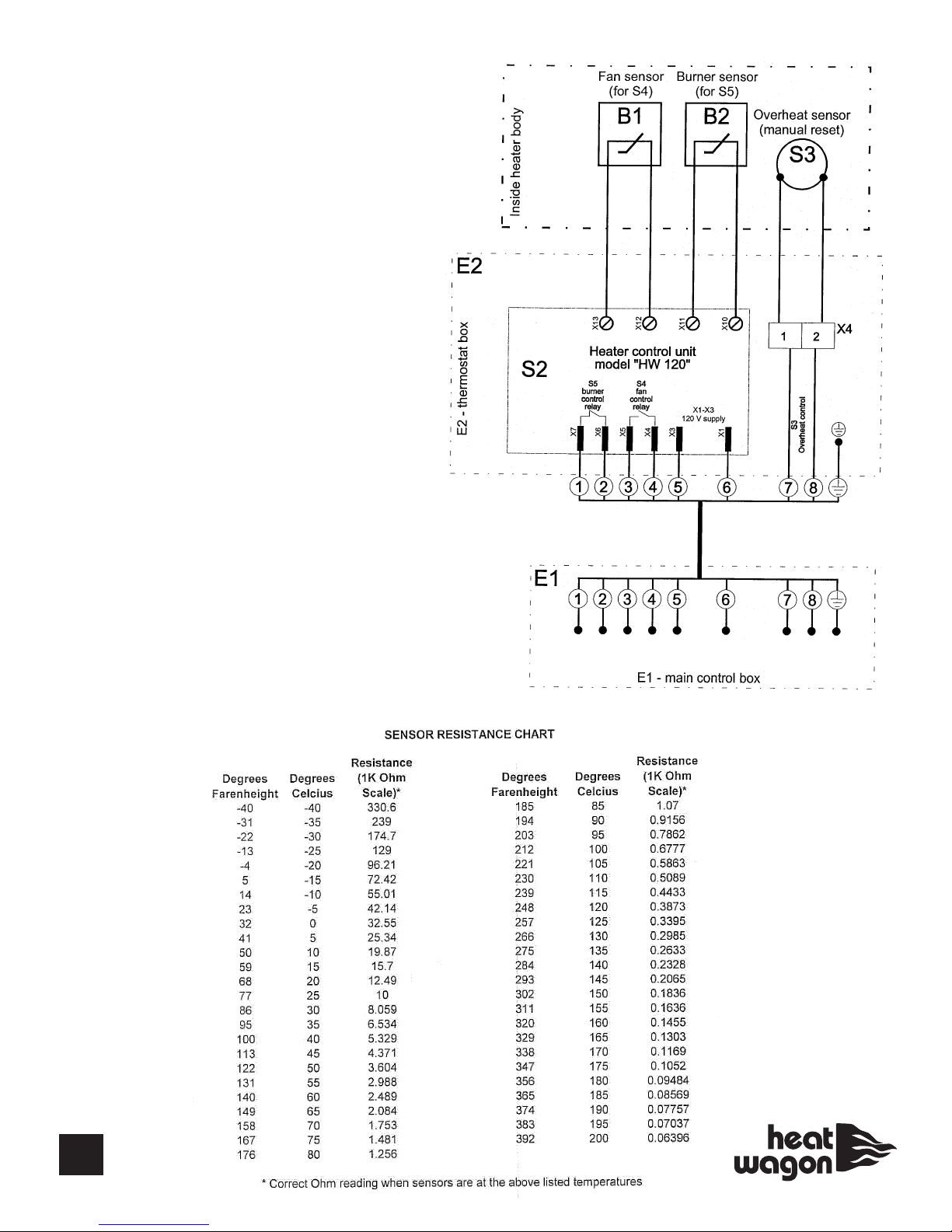

• On the heater control unit (HCU) disconnect the wires from terminals X10 and

X11. Using an ohm meter, check the resistance between the two wires using

the 1K ohms chart on page 16.

• On the main terminal block, check for 120 volts between terminals 8 and N when

the 3-position switch is in the HEAT position.

• Nozzle is 3 G H x 80º A.

• Use a high pressure gauge (160 SI) with a 1/8” N T inlet. Install gauge in the

pressure tap port located on the top of the fuel pump. Run the unit and adjust

the manifold pressure by turning the pressure adjusting screw (on the right hand

side of the fuel pump) in or out until the gauge reads 110 SI.

• Check for dirt or ice buildup on the air inlet or blower wheel. If using duct on the

air outlet, insure the back pressure does not exceed a static pressure of .5” W.C.

• Adhere to the proper shut down procedures. ower must remain at the unit until

it cools down fully. Blower will shut down on its own when cool. Test overheat

limit switch for continuity between the two male terminals at room temperature.

Replace if overheat limit switch fails test.

VF400 TROUBLESHOOTING

Symptom Possible Causes Possible Solutions

8

9

3. I get the

burner motor

to come on,

but the heater

won’t ignite.

4. The heater

has a loud

rumbling

sound.

• Fuel pressure or volume

• Air inlet damper adjustment

• Ignition electrodes

• Electronic igniter

• Solenoid valve

• Air damper setting

• Dirt on burner blower wheel

• Flue pipe setup or flue pipe

restrictions

• Fuel pump pressure

• Fuel nozzle size

• Restricted heat exchanger

• Use a high pressure gauge (160 SI) with 1/8” N T inlet. Install gauge in the

gauge port located on top of the fuel pump. Run the heater. Adjust the

pressure by turning the pressure adjusting screw (located on the right hand side

of the fuel pump) counter clockwise until the gauge reads 110 SI.

• Rough setting at 6.75 open. Minor adjustments from the rough settings can be

made to achieve a smooth sounding burner with no soot from the flue pipe.

• Clean with fine sandpaper. Make sure it is free from buildup or cracks.

• Disconnect fuel solenoid valves and turn on the burner. ull the igniter (using

insulated pliers) away from the electrodes slowly. A rainbow colored arc should

travel between the igniter and electrode bus bars at a distance of 3/8 of an inch

for a duration of 4-5 seconds.

• If there is power at the flame safeguard control and no power out to the

solenoid valves, replace the flame safeguard control. Check for continuity

between the wires on the solenoid valve coil.

• Rough setting at 6.75 open on scale. Minor adjustments from the rough

settings can be made to achieve a smooth sounding burner with no soot from

the flue pipe.

• Clean the burner blower wheel with a small brush.

• Refer to the flue pipe chart in this manual. Check flue for restriction.

• Use a high pressure gauge (0-160 SI) with 1/8” N T inlet. Install gauge in the

gauge port located on top of the fuel pump. Run the heater. Adjust the

pressure by turning the pressure adjusting screw (located on the right hand side

of the fuel pump) counter clockwise until the gauge reads 110 SI .

• Nozzle is 3 G H x 80º A.

• Refer to the cleaning instructions in this manual.

VF400 TROUBLESHOOTING

Symptom Possible Causes Possible Solutions

10

5. The heater

blows black

smoke out of

the vent stack.

6. The burner

seems to

cycle on and

off more than

what it should.

• Air damper setting

• Dirt on burner blower wheel

• Flue pipe setup or flue pipe

restrictions

• Fuel pump pressure

• Restricted fuel filter

• Incorrect fuel nozzle size

• Restricted heat exchanger

• Fuel pump pressure

• Restricted fuel filter

• Dirt on main air blower or improper setup

of outlet air duct

• Burner sensor

• Heater Control Unit (HCU)

• Rough setting at 6.75 open on scale. Minor adjustments from the rough

settings can be made to achieve a smooth sounding burner with no soot from

the flue pipe.

• Clean the burner blower wheel with a small brush.

• Refer to the flue pipe chart in this manual. Check flue for restriction.

• Use a high pressure gauge (0-160 SI) with 1/8” N T inlet. Install gauge in the

gauge port located on top of the fuel pump. Run the heater. Adjust the

pressure by turning the pressure adjusting screw (located on the right hand side

of the fuel pump) counter clockwise until the gauge reads 110 SI.

• Clean or replace fuel filter.

• Nozzle is 3 G H x 80º A.

• Refer to the cleaning instructions in this manual.

• Use a high pressure gauge (0-160 SI) with 1/8” N T inlet. Install gauge in the

gauge port located on top of the fuel pump. Run the heater. Adjust the

pressure by turning the pressure adjusting screw (located on the right hand side

of the fuel pump) counter clockwise until the gauge reads 110 SI.

• Clean or replace fuel filter.

• Check for dirt or ice buildup on the air inlet or blower wheel. If using duct on

the air outlet, insure the back pressure does not exceed a static pressure of

.5” WC.

• On the heater control unit (HCU) disconnect the wires from terminals X10 and

X11. Using an ohm meter, check the resistance between the two wires using

the 1K ohms chart on page 16.

• If all of the above check good, replace the HCU.

VF400 TROUBLESHOOTING

Symptom Possible Causes Possible Solutions

11

7. The burner

starts, but the

main fan

never comes

on.

8. The burner

continues to

run, but the

fan cycles on

and off.

• Fan sensor

• Heater Control Unit (HCU)

• Blower motor relay

• Blower motor

• Fuel pump pressure

• Fan sensor

• Heater Control Unit (HCU)

• On the heater control unit (HCU) disconnect the wires from terminals X12 and

X13. Using an ohm meter, check the resistance between the two wires using

the 1K ohms chart on page 16.

• Turn the 3-position main switch to the fan position. If the blower runs, check the

fan sensor. If it is good, replace the HCU.

• Turn the 3-position main switch to the fan position. If the relay pulls in, check

for voltage between the L1 and L2 terminals. Then check the voltage between

terminals T1 and T2. The voltage should be the same. If it is much lower,

replace the relay.

• Turn the 3-position main switch to the fan position. Check for voltage between

terminals T1 and T2 on the motor relay. If the voltage is good, replace the

motor.

• Use a high pressure gauge (0-160 SI) with 1/8” N T inlet. Install gauge in the

pressure tap port located on top of the fuel pump. Run the heater. Adjust the

pressure by turning the pressure adjusting screw (located on the right hand side

of the fuel pump) until the gauge reads 110 SI.

• On the heater control unit (HCU), disconnect the wires from terminals X12 and

X13. Using an ohm meter, check the resistance between the two wires using

the 1K ohms chart on page 16.

• Turn the 3-position main switch to the fan position. If the blower runs, check the

fan sensor. If it is good, replace the HCU.

VF400 TROUBLESHOOTING

Symptom Possible Causes Possible Solutions

12

Heat Wagon VF400 Parts List

ITE PART# DESCRIPTION

1 HWP 2109001 HEATER FRAME

2 HWP 2109002 COVER PLATE

3 HWP 2109003 S DE PANELS (2)

4 HWP 2109004 REAR HANDLE

5 HWP 2109005 BOTTOM PLATE

6 HWP 2109006 FLUE COLLAR

7 HWP HW1065 WHEEL (2)

8 HWP 2109008 WHEEL SHAFT

9 HWP 2109009 BURNER CHAMBER ASSEMBLY

10 HWP 2109010 FAN GUARD, LEFT

11 HWP 2109011 FAN GUARD, R GHT

12 HWP 12440 FAN, COMPLETE

13 HWP 40900 NLA

14 HWP 2109014 FORKL FT EYE

15 HWP 120008 BURNER VF400

16 HWP 2109016 BURNER COVER

17 HWP 211153 O L PREHEAT CO L

18 HWP 120009 O L F LTER-COMPLETE

19 HWP 120004 O L WAND

20 HWP 120005 O L WAND HOLDER

21 HWP 120020 O L HOSE (2 PCS.)

22 HWP 41000 MA N CONTROL BOX

23 HWP 2109023 BRACKET, MA N CONTROL BOX

24 HWP 120021 MA N SW TCH

25 HWP 21800 OVERHEAT L M T SW TCH

25A HWP 21800 OVERHEAT L M T SW TCH(bimetallic)

25B HWP 21400** OVERHEAT L M T (CAP LLARY)

ITE PART# DESCRIPTION

26 HWP 40850 THERMOSTAT BOX

27 HWP 20579 HEATER CONTROL UN T

28A HWP 20581 FAN SENSOR (FOR POS. #27), 4” TUBE

28B HWP 20583 FAN SENSOR, 9” TUBE

29 HWP 20582 BURNER SENSOR (POS. #27)

30 HWP HC1020 POWER CORD & PLUG

NOT SHOWN N D AGRAM

SFP 2436 CONTACTOR

HWP 46950 CAPAC TOR

HWP 80200 POWER CORD & PLUG (2 PCS.)

HWP 2109031 RAD AT ON SH ELD (UPPER)

HWP 12000 SMOKE FLUE W/RA N CAP

SFP 2453 REMOTE THERMOSTAT

HWP 100428 BURNER GASKET

HWP 21724011 FLANGE ADJ. FOR 12008

HWP 40850SS S L CONE SEAL - 40850 THERM. BOX

HWP 210047 RUBBER EDGE SEAL (SOLD PER FOOT)

(30 FEET PER HEATER)

HWP 180036 K T TO CHANGE OVERHEAT L M T

HWP 65900 RESTRA NT FOR SENSORS

HWP 12009B ELEMENT W/RUBBER GASKET

HWP HV1060 0-300 PS L QU D F LLED GAUGE

HWP F102GG1 BLOWER MOTOR SUPPORT

HWP SP12440 MOTOR FOR 12440 FAN ASSY.

HWP 180036 H GH L M T CHANGEOVER K T

SFP 2436 CONTACTOR, MOTOR START NG RELAY

ACC WD1225 OPT ONAL DUCT 12”x25’

18

Also see Control Box Parts page 16.

**Note: Overheat limit switch - New design (capillary tube)

S/N M2728-2746, M4769 and greater

25A

25B

28A

28B

25B (Reset)

13

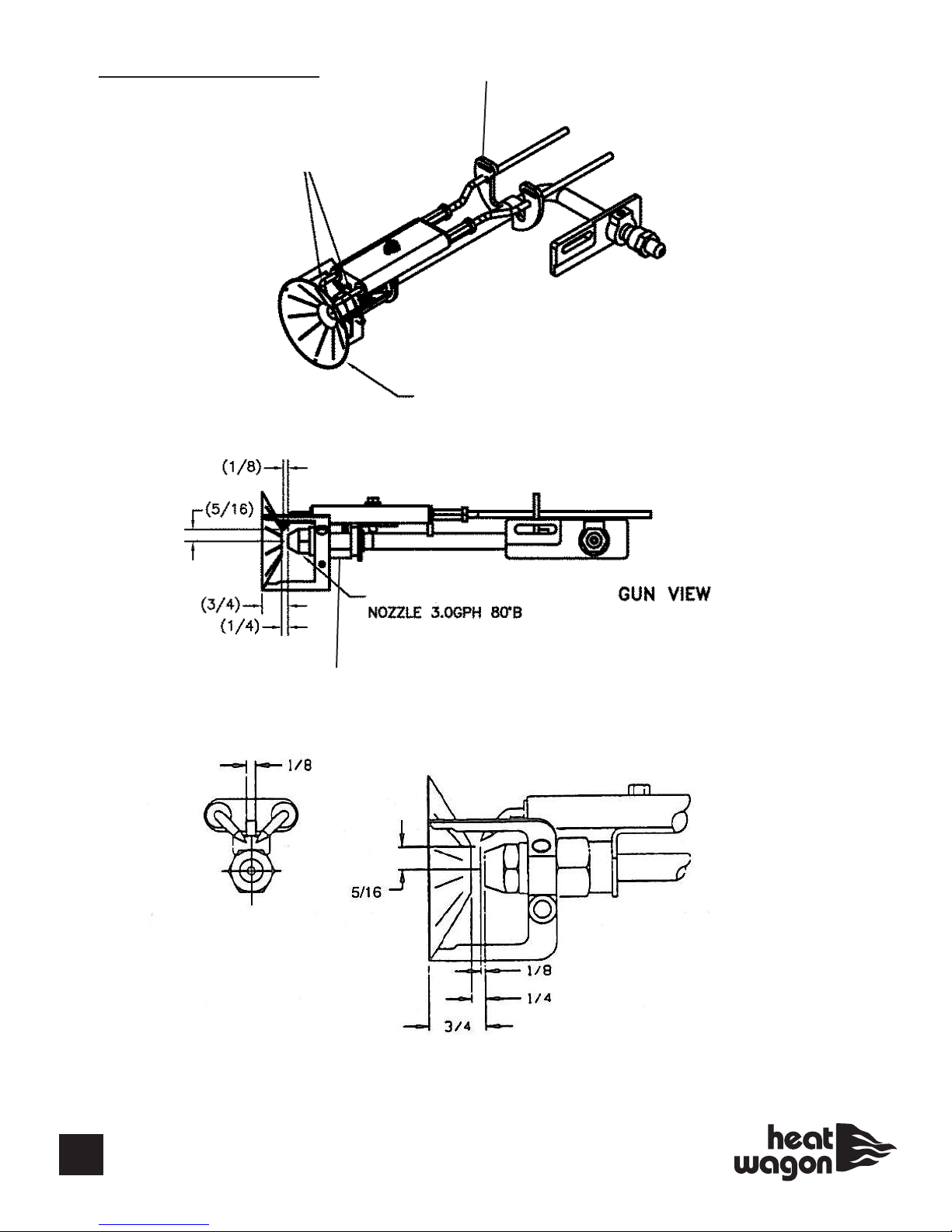

WAYNE BURNER

PARTS BREAKDOWN

pg. 14

HW 100926013

Gun Assembly

See Gun View

HW 20627

120V Motor

HW 21642

Blower Wheel

HW 100386

Coupling

HW 100386

Coupling

31946-003

Tube/Flange

HW 100531-001

Air Cone

HW 13495

Fuel ump

HW 63266013

Static Baffle 30º

12” Setting

HW 13666

Cad Cell

Fan Setting G2038

EX LODED VIEW

EX LODED VIEW

HW 21659

Ignition Transformer

HW 13077

rimary Control

15 Sec.

Flame Safeguard

Control

HW 14409

Kip Oil Valve

ASSEMBLED VIEW

14

ELECTRODE SETTING

HW 21684 - Electrodes, 2 iece Set

HW 100989061 - 1 iece Electrode

HW 13276 - Buss Bar Support

HW 100393-001

Flamelock Assembly

HW 32101

HW 12362 - Nozzle Adapter

15

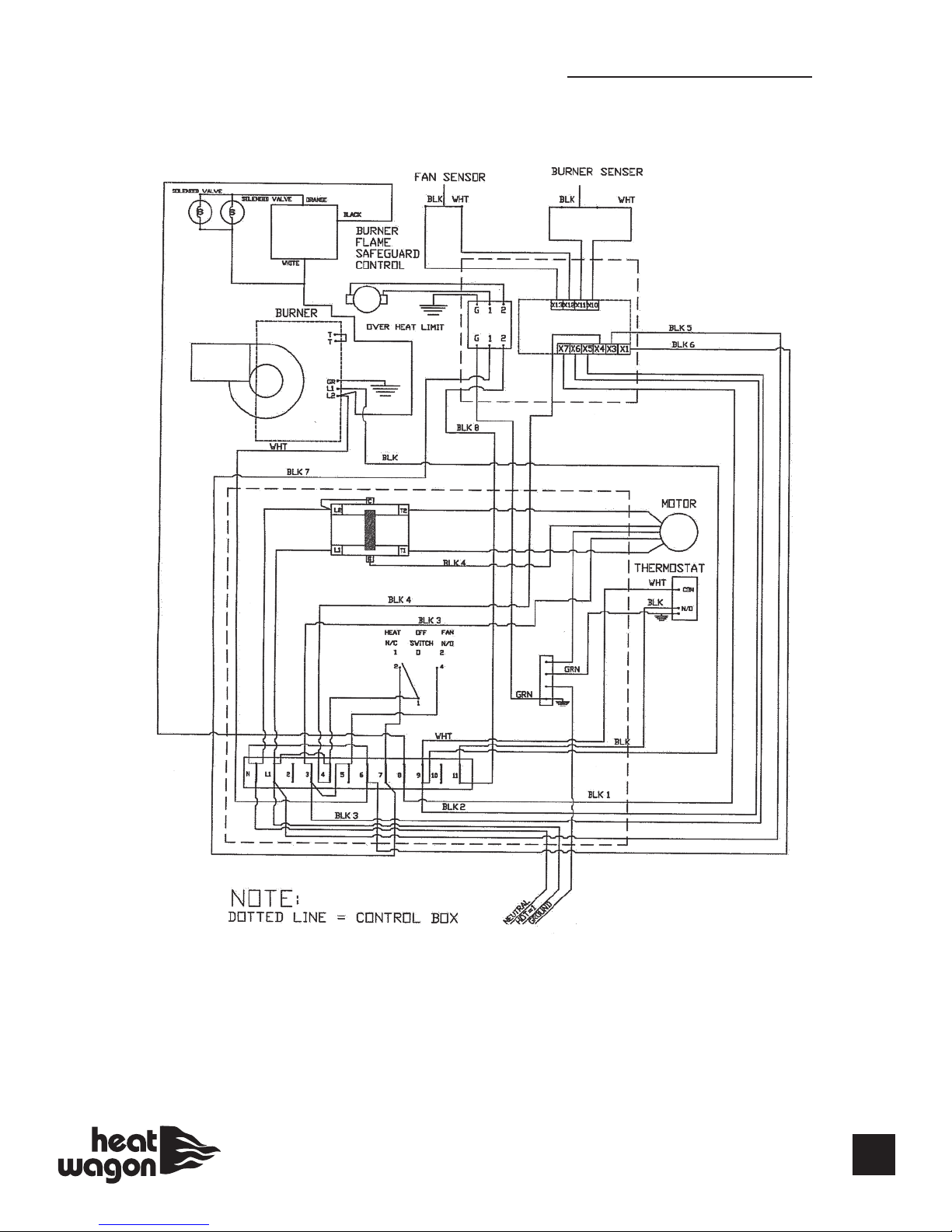

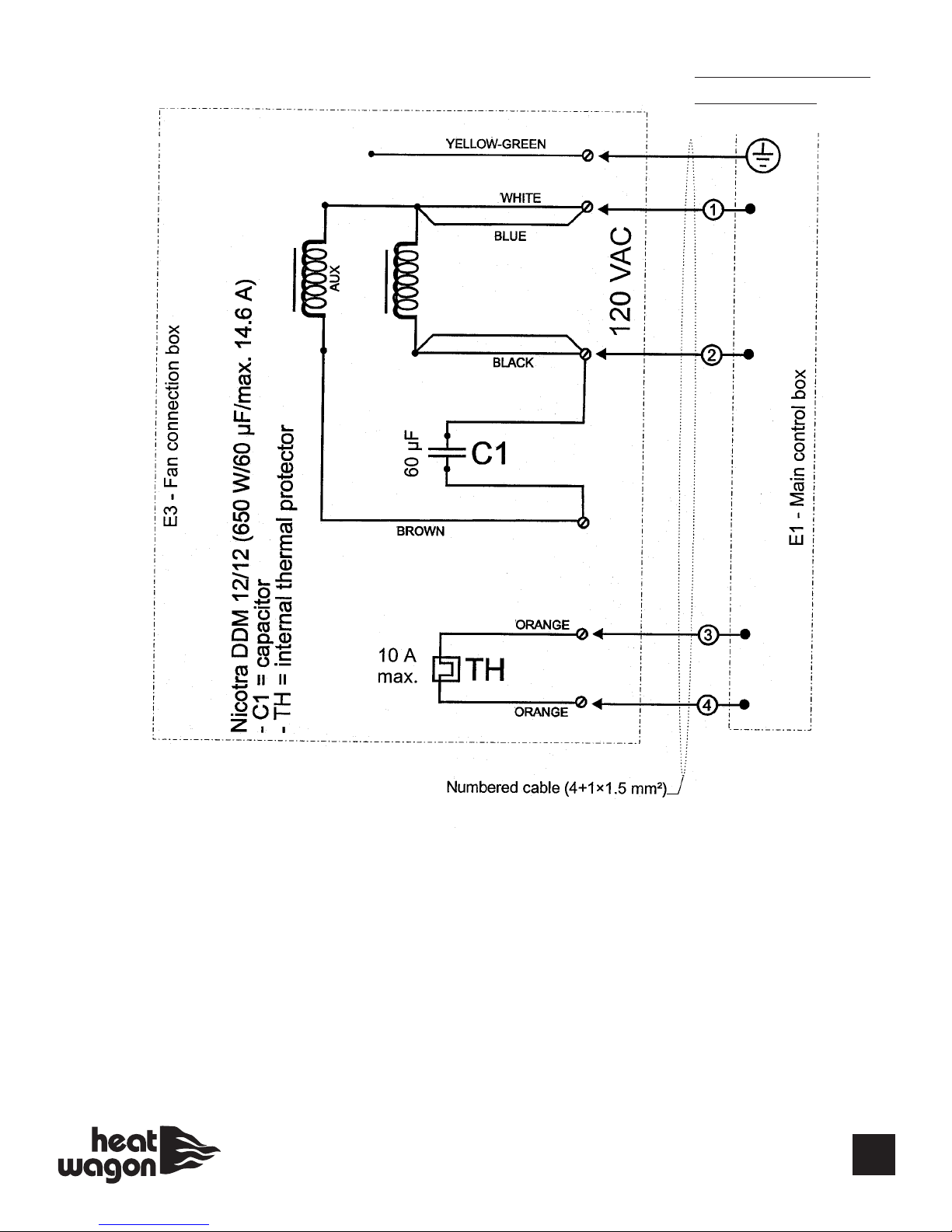

120 Volt 1 PH CONTROL BOX WIRING

120 Volt 1 PH

ITE PART# DESCRIPTION

E1 HWP 41000 MA N CONTROL BOX

E2 HWP 40850 THERMOSTAT BOX

E3 HWP 40900 FAN CONNECT ON BOX

S1 HWP 26400 MA N SW TCH

S2 HWP 20579 HEATER CONTROL UN T,

MODEL HW120

B1 HWP 20581 FAN SENSOR (for S4)

HWP 20583

B2 HWP 20582 BURNER SENSOR (for S5)

S3 HWP 21800 OVERHEAT L M T SW TCH (B METALL C)

HWP 21400 OVERHEAT L M T (CAP LLARY)

X1 HWP 36701 TERM NAL BLOCK (E1)

X2 HWP 36100 GROUND NG BLOCK (E1)

HWP HC1020 POWER CABLE & PLUG

X4 HWP 36701 TERM NAL BLOCK (E2)

X5 HWP 36701 TERM NAL BLOCK (E3)

16

120 Volt 1 PH

MAIN

RED

BLOWER OTOR

SCHE ATIC

17

18

EXHAUST FLUE PIPE GUIDELINES

CAPACITY OF TYPE B DOUBLE-WALL

VENTS SERVING A SINGLE DRAFT

HOOD-HEATER x 1000 BTU'S

FOR INDOOR APPLICATIONS

8101214

TOTAL

VENT

HEIGHT((HH))F

EET

LATERAL

LENGTH

((LL))FEET

60370 570 850 1170

2285 455 650 890

6273 435 630 870

12 255 406 610 840

80415 660 970 1320

2322 515 745 1020

8303 490 720 1000

16 281 458 685 950

10 0 450 720 1060 1450

2355 560 850 1130

10 330 525 795 1080

20 300 486 735 1030

15 0 525 840 1240 1720

2414 675 985 1350

15 373 610 905 1250

30 328 553 845 1180

20 0 575 930 1350 1900

2470 755 1100 1520

10 443 710 1045 1460

20 410 665 990 1390

30 380 626 945 1270

30 0 650 1060 1550 2170

2535 865 1310 1800

20 473 784 1185 1650

40 415 705 1075 1520

VENT DIAMETER (D) INCHES

F

19

Oil Fired

Fuel Tank

VF400 Tank (FT400)

• 75 gallon tank

• Single wall tank

• Forkli t capability rom all our sides

• Minimum 25 hour run time

• 160 lbs. (empty) - 750 lbs. ( ull)

Immersion Heater for

Fuel Tank (FT400HT)

• 120V (1000 watts)

• Keeps uel at optimal low

rate and prevents uel “gelling”

• Must be used in conjunction

with the FT400 uel tank

Circulation Fuel Preheater

(FHTR400)

• Ensures quick smooth “cold weather” start-up

• Independently tested & certi ied to -20ºF

• Standard on VF1000

• Optional on VF400

Heat Wagon Offers You More Options

We Stock A Complete Line Of Parts & Accessories

DUCTING

THER OSTAT

LOCK BOXES

HOSES

REGULATORS

342 N. Co. Rd. 400 East

Valparaiso, IN 46383

219-464-8818 • Fax 219-462-7985

www.heatwagon.com

Table of contents

Other Heatwagon Heater manuals

Heatwagon

Heatwagon VF900SC The Dragon Wagon Manual

Heatwagon

Heatwagon 950H(L) Manual

Heatwagon

Heatwagon p1800 Manual

Heatwagon

Heatwagon DG250 Manual

Heatwagon

Heatwagon 21103000 Manual

Heatwagon

Heatwagon 1800B(L) Manual

Heatwagon

Heatwagon 2730C Manual

Heatwagon

Heatwagon VG400 Manual

Heatwagon

Heatwagon 750NEF Manual

Heatwagon

Heatwagon VG600A Manual

Heatwagon

Heatwagon DF400 Manual

Heatwagon

Heatwagon S1505A Manual

Heatwagon

Heatwagon DG250 Manual

Heatwagon

Heatwagon VG500 Manual

Heatwagon

Heatwagon VG1000 Manual

Heatwagon

Heatwagon HVF110 Manual

Heatwagon

Heatwagon HVF210HD Manual

Heatwagon

Heatwagon HRF115 Manual

Heatwagon

Heatwagon VG600 Manual

Heatwagon

Heatwagon DG250 Manual