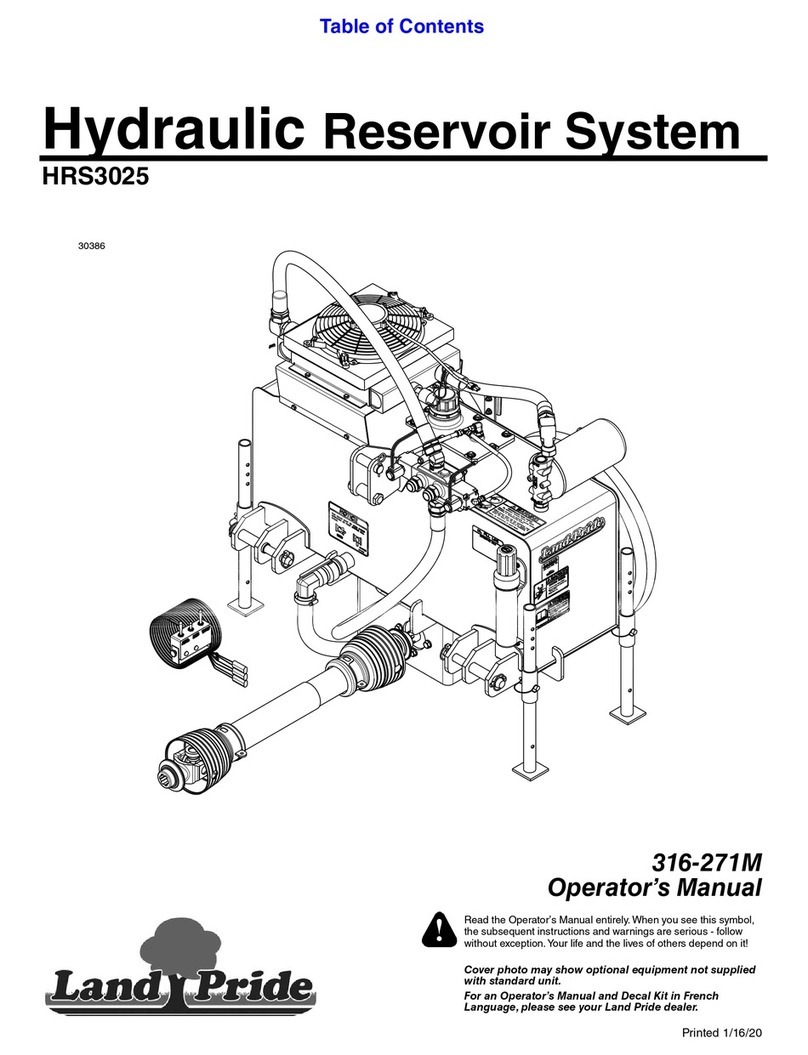

Hedensted Gruppen HG FEEDER 600 User manual

3. december 2012

USERS MANUAL

HG FEEDER 600

Telephone 0045 75891244

Hedensted Gruppen –for professional farmers

2

Telephone 0045 75891244

Hedensted Gruppen –for professional farmers

3

1. Table of contents.

1. Table of contents. ..................................................................................3

2. Guarantee provisions.............................................................................5

3. Precautions............................................................................................ 7

3.1 Training ....................................................................................... 10

3.2 Preparations................................................................................ 10

3.3 Daily control................................................................................. 11

4. Operation............................................................................................. 12

4.1 Operating instruments................................................................. 13

4.2 Engine operation......................................................................... 14

4.3 Tumbler switches. ....................................................................... 16

4.4 Feeding computer (extra equipment) .......................................... 17

4.5 Throttle hand lever. ..................................................................... 17

4.6 Regulation of feed amount and water.......................................... 18

4.7 Main switch..................................................................................18

4.8 Driving pedal. .............................................................................. 18

4.9 Feeding pedal.............................................................................. 19

5. Water tank and water filling up............................................................. 20

5.1 Water emptying, cleaning –dosing pump.................................... 20

6. Adjustment of driving comfort............................................................... 21

7. Check before start................................................................................ 22

7.1 Oil level engine............................................................................ 22

7.2 Oil level hydraulic. ....................................................................... 22

7.3 Fuel, refueling.............................................................................. 23

7.4 Cooling water. .............................................................................24

7.5 Air intake to water cooler............................................................. 24

7.6 Air intake to oil cooler.................................................................. 25

8. Driving and feeding.............................................................................. 26

9. Maintenance ........................................................................................ 28

9.1 Engine oil and oil filter change..................................................... 29

9.2 Changing diesel filters and bleeding............................................ 30

9.3 Cleaning/change of air filter......................................................... 30

Telephone 0045 75891244

Hedensted Gruppen –for professional farmers

4

9.4 Change of hydraulic oil and hydraulic filter.................................. 31

9.5 Lubrication................................................................................... 32

9.6 Maintenance cleaning.................................................................. 33

9.7 Fuse box...................................................................................... 33

9.8 Tyre pressure .............................................................................. 34

10. Towing the machine...........................................................................35

11. FAQ. .................................................................................................. 36

12. Hydraulic diagram.............................................................................. 37

13. Electric diagram................................................................................. 38

14. Spare parts. ....................................................................................... 41

15. Technical data.................................................................................... 48

16. EC Declaration of Conformity............................................................. 49

Telephone 0045 75891244

Hedensted Gruppen –for professional farmers

5

2. Guarantee provisions.

The manufacturer of this machine gives a 12 months guarantee (max.

1000 working hours). The guarantee period starts at the delivery date.

The guarantee includes:

Components which have to be changed or repaired because of

material or fabrication defects.

The guarantee does not include wearing and consumer parts such

as:

Feeding pump, Tyres, Bulbs, Filters, Oil and so on.

The manufacturer`s guarantee stops if:

The machine is used in a wrong way.

The machine is used without following the users manual and the

precautions.

The service schedule is exceeded, or non original spare parts are

used such as filters.

The machine is used after a defect is discovered, if this causes a

more expensive repair than the original defect.

The owners own insurance should cover:

Fire, burglary and malicious damage.

Water and frost damages.

Corrosion damages caused by battery acid.

Damages caused by wind and weather.

The manufacturer`s guarantee does not cover these cases.

Approval of claim for compensation:

Provides that the defect part is shown to the manufacturer or a

representative of the firm within 2 weeks after the damages is emerged.

Telephone 0045 75891244

Hedensted Gruppen –for professional farmers

6

The property in the damaged parts is transferred to the supplier of the new

parts.

The guarantee only replaces components not:

Freight charges.

Costs for waiting, working hours for the machine owner and travel

costs.

Operation loss and other following costs.

Further

Prior to the guarantee repair the manufacturer has to be contacted in order

to agree on the procedure.

These guarantee provisions can only be changed through separate

agreement.

Telephone 0045 75891244

Hedensted Gruppen –for professional farmers

7

3. Precautions

Guidance in safe use of the HG Feeder 600:

IMPORTANT!

WARNING!

WARNING!

READ THE USERS MANUAL

If you are not informed about certain details

concerning this machine, there can be some risky

situations.

Read the users manual thoroughly before using the

machine.

CARBON MONOXIDE

Dangerous carbon monoxide from the exhaust of the

machine can cause sickness, faint and death.

Do not use the machine in closed and small rooms.

HOT PARTS

Hot parts can cause serious burnings. Do not touch

the engine or the exhaust during running or when the

engine just is switched off.

Telephone 0045 75891244

Hedensted Gruppen –for professional farmers

8

WARNING!

WARNING!

WARNING!

FIRE HAZARD

Explosive fuel can cause fire and serious burnings.

Stop the engine and let it cool off before filling in fuel.

The engine always has to be switch off during filling.

HIGH VOLTAGE

The engine generates high voltage which can cause

bodily damage or death.

Do not touch the wires while the engine is running.

ROTATING PARTS

Rotating parts can cause serious damage. Keep

hands, feet, hair and clothes away from all moveable

parts. Do not use the machine without the enclosed

shields and so on.

Telephone 0045 75891244

Hedensted Gruppen –for professional farmers

9

WARNING!

WARNING!

WARNING!

EXPLOSIVE GAS

Explosive gas from the battery can cause fire and

serious corrosion damages.

Only charge the battery in a well ventilated place.

Keep all flammable sources away.

DANGER

Sudden start can cause serious damage and

death. At parking and service the engine has to be

stopped and the ignition key removed.

NOISE

Long stay in noise can damage the hearing. Use of

ear defenders is recommended.

Telephone 0045 75891244

Hedensted Gruppen –for professional farmers

10

3.1 Training

Read the Users Manual thoroughly. You ought to have knowledge to the

operating handles/switches and correct use of the equipment.

Do not let children or persons, who have no knowledge to the instructions,

use the machine. The law may have stated an age limit for persons who

may use the feeding machine.

Remember the driver is responsible for accidents or dangerous situations

that could cause damages towards other human beings or their property.

The driver should be carefully instructed in using the machine. The

instructions should especially pay attention to the following:

The need of being carefully and concentrated when you work with

automotive machines.

Form a general view of what happens in front/behind the machine

especially during feeding, where other people are present.

The most important causes for accidents:

Driving too fast, especially with a filled up container.

Turning with high speed, especially with feed in the container.

Lack of a general view.

The driver`s knowledge to the machine is insufficient.

The terrain conditions are too steep.

3.2 Preparations

When you drive do not wear loose clothes, which can grasp nesting

boxes, doorways and so on. Always wear nonslip shoes in order to

operate the pedals in a safe way.

-Keep the fuel in cans that are approved to the purpose, and out of reach

for children and unauthorized persons.

-Only fill in fuel outdoors. Smoking is forbidden at filling up.

-Fill in fuel before starting the engine. Never remove the cover on the fuel

tank or fill in fuel, while the engine is running or hot.

Telephone 0045 75891244

Hedensted Gruppen –for professional farmers

11

-If you spill fuel do not try to start the engine, but remove the machine from

the spot, where the fuel was spilled, in order to avoid setting fire to the

fuel. If you spill fuel on the exhaust or out on the engine, then wait until the

fuel is evaporated, or else a fire could arise.

-If you get diesel or engine oil on your skin, wash your skin carefully with

soap.

-Inhalation of fuel mists or oil mists are insanitary.

-Consuming fuel or oil is dangerous.

3.3 Daily control

At visual control the following has to be checked after every filling up fuel:

- That there is no leak in the hydraulic system at tubes, tank and so on.

- That there is no leak in the fuel system at tubes, filters, tank .

- That all bolts, nuts and so on are securely tightened.

- That the silencer is tight.

- That the admission of air behind the seat and the rotating blower are free

of wool.

- That there is no spilt engine oil around the oil filler neck.

- That the air pressure in the tires is checked once a week.

- That the running pedal easily goes to the middle position in idling. (That

the machine stands still, when you let go of the running pedal).

Telephone 0045 75891244

Hedensted Gruppen –for professional farmers

12

4. Operation

Do not let the engine run in small closed rooms, where a dangerous

carbon monoxide can be accumulated.

Warning: Inhalation of carbon monoxide can cause poisoning and

possible death.

Do not use the machine in places with flammable dust or explosive gases

or where the exhaust gets in contact with ignitable material.

Use as far as possible only the machine in daylight or in good artificial

lighting.

When you start the engine, you

must not rest the feet on the

pedals, they have to be placed on

the running board.

Notice that the driving ability of

the machine is changed a lot from

an empty to a filled feeding

container, because the centre of

gravity is moved highly up at a

filled container.

When you drive with a filled

container pay attention to the fact that the machine can overturn, if you

drive with high speed in a curve or on slopes with more than 15 degrees

tilt

You obtain pleasant driving if you operate the running pedal with smooth

movement of the foot. Remember that the operating speed increases

proportional to the press on the running pedal. It goes both forward and

backward.

When you leave the machine you have to remove the ignition key from the

dash board.

15°

Telephone 0045 75891244

Hedensted Gruppen –for professional farmers

13

4.1 Operating instruments

The below shows the position of the different operating instruments on the

HG Feeder 600. See the following pages for a deepening description.

1. Arbejdslampe med on/off kontakt

1Working lamp

2. Engine operation.

3. Tumbler switches for feeding method, reverse pump and water.

4. Feeding computer (extra equipment).

5. Throttle hand lever.

6. Regulation of amount of feed and water supply.

7. Main switch.

8. Running pedal.

9. Feeding pedal.

10.Water refill and water gauge.

10

0

1

2

3

6

5

4

7

8

9

Telephone 0045 75891244

Hedensted Gruppen –for professional farmers

14

4.2 Engine operation

The engine operation and the ignition key are mounted on the dash board

in the right side. The operation contains light indicator, preheater and hour

meter. When the engine runs the operation supervises the condition of the

engine. If the engine is overheated or there is a lack of oil pressure the

engine stops automatically.

Afterwards it informs you about the fault through the light indicators.

Start of the engine (Preheater):

If you start a cold diesel engine it has to be preheated. Turn the key

against right to position 1. The lamp ”preheater” lights 15 seconds, at the

same time the engine is preheated. When the lamp switches off you turn

the key to position 2 and the engine starts. When the engine runs you let

go of the key.

If you start a warm engine the lamp “preheater” does not light, and the

engine can start at once.

Hour meter:

The hour meter tells you how many hours the machine has operated. The

hour meter is activated when you start the engine.

Hour meter.

Ignition.

Start.

Status

Charging lamp

Oil lamp

Temperature

Preheater

Telephone 0045 75891244

Hedensted Gruppen –for professional farmers

15

Status:

The status lamp shows the condition of the engine. If it lights green the oil

pressure, the temperature and the generator are ok. No light indicates that

the engine properly has been stopped by the control unit in order to

protect the engine. So the missing green light means error, and one of the

other lamps will light red in order to indicate the cause.

Charging lamp:

The charging lamp indicates the function of the generator. The lamp lights

red, if the generator does not load correctly on the battery.

In this case check the generator of the machine.

Oil lamp:

The lamp indicates the lubricating oil pressure of the engine. If the lamp

lights red the oil pressure is not high enough, this can damage the engine.

In this case the control unit will stop the engine in order to protect it. The

status lamp switches off and the oil lamp lights in order to indicate the

cause.

Temperature:

The lamp indicates the temperature of the engine. If the lamp lights red the

cooling water temperature is too high, this can damage the engine. In this

case the control unit will stop the engine in order to protect it. The status

lamp switches off and the temperature lamp lights in order to indicate the

cause.

Zero position of protection stop:

If the engine has been stopped by the control unit, the cause is shown via

the control lamps. When the cause of the error is traced and repaired, you

turn the key left to position 0. Wait 10 seconds and turn the key to position

1. The control unit tests the system and lights shortly with all the lamps.

The engine is ready for a start.

Telephone 0045 75891244

Hedensted Gruppen –for professional farmers

16

4.3 Tumbler switches.

On the tumbler switches placed on the dash board you can change

between the different functions of the feeding pump.

Reverse:

On the reverse button there is a possibility

of running backwards with the feeding

pump. Activate the reverse function by

pressing the white spot, and then press the

feeding pedal in order to make the pump

running.

Water:

Activation of the water pump. When you

press the white spot of the tumbler switch you turn on the water dosing,

so that the feed is supplied with an adjustable amount of water.

MAN/AUTO.

On the button you can change between manual and automatic feeding. At

automatic operation you activate the feeding pump when you press the

feeding pedal, and the feeding pump steers the amount of feed and the

interval between the lumps.

(Feeding computer is extra equipment).

At manual running the operator steers the feeding amount manual by

activating the feeding pedal.

Telephone 0045 75891244

Hedensted Gruppen –for professional farmers

17

4.4 Feeding computer (extra equipment)

The feeding computer secures a homogeneous

draining of feed. The computer steers the lump

amount and the interval they have to come in.

The operator can adjust the interval time so that

it fits exactly to the operator`s working speed.

For further information see the Users manual for

Twinca Easy.

4.5 Throttle hand lever.

The throttle hand lever is mounted on

the left side on the dash board. The

turns on the diesel engine increases

when you pull the throttle hand lever

against yourself. If the hand lever

cannot stay in the chosen position,

you tighten the center nut a little, so

that the friction in the turning function

is increased.

Telephone 0045 75891244

Hedensted Gruppen –for professional farmers

18

4.6 Regulation of feed amount and water.

With the water regulation you can decide the amount of water that is

mixed into the feed, when the feeding pump is

activated.

The feeding pump regulator adjusts the orbital

velocity for the feeding pump, so that there can

come more or less feed in a certain period.

Indication for adjustment you find over the

regulators.

4.7 Main switch.

The main switch is placed on the left side of the

feeding machine. It switches off all power from the

battery and the rest of the electric supply mains.

4.8 Driving pedal.

The driving pedal is placed to the left on the

machine. Notice that the pedal has to be activated

softly, because the speed of the machine is

proportional to the deflection on the pedal. And the

driving will be more pleasant, when you operate the

pedal with smooth movements. For adjustment

of the pedal see the section “adjustment of driving

comfort”.

Important: At very low temperatures the braking distance can be

longer until the oil is getting warm.

Telephone 0045 75891244

Hedensted Gruppen –for professional farmers

19

4.9 Feeding pedal.

The feeding pedal is placed to the right on

the machine.

The pedal has to be activated with the foot

every time, there has to be pumped out feed.

Telephone 0045 75891244

Hedensted Gruppen –for professional farmers

20

5. Water tank and water filling up

In front of the machine you find the water tank. The tank makes it possible

to bring along water, and mix it currently in the feed, so that the correct

consistence is obtained.

The filler neck to the water tank is placed on the top

edge of the water tank in front of the feed tank.

Dismount the tank cap by turning anticlockwise.

At the front of the feed tank you

find the water gauge for the

water tank. The indicator is made so that it is easy to

change if there is dirt inside.

You read the water level of the tank in liters at the

belonging scale.

5.1 Water emptying, cleaning –dosing pump

In order to lighten the cleaning and emptying

of the tank you can tip the feed tank, so that

the water runs out of the filler neck. Is the

tank tipped you can dismount the cover in

the bottom of the tank, it makes cleaning

easier.

6. Adjustment of driving

comfort

The dosing pump, which presses the water

out into the feeding pump, is placed under

the dash board in the left side of the

machine. The pump only runs when you

activate the water on the tumbler switch and

the feeding pedal.

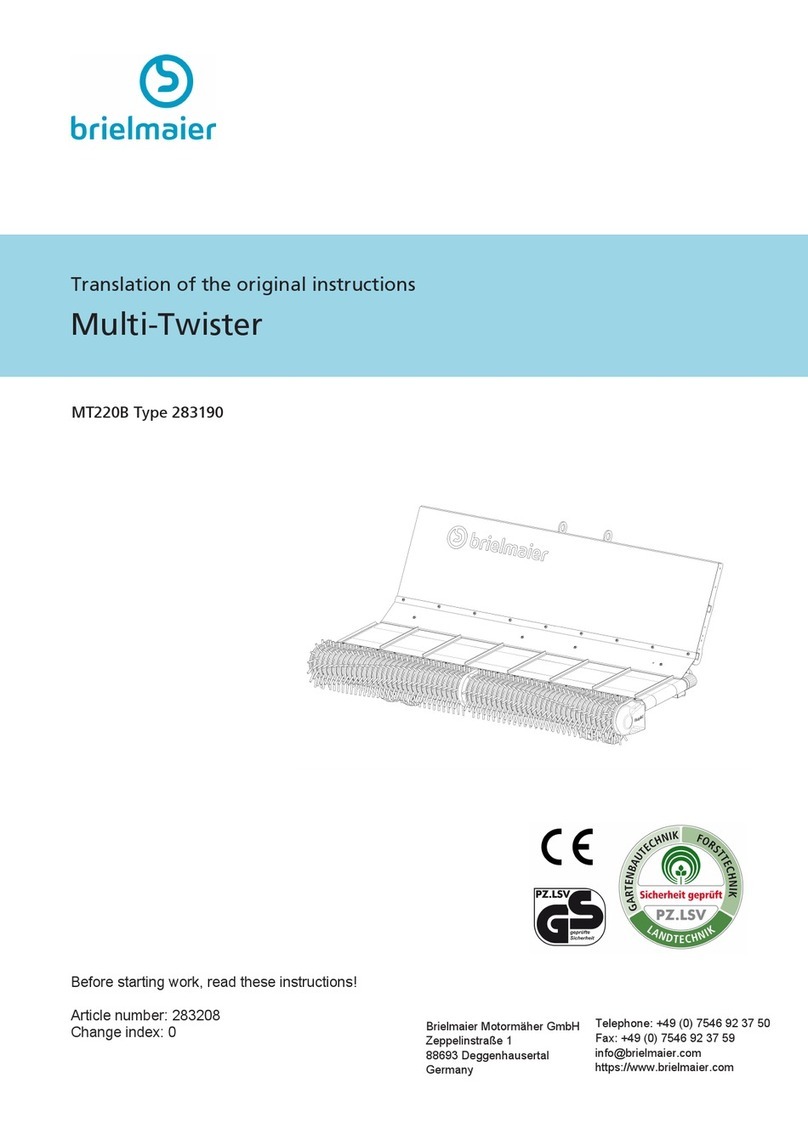

Table of contents

Popular Farm Equipment manuals by other brands

GREAT PLAINS

GREAT PLAINS 3P1006NT Original instructions

Agria

Agria 8100 Series operating instructions

Unverferth

Unverferth Killbros SeedVeyor 102 manual

Walinga

Walinga Grain-Vac 7614F Operator's manual

BE

BE AGRI EASE BE-EFGC F Series Operations & parts manual

Cosmo

Cosmo CX 1500 User and maintenance manual

brielmaier

brielmaier Multi-Twister MT220B Translation of the original instructions

Spearhead

Spearhead TRIDENT 400 Operator's instruction manual

GREAT PLAINS

GREAT PLAINS 2 Series Operator's manual

Gaspardo

Gaspardo M Use and maintenance / spare parts

Rotomec

Rotomec HURRICANE H40-048 Operator's manual

Raven

Raven FLOWMAX 220 quick start guide