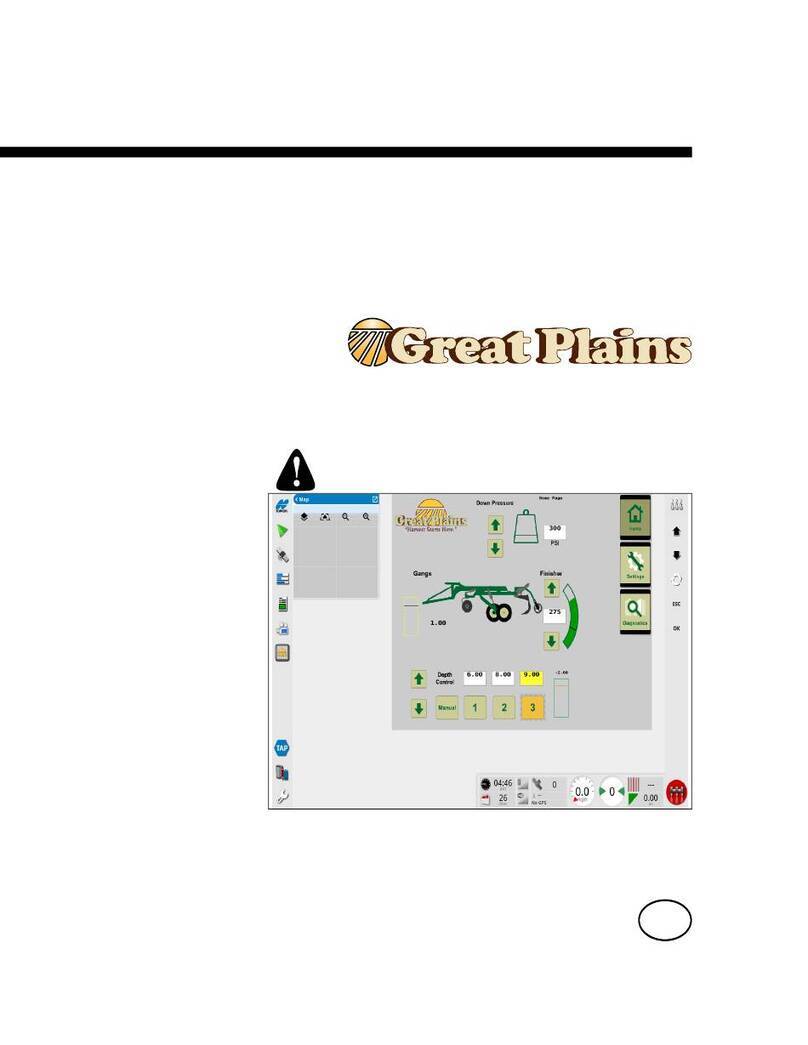

GREAT PLAINS 3P1006NT User manual

Other GREAT PLAINS Farm Equipment manuals

GREAT PLAINS

GREAT PLAINS Yield-Pro 3PYPA User manual

GREAT PLAINS

GREAT PLAINS HT1100-35 User manual

GREAT PLAINS

GREAT PLAINS YP4425A User manual

GREAT PLAINS

GREAT PLAINS PL5700 User manual

GREAT PLAINS

GREAT PLAINS NP2540 User manual

GREAT PLAINS

GREAT PLAINS Plains Plow Series II User manual

GREAT PLAINS

GREAT PLAINS YP1630F-1630 User manual

GREAT PLAINS

GREAT PLAINS 3P500 User manual

GREAT PLAINS

GREAT PLAINS 6000 Series User manual

GREAT PLAINS

GREAT PLAINS MC5109 Max-Chisel User guide

GREAT PLAINS

GREAT PLAINS 605NT User manual

GREAT PLAINS

GREAT PLAINS 1205NT Guide

GREAT PLAINS

GREAT PLAINS YP-625 User manual

GREAT PLAINS

GREAT PLAINS Yield-Pro PL5800 User manual

GREAT PLAINS

GREAT PLAINS MC5109 Max-Chisel User manual

GREAT PLAINS

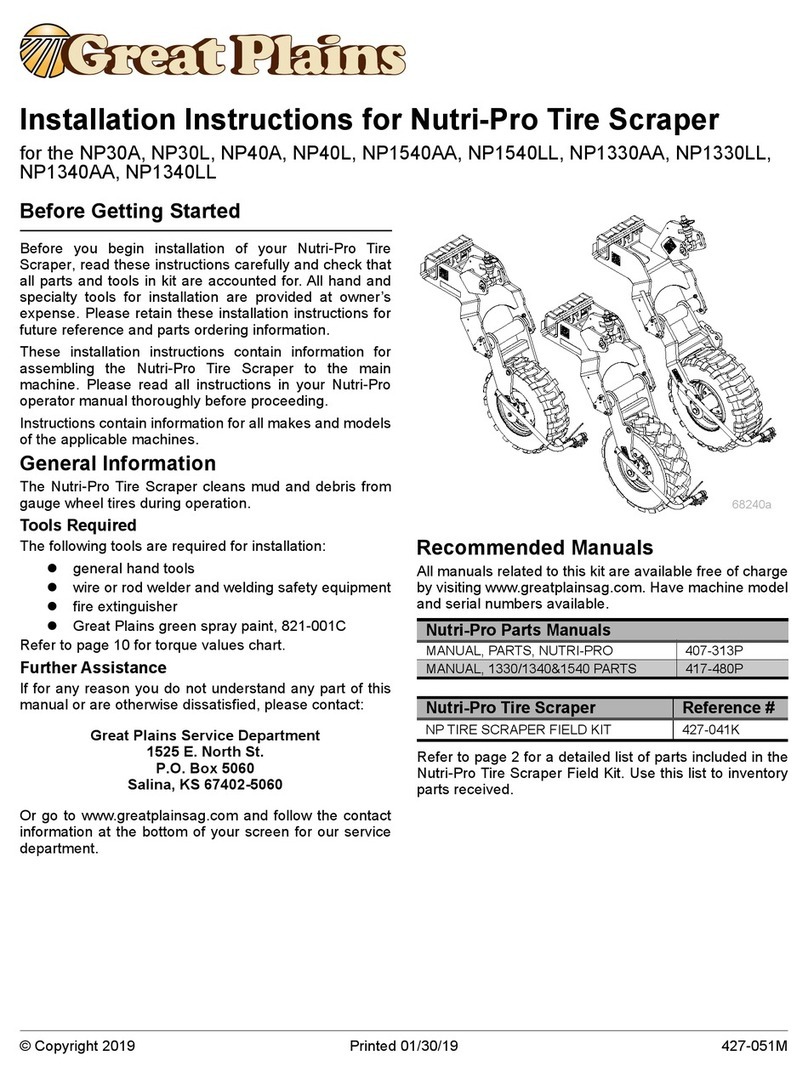

GREAT PLAINS Nutri-Pro NP30A User manual

GREAT PLAINS

GREAT PLAINS PL5200 User manual

GREAT PLAINS

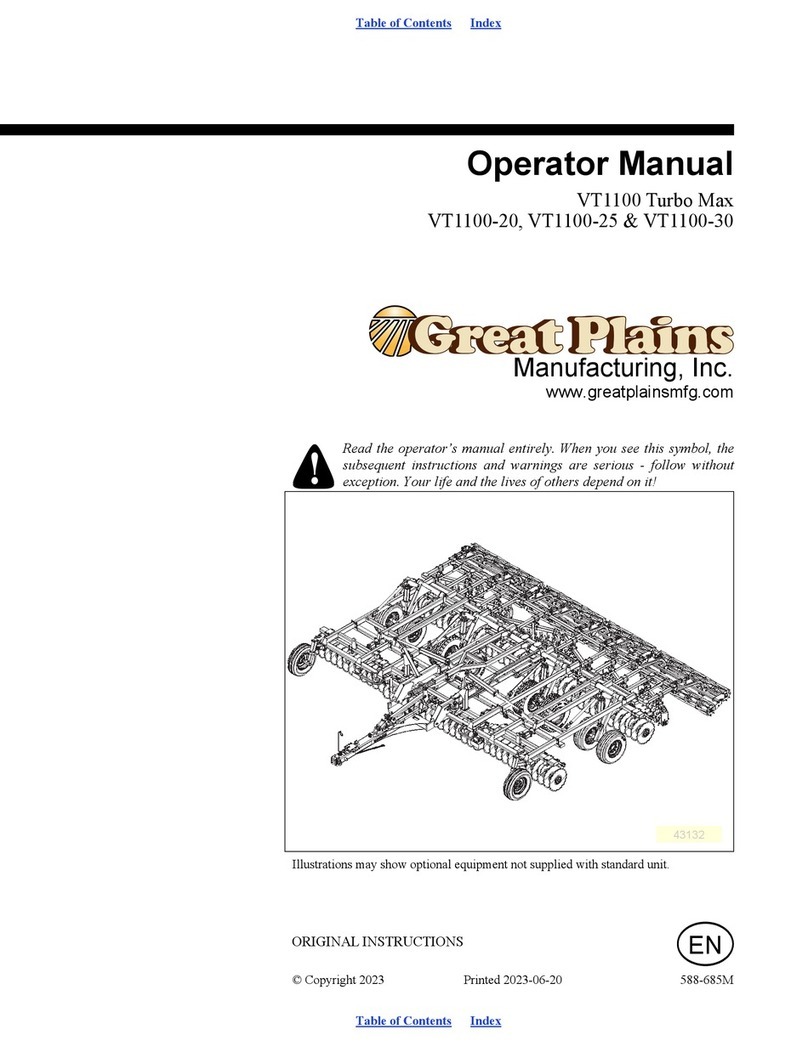

GREAT PLAINS VT1100 Turbo Max User manual

GREAT PLAINS

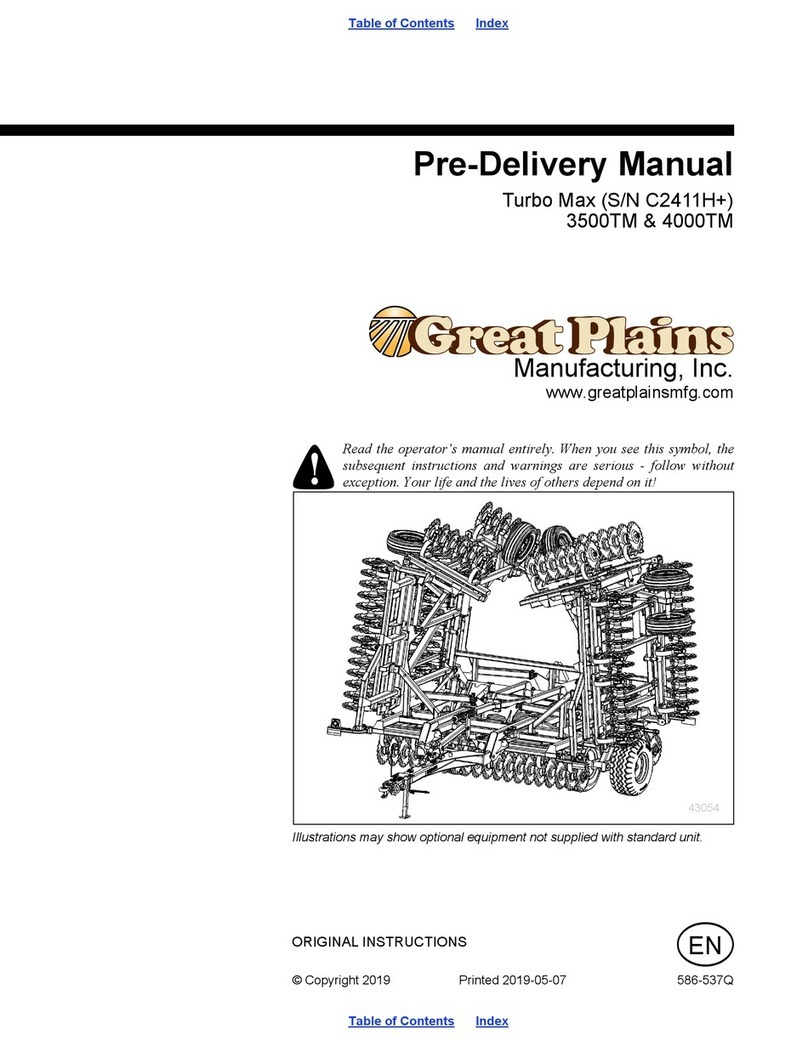

GREAT PLAINS Turbo Max 3500TM User manual

GREAT PLAINS

GREAT PLAINS 5109 User manual