Hefter TF MEGA-A User manual

Be sure to read this manual prior to use.

Please leave this manual at the site of use for easy reference.

TF MEGA-A

FOLDER

Instruction Manual

Introduction

Be sure to read this manual prior to using the product.

After reading, leave the manual at the site of use for easy reference whenever questions related to the

product arise in the future.

Symbols

In this manual, several symbols are used to indicate important warnings. Please make sure to read

instructions accompanied by these symbols. These symbols have the following

meanings.

Describes instructions which must be followed in use.

Be sure to read the instructions to avoid problems due to incorrect operations.

Indicates supplementary or useful information.

Describes names of related items and supplementary instructions.

Trademark

The product name and company name used in this manual are trademarks or registered trademarks of the

respective companies.

For EU

DECLARATION OF CONFORMITY

HEFTER Systemform GmbH, Am Mühlbach 6, 83209 Prien am Chiemsee, Germany, declares that the product (or products) complies with the

provisions dened in the regulations. The reference table is mentioned below.

Name of product Model

Regulation

Low Voltage Directive

2006/95/EC

under

Electromagnetic Compatibility

Directive

2004/108/EC under

Paper Folder TF MEGA-A IEC60950-1: 2005 + EN60950-1:

2006 + A11: 2009

EN61000-6-3: 2007

EN 55014-1: 2006

EN 55014-2: 1997 + A1: 2001 + A2:

2008

EN61000-3-2: 2006

EN61000-3-3: 2008

En

KONFORMITÄTSERKLÄRUNG

HEFTER Systemform GmbH, Am Mühlbach 6, 83209 Prien am Chiemsee, Deutschland, erklärt hiermit, dass das Produkt (oder die Produkte) die in den

Vorschriften denierten Bestimmungen erfüllt. Die Bezugstabelle ist unten aufgeführt.

Bezeichnung des

Produkts Modell

Richtlinie

Niederspannungsrichtlinie

2006/95/EG

unter

Richtlinie zur elektromagnetischen

Verträglichkeit 2004/108/EG unter

Papierfalzmaschine TF MEGA-A IEC60950-1: 2005 + EN60950-1:

2006 + A11: 2009

EN61000-6-3: 2007

EN 55014-1: 2006

EN 55014-2: 1997 + A1: 2001 + A2:

2008

EN61000-3-2: 2006

EN61000-3-3: 2008

Ge

DECLARATION DE CONFORMITE

HEFTER Systemform GmbH, Am Mühlbach 6, 83209 Prien am Chiemsee, Allemagne, déclare que le ou les produits sont conformes aux dispositions

dénies par la réglementation. Un tableau de référence est proposé ci-dessous.

Nom du produit Modèle

Réglementation

Directive Basse tension

2006/95/CE

en application de la

Directive sur la compatibilité

électromagnétique 2004/108/CE en

application de

Plieuse de papier TF MEGA-A IEC60950-1: 2005 + EN60950-1:

2006 + A11: 2009

EN61000-6-3: 2007

EN 55014-1: 2006

EN 55014-2: 1997 + A1: 2001 + A2:

2008

EN61000-3-2: 2006

EN61000-3-3: 2008

Fr

DICHIARAZIONE DI CONFORMITÁ

HEFTER Systemform GmbH, Am Mühlbach 6, 83209 Prien am Chiemsee, Germania, dichiara che il prodotto (o i prodotti) è/sono conforme/i ai requisiti

deniti dalle norme sottoelencate. La tabella di riferimento è riportata qui di seguito.

Nome del prodotto Modello

Direttiva Bassa Tensione

Direttiva 2006/95/CE relativa

alle apparecchiature a bassa

tensione

Direttiva di compatibilità

elettromagnetica 2004/108/CE in

base a

Macchina piegantesi di

carta

TF MEGA-A IEC60950-1: 2005 + EN60950-1:

2006 + A11: 2009

EN61000-6-3: 2007

EN 55014-1: 2006

EN 55014-2: 1997 + A1: 2001 + A2:

2008

EN61000-3-2: 2006

EN61000-3-3: 2008

It

DECLARACIÓN DE CONFORMIDAD

HEFTER Systemform GmbH, Am Mühlbach 6, 83209 Prien am Chiemsee, Alemania, declara que el producto (o los productos) cumple con las

disposiciones previstas en los reglamentos. Seguidamente se indica la tabla de referencia.

Nombre del producto Modelos

Reglamentación - Reglamentaciones

Directiva sobre baja tensión

2006/95/CE,

según

Directiva sobre compatibilidad

electromagnética 2004/108/CE,

según

Máquina que dobla de

papel

TF MEGA-A IEC60950-1: 2005 + EN60950-1:

2006 + A11: 2009

EN61000-6-3: 2007

EN 55014-1: 2006

EN 55014-2: 1997 + A1: 2001 + A2:

2008

EN61000-3-2: 2006

EN61000-3-3: 2008

Sp

For North America

Note:

This equipment has been tested and found to comply with the limits for a Class B digital device, pursuant to Part 15 of the FCC Rules. These limits are

designed to provide reasonable protection against harmful interference in a residential installation. This equipment generates, uses and can radiate

radio frequency energy and, if not installed and used in accordance with the instructions, may cause harmful interference to radio communications.

However, there is no guarantee that interference will not occur in a particular installation. If this equipment does cause harmful interference to radio

or television reception, which can be determined by turning the equipment o and on, the user is encouraged to try to correct the interference by

one or more of the following measures:

– Reorient or relocate the receiving antenna.

– Increase the separation between the equipment and receiver.

– Connect the equipment into an outlet on a circuit dierent from that to which the receiver is connected.

– Consult the dealer or an experienced radio/TV technician for help.

Disposal of Old Electrical & Electronic Equipment

is symbol (the symbol of the crossed out wheeled

bin) indicates that in European countries this product

should not be disposed of as household waste.

Please recycle where facilities exist by checking with

your local authority or supplier for recycling advice.

By ensuring this product is disposed of correctly

through proper treatment, recovery and recycling,

you will help prevent potential negative eects on the

environment and human health.

En

Entsorgung von alten elektrischen und

elektronischen Ausrüstungsteilen

Dieses Symbol (das Symbol mit dem durchgekreuzten

fahrbaren Müllbehälter) zeigt an, dass dieses Produkt

in europäischen Länden nicht als Haushaltsmüll

entsorgt werden darf. Bitte informieren Sie sich bei

Ihren örtlichen Behörden oder bei Ihrem Händler

hinsichtlich einer Empfehlung für die Entsorgung

und führen Sie die betreenden Teile dort, wo solche

Einrichtungen vorhanden sind, einem Recycling-

Prozess zu.

Indem sie sicherstellen, dass das betreende Produkt

durch richtige Behandlung, Rückführung und Recycling

entsorgtwird, tragen Sie dazu bei, möglichen negativen

Auswirkungen auf die Umwelt und die menschliche

Gesundheit vorzubeugen.

Ge

Elimination du matériel électronique et électrique

usagé

Ce symbole (une poubelle marquée d’une croix)

indique que dans les pays européens, ce produit ne

doit pas être éliminé comme des ordures ménagères.

Recyclez-le dans les sites adaptés qui vous seront

indiqués par les autorités locales ou renseignez-vous

auprès de votre fournisseur.

En veillant à ce que ce produit soit éliminé

correctement avec un traitement, une collecte et un

recyclage adaptés, vous contribuez à éviter son action

nocive potentielle sur l’ environnement et la santé

humaine.

Fr

Smaltimento di attrezzature elettriche ed

elettroniche consumate

Questo simbolo (il simbolo della pattumiera con rotelle

barrata) indica che nei paesi europei questo prodotto

non deve essere buttato nei rifiuti domestici.

Per favore smaltire in luogo addetto al riciclo, dove

esistente, chiedendo informazioni alle autorità locali o

a chi fornisce consulenza a proposito.

Garantendo uno smaltimento adeguato di questo

prodotto (trattamento, recupero e riciclo corretto),

aiuterete a prevenire eetti negativi sull’ambiente e

sulla salute dell’uomo.

It

Eliminación de residuos de aparatos eléctricos y

electrónicos

Este símbolo (un cubo de basura tachado) indica

que en los países europeos este producto no deberá

eliminarse como si se tratara de un residuo doméstico.

Solicite asesoramiento sobre reciclaje a las autoridades

locales o a su distribuidor, y siga la normativa en

materia de gestión medioambiental y reciclaje de este

tipo de residuos.

Si toma las medidas pertinentes para que este

producto se elimine mediante un tratamiento,

recuperación y reciclaje adecuados, contribuirá a evitar

posibles efectos negativos en el medio ambiente y la

salud humana.

Sp

For EU

i

Safety Precautions

Safety Precautions

In this manual, operations and handling of the unit which are hazardous are described using the following

marks to prevent personal injury or property damage to the user and others.

Ignoring this mark could result in the possibility of

serious injury or even death.

Ignoring this mark could result in the possibility of injury

or physical damage.

This mark indicates a“Warning”or “Caution”.

A graphic may be shown inside the mark to describe the warning or caution more specically.

This mark indicates a forbidden action.

A graphic may be shown inside the mark to describe the forbidden action more specically.

This mark indicates actions that must be performed.

A graphic may be shown inside the mark to describe the action to be performed more specically.

Power Supply

• This unit shall be installed near the socket-outlet where the plug on the power supply cord is easily

accessible.

• Make sure the power supply used is always within the following range.

Power supply : 220-240 V AC, 50 Hz (EU)

120 V AC, 60 Hz (North America)

• When you power other appliances from the same AC outlet, make sure that the combined power

consumption does not exceed the power supply capacity.

Rated current (Rated power) : 0.5 A (EU), 0.85 A (North America)

Use only the power supply voltage specied on the main nameplate.

Using other voltages could result in a re or an electrical shock.

Make sure that the combined power consumption of the appliances to be

connected does not exceed the capacity rating of the power outlets or plug

receptacles.

Exceeding the capacity rating could cause the power outlets, plug receptacles, or power extension cords to

overheat and catch a re.

ii

Safety Precautions

Operating Environment

Operate this unit in the following environment.

• where the temperature range is between 5 and 35°C/41 and 95°F (-10 to +50°C/14 to 122°F in storage)

• where the humidity range is between 20 and 80% RH (10 to 90% RH in storage, however no condensation)

• which is not subject to direct sunlight

• which is reasonably free from dust

• which is subject to little or no vibration

• which is free from air-borne salt

• where there are no harmful chemicals

• where the unit is not exposed to water

Keep this unit and the power cord away from heaters and heater vents.

Excessive heat could melt the cover or power cord covering, and result in a re or an electrical shock.

Do not place metal objects or vessels containing liquids on top of the unit.

The entry of any metal object or liquid could result in a re or an electrical shock.

Do not insert any metal or easily-combustible object inside this unit.

This could result in a re or an electrical shock.

Do not use ammable sprays inside or near the unit (e.g. when cleaning the

unit).

Such ammable gas may ignite and cause a re or combustion.

Do not install this unit in a location where there is excessive humidity or

where contact with water is possible.

Poor choice of location could result in deterioration of the insulation, a re or an electrical shock.

Install this unit on a level, stable stand or oor, with sucient space around it.

Failure to do so could result in the unit overturning and causing injury.

Disconnect the power plug from the power outlet before attempting to move

this unit.

Failure to do so could result in power cord damage, a re or an electrical shock.

Always disconnect the power plug from the power outlet when the unit is not

to be used for an extended period.

Failure to do so could result in a re due to leakage current if the insulation should deteriorate.

iii

Safety Precautions

Maintenance / Other

Do not damage the power cord or power plug.

Do not scratch, alter, bend, twist, pull or place heavy objects on the power cord or power plug.

This could result in damage, a re or an electrical shock.

Do not touch the power switch with wet hands.

Otherwise electric hazards may occur.

Do not remove the cover or back panel.

This unit contains high-voltage components that could cause an electrical shock.

Do not disassemble, modify or repair this unit.

There is a danger of re, electrical shock or injury.

Contact your dealer when repairs are necessary.

If any foreign object such as metal or liquid should enter this unit,

immediately turn the unit o at the power switch and disconnect the power

plug from the power outlet.

Failure to do so could result in a re or an electrical shock.

Contact your dealer immediately.

Before cleaning this unit, turn the unit o at the power switch and disconnect

the power plug from the power outlet.

Accidental operation of the unit during cleaning could result in injury.

Remove any dust that accumulates on the power plug prongs and the surface

of the plug from which the prongs extend.

Accumulated dust could result in a re.

Always grip the plug when disconnecting the power plug from the power

outlet.

Forcibly pulling on the power cord could cause damage, resulting in a re or an electrical shock.

Do not touch or insert foreign objects into any rotating part during operation.

This could result in injury.

iv

Safety Precautions

WARNING / CAUTION Labels

"WARNING" and "CAUTION" labels are pasted on the machine to ensure user safety.

Do not remove or change them.

When the labels become dirty or are lost, be sure to contact your dealer for a new one.

When changing a fuse, make

sure that the fuse rating is same

as that indicated on this label.

North America

EU

H

H

v

Contents

Contents

Safety Precautions .............................................i

Power Supply.................................................................................i

Operating Environment ...........................................................ii

Maintenance / Other ............................................................... iii

WARNING / CAUTION Labels................................................ iv

Chapter1Before Operation

1. Features................................................... 1-1

2. Setting Up the Machine ......................... 1-2

2-1. Components.............................................................. 1-2

2-2. Removing the Press Release Lever................... 1-3

2-3. Locking the Bearing Support Levers ............... 1-4

2-4. Attaching the Parts ................................................. 1-5

3. Names and Functions............................. 1-8

4. Describing Control Panel..................... 1-10

5. Screen Menus........................................1-11

6. Handling Paper.....................................1-12

6-1. Paper Used ...............................................................1-12

6-2. Precautions on Stacking Paper ........................1-12

7. Emergency Stop....................................1-14

Chapter2Basic Operation

1. Standard Folding of Standard Paper.... 2-1

1-1. Standard Paper......................................................... 2-1

1-2. Standard Folding ..................................................... 2-2

1-3. Operation Procedures ........................................... 2-2

Chapter3Advanced Operation

1. Standard Folding of Special Paper ....... 3-1

1-1. Single Folding Thick Paper................................... 3-1

1-2. Double Folding Thick Paper................................ 3-2

1-3.

Double Folding B6 Thin Paper (EU)/Small

Thin Paper (North America)............................................3-4

2. Custom Folding of Standard Paper ...... 3-7

3.

Standard Folding of Non-Standard Size

Paper..............................................................3-11

4. Cross Folding ........................................3-13

4-1. Cross Folding Standard Size Paper.................3-14

4-2. Cross Folding Non-Standard Size Paper.......3-17

5. Using Art Paper and Coated Paper..... 3-19

5-1. Characteristics of Art Paper and Coated

Paper...........................................................................3-19

5-2. Operation Procedures .........................................3-19

6. Correcting Folding Misalignment.......3-20

6-1. Correcting Folding Misalignment along

Vertical Length of Paper .....................................3-20

6-2. Correcting Folding Misalignment along

Sides of Paper..........................................................3-23

Chapter4

Troubleshooting Guide

1. Correcting Deformed Folding ....................... 4-1

2. Removing Jammed Paper...................... 4-1

2-1. When Paper Has Jammed Near the Paper

Feed Ring .................................................................... 4-1

2-2. When Paper Has Slipped at the Paper

Feed Section.............................................................. 4-2

2-3. When Paper Has Coiled Around the Rubber

Roll................................................................................. 4-3

2-4. When Paper Has Jammed at the First

Folding Plate.............................................................. 4-4

2-5. When Paper Has Jammed at the Second

Folding Plate.............................................................. 4-5

2-6. When Paper Has Jammed Near the

Stacker.......................................................................... 4-7

3. Error Messages ....................................... 4-8

4. Troubleshooting..................................... 4-9

Chapter5Cleaning the Unit

1. Cleaning Each Section............................ 5-1

1-1. Cleaning the Rubber Roll ..................................... 5-1

1-2. Cleaning the Paper Feed Rings.......................... 5-2

1-3. Cleaning the Paper Separator ............................ 5-3

1-4. Cleaning the Paper Sensor .................................. 5-4

1-5. Cleaning the Ejection Gate Sensor................... 5-4

1-6. Cleaning the Paper Ejection Belts..................... 5-4

Chapter6Appendix

Specication.................................................. 6-1

1-1

Chapter1 Before Operation

Chapter1 BeforeOperation

1. Features

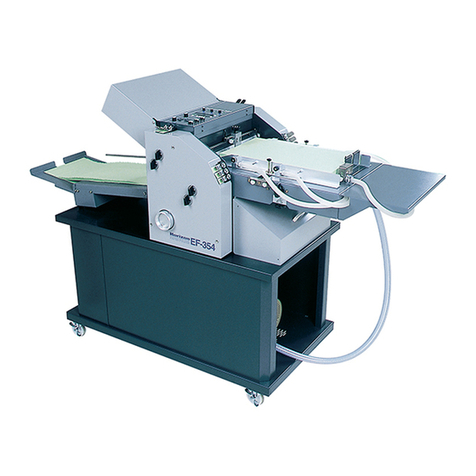

The TF MEGA-A is designed to fold paper into six popular folding modes and is capable of folding the

following number of sheets:

For EU

Approximately 125 sheets of paper per minute when single folding A4 size ne quality paper 64 g/m2

For North America

Approximately 135 sheets of paper per minute when single folding 11 lb of ne quality LT paper

Single fold Double fold Irregular accordion fold Letter fold Accordion fold Gate fold

The TF MEGA-A is also able to create cross single fold and cross letter fold as shown in the gure.

Cross fold Cross single fold

Cross letter fold

Note that the nish of cross folding is not as accurate as that of the six folding modes mentioned

above.

(Fold out) (Z fold)

1-2

Chapter1 Before Operation

2. Setting Up the Machine

2-1. Components

[1] [2] [3]

[4] [5] [6]

[7]

220 to 240 V (For EU)120 V (For North America)

No. Name Qty. Remark

[1] First folding plate 1 Attached to the right upper section on the operator's side.

[2] Second folding plate 1 Attached to the right lower section on the operator's side.

[3] Instruction manual 1 This manual

[4] Scale label 1 Used to measure non-standard size paper. Attach the scale.

[5] Guide plate unit 1 Used when folding B6 size thin paper into four. (EU)

Used when folding small sized medium thickness paper into four.

(North America)

[6] Cross folding lever 1 Used when cross folding paper.

[7] Power cord 1

1-3

Chapter1 Before Operation

2-2. Removing the Press Release Lever

The press release levers are attached to the unit at shipment to prevent the rubber roll from becoming

distorted. Be sure to remove them when setting up the machine.

The two types of press levers are attached to either side of the rubber roll.

Press release lever (A)

Operator’s side

Rubber roll

Press release lever (B)

Press release lever (A)

Press release lever (B)

Non-operator’s side

Rubber roll

The machine will be damaged if it is used without removing the lever.

1 To remove the press release lever (A) on the non-operator’s side, push it inwards and

pull it out.

Press release lever (A) Press release lever (A)

2 To remove the press release lever (A) on the operator’s side, push it inwards and pull it

out.

3 To remove the press release lever (B) on the non-operator’s side, push it inwards and

pull it out.

Press release lever (B) Press release lever (B)

4 To remove the press release lever (B) on the operator’s side, push it inwards and pull it

out.

1-4

Chapter1 Before Operation

2-3. Locking the Bearing Support Levers

The bearing support levers are released at shipment to prevent the rubber roll from becoming distorted.

After removing the press release levers, be sure to lock the bearing.

Support paper feed plate

Paper receiving

stopper

Paper receiving

tray

1 Unfold the paper receiving tray.

2 Unfold the support paper feed plate.

• If you unfold the support paper feed

plate before unfolding the paper

receiving tray, the paper receiving

stopper may be damaged. Make sure

that you unfold the paper receiving tray

rst.

• The paper receiving tray and support

paper feed plate are foldable so that you

can easily move or store the machine.

Make sure that you unfold them before

using the machine.

Top cover

3 Open the top cover.

Bearing support lever

Operator’s side

4 Turn the bearing support lever on the

operator’s side in the direction of the

arrow.

The bearing will be locked.

1-5

Chapter1 Before Operation

Bearing support lever

Non-operator’s side

5 Turn the bearing support lever on the

non-operator’s side in the direction of

the arrow.

The bearing will be locked.

Because the bearing support lever presses

down the rubber roll, if it is not locked,

thick paper may not be folded properly.

6 Close the top cover.

2-4. Attaching the Parts

1 Attach the second folding plate.

Second folding plate

Lock lever

UNLOCK

LOCK

1) Move the lock lever of the second folding

plate to the position of“UNLOCK.”

2) Slide the second folding plate to the

machine along the shaft on each side of the

frame, then insert the U-shaped gutter on

the edge of each side into the shaft located

on the back of the frame.

3) Move the lock lever to the position of

“LOCK.”

1-6

Chapter1 Before Operation

First folding plate

UNLOCK

LOCK

Lock lever

2 Attach the rst folding plate.

1) Move the lock lever of the rst folding plate

to the position of “UNLOCK.”

2) Slide the rst folding plate to the machine

along the shaft on each side of the frame,

then insert the U-shaped gutter on the

edge of each side into the shaft located on

the back of the frame.

3) Move the lock lever to the position of

“LOCK.”

Connector 1

Control cable 1

Control cable 2

1

2

2

1

Connector 2

3 After attaching the folding plates,

connect the control cable of the rst

folding plate to the connector "1" and

that of the second folding plate to the

connector "2."

• Be careful not to connect the control

cable to a wrong connector.

• Be sure to turn o the power before

connecting or disconnecting the

control cable. Otherwise the unit will

malfunction.

Guide plate unit

4 Place the guide plate unit on the

magnet under the top cover.

Cross folding lever

5 Insert the cross folding lever to the

shaft located on the operator's side

under the top cover.

1-7

Chapter1 Before Operation

Memo

1-8

Chapter1 Before Operation

3. Names and Functions

[1]

[2]

[3]

[4]

[5]

[6]

[7]

[8]

[9]

[10]

[11]

[13]

[14]

[15]

[16] [17]

[18]

[12]

Under the main cover

Paper feed tray (operator’s side)

1-9

Chapter1 Before Operation

No. Name Function

[1] First folding plate Guide plate for deciding a paper folding position. First folding is

made using this plate.

[2] Control panel Used when operating the machine. Error messages are also

displayed on the LCD display.

[3] Second folding plate Paper folded at the rst folding plate is sent to the second folding

plate. Second folding is made using this plate. This plate is not

used when folding paper into two.

[4] Power switch Turns on and o the power.

[5] Paper receiving tray Receives folded paper ejected out.

[6] Paper receiving stopper Stops paper ejected out from the machine.

[7] Stacker rollers Ejects folded paper from the machine.

[8] Paper set lever When lowered, the paper feed tray is raised.

[9] Support paper feed plate Supports paper stacked on the paper feed tray.

[10] Paper feed tray Used to stack paper to be folded.

[11] Side guide Holds paper stacked on the paper feed tray.

[12] Top cover Prevents the user from touching the moving parts.

[13] Jam correction knob Removes paper jammed around the rubber roll by turning the

knob.

[14] Paper feed ring Feeds paper into the machine.

[15] Rubber roll Sends paper to the rst folding plate.

[16] Separating pressure adjustment dial Adjusts the paper separating pressure.

[17] Paper feed pressure adjustment knob Adjusts paper feed pressure.

[18] Slant correction paper feed knob Corrects misalignment along sides of paper.

1-10

Chapter1 Before Operation

4. Describing Control Panel

[1]

[2][3][4][5][6][7][8][9][10]

[12][13][14][15]

[11]

No. Name Function

[1] Counter/LCD display A paper size, folding mode, the number of folded paper or error

messages are displayed.

[2] key When pressed, the machine stops.

[3] key When pressed, the machine starts folding operations.

[4] C (clear) key • When the machine is stopped with paper on the paper feed tray,

pressing this key for more than two seconds makes the counted

number return to "0."

• When a mis-feed has occurred, pressing this key clears the

message.

• When set to subtract count, pressing this key cancels the subtract

count mode and returns to the add count mode.

[5] (test) key Starts test folding.

[6] key, key Sets the details for non-standard size paper, custom folding or

folding position correction, species the number for subtract

count, or changes the stacker rollers position.

[7] (count) key Switches the count mode from add count to subtract count.

[8] (stacker roller position correction)

key

Corrects the automatically set position of the stacker rollers.

[9] (second folding stopper

adjustment) key

Adjusts the automatically set folding position or species the size

of custom folding.

[10] (rst folding stopper adjustment)

key

Adjusts the automatically set folding position or species the size

of custom folding.

[11] (paper length setting) key Species the paper length when folding non-standard size paper

in a standard folding mode.

[12] Folding mode, paper feed/eject

direction lable

Shows the paper feed direction and front/back of paper and how

folded paper is discharged from the machine. Use this label when

selecting a folding mode using the folding mode key.

[13] (folding mode) key Selects a folding mode (six patterns).

[14] (paper size) key Selects a paper size from A3, B4, A4, B5, A5, B6, LP (non-standard

size) and CF (paper for custom folding). (EU)

Selects a paper size from LD, LG, LT, ST/IN, LP (non-standard size)

and CF (paper for custom folding). (North America)

[15] Paper feed pressure label Refer to this label when setting paper feed pressure according to

the paper quality.

Table of contents

Other Hefter Folding Machine manuals