IV

5. Installation................................................................................ 59

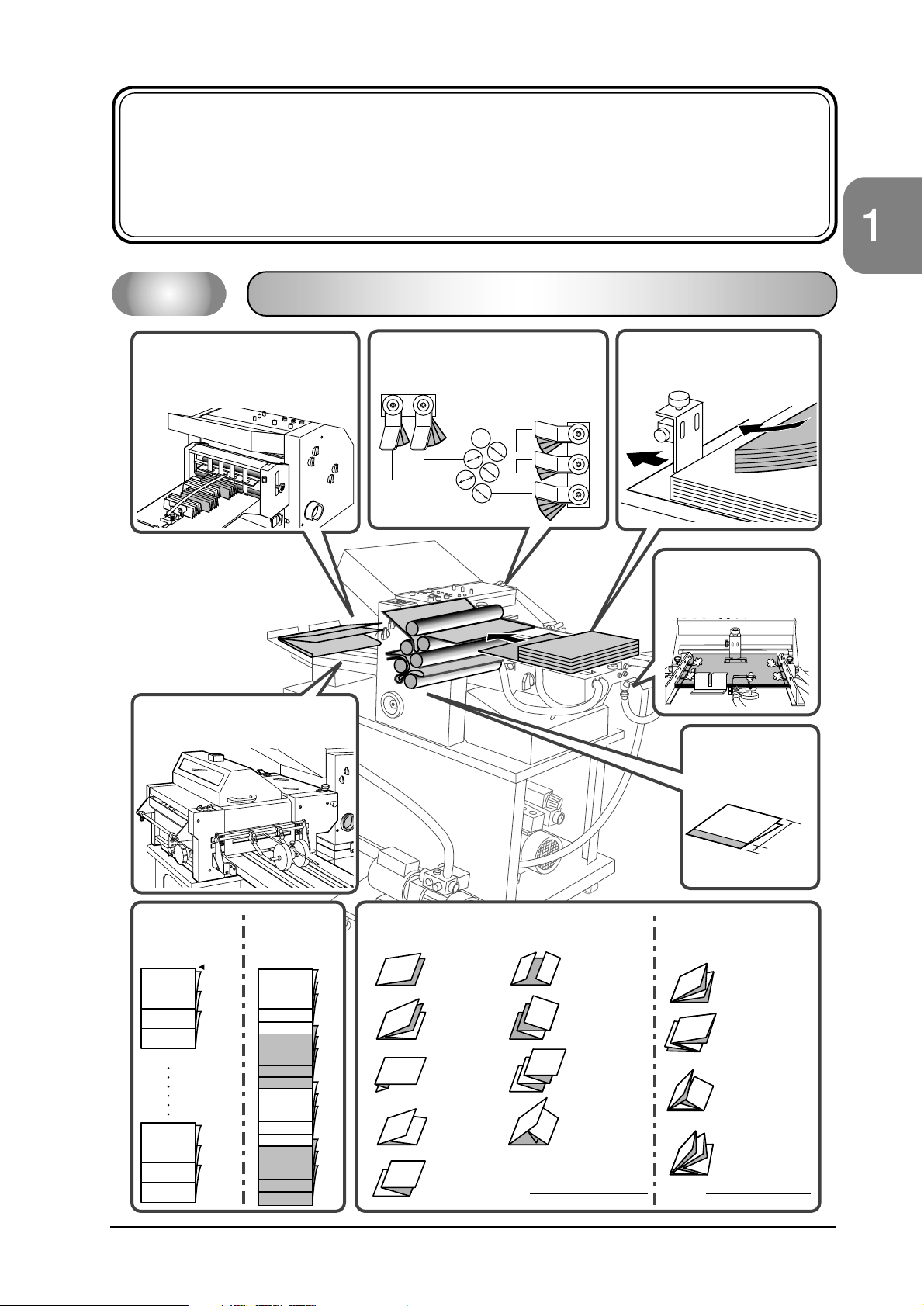

5-1 Installation Overview for the EF-354 ..............................................................59

5-2 Installing the Blower and Vacuum Pump .......................................................60

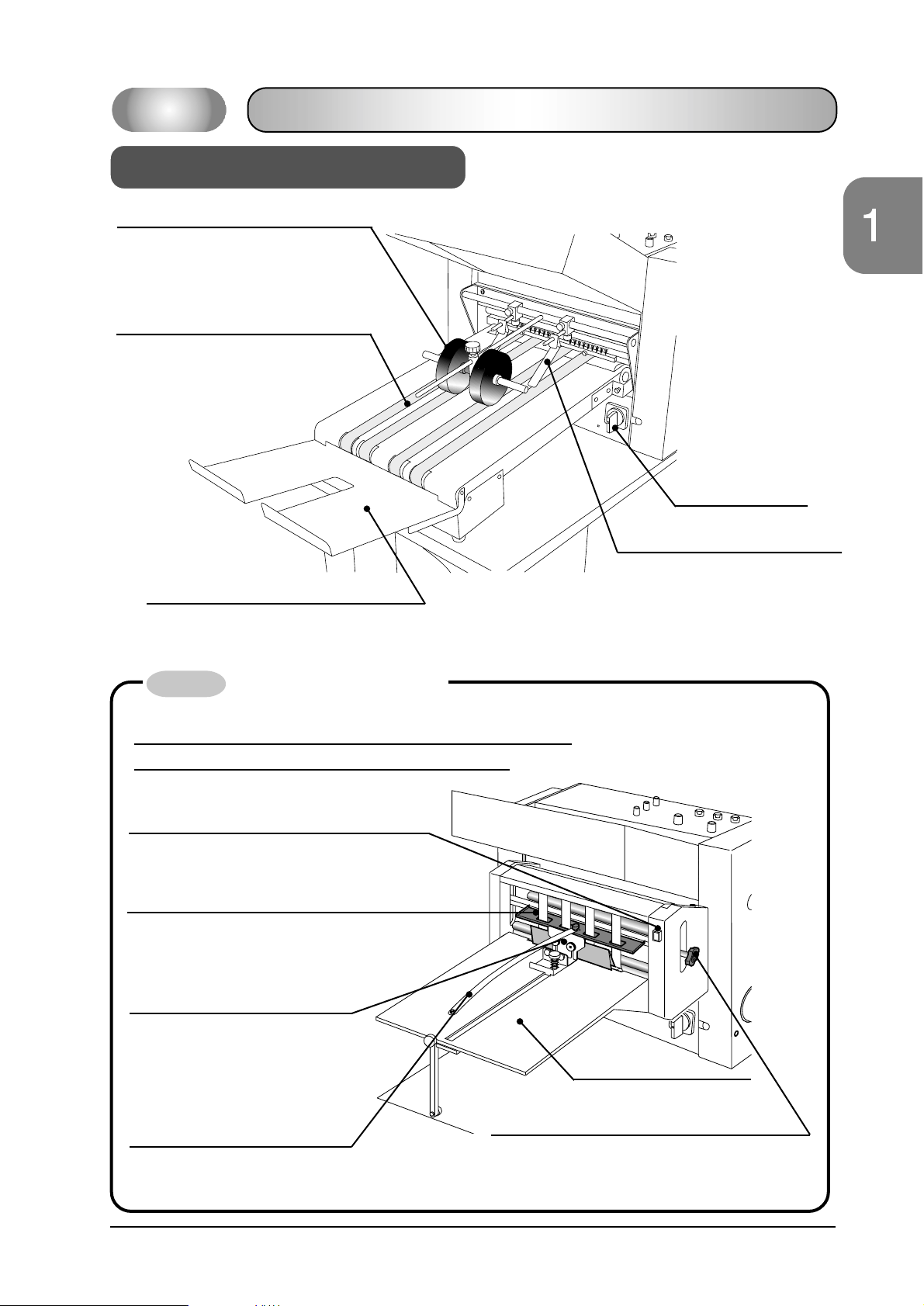

5-3 Installing the Delivery Section ..........................................................................61

5-4 Installing the Feed Section ................................................................................63

5-5 Installing the Buckle Plates ............................................................................... 64

5-6 Checking the Pump Rotation Direction........................................................... 65

5-7 Installing the Optional Standing Delivery ....................................................... 67

5-8 Installing the Optional Cross Folder................................................................69

6. Additional Information ........................................................... 73

6-1 Specifications ......................................................................................................73

6-2 Accessories ..........................................................................................................74

6-3 Accessories for Optional ED-354 Standing Delivery ......................................77

6-4 Accessories for Optional KTU-35 Cross Folder .............................................78

6-5 Index....................................................................................................................80

4. Maintenance ............................................................................. 55

4-1 Cleaning the Counter Sensor ............................................................................55

4-2 Cleaning the Vacuum Pump Filter ..................................................................56

4-3 Cleaning the Sheet Sensor on the Optional KTU-35 ......................................57

4-4 Replacing the Battery ........................................................................................58

3-4 Problems During Folding When Using Cross Folder..................................... 45

3-5 Problems With Fold Quality When Using Cross Folder ................................46

3-6 Other Problem ...................................................................................................46

3-7 Adjusting a Clearance between Buckle and Fold Roller ...............................48

3-8 Removing a Sheet Jam ......................................................................................49

3-9 Resetting the Circuit Breakers ......................................................................... 50

3-10 Opening the Soundproof Buckle Cover (If Installed) ..................................51

3-11 Removing a Sheet Jam When Using the KTU-35 ......................................... 52

3-12 Resetting the Motor When Using the KTU-35 ..............................................53