Hegrom Compact C-4 User manual

WELCOME to the HERGÓM family.

Thank you for choosing our built in CAST IRON STOVE.

All its pieces are manufactured in cast iron which guarante -

es that it will serve you for many, many years. All our stoves are

manufactured in special boiler plate.

We are sure that your new CAST IRON STOVE will be enti -

rely to your satisfaction.

To possess a HERGOM STOVE shows an eye for excep -

tional quality.

Please, read all the manual. Its aim is to make you familiar

with your STOVE giving guidelines for its installation, operation

and maintenance which will be very useful. Keep it and refer to

it when necessary.

If after reading this manual you need any further clarification

please contact your normal supplier or call the factory directly.

INDUSTRIAS HERGÓM, S.A., does not take any responsibility whatsoever for the dama-

ges caused by or resulting from alterations to its products that have not been authorised in wri-

ting or for defective installations.

Furthermore, it reserves the right to modify its finished products without prior war-

ning.

Industrias Hergom, S.A., with registered offices in Soto de la Marina - Cantabria Spain, of-

fers a TWO-YEAR warranty for all its products.

The geographical coverage for this warranty only includes the countries in which Industrias

Hergóm, S.A. has a subsidiary company or an official importer that carry out the distribution of

its products and where the Community Directive 1999/44/EC is obligatory.

The warranty will come into force as from the date of the purchase of the product stated on

the warranty card and only covers the damages or breakages due to manufacturing defects or

faults.

I M P O R T A N T

13

The safety and performance of the C-4 stove will greatly de-

pend on its correct installation.

It is very important to install the stove correctly.

To ensure that your stove is installed correctly it is advisable

that this job is done by a professional.

Although the Compact C-4 stove gives out heat by radiation,

directly heating walls, ceilings etc. this is mainly done by forced air

convection thanks to the ventilators incorporated in the stove which

direct the heat to the furthest parts of the room.

A. ASSEMBLY

To install the Compact C-4 stove you will first have to build a

chimney (“draught”) with suitable metal tubes until it is 1 metre abo-

ve the highest part of the roof.

If there is already a chimney, then the stove has to be installed

by extending the already existing chimney using a tube to join the

smoke exit of the apparatus to the existing chimney.

It is very important that the joints between the sections of the

chimney are well sealed. (See fig. 11).

B. POSSIBILITIES OF A HOT AIR EXIT (Fig. 2.)

EXIT THROUGH THE FRONT UPPER GRILL (A). Turn the

control 8 to the left hand limit.

EXITS THROUGH THE CANOPY (B) AND / OR TO OTHER

ADJACENT ROOMS. Turn the control 8 to the left hand limit.

The connection of the hot air exits (C) through the grills (B) of

the canopy, and to adjacent rooms can be carried out using flexi-

ble metal tubes.

To use this option you must take off the covers over the air

exits (C) of the apparatus.

Whatever type of hot air exit you choseit is advisable to install

grills in the upper part of the canopy and in the lower part of the

14

2. INSTALLATION

1. PRESENTATION

1. Front

2. Hot air exit control

3. Primary air collector

4. Stove door handle

5. Stove inside side

6. Stove inside rear

7. Air entrance grill

8. Stove inside base

9. Ashpan door handle

10. Ashpan door

11. Ash emptying cover

12. Stove door

13. Exterior steel plate casing

1

2

3

4

5

6

7891011712

13

Fig. 1

inset to allow the hot air to circulate around the inside of the stove

thus:

- bringing extra hot air to the room

- and preventing possible cracks in the covering

HERGÓM has decorative grills of 25x20 and 50x20 cm which

can be supplied as optional extras.

1. Chimney pipe

2. Hot air exit to the room

3. Grill

4. Flexible metal pipe

5. Metal clamp

6. Chimney collar

7. Hot air collar diameter 125

8. Hot air exit control

9. Hot air exit to the room

10. Cold air entrance from the room.

Fig. 2

12

3

4

8

69

10

10

2

3

4

5

7

8

9

15

C. CHIMNEY

The performance of the Compact C-4 stove depends on:

a) The chimney

b) The way it operates

c) The quality of fuel used

After several years of use you may change the type of fuel

used but once the chimney has been installed it can not be ea-

sily changed. Therefore the following information may help you

decide whether to use the existing chimney or to build a new

one.

This information will help you to make the correct decision.

1. How chimneys work

Some basic knowledge about the way chimneys work will

help you get the maximum performance of your stove. The func-

tion of a chimney is:

a) To take the smoke and fumes out of your house without

any risk.

b) To produce enough draught in the stove to keep the fire

burning.

What is the draught?

This is the tendency of hot air to rise.

When the Compact C-4 is lit the hot air rises up the chimney

and goes outside the house. The chimney heats up and keeps

the draught flowing. The draught will not flow properly until the

stove and the chimney are hot.

The draught is affected by the location, size and height of the

chimney.

The following points should be taken into account:

Chimneys inside the house are warmer and maintain a bet-

ter draught.

The suggested size of the chimney will give a good draught.

The height of the chimney affects the draught, the higher the

chimney the better the draught.

The chimney should be at least 1 metre above the highest

part of the roof.

There are other factors which affect the draught.

Trees and high rise buildings near your house.

Wind speed. Generally continuous strong winds increase the

draught but stormy weather reduces the draught.

The outside temperature. The colder the weather the better

the draught.

The barometric pressure. On rainy, damp or windy days the

draught is generally weak.

The intensity of the fire. The hotter the fire the stronger the

draught.

Cracks in the chimney, air inlets through a piping joint, other

devices connected to the chimney etc. can impair the draught.

2. Soot formation and cleaning.

When wood is slowly burnt tar and other organic vapours are

formed which when combined with air humidity form soot. Soot

vapours can condense if the chimney walls are cold. If the soot

catches fire then very high flames are produced. Any accumu-

lation of soot has to be cleaned.

As the accumulation of soot depends on so many different

things it is very difficult to say when the chimney has to be cle-

aned.

A visual inspection is the only sure way to tell whether your

chimney is free from soot.

So, please install your stove so as to give you easy access

to the chimney.

3. Options

There are two ways to build a chimney for your Compact C-

4 stove:

a) A brick work chimney

b) A pipework flue

Studies have shown that there is little difference in their per-

formance regarding the strength of the draught. The ultimate

choice rests with the owner, depending on the type of dwelling.

Whenever possible situate your chimney inside your house.

This way there will be a better draught, less soot and it will last

longer.

The advantages of brick work chimneys are:

a) With bricks and tiles the smoke stays warmer longer.

b) The heat absorbing characteristics of bricks allows you to

keep your house warm for longer after the fire has gone out.

c) It can be built to the owner’s taste.

d) If well built they can be more fire resistant than metal

chimneys.

Brick chimneys should be well lined to keep the smoke hot.

They should be built using corrosion proof high temperature

resistant materials.

As their size is the most important factor they can be round,

square etc.

Brick chimneys for the Compact C-4 should comply with the

measurements stated in section (9) TECHNICAL INFORMA-

TION.

The advantages of pipework flues are:

a) Easy installation

b) They allow slight changes in the pipework routing giving

greater flexibility in choosing the chimney location.

c) Round elbows give a better draught than angular shaped

ones.

4. Rules

The following is a list of rules to be followed when building a

chimney:

a) Always use fire resistant and non inflammable material.

Do not use cement fibre piping for the first two or three meters.

b) Choose the most vertical and straight route possible. Do

not connect several appliances to the same chimney.

16

c) Do not install the duct outlet in areas near buildings. If the-

re are adjacent buildings then the outlet duct must be higher than

the highest building.

Fig. 9

Fig. 10

Fig. 5

Fig. 6

Fig. 7

Fig. 4

Fig. 3

g) It is very important that the chimney is one metre higher

than the highest part of the house.

h) So that the cowls do not impede the draught

Fig. 8

d) For the piping choose aplace which is the least exposed to

cooling influences as possible. If possible, the chimney should be

inside the house.

e) The inner walls should be perfectly flat and free from any

obstacles. Avoid any bends where the pipe joins the brick chim-

ney.

f) It is very important that the joins of the pipes are well sea-

led to cover any possible cracks which will allow air to enter .....

The following procedure is to test that the chimney is water

tight:

Cover the exit in the roof.

Put paper and wet straw in the lower part of the chimney and

light them.

See if any smoke comes out of any possible cracks and seal

them.

INCORRECT INCORRECTCORRECT CORRECT

INCORRECT CORRECT

INCORRECT CORRECT

INCORRECT CORRECT INCORRECT CORRECT

INCORRECT CORRECT

INCORRECT CORRECT

Pipe of insufficient

length

Correct

deviation

A tile to close the chimney

At least one

metre higher

Smoke escape

(cover)

Papers and

wet straw

Too flat a deviation

Ash

accumulation

At least the

same diameter Ø

i) Clean the chimney at least once a year

Ø

j) If the chimney pipes are metal then their joints must be sea-

led with refractory paste.

k) Exterior metal chimneys must be constructed with double

heat resistant pipes especially when solid flues are used.

5. Assembly in existing chimneys

When you take advantage of existing chimneys it is advisable

to put one or twometers of metal piping in the interior of the chim-

ney making sure that the opening between the chimney and the

pipes is sealed. (see Fig. 11)

IMPORTANT:

The whole weight of the chimney must never rest on the Com-

pact stove.

17

Fig. 11

3. THE ELECTRICAL INSTALLATION

Fig. 12

Fig. 13

A. WIRING AND ELECTRICAL COMPONENTS

B. POSITIONS OF THE SWITCH

POSITION “O”; Ventilators stopped. If the temperature of the

air for heating reaches approximately 50 degrees, the THER-

MOSTAT starts up the ventilators at 750 revs per minute.

When the Compact C-4 is used it should be connected to the

electricity system to prevent it from over-heating. (Pilot light 8 on).

POSITION “I”: (COMFORTABLE) The ventilators operate to-

gether at 875 revs per minute.

POSITION “II”: (STRONG). The ventilators operate together

at 1,750 revs per minute.

We recommend

POSITION “I” (COMFORTABLE) When the stove operates

normally

POSITION “II”: (STRONG) When maximum heat is required.

POSITION “O”: When it is not being used.

Swith

ELECTRICAL PLAN

Thermostat

RED

GREEN

220 V

15 W / 20 W

220 V

15 W / 20 W

1. The right ventilator

2. The left ventilator

3. Switch

4. Strip

5. Resistance

6. Thermostat connection

7. Operation pilot (Red)

8. Connection pilot (Green)

9. Thermostat

10. Thermostat support

Seal

18

4. TO DISMANTLE GRILLS AND VENTILATORS

Instructions

A) To dismantle the grills, pull them out until they come out of

place (10).

B) to dismantle the ventilators (4) loosen the nuts (3) and ta-

ke them out.

1. Front

2. Fixed supports to the inside plate

3. Nut

4. Ventilator

5. Pilot showing that the stove is operating

6. Case spring

7. Pilot showing connection

8. Switch

9. Grill

10. Grill insulation

11. Handle to close the ashpan

12. Ashpan door

13. Oven door

14. Door join

15. Clamp to hold the glass

16. Glass

17. Ashpan door closure

Fig. 14

5. LIGHTING AND HEAT REGULATION

A. LIGHTING

Turn the handle of the ashpan door from 0 degrees to 90 de-

grees to allow more air for combustion. The door will partly open.

To increase burning and to prevent the formation of tar it isre-

commended to put the ashpan door handle at 90 degrees to allow

plenty of air for combustion.

This situation should be maintained atthe beginning of lighting

to get the stove and chimney to heat up quickly, preventing the for-

mation condensation of tar (soot).

It is vital

Once the stove is hot the ashpan door should be closed.

Fig. 15

Fig. 16

B. SECONDARY AIR

The Compact C-4 stove has a system of bringing secondary

air for combustion, directing it through the smoke baffle-collector

which allows a double combustion and means that the fuel is burnt

at peak efficiency. (Fig. 16).

13 14 15 16 17 14 1 2 3

4

2

7

6

589610116963

2

3

4

2

12

1

Partly open

Closed Completely

open

OBSERVATION:

Due to the complete water tightness and the evenly distri-

buted air intake of the Compact C-4 stoveduring normal operation

it is recommended that when fuel is being put on the stove the do-

or is opened slowly.

0º

90º

180º

19

Fig. 18

A. THE ENAMELLED CAST IRON FRONT.

Cleaning should preferably be done when the stove is cold

using slightly soapy water and a damp cloth.

B. THE GLASS OF THE DOOR

1. Cleaning

Glass cleaners for stoves work quite well.

Never try to clean the stove when it is working.

We recommend the use of the HERGOM glass cleaner.

2. Replacement

The glass of your stove is heat resistant and especially manu-

factured for wood and/or coal burning stoves.

If it is accidentally broken it must be replaced by one the sa-

me. Please contact our distributor so that he can give you a re-

placement together with the assembly and joining instructions.

C. BAFFLE (SECONDARY AIR COLLECTOR)

Dismantling (See Fig. 17)

Slide the collector “A” forwards until the connection sleeves co-

me out of their fixings and the collector falls. (Instruction “F”).

6. CLEANING

D. CLEANING OUT THE ASHES

The Compact stove has an ashpan under the bottom of the

stove.

To get rid of the ashes take the blind grill out (using a protec-

tive glove) using the door handle. Put it into the hole for the same

and take it out of its place using a slight levering action.

Brush the ashes into the ashpan

Take the ashpan out and clean it.

Fig. 19

HERGÓM has the following accessories for the Compact C-4

stove.

Glazed enamel steel pipes

Stainless steel pipes

Elbows and cowls for the chimney

7. OPTIONAL ACCESSORIES

Fig 17. Detailed dismantling of the baffle plate.

20

There are possible risks to bear in mind when operating you

solid fuel stove, regardless of the brand.

These risks can be minimised if you follow the instructions and

recommendations in this manual.

Below is a list of rules and advice but aboveall you shoulduse

your common sense.

1. Keep all inflammable materials (furniture, curtains, clothing

etc) at least 0.90 m from the stove.

2. Ashes should be removed from the stove in a metal con-

tainer and taken outside the house immediately.

3. Liquid fuel should never be used to light your stove.

Keep any inflammable liquid (oil, petrol, alcohol etc.) far away

from your stove.

4. Inspect your chimney regularly and clean it when neces-

sary.

5. Do not situate it near inflammable walls or walls which ha-

ve any type of covering which could be damaged by high tempe-

ratures (varnish, paint etc.)

8. SAFETY

9. TECHNICAL SPECIFICATIONS

Fig. 20

Model Measurements (mm)

C-4/70

Stove measurements (mm)

Height

370 560 370105450467630600700

A B C D E

Diamet er 175

200x200 5-6

10.900

Width Depth

Kg

Plate piping

(mm)

Works pipe

(mm) Height *

(m)

Kcal/h

Weight

Chimney measurements

Power

Ventilator motor: Tension 220 V. Power 2x13 W.

Draught = 2 mmca

* For other heights contact the Distributor or Manufacturer.

Heat resistant paint, for cast iron pieces and plate.

Refractory paste, for water tightness and seals.

Anti-soot, a powerful catalyser to eliminate unburnt particles.

Fire lighters, for a rapid and clean fire.

Window cleaner, the perfect product to eliminate carbonised

grease from the glass of stoves, fire places etc.

10. MAINTENANCE PRODUCTS

C

D

E

A

B

21

Fig. 21

1. Door frame

2. Interior fixing glass clamp

3. Glass

4. Glass lateral fixing clamp

5. Right rear cover

6. Plate base

7. Left rear cover

8. Stove rear

9. Stove front

10. Ashpan emptying cover

11. Left exterior side

12. Left lateral interior side cover

13. Left interior stove side

14. Hot air exit control handle

15. Hot air exit grill

16. Grill positioning spring

17. Exterior top

18. Primary air baffle

19. Door hinge

20. Stove interior top

21. Door closure bar

22. Right interior side

23. Exterior rear

24. Bottom rear stove interior

25. Right lateral interior side cover

26. Right exterior side

27. Upper side glass fixing clamp

28. Secondary air collector

29. Operation pilot

30. Connection pilot

31. Right lateral grill

32. Switch

33. Ashpan door control

34. Ashpan door handle

35. Ashpan door knob

36. Grill position spring

37. Right ventilator protective screen

38. Thermostat support

39. Ashpan door

40. Ashpan door hinge

41. Eccentric ashpan door

42. Left ventilator protective screen

43. Stove door handle

44. Stove door closure

45. Left lateral grill

11. STOVE COMPONENTS

17

16 15

18

19 20 21 22 23 24 25

16

15

14

13

12

11

10

9

8

7

6

6 5 4 3 2 1 44 33 43 42 41 40 39 38 37 36

36

4 45 36

36

34

23

24

26

25

27

28

29

30

31

32

33

Table of contents

Popular Stove manuals by other brands

RAIS/attika

RAIS/attika NEXO Series manual

Green Stoves

Green Stoves 4KW Installation and operating instructions

Masport

Masport F40 Installation and operating instructions

Dimplex

Dimplex ROTHESAY RSY20BR manual

Ravelli

Ravelli Francesca 2015 brochure

Mareli Systems

Mareli Systems AURORA SLIM Assembly and exploitation manual

Hunter

Hunter Double Herald 14 CE Installation and operating instructions

Termofor

Termofor Angara 2012 Operation manual

Travis Industries

Travis Industries 99300687 installation instructions

United States Stove Company

United States Stove Company Logwood 1261 owner's manual

Ashley

Ashley AW2520E-P Owner’s Instruction and Operation Manual

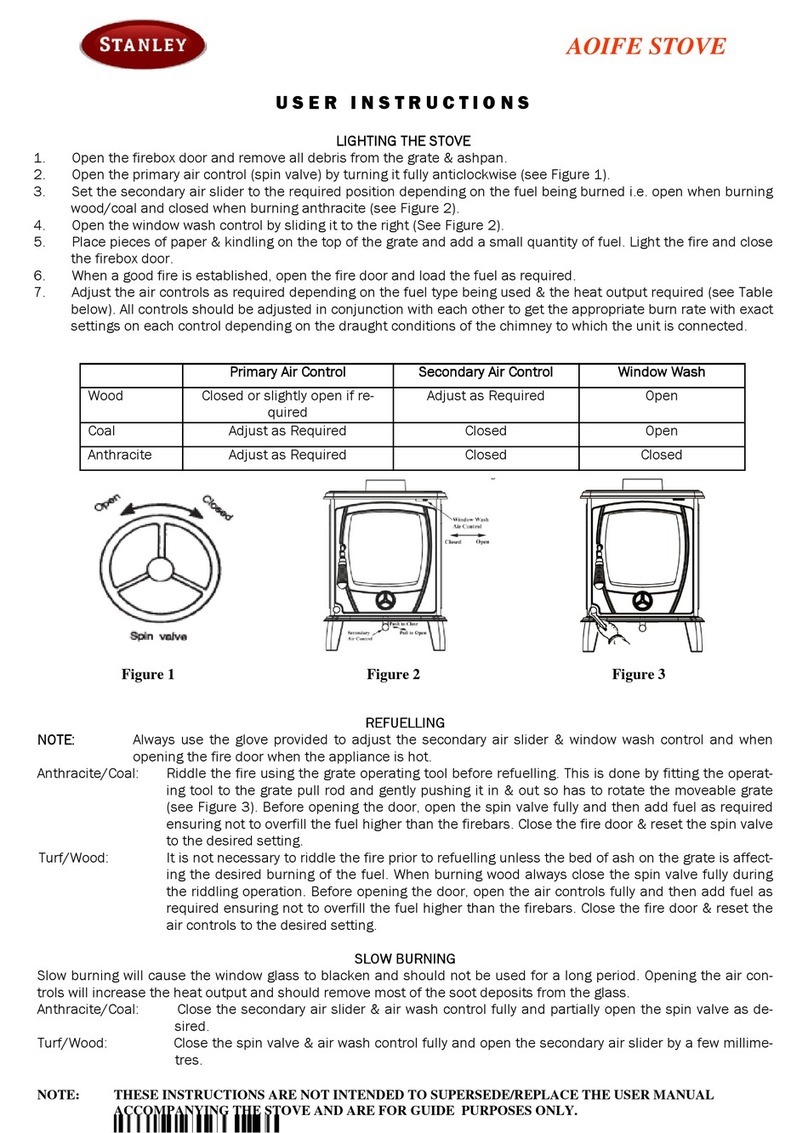

Stanley

Stanley Aoife User instructions