Termofor Angara 2012 User manual

Angara 2012

The wood-burning sauna stove

OPERATION MANUAL

Made in Russia

2

Warmth comes from Siberia

Thank you for purchase of «Termofor» Company’s products.

This maintenance manual is intended to learning of work principle, operating rule and service regulations of

the wood-burning sauna stove «Angara 2012» (hereinafter –the stove). The maintenance manual contains

instructions needed for correct and safe operation of the stove.

Persons will be allowed to installation and operation of the stove after learning this manual.

With regards,

The company «Termofor»

This document is protected by copyright law. Whole or part reproduction of this document is banned

without preliminary notice and receipt of permission from the company «Termofor».

The company «Termofor» reserves the right to make modifications in the construction of the stove

which do not decline the useful quality without updating its accompanied documentation.

3

TABLE OF CONTENTS

1. Application ........................................................................................................................4

2. Design features ..................................................................................................................4

3. Characteristic of existing heat-resistant steel. Expressions and commentaries .................4

4. Model series ......................................................................................................................5

5. Specifications ....................................................................................................................5

6. Stove structure and operation ............................................................................................8

7. Marking and packing of the stove .....................................................................................10

8. Suitable application ...........................................................................................................10

9. Servicing ............................................................................................................................25

10. Current repair ....................................................................................................................26

11. Warranty ............................................................................................................................28

12. Storing ...............................................................................................................................28

13. Carriage .............................................................................................................................28

14. Utilization...........................................................................................................................29

15. Delivery set .......................................................................................................................29

4

1. APPLICATION

The wood-burning sauna stove «Angara 2012»for heating of sauna’s steam room and its adjacent

rooms. Also, the stove is destined for steam generation and water heating.

The stove is destined for private use in Russian sauna and renders possible to get all comfortable

combinations of temperature and humidity of air.

ATTENTION! If using of the stove «Angara 2012»for commercial purposes and, also,

continuous heating of stove for more than 10 hours, when working load will increase six-

tenfold. Period of working time of the stove greatly is reduced at such conditions and

manufacturer declines all warranties.

2. DESIGN FEATURES

In closed stones section heated by a circular flame flow, the stones are heated to a temperature of

600 ° C.

Water is supplied into the hottest central part of the closed stones section through a funnel .

It is comfortable to steam a sauna whisk on traditional open heater.

The concept of thermal strength uniformity implemented in the stove. The firebox parts thickness

at the greatest thermal and mechanical load is increased by 1.5 times. The stone section bottom and

the firebox sidewalls reinforced with stringers made of heat-resistant steel.

The heat exchanger of new design for hot water allows its heating directly by flame radiation,

rather than through the stove wall.

Large translucent screen and expanding fuel channel provide tocomfortably overlookthe flames

from different angles ( in "vitra" modification).

Updated attractive design. Decorative exterior elements are made using modern technology.

3.CHARACTERISTIC OF EXISTING HEAT-RESISTANT STEEL.

EXPRESSIONS AND COMMENTARIES

Heat-resistant or scaling resistance means capacity of metal to stand against corrosive attack of gases

at high temperatures (not to be confused with high-temperature strength).

Heat-resistant of steel is enhanced by chrome doping. Chrome creates an inactive film on a surface of

steel, which does not be subjected by corrosion till limiting temperature called as temperature of oxide scale

formation beginning.

Heat-resistant of steel and temperature of oxide scale formation beginning rises with increase of

chrome content.

Steel is deemed heat-resistant when it contents mass fraction of chrome 13 % and more.

Steel divides into low-alloyed, medium-alloy and highly alloyed depending on alloying elements

content.

Steel is deemed highly alloyed when it contents alloying elements 10% and more.

Colloquially, popular phrase "stainless steel" is not standardized expression. Expression "corrosion

resistant steel" corresponds with this expression in modern materials science.

5

A key differentiator of corrosion resistant steel is chrome content 12,5% and more.

Steel used in manufacture of stoves «Angara 2012» - is heat-resistant, highly alloyed,

corrosion resistant (stainless) in accordance with above stated characteristics.

Temperature of oxide scale formation beginning of applied steel is not less 750C, and it is confirmed

by certificates of manufacturers.

For comparison: temperature of oxide scale formation beginning of constructional or "carbon" steel is

no more than 400C, it is greatly low than temperature of walls of functioning wood-burning stove.

Heat-resistant steel is more expensive than traditionally applied "carbon" steel. Its share in

manufacturing costs of stove corresponds near 50%. Therefore, in the process of selection chemical

compositions of steel, a manufacturer excludes those alloying elements and technical operations its

processing which don't increase heat-resistance and lead to unjustified increase in the cost.

Stereotypical perception of stainless steel as mirror surface is erroneous. Mirror surface of household

stainless steel products is achieved by special expensive removal of dark oxide film from surface of sheet.

This action is not needed under manufacture of wood-burning stoves.

The manufacturer considers that buyers of stoves «Angara 2012» shall only pay for those special

characteristics of steel which are needed for its using into wood-burning stoves.

Upon storage and operation of stoves in condition of higher humidity, traces of surface corrosion on

non-painted area are allowed. These traces don't influence upon operational characteristics of product.

4. MODEL SERIES

Basic models «Angara 2012» and «Angara 2012 Vitra» are produced in lots. These models have

general design features and operating principle. Differences between models consist in dimensions, the type

of the fuel channel and door.

The model «Angara 2012» has modification with a short fuel channel.

All models can be completed by an integrated heat-transfer device. The stove has various color

version of a convector.

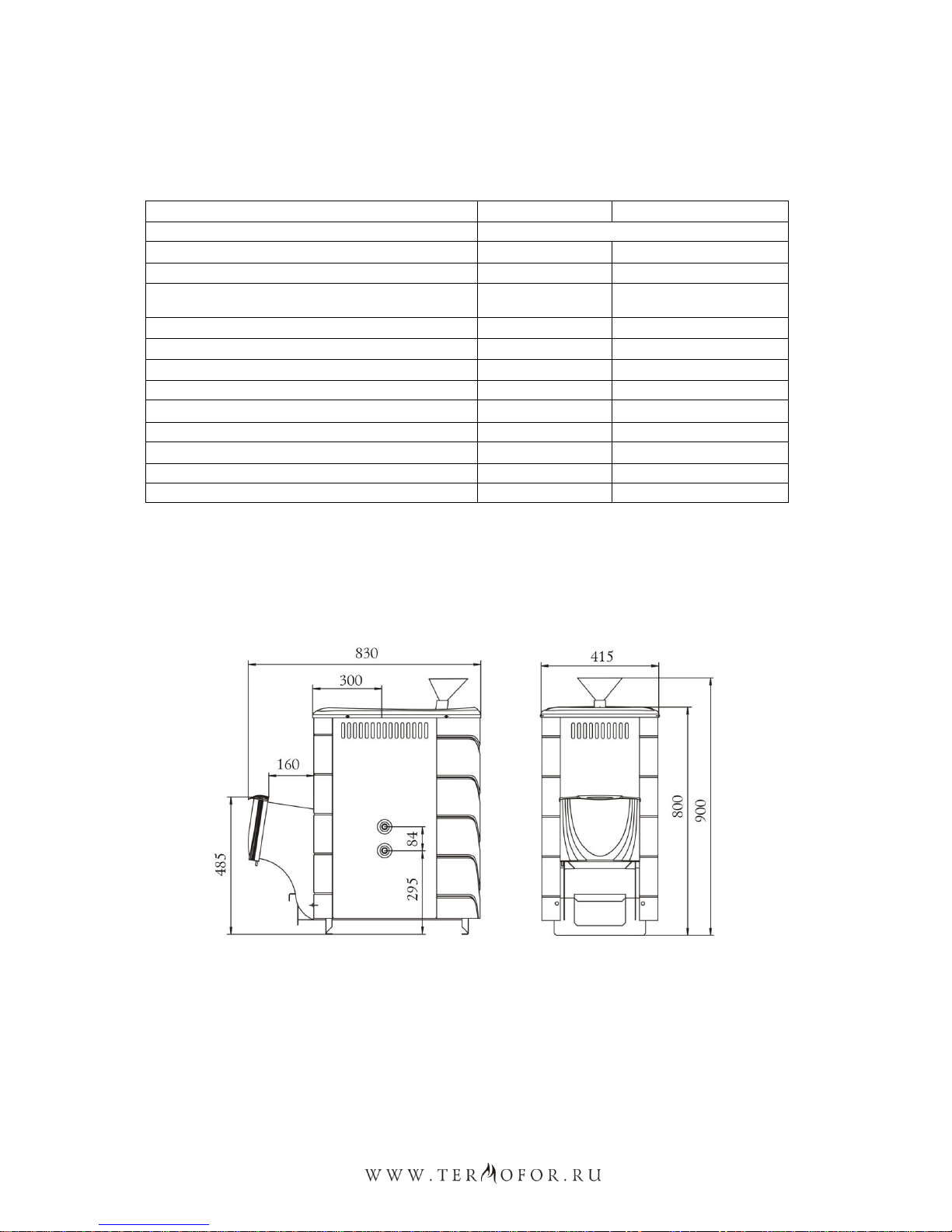

5. SPECIFICATIONS

Specifications are presented in Table 1. Overall sizes of stove are presented in figures 1-3. Installation

dimensions of the stove (aperture under fuel channel) are presented in clause 8.6.

There are following acceptable fuel types: fuel wood, peat briquette, woodchip briquette for enclosed-

type heaters.

Recommended volume of hot-water tank of a samovar type «Baykal»is 55-72 l. Recommended

volume of outboard hot-water tank is 63 l.

Heat time of a vapor room from 20C till 100C is approximately 60 min subject to correct thermal

protection.

ATTENTION! Hot-water tanks and heat exchange unit of samovar type «Kostakan»

aren’t included into delivery set.

6

The capacity of built-in heat exchange unit (for the model with the heat exchange unit) equals to 0.65l.

The size of the connecting thread of heat exchange unit fitting equals to G3/4. Mounting dimensions are

presented in figure 2.

Table1. Specifications of the stove with stones section «Angara 2012» and «Angara 2012 Vitra».

Model

Angara 2012

Angara 2012 Vitra

Calculated capacity size for space heating, CBM

8-18

Width, mm

415

500

Depth, mm (total)

830

850

Depth, mm (without including length of a fuel

channel)

595

595

Height, mm

900

900

Mass, kg

58

65

Capacity size of stones section, l

42

42

Mass of loaded stones, kg

70

70

Capacity size of combustor, l

40

40

Maximum capacity of fuel load, l

30

30

Maximum length of a log, mm

500

500

Diameter of attachable a flue, mm

115

115

Minimal height of a flue from fire-bar, m

5

5

ATTENTION! Maximum capacity size for space heating is determined by terms of

providing with effective convection heat transfer and standards of overall thermal

resistance of walling by SNIP (СНиП) (construction norms and rules) 23-02-2003.

Figure1. Overall sizes of the stove «Angara 2012»

7

Figure2. Overall sizes of the stove «Angara 2012 Vitra».

Figure3. Overall sizes of the stove «Angara 2012» with a short fuel channel.

8

6. STOVE STRUCTURE AND OPERATION

«Angara 2012» stove designed for operation in the intense combustion mode while temperature

increasing in the sauna room, and in the economy combustion mode to maintain the selected temperature.

The stove overall look and the main elements layout are shown in Figure 4.

«Angara 2012» stoves's firebox and stones section (1) made of heat-resistant high-alloy steel with a

chromium content not less than 13% with the wall thickness of 3 mm.

«Angara 2012» stove design scheme provides effective heat exchange. The stove stones section

consists of two components: an external open section (1), divided into two parts and internal closed one (7).

A special funnel provided for water supplying into the inner section (6).

External stones section (1), divided into two parts, provides the best use of heated stones mass and

temperature stability in the steam room. The large mass of stones laid into the internal section is a powerful

steam generator.

The internal stones section round shape protects against soot accumulation on the firebox walls.

Convector casing (2) covering the stove heating surfaces accelerates air heating in the steam room

forming a strong convection flow. Besides of that, it shades hard infrared radiation emitted from the hot

firebox walls, which creates soft warmth in the steam room and serves to protect against accidental contact

with the stove during its operation.

Through the special duct (8) secondary air is supplied into the stove flue ducts for exhaust gases post-

combustion and the stones section effective heating.

Outside-mounted fuel channel allows the stove firing in an adjacent room. Model with a short fuel

channel is for those who prefer to fire the stove inside the steam room.

Firebox door, rotating hinged opens at an angle required for a comfortable and safety fuel loading.

«Angara 2012 Vitra» model door manufactured in two interchangeable versions: the steel door (11)

with an outer panel self-cooling property and the door of the original design with translucent screen made

of heat-resistant glass SchottRobax ® (12).

«Angara 2012 Vitra» model completed with a panoramic fuel channel (4) and the door with

translucent screen made of heat-resistant glass SchottRobax ® with diagonal of 17cm (3). There is a gap in

the upper part of the door for pyrolysis self-cleaning of the translucent screen from soot settling.

Heat-resistant glass screen allows you to monitor combustion process and simply enjoy living fire.

The fire-bar (9) made of solid cast iron installed in the lower part of the firebox. The ash box with

sliding ash drawer (10) is under the firebox.

With the stove operation, primary air required for combustion is supplied through the ajar ash drawer

(4) and bar (9) to the fuel. The bar provides combustion process acceleration and a powerful high-

temperature flame at the ignition moment. It provides a uniform wood burning which is so necessary for a

bathhouse stove.

Ash falls into the ash box through the gaps of the bar and you can easily clean the stove without

combustion process interrupting.

Combustion gases are directed into the chimney through the flue pipe with diameter of 115 mm.

In the model with a heat exchanger the exchanger mounted within the firebox on the sidewall, there

are symmetrical openings closed with plugs on the firebox opposite wall. The heat exchanger provides

water heating in the outside tank and its location inside the firebox accelerates heating process greatly.

The stove components without large thermal load are made of structural steel.

9

The stove outer surface is covered with a heat-resistant organosilicon enamel of KO-868 type

ATTENTION! The manufacture reserves the right to introduce changes into the sauna

stove design not impairing its consumer properties.

«Angara 2012 Vitra»

«Angara 2012»

1. External stones section

2. Convector casing

3. Door with translucent screen made of heat-

resistant glass SchottRobax ® with diagonal of

17cm

4. Panoramic fuel channel

5. Chimney (chimney flue. It is outside the scope

of supply)

6. Special funnel for water supplying into the

inner section

7. Internal closed stones section

8. Fire box

9. Cast iron stove bar

10. Ash box with sliding ash drawer

11. Steel door

12. Door with translucent screen

Figure 4. layout of the main elements of the stove ―Angara 2012‖. Modification with heat exchange unit.

10

7. MARKING AND PACKING OF THE STOVE

7.1. Marking

On a stove there is an information code plate with details about a model of a stove, its mass, factory

serial number, production date of a stove and other technical features, and also the information on

certificates for this model.

7.2. Packing

A stove is packed in a transport pack. Maintenance manual in a packaging bag and components are

enclosed in the stove combustor.

On a pack of a stove at the front part there is a label with information about a model of a stove, its

mass, design features and production date.

7.3 Procedure of remove the packaging by a consumer

1. Cut a packing tape

2. Remove cardboard boxes

3. Remove a polyethylene

4. Pull from a stove maintenance manual and components (if available) and take off a packing

5. Take away blocks and turn off fixing bolts

6. Remove advertising stickers from a surface of a protective film.

8. SUITABLE APPLICATION

8.1. Operational constraints

ATTENTION! Don’t use the stove for industrial premises of categories A (А), B (Б), V (В)

of fire and explosion safety in accordance with NPB (НПБ) 105-95 (classification of

premises and buildings of fire and explosion safety).

ATTENTION! Don’t use matters as fuel which aren’t mentioned under point 5.

ATTENTION! Expressly prohibited using charcoal and coal briquettes as fuel.

ATTENTION! Don’t use alcohol-containing means, benzene, kerosene and other highly

inflammable matters for ignition. Don’t use a glossy paper, trimmings of wood particle

boards, laminated flooring board, orgalite because these matters would evolve noxious

substances under burning, and would be cause of outburst and damage of a stove.

ATTENTION! Don’t use the stove with an empty heat exchange unit and a hot-water tank

or an unconnected system of water heating (if available).

ATTENTION! Don’t use the stove inappropriately.

ATTENTION! Don’t use the stove in autohouses, trailers and tents.

ATTENTION! Don’t commit overheating of the stove at the time of its operation.

11

Overheating of the stove can be identified by red glow of the metal in the dark.

This situation can appear upon the uncontrolled air supply into the fire box. For example, when the

door is open. The stove warming up may lead to dangerous conditions of the stove operation and its

premature breakdown.

8.2. Commissioning of the stove

ATTENTION! At the time of the first heating of the stove applied on the metal industrial

oils and light volatile compounds of organosilicone enamel evolve smoke and smell,

which aren’t evolved in the following.

People having chest troubles and owners of the pets susceptible to smoke (for example birds) should

take precaution measures.

The first heating of the stove it is necessary making open-air with fire prevention discipline, at least

one hour, with charging of a fire box in half in the regime of active combustion.

For correct operation of the stove, at the time of the first heating it is necessary to organize a

temporary flue with height at least 2m.

For the model of stove with built-in heat exchange unit it is necessary to organize temporary water

heating system during the first pre-heating.

ATTENTION! Don’t make mechanical action to a surface of a stove till complete cooling

and final polymerization of paint at the time of the first heating in order to avoid damage

of a lacquer coating.

ATTENTION! The first heating of the model «Vitra» shall be carried out with opened

door of combustor to prevent smoked translucent screen.

Please, make sure in normal functioning of the all components of the stove and protective

constructions. A faulty stove is not permitted to operation.

An efficient stove:

Doesn’t have external damages of a carcass.

A door freely revolves on hinges, closely adjoins to a carcass and is efficiently fixed by a lock.

A translucent screen on a door (if available) doesn’t have damages.

Fire bar is safe without burnouts and cracks.

An ash drawer has to freely move and it closely adjoins to a carcass in the closed position.

A heat exchange unit (if available) doesn’t have any damages.

8.3. Stones for stones section

It is necessary to load special stones into stones section. The manufacturer recommends using

gabbrodiabase, peridotite, talcum peach, jadeite. These volcanic rocks possess a beautiful pattern and

composed of durable minerals against physical and chemical action. Also, these volcanic rocks don’t

contain harmful impurities. These volcanic rocks possess considerable heating capacity, stand against large,

repeated temperature differential. Also, stones are fireproof and don’t break. Irregular shape of stones and

difference of its sizes provide maximum filling of stones section and maximal area of heat output.

ATTENTION! Stones of unknown origin can contain, numerously, harmful sulfides and

radionuclides, which make its useless and even dangerous for using in a sauna.

12

Stones shall be rinsed by scrub brush in flowing water before load.

Do not put stones higher than a top level of the stove, because stones will not heat-up to temperature

needed for quality steam formation.

Attention! Exclude the possibility of excessive water supply to the non-burning hot stones.

In this case the intensive stones section walls oxidation process will take place due to the

direct contact of water and metal. This reduces the service time of the stones section and

as the result of its burning-through.

Attention! Hot steam exhaust from the stones section takes place when water is supplied

to the non-burning hot stones. Supply water carefully.

During the long use of the stove it is necessary to carry out the shift of stones not less than once per

year. At the same time the pebble gravel should be removed and destroyed stones should be replaced with

the new ones.

8.4. Preparation of premises to installation of the stove

Protect from fire constructions of premises:

•Walls (or partition) of inflammable materials have to be protected with plaster with

thickness 25 mm on an expanded metal or a metal plate on an asbestos paper with thickness

10 mm, from a floor to a level of 250 mm above the top of the stove.

•A wall (or partition), through which fuel channel pass, shall be from nonflammable materials

from a floor to a level of 250 mm above the top of the stove. Recommended thickness of a

wall is 125 mm.

•A floor under the stove has to be protected by a foundation from brick at least two coating or

other nonflammable material at a distance of 380 mm from a wall of the stove.

•A floor of inflammable and combustible with difficulty materials in front of a door of a

combustor has to be protected with a metal plate with size 700×500 mm with length its side

along the stove.

•Make a fireproof partition in a passage of a flue through a ceiling.

•At the time of installation of a flue in premises with a roof of inflammable materials a flue

has to be protected with a spark arrester of gauze with an opening with size no more 5×5

mm, also have to block with nonflammable roofing materials a space around a chimney.

ATTENTION! A place of installation the stove and chimney will be done in accordance

with SNIP (СНиП) (construction norms and rules) 41-01-2003 or, in accordance with

technical standards of a country, where the stove would be exploited.

8.5. Air change in a steam room

It is recommended to organize a balanced system of ventilation for provision of good air change (see

figure 6).

A hole for fresh air intake (9) with a section about 100 square centimeters is made in a floor as closely

as possible to the stove or under the stove.

A hole for used air exhaust (6) is made in a wall just below of a level of a ceiling as far as possible

from the stove. For more moist and cold air exhaust, a vertical box (8) is installed to a top hole. A vertical

box possesses a vent hole at a distance not more than 50 cm from a floor.

13

It is recommended to install adjustable latches (7) in air inlet and exhaust outlet for possibility to

control air exchange.

ATTENTION! It is necessary to provide constant inflow of fresh air into the room where

the stove is operating. The breach of the condition may lead to unstable operation of the

stove and appearance of dangerous situations such as poisoning with carbon monoxide,

fire breaking-out.

8.6. Stove assembly

ATTENTION! All the stove assembly and stones setting into the stones section works shall

be carried out only after total cooling off of the stove.

ATTENTION! The stove is heavy. Make sure that you have the possibilities and equipment

for its moving.

ATTENTION! It is prohibited to install the stove in the places where the stove will create

obstacles for people moving during evacuation.

ATTENTION! It is necessary to carry out the installation of smoke sensors and gas

detectors in the rooms where the stove is installed.

Mount the stove to the specially prepared place. Make sure that the stove is assembled and installed

correctly.

Provided after reading this manual you still have any doubts concerning the stove correct installation

you should consult the stove assembly specialist who is aware of all the aspects of safe and correct

installation of stoves.

A scheme of installation of the stove is presented in figure 6. Distance from the door of the combustor

till the wall opposite will be at least 1250 mm. Distance between the top of the stove and an unguarded

ceiling will be at least 1200 mm.

Distance between an external surface of the stove, flue and wall will be at least 500 mm, for

constructions of inflammable materials will be 380 mm, for constructions of inflammable and combustible

with difficulty materials which are protected by a metal plate on an asbestos paper with thickness 10 mm or

with plaster on expanded metal with thickness 25 mm.

Do not install the stove into the niche in a wall or into the fire place.

Distance from the side of a fuel channel till a wall shall be at least 30 mm. If thickness of a wall is 125

mm then a door of a combustor will have the most correct position.

Wall opening for fuel channel from the level of support feet shall have the following dimensions

(height × width):

for «Angara 2012 2011» models —480×270 mm.

for «Angara 2012 2011 Vitra»models —545×410 mm.

14

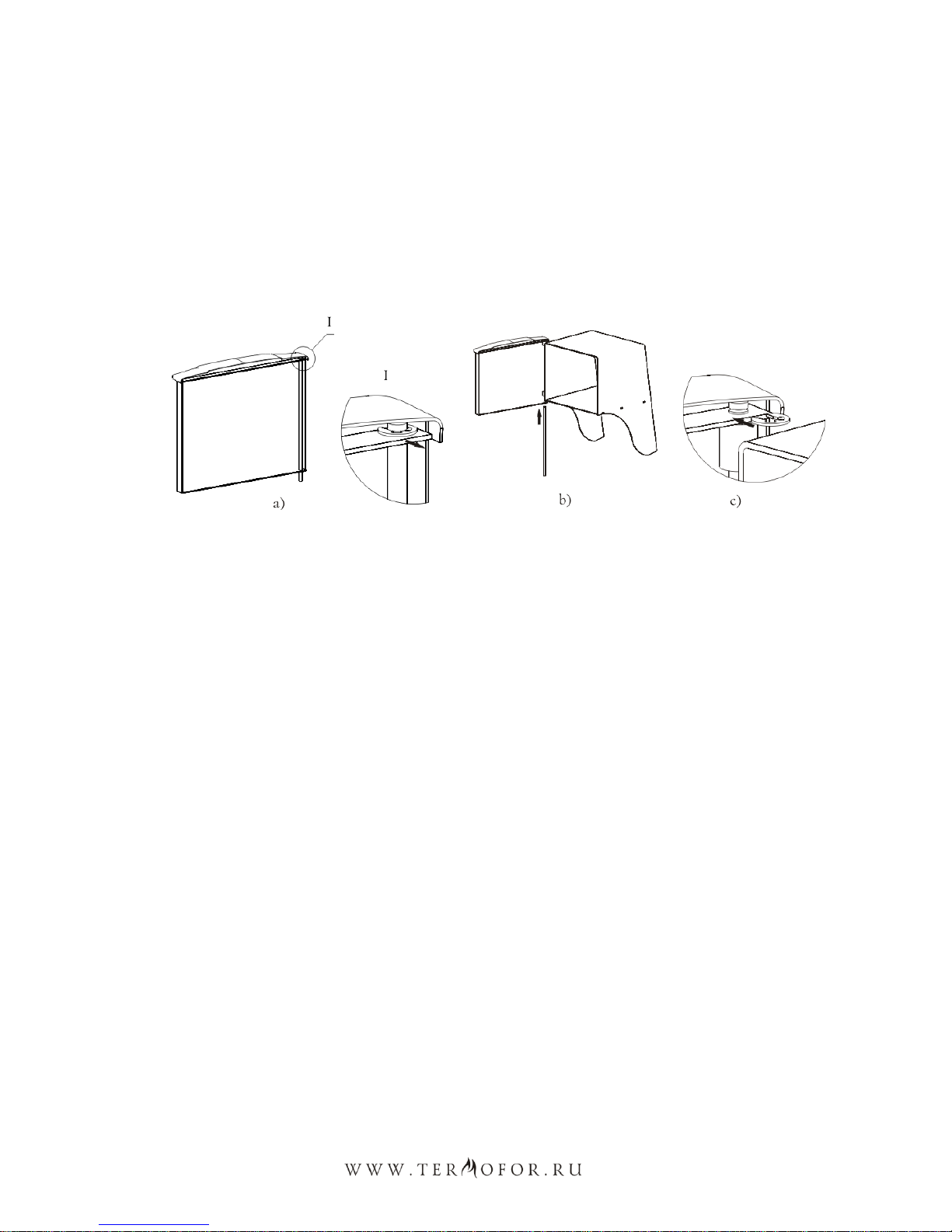

For installation of the model «Vitra» on the site of

operation it is necessary:

1. Unscrew self-tappers 8 ps. that fixes a door with a

frame to a fuel channel and remove a door; (see

Figure 5)

2. Install the stove on the site of operation (edge of a

fuel channel shall emerge from another side of a

baffle);

3. Install back a door with a frame. I will be fixed by

self-tappers.

Figure 5. Door disassembling under

installation of the stove «Vitra»

a metal plate on a heat-insulation

material (an asbestos paper with

thickness 10 mm)

wood (inflammable material)

a thermal insulation of a

nonflammable material

(haydite/dross/ basalt wool)

bricks and so on (a nonflammable

material)

a material of foundation

(nonflammable)

1. A sheet in front of a combustor

2. A flue cover

3. Flue with a thermal insulation of

type «sandwich construction»

4. An overlap of a nonflammable

material for a roof

5. A roof splicing

6. A hole for used air exhaust

7. Adjustable latches

8. A vertical box

9. A hole for fresh air intake

10. Start-sandwich

Figure 6. Installation of the stove in

inflammable material premise

15

For the models «Angara 2012», the stove is installed on the site and then a door put on a fuel channel.

A door is included in a delivery set.

Installation of a door on the models «Angara 2012»:

1. Remove a stop quick-detachable collar, then remove the axis out of the door, see figure 7 a;

2. Install the door on sleeves of a fuel channel and unite holes;

3. Set an axis from bottom to top through holes. Place a groove under a collar in the top part of an

axis, see figure 7.b;

4. Install a stop quick-detachable collar in a groove on an axis, see figure 7.c.

Figure 7. Assembly of the door under installation of the stove «Angara 2012».

The stones shall be set into the stones section after the end of the stove mounting and its connection to

all the necessary systems.

8.7. Stove pipe assembly

During the use of the stove, the stove pipe shall be treated very carefully.

Stove pipe (chimney stack) –is the means of air ventilation of exhausted gases, it provides the draught

that facilitates the constant air intake into the heating equipment necessary for normal burning process. The

stove is designed only for operation with natural draught.

The stove shall have its own stove pipe.

ATTENTION! It is prohibited to connect the stove to any air ducts except for the cases

when the air duct is designed only for operation as the stove pipe.

ATTENTION! It is prohibited to connect the stove to the stove pipe that is connected to

another equipment or heating unit.

ATTENTION! The stove does not draw. The draught is made only with the stove pipe.

The stove pipe has two functions for the stove trouble-free operation. The first –is the piping of

exhaust gases generating during the fuel combustion. The second –is draught for air intake into the fire

chamber for combustion maintenance.

Draught –is the natural air or gases movement through the stove pipe. It generates due to the feature

of warm air to go upwards.

16

As far as the warm air moves in the stove pipe the low pressure is generated in the place of the stove

connection to the stove pipe. The greater pressure from the outside of the stove makes the air move into the

area of lower pressure –into the area of fire box. Thus the air intake into the fire chamber happens. This

constant air inflow is the draught.

The stove won’t be operating effectively if there is no draught of the definite value.

The optimal draught for operation of stoves of «Termofor» trademark equals to 12±2 Pa.

Provided the excessive draught the considerable air flow will be entering the fire chamber and this will

lead to the stove overheating. Fire hazard may appear.

With the insufficient draught the insufficient amount of air for fuel proper and complete combustion

will be entering the fire chamber and this may lead to smoke generation in the room. The creosote

generation increases upon the formation of excessive smoke in the stove pipe and that may ignite creating

the fire hazard in a house.

Creosote —is colourless (sometimes yellowish or yellow-green), inflammable, hardly soluble in

water oily liquid with strong smell and pungent taste extracted from wood and coal tar. This is the mixture

of phenols mainly guaiacol and cresols. Soluble in alcohol and ether. Poisonous.

Creosote will inevitably be generated in your stove and stove pipe. To reduce the speed of its

generating it is necessary to:

Use only dried billets that were dried during the period for not less than one year.

Use hardwood of broadleaf woods that is more compact (more heavy) and combust with the higher

temperature.

Before the use of the stove check and amend all that can influence the draught. Reducing or increasing

of draught may influence the draught by set of different factors, some of them may change in the course of

time. Factors influencing the draught:

Atmospheric pressure –may act from outside of a room, from inside and from both side by turns.

Weather conditions to which the high pressure conforms (clear and cold days) usually create the perfect

conditions for combustion.

Negative pressure outside the heated room –is created with the help of ventilation facilities such as:

ventilation inside the sauna room, draft hood, equipment for clothes drying, boilers with forced draught.

Upon the negative pressure the air flow in the stove pipe will go backwards at that ―negative draught‖ or

―backdraught‖ is created.

Negative pressure can be neutralized by opening the door or window in the room with the stove.

The stove pipe temperature –the draught in the warmed up stove pipe is better than in the cold one.

The cold stove pipe quickly cools off hot gases going upwards and this will prevent their further going

upwards. Combustion of the first fuel charge will be enough for the stove pipe warming.

Stone stove pipes and stove pipes with section larger than the heating device are warmed up for a

considerably longer period of time.

The chimney stack shall have minimal number of elbows. The straight pipe is preferable. The use of

more than two piping may lead to the draught loss and possible smoke generation.

The manufacturer recommends to use modular thin-walled chimney stacks made of high-alloy,

corrosion-resisting steel of «Termofor» trademark with the diameter of 115 mm. They are effective, durable

and required thee minimum expenses for assembling and during operating.

For reliable fastening of the units together it is necessary to use «collar-strainer»; the use of self-

drilling screws is allowed if necessary.

17

In case of installation of thick-walled metal, ceramic, asbestos-cement or other chimney stack of

greater weight it is necessary to unload the stove from its weight.

ATTENTION! The manufacturer shall not be responsible for the influence of external

factors on the reduction of natural draught in the stove pipe.

ATTENTION! It is prohibited to use chimney stacks with galvanic coating.

ATTENTION! Do not use pipes from different manufacturers in the stove pipe.

ATTENTION! To avoid the smoke blowing into the heated room all the places of chimney

stack units connection against each other and the stove it is necessary to compact with

high-temperature sealant (not less than 1000°С) providing the air-tightness of the pipe

junctions.

ATTENTION! The junction of stove pipe units in overlaps and fire block is prohibited.

ATTENTION! The section of chimney stack located in the zone of sub-zero temperatures

shall be obligatory heat insulated by non-combustible material, withstanding

temperatures not less than +400 °С.

The ideal solution for chimney stack –is the installation of ready-made pipe units with heat insulation

of ―sandwich‖ type of «Termofor» trademark.

In case of connection of the stove to fixed built-in stove pipe or in other cases it is not recommended

to deflect the axis of chimney stack from the vertical line for more than 45°.

ATTENTION! sauna stove and chimney stack assembly shall be carried out by qualified

workers from the specialized construction and installation company in compliance with

the requirements of SNIP 41-01-2003 (construction norms and rules) or in compliance

with technical norms of the country where the stove will be used.

ATTENTION! It is strictly prohibited to make dismountable the connections of the stove

with the stove pipe or other structural elements of the room.

ATTENTION! In case of fire in the stove pipe shut the dampers of air supply into the fire

chamber, leave the room and immediately call the firemen.

In case of fire in the stove pipe it is necessary to have a clear scheme of actions that shall be elaborated

by consulting the specialist. After the fire in the stove pipe will die down, the stove pipe shall be cleaned

and checked for the destructions. Make sure that there are no flammables around the stove pipe.

8.8. Stoves with heat exchange unit

Stoves with heat exchange unit help to locate the tank for hot water outside the steam room and install

it in wash room. «Termofor» heat exchange units are produced in two variants:

1) heat exchange unit of «samovar» type installed at the outlet nozzle of the stove pipe (do not

supplied as part of package);

2) built-in heat exchange unit, installed at the wall of fire chamber inside the stove (supplied with the

stove of corresponding model);

18

For the first variant water in the heat exchange unit is heated due to hot gases piped into chimney

stack. Such heat exchange unit can be moved by its connecting pipe in any direction.

For the second variant –water heating is carried out due to the direct contact of heat exchange unit

walls with the flame in the fire chamber.

Built-in heat exchange unit with factory assembly is installed from right (or left) side of the stove. If

necessary it can be shifted to another side of the stove –this will allow to install the hot water tank from the

side convenient to the Consumer.

Heat exchange units are made of heat-resisting high-alloy stainless steel with the content of chromium

not less than 13%.

«Termofor» company recommends along with «Angara 2012» sauna stove use the heat exchange unit

«Kostakan» of «samovar» type of «Termofor» trademark.

8.9. Shift of built-in heat exchange unit

Holes in fire chamber and convector walls (in models with heat exchange unit) for the connecting

pipes output are on the both sides of the stove that is why the heat exchange unit can be shifted if necessary

to another side.

It is recommended to carry out the shift of built-in heat exchange unit before the stove assembly.

Provided the stove has been already installed and is in use then it is necessary to carry out its disassembling.

ATTENTION! All works shall be carried out when the stove is fully cooled off.

For heat exchange unit shift to another side it is necessary (convector and heat exchange unit fastening

for all models of «Angara 2012» sauna stove are analogous):

1. Remove the convector frame by unscrewing 4 self-drilling screws (figure 8);

2. Remove the convector by unscrewing 5 self-drilling screws (figure 9);

3. Remove the heat exchange unit (figure 10) by unscrewing 2 nuts and taking it off the holes, the

gaskets shall stay on the nipples;

4. Remove 2 blind plugs by unscrewing nuts and taking off the blind plugs from the holes;

5. Insert the heat exchange unit into the holes on the other side of the stove and fasten it with nuts;

6. The rest holes shall be fastened with blind plugs;

7. Carry out the convector assembly in the reverse order (see cl. 2-1).

Figure 8. Disassembling of «Angara

2012» sauna stove convector frame

Figure 9. «Angara 2012» sauna stove convector

disassembling

19

ATTENTION! During the heat exchange unit shift the gaskets made of non-combustible

material shall be located from the inner side of the fire chamber.

Figure 10. «Angara 2012» sauna stove heat exchange unit and blind plugs disassembling

8.10. Installation of a water heating system

ATTENTION! Don’t connect a heating system to a heat exchange unit.

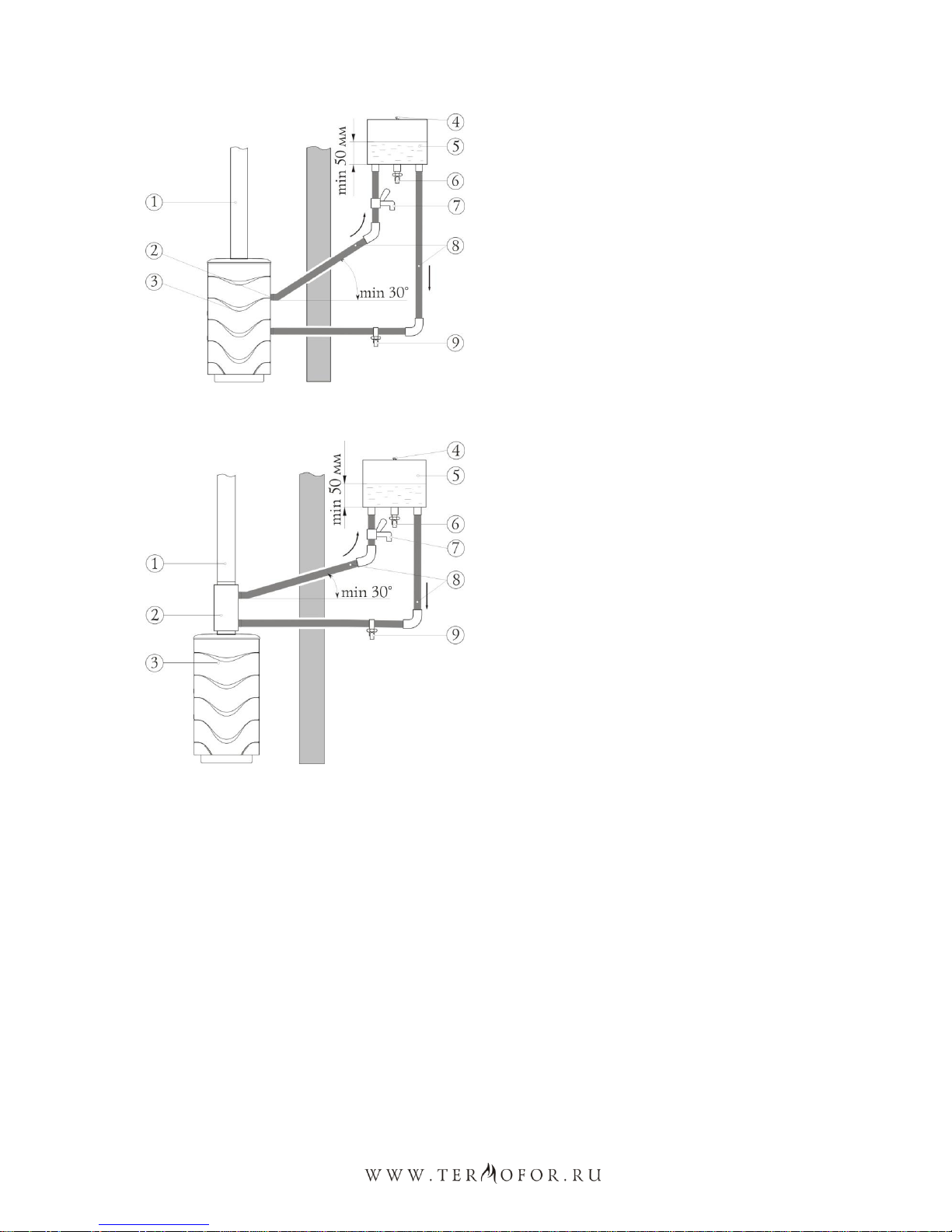

A general scheme of installation of a water heating system is presented in figure 11 –with a fixed heat

exchange unit; 12 –with heat exchange unit of «samovar» type. Elements of a water heating system

including a heat exchange unit aren’t supplied as part of delivery set.

A water heating system consists of:

•A heat exchange unit (2) with two fitting adapter;

•Connective pipes (pipeline) (8);

•An outboard tank (5) for hot water with two fitting adapters for connecting to a heat transfer

system and one fitting adapter for installation of a tap of hot water distribution;

•A tap for hot water (6), a threeway tap (7) and a tap for water drain from a system (9).

At the time of installation of a water heating system, a bottom of an outboard tank for hot water shall

be over of a level of a top fitting adapter of a heat transfer device no less than 30 cm.

ATTENTION! At the time of pipelines installation, don’t permit its sagging in horizontal

segments. It is recommended to install these pipelines at an angle of up no less than 30°.

ATTENTION! Don’t use pipes with work temperature of operation less than +95°C for a

water heating system.

20

1. Chimney

2. Fixed heat exchange unit

3. Stove «Angara 2012»

4. Connection with atmosphere

5. Outboard tank for hot water

6. Tap for hot water

7. threeway tap

8. Connective pipes

9. Tap for water drain

Figure 11. Scheme of installation of a water

heating system with using the fixed heat exchange

unit

1. Chimney

2. Heat exchange unit «Kostakan» of

«samovar» type

3. Stove «Angara 2012»

4. Connection with atmosphere

5. Outboard tank for hot water

6. Tap for hot water

7. Connective pipes

8. Connective pipes

Figure 12. Scheme of installation of a water

heating system with using the heat exchange unit

«Kostakan» of «samovar» type

ATTENTION! Don’t use connecting elements of a pipe fitting with nominal width less

than nominal width of fitting adapter of a heat exchange unit.

ATTENTION! It is prohibited to exceed the operating pressure in the water heating

system for more than 0.05 MPA (0,5 kgs/cm²) during the use of «Angara 2012»bath stove

with the heat exchange unit.

ATTENTION! Pressure test of the system by higher pressure shall be carried out when the

heat exchange unit is switched off.

ATTENTION! Only clear water shall be filled to a water heating system. It shall meet

requirements of quality in the context of salt, iron, lime content and other.

If necessary to get hot water at a short time then it will be permitted to make water distribution before

its entry to a tank. For this purpose, it is necessary to connect a threeway tap (7) to a pipe of hot line

This manual suits for next models

1

Table of contents

Popular Stove manuals by other brands

Golden Eagle

Golden Eagle WOOD PELLET STOVE Operating & installation manual

Anvil

Anvil STA0001 R02 Installation operation and care

Elite Products

Elite Products EDB-302F instruction manual

Stuv

Stuv 16/58-cube Installation, user and servicing instructions

Artel

Artel NCA115-2A manual

United States Stove Company

United States Stove Company KP5522 manual