Heidolph RotaChill Large User manual

Table of contents

Languages:

Other Heidolph Chiller manuals

Popular Chiller manuals by other brands

Carrier

Carrier Model F-30HR Installation, Start-Up and Service Instructions

B&D

B&D Chill-O-Matic IN1500BKB Care & maintenance

Daikin

Daikin EWAQ016BAW Installation and operation manual

Clint

Clint idroinverter CHA/IK Series INSTALLATION, USE AND MANTEINANCE MANUAL

Apach

Apach ASH05K user manual

Trane

Trane AquaStream CGWN 205 Installation operation & maintenance

Carrier

Carrier AquaForce PUREtec 30XBEZE 200 Installation, operation and maintenance instructions

Nordcap

Nordcap NUOVAIR N150T1 Industry Maintenance manual

SMC Networks

SMC Networks HRS090 Series manual

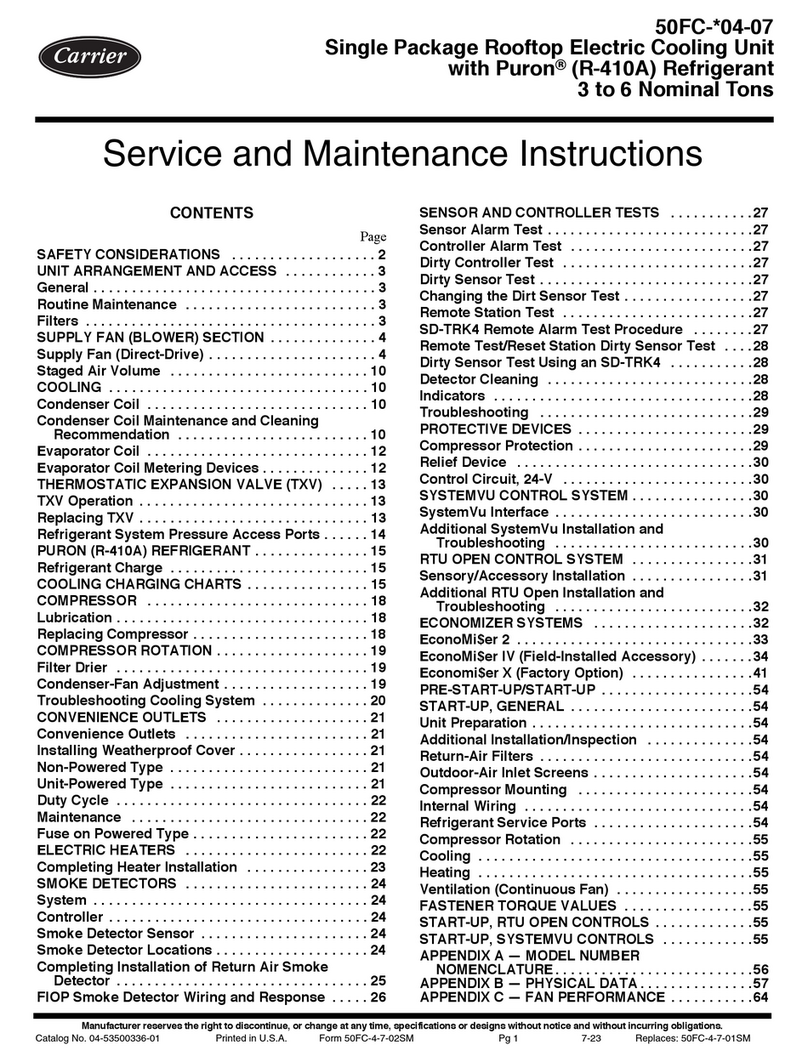

Carrier

Carrier 50FC 04 Service and maintenance instructions

MYDAX

MYDAX 1M9W-S Instruction, operations & maintenance manual

CIAT

CIAT AquaCIAT LD Series user guide

ritetemp

ritetemp R422D Installation & maintenance guide

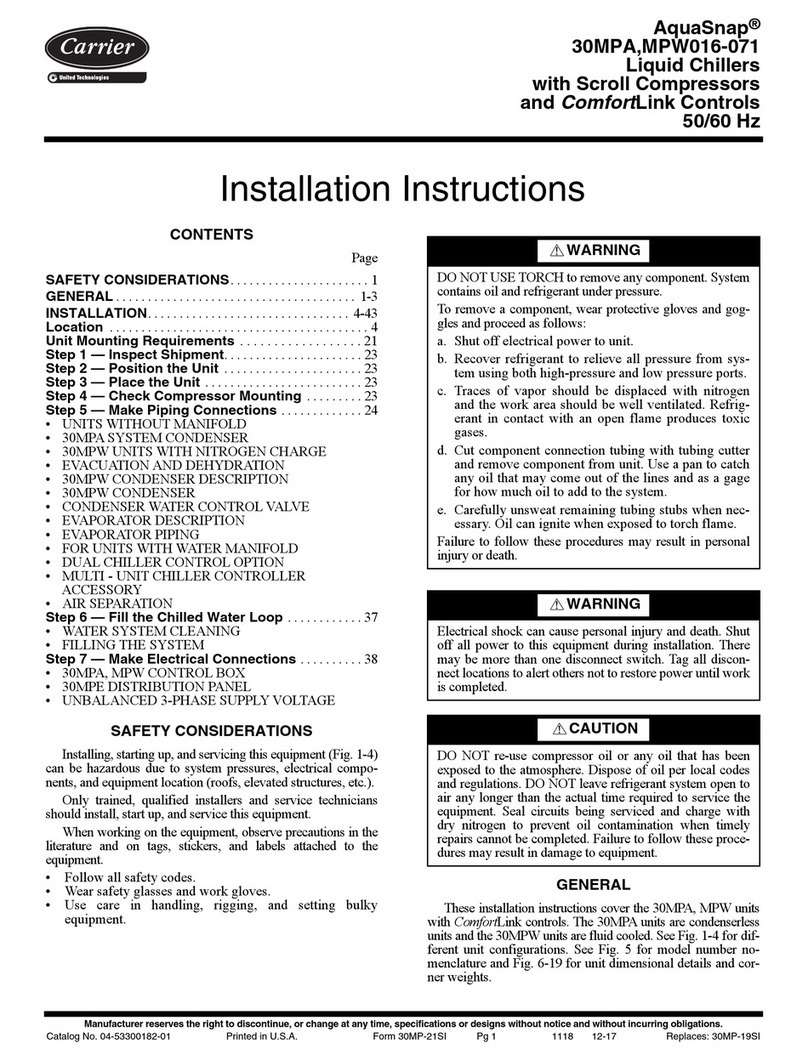

Carrier

Carrier AquaSnap 30MPA050 installation instructions

Acson international

Acson international IOM-A5PADW-2101 Operation manual

McQuay

McQuay Seasonpak ALR-035A Installation and maintenance data

Bally

Bally 500 Installation and operation manual

American Panel

American Panel AP20BC Series Installation & operator's manual