Contents

Contents

About this Document 4

Version and variants ...........................................................................................4

About this manual ..............................................................................................4

Symbols and keywords........................................................................................5

Safety Instructions 6

General safety instructions...................................................................................6

EU Declaration of Conformity.........................................................................6

Intended use...............................................................................................6

Installation .................................................................................................7

Qualications of personnel ............................................................................7

Operating company’s obligations...........................................................................8

Installation site ...........................................................................................8

Modications to the device............................................................................8

Safety of personnel......................................................................................8

Safety during use ...............................................................................................9

Disposal ............................................................................................................9

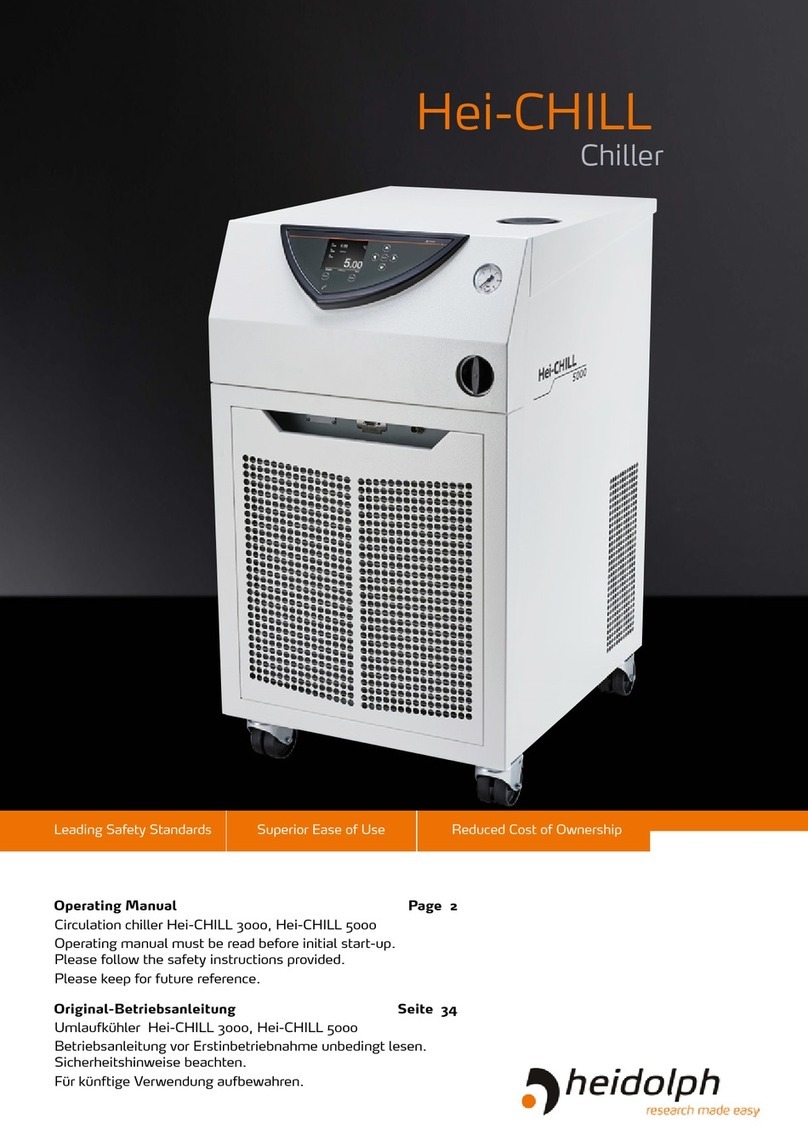

Device Description 10

Device overview ...............................................................................................10

Device overview Hei-CHILL 250 / 350 / 600 / 1200 ........................................10

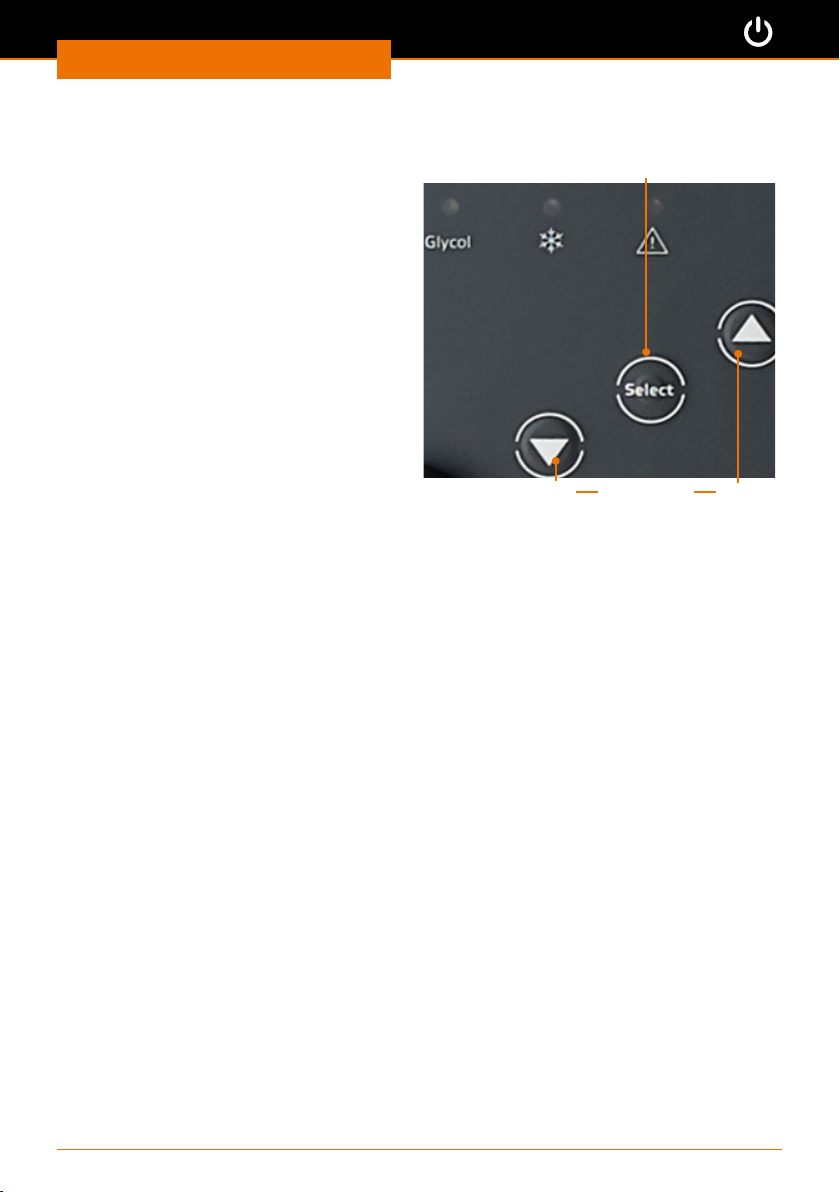

Hei-CHILL control panel..............................................................................11

Start Up 12

Setting up the device ........................................................................................12

Connecting/disconnecting the power cord ............................................................13

Switching the device on and o ..........................................................................13

Filling with thermal uid ....................................................................................14

Filling for the rst time ...............................................................................15

Menu navigation...............................................................................................17

Entering the temperature setting ........................................................................18

Setting the temperature limits.....................................................................18

Setting the temperature setpoint .................................................................20

Operation 21

Overview of menu structure...............................................................................21

Temperature control operation............................................................................22

Interfaces........................................................................................................23

RS 232 interface........................................................................................23

Interface commands ..................................................................................24

Cable and interface test for RS232 ...............................................................25

Alarm output.............................................................................................26

Autostart ..................................................................................................27

Restoring the factory settings.............................................................................28

Operating Manual