CE

All the products are in con ormity with the ollowing

European provision:

-Low voltage Directive

-Electomagnetic Compatibility

ROHS

Your air conditioning product is marked with this

symbol.This means that electrical and electronic

products shall not be mixed with unsorted

household waste.Do not try to dismantle the

system yoursel :the dismantling o the air

conditioning system,treatment o the re rigerant,o oil and o

other part must be done by a quali ied installer in accordance

with relevant local and national legislation.Air conditioners

must be treated at a specialized treatment acility or reuse,

recycling and recovery.By ensuring this product is disposed

o correctly,you will help to prevent potential negative cons-

equences or the environment and human health.Please

contact the installer or local authority or more in ormation.

Battery must be removed rom the remote controller and dis-

posed o separately in accordance with relevant local and

national legislation.

The products are ul illed with the requirements in the

directive 2011/65/EU o the European parliament and o

council on the Restriction o the use o Certain Hazardous

Substances in Electrical and Electronic Equipment(EU

RoHS Directive)

WEEE

In accordance with the directive 2012/19/EU o the European

parliament,herewith we in orm the consumer about the dis-

posal requirements o the electrical and electronic products.

DISPOSAL REQUIREMENTS:

Contains luorinated greenhouse gases

covered by the Kyoto Protocol

This product contains luorinated greenhouse gases covered

by the Kyoto Protocol.Do not vent into the atmosphere.

Re rigerant type:R32

GWP*value:675

GWP=global warming potential

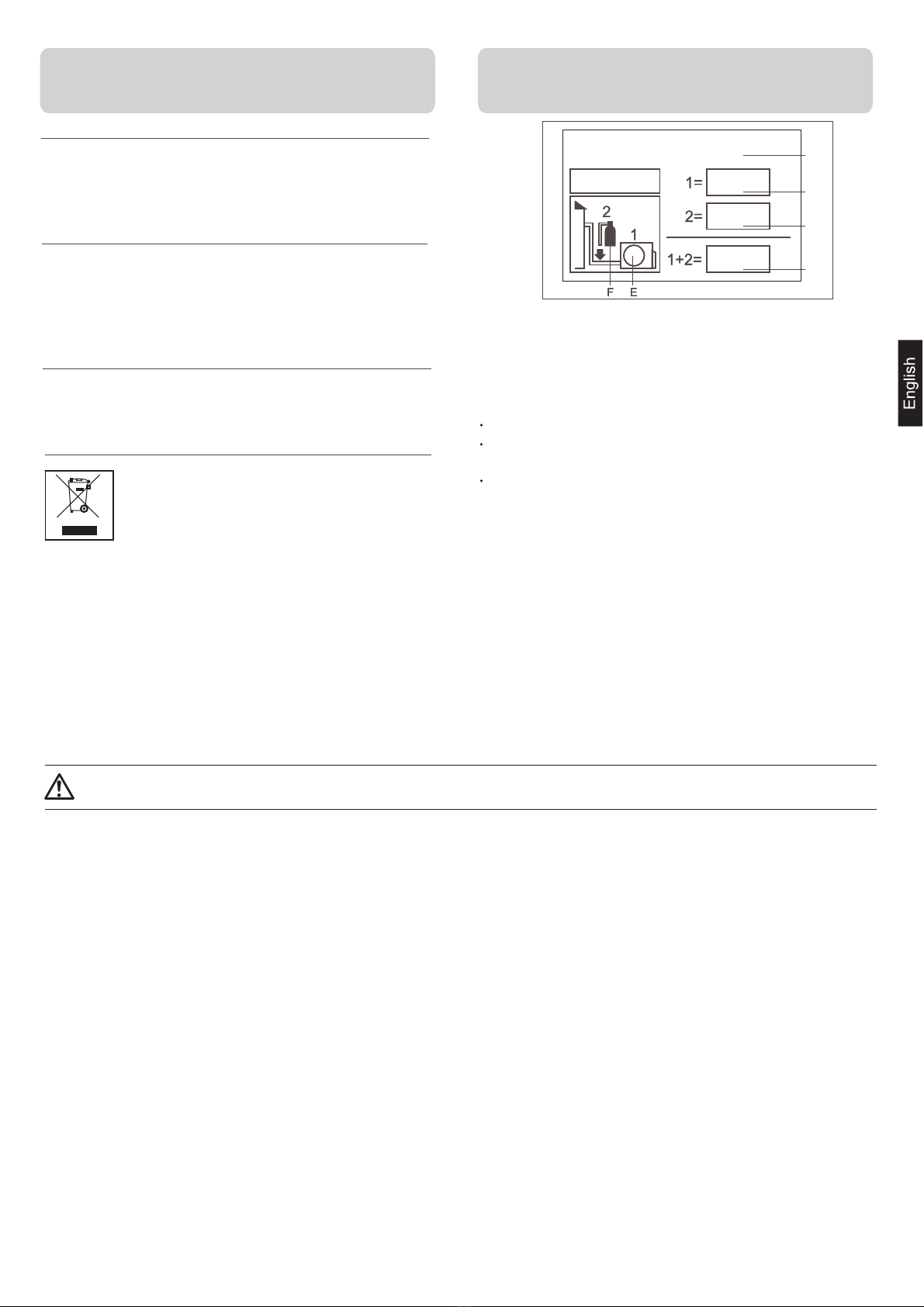

Please ill in with indelible ink,

1 the actory re rigerant charge o the product

2 the additional re rigerant amount charged in the ield

and

1+2 the total re rigerant charge

on the re rigerant charge label supplied with the product.

The illed out label must be adhered in the proximity o the

product charging port(e.g.onto the inside o the stop value

cover).

A contains luorinated greenhouse gases covered by the

Kyoto Protocol

B actory re rigerant charge o the product:see unit name

plate

C additional re rigerant amount charged in the ield

D total re rigerant charge

E outdoor unit

F re rigerant cylinder and mani old or charging

Air conditioner working temperature: cooling -10~46 degree, heating -15~24 degree.

The single indoor unit will reduce in heating e iciency i the ambient temperature is under 0 degree.

WARNING

EUROPEAN REGULATIONS

CONFORMITY FOR THE MODELS

IMPORTANT INFORMATION REGA-

RDING THE REFRIGERANT USED

1

A

B

C

D

kg

kg

kg

R32

I the supply cord is damaged, it must be replaced by the manu acturer, its service agent or similarly

quali ied persons in order to avoid a hazard.

This appliance is not intended or use by persons (including children) with reduced physical, sensory

or mental capabilities, or lack o experience and knowledge, unless they have been given supervision

or instruction concerning use o the appliance by a person responsible or their sa ety.

Children should be supervised to ensure that they do not play with the appliance.

This appliance can be used by children aged rom 8 years and above and persons with reduced physical,

sensory or mental capabilities or lack o experience and knowledge i they have been given supervision

or instruction concerning use o the appliance in a sa e way and understand the hazards involved.

Children shall not play with the appliance. Cleaning and user maintenance shall not be made by children

without supervision.

The appliances are not intended to be operated by means o an external timer or separate remote-

control system.

Keep the appliance and its cord out o reach o children less than 8 years.

The A-weighted sound pressure level is below 70 dB.

This appliance is intended to be used by expert or trained users in shops, in light industry and on arms,

or or commercial use by lay persons.

Disconnect the appliance rom its power source during maintenance service and when replacing parts.