return to the area unless you have properly ventilated the area and are certain that ventilation is sufficient,

so this concentration does not happen again.

•Petrol and oil are extremely flammable and explosive under certain conditions. Do not smoke and keep

flames, sparks or heat sources away from the machine.

Do not smoke while transporting fuel, when you fill out the deposit or when you are working.

•Do not refuel fuel in locations where there is the presence of open flames, sparks or heat sources. Fill the

tank always in well-ventilated areas and with the motor stopped. Do not overflow fuel when trying to

overfill the fuel tank. In the event of a fuel leak, be sure to clean these leaks completely before starting,

move the machine away from the spillage area and avoid any source of ignition until all vapors are gone.

Add fuel before starting the machine.

•Never remove the cap of the fuel tank while the engine is running or when the machine is hot.

•Do not refuel in enclosed spaces, in poorly ventilated areas or near flames.

•Make sure the cap of the fuel is tightly and correctly closed while you are using the machine.

•Make sure to correctly and tightly close the cap on the fuel after refilling.

•Always store the fuel in approved containers that comply with European regulations.

•Do not use fuel that it has been stored for longer than 2 months. A fuel that has been stored for too long

will cause the starting of the machine to be more difficult and unsatisfactory engine performance. If the

fuel has been in the tank of the machine for more than twomonths, take it out of the machine and replace

it with one in perfect condition.

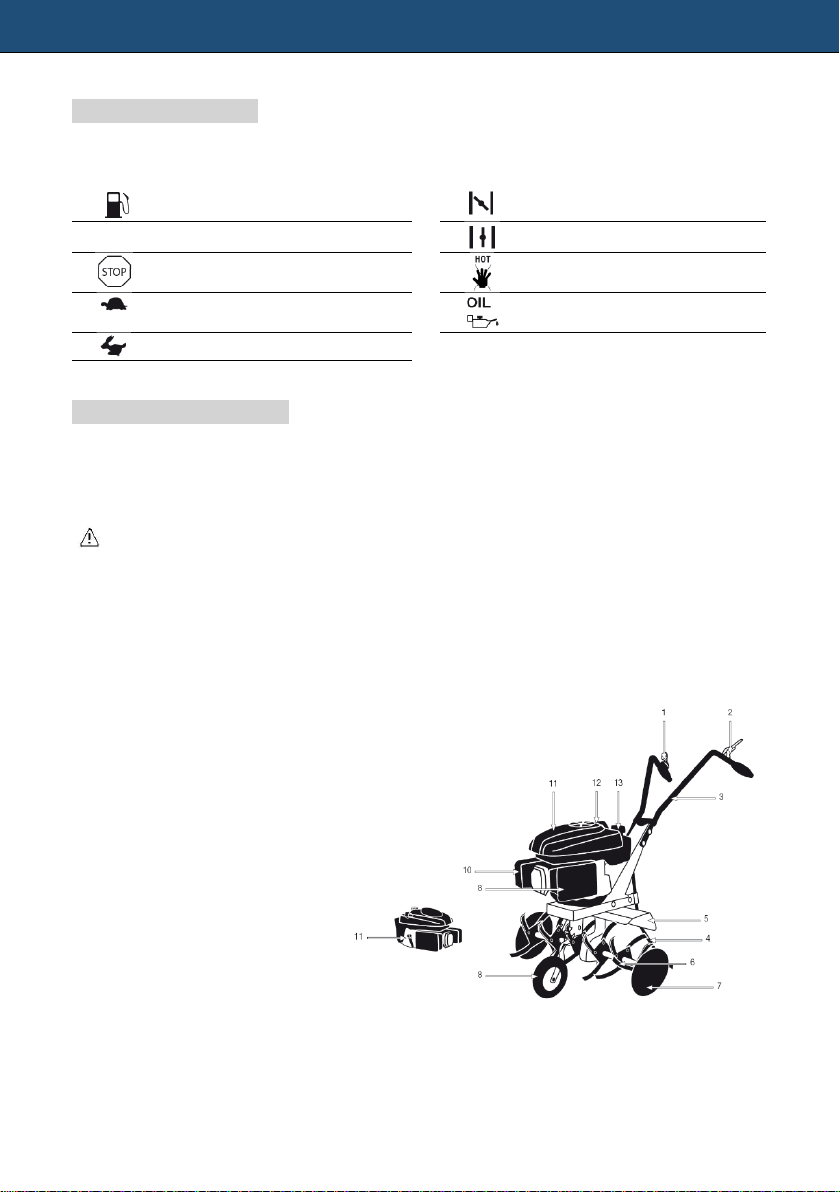

2.5. CARE AND USE OF THIS MACHINE

Use this machine only to till the land. Do not use this rotary tiller for other purpose not intended. The

use of this rotary tiller for uses other than the designated operations may result in dangerous

situations.

•Use this machines’ accessories, tools, etc. in accordance with these instructions and as intended, taking

into account the working conditions and the work to develop. The use of this rotary tiller for uses other

than the designated operations may result in dangerous situations.

•Check that all the safety devices are installed and in good condition.

•Remember that the machine operator is responsible for the dangers and accidents caused to other people

or things. The manufacturer will not be in any way liable for damages caused by improper or incorrect use

of this machine.

•The cutting tool is very sharp. Not following the instructions may cause severe damage.

•Keep your body away from the cutting tool while using the machine.

•Do not force this machine. Use this machine to the correct application. Using the machine for the type of

work meant to be done will allow you to work better and more safely.

•Do not use this machine if the switch does not change between “open” and “closed”. Any machine that

cannot be controlled with the switch is dangerous and must be repaired.

•Before starting work with the machine, check that the milling cutters are not in contact with any object

and that they can move freely.

•Do not use the machine on steep slopes where your safety cannot be guaranteed. If you are working on

slopes slow down your work pace and ensure you have a good stability.

•Keep this machine maintained and in proper condition. Check that the moving parts are not misaligned or

locked, that there are no broken parts or other conditions that may affect the operation of this machine.

Whenever this machine is damaged, repair it before use. Many accidents are caused by poorly maintained

machines.

•Keep the machine handles dry and clean. Greasy or oily handles are slippery and cause loss of control over

the machine.

Turn off the machine, disconnect the spark plug and make sure that the cutting tool has stopped

before making any adjustments, filling with fuel, changing accessories, cleaning, transportation

and storage of this machine. Such preventive safety measures reduce the risk of accidental

starting of this machine.