Heinzmann Theseus AT 01 User manual

Heinzmann GmbH & Co. KG

Engine & Turbine Controls

Am Haselbach 1

D-79677 Schönau (Schwarzwald)

Germany

Phone +49 7673 8208-0

Fax +49 7673 8208-188

www.heinzmann.com

V.A.T. No.: DE145551926

HEINZMANN®

Electronic Speed Governors

Analogue Generator Power Controller

and Synchronizer

THESEUS AT 01

Copyright 2004 by Heinzmann GmbH & Co KG. All rights reserved. This document may not be reproduced or handed on to third parties.

Manual E 98 004-e / 08-06

Read this entire manual and all other publications appertaining to the

work to be performed before installing, operating or servicing your

equipment.

Practice all plant and safety instructions and precautions.

Failure to follow instructions may result in personal injury and/or

damage to property.

HEINZMANN will refuse all liability for injury or damage which

results from not following instructions

Please note before commissioning the installation:

Before starting to install any equipment, the installation must have been

switched dead!

Be sure to use cable shieldings and power supply connections meeting

the requirements of the European Directive concerning EMI.

Check the functionality of the existing protection and monitoring

systems.

To prevent damages to the equipment and personal injuries, it is

imperative that the following monitoring and protection systems

have been installed:

Overspeed protection acting independently of the speed governor

Overtemperature protection

HEINZMANN will refuse all liability for damage which results from

missing or insufficiently working overspeed protection

Generator installation will in addition require:

Overcurrent protection

Protection against faulty synchronization due to excessive frequency,

voltage or phase differences

Reverse power protection

Overspeeding can be caused by:

Failure of the voltage supply

Failure of the actuator, the control unit or of any accessory device

Sluggish and blocking linkage

Warning

Danger

Danger

Danger!

High

Voltage

Danger

Electronically controlled injection (MVC) will in addition require

to observe the following:

With Common Rail systems a separate mechanical flow limiter must

be provided for each injector pipe.

With Pump-Pipe-Nozzle (PPN) and Pump Nozzle (PNE) systems fuel

release may be enabled only by the movement of control piston of the

solenoid valve. This is to inhibit fuel from being delivered to the

injection nozzle in case of seizure of the control piston.

The examples, data and any other information in this manual are

intended exclusively as instruction aids and should not be used in any

particular application without independent testing and verification by

the person making the application.

Independent testing and verification are especially important in any

application in which malfunction might result in personal injury or

damage to property.

HEINZMANN make no warranties, express or implied, that the

examples, data, or other information in this volume are free of error,

that they are consistent with industry standards, or that they will meet

the requirements for any particular application.

HEINZMANN expressly disclaim the implied warranties of

merchantability and of fitness for any particular purpose, even if

HEINZMANN have been advised of a particular purpose and even if a

particular purpose is indicated in the manual.

HEINZMANN also disclaim all liability for direct, indirect, incidental

or consequential damages that result from any use of the examples,

data, or other information contained in this manual.

HEINZMANN make no warranties for the conception and engineering

of the technical installation as a whole. This is the responsibility of the

user and of his planning staff and specialists. It is also their

responsibility to verify whether the performance features of our devices

will meet the intended purposes. The user is also responsible for correct

commissioning of the total installation.

Warning

Warning

Danger

Contents

THESEUS Analogue AT 01

Contents

Page

1 Safety Instructions and Related Symbols ........................................................................... 1

1.1 Basic Safety Measures for Normal Operation................................................................. 2

1.2 Basic Safety Measures for Servicing and Maintenance.................................................. 2

1.3 Before Putting an Installation into Service after Maintenance and Repair Works ......... 3

2 Application............................................................................................................................. 4

2.1 General ............................................................................................................................ 4

2.2 Load Measuring and Share Device.................................................................................. 4

2.3 Synchronizer Device ....................................................................................................... 4

2.4 Load Ramp Device.......................................................................................................... 5

3 Block Diagram....................................................................................................................... 6

4 Mode of Operation................................................................................................................ 7

4.1 General ............................................................................................................................ 7

4.2 Load Measuring and Sharing Device.............................................................................. 7

4.3 Synchronizer Device ....................................................................................................... 8

4.4 Load Ramp Device.......................................................................................................... 8

5 Technical Data....................................................................................................................... 9

5.1 General ............................................................................................................................ 9

5.2 Load Measuring and Sharing Device.............................................................................. 9

5.3 Synchronizer Device ..................................................................................................... 10

5.4 Load Ramp Device........................................................................................................ 10

6 Electrical Connection.......................................................................................................... 11

6.1 Table of Terminal Connections and their Functions..................................................... 11

6.2 Connection of Bus Voltages and Current Transformers ............................................... 13

6.3 Connection with Control Unit of Series E 1 - F and E 2 - F ......................................... 14

6.4 Connection with Control Unit of Series E 6 up to E 40................................................ 14

6.5 Connection with Control Unit of Series E 2000............................................................ 15

6.6 Connection to more THESEUS Units AT 01 in Parallel Operation ............................. 15

6.7 Connection of Load Setpoint Potentiometer in Parallel Mains Operation.................... 16

6.8 Connection of Load Control Unit in Controlled Mains Supply Operation................... 16

6.9 Connection of External Base Load................................................................................ 17

6.10 Connection of External Load Limitation..................................................................... 17

6.11 Connection of External Droop, if necessary................................................................ 18

7 Measurement ....................................................................................................................... 19

Contents

THESEUS Analogue AT 01

8 Commissioning .................................................................................................................... 20

8.1 Mean and Position of Adjusting Potentiometers and Testpoints .................................. 20

8.2 Mean and Position of LED’s......................................................................................... 22

8.3 Initial Setting Up Procedure.......................................................................................... 24

8.4 Initial Setting of the Speed Governor............................................................................ 24

8.5 Adjustment of Synchronizer Device ............................................................................. 25

8.6 Adjustment of Load Sharing Device in Island Parallel Operation................................ 26

8.7 Adjustment of Load Share Device in Base Load Mains Operation .............................. 27

8.8 Adjustment of Load Sharing Device with Controlled Mains Supply............................ 29

8.9 Adjustment of Load Limitation..................................................................................... 29

8.10 Adjustment of Forward Power and Reverse Power Relays......................................... 30

8.11 Adjustment of Droop, if necessary.............................................................................. 30

8.12 Adjustment of Load Ramp Device.............................................................................. 31

9 Ordering Specification........................................................................................................ 33

10 Figure List.......................................................................................................................... 34

11 Order Specifications for Manuals.................................................................................... 35

1 Safety Instructions and Related Symbols

THESEUS Analogue AT 01 1

1Safety Instructions and Related Symbols

This publication offers wherever necessary practical safety instructions to indicate inevitable

residual risks when operating the engine. These residual risks imply dangers to

persons

product and engine

environment.

The symbols used in this publication are in the first place intended to direct your attention to

the safety instructions!

This symbol is to indicate that there may exist dangers to the engine, to

the material and to the environment.

This symbol is to indicate that there may exist dangers to persons.

(Danger to life, personal injury))

This symbol is to indicate that there exist particular danger due to

electrical high tension. (Mortal danger).

This symbol does not refer to any safety instructions but offers important notes for

better understanding the functions that are being discussed. They should by all

means be observed and practiced. The respective text is printed in italics.

The primary issue of these safety instructions is to prevent personal injuries!

Whenever some safety instruction is preceded by a warning triangle labelled “Danger” this is

to indicate that it is not possible to definitely exclude the presence of danger to persons,

engine, material and/or environment.

If, however, some safety instruction is preceded by the warning triangle labelled “Caution”

this will indicate that danger of life or personal injury is not involved.

The symbols used in the text do not supersede the safety instructions. So please do not

skip the respective texts but read them thoroughly!

Note

Warning

Dan

g

er

Danger!

High

V

olta

g

e

1 Safety Instructions and Related Symbols

2THESEUS Analogue AT 01

In this publication the Table of Contents is preceded by diverse instructions that

among other things serve to ensure safety of operation. It is absolutely imperative

that these hints be read and understood before commissioning or servicing the

installation.

1.1 Basic Safety Measures for Normal Operation

•The installation may be operated only by authorized persons who have been duly

trained and who are fully acquainted with the operating instructions so that they are

capable of working in accordance with them.

•Before turning the installation on please verify and make sure that

- only authorized persons are present within the working range of the engine;

- nobody will be in danger of suffering injuries by starting the engine.

•Before starting the engine always check the installation for visible damages and make

sure it is not put into operation unless it is in perfect condition. On detecting any faults

please inform your superior immediately!

•Before starting the engine remove any unnecessary material and/or objects from the

working range of the installation/engine.

•Before starting the engine check and make sure that all safety devices are working

properly!

1.2 Basic Safety Measures for Servicing and Maintenance

•Before performing any maintenance or repair work make sure the working area of the

engine has been closed to unauthorized persons. Put on a sign warning that

maintenance or repair work is being done.

•Before performing any maintenance or repair work switch off the master switch of the

power supply and secure it by a padlock! The key must be kept by the person

performing the maintenance and repair works.

•Before performing any maintenance and repair work make sure that all parts of engine

to be touched have cooled down to ambient temperature and are dead!

•Refasten loose connections!

•Replace at once any damaged lines and/or cables!

•Keep the cabinet always closed. Access should be permitted only to authorized

persons having a key or tools.

1 Safety Instructions and Related Symbols

THESEUS Analogue AT 01 3

•Never use a water hose to clean cabinets or other casings of electric equipment!

1.3 Before Putting an Installation into Service after Maintenance and Repair

Works

•Check on all slackened screw connections to have been tightened again!

•Make sure the control linkage has been reattached and all cables have been

reconnected.

•Make sure all safety devices of the installation are in perfect order and are working

properly!

2 Application

4THESEUS Analogue AT 01

2Application

2.1 General

The analogue generator power controller and synchronizer THESEUS AT 01 has been

designed to work in conjunction with any of the HEINZMANN analogue electronic

governors to make a complete generator management. It can also be used with competitors'

electronic governors by the addition of a small interface card.

The new concept of the AT 01 is the introduction of integrating load sharing,

synchronising and load ramping for soft switching load on and off inside one printed

circuit card which utilises a common set of voltage and current transformers. Costly wiring

between the single units are not necessary.

2.2 Load Measuring and Share Device

Isochronous load sharing is also incorporated using three phase voltage and current inputs

which are multiplied together to produce a true kilowatt output about all three phases. The

resultant kilowatt output is then fed into our standard load sharing concept that will allow

up to 15 engines to be parallelled together at the same time and share load to within ±2%.

There is a meter output 0-5V or 0-1 mA indicating kilowatts and also a forward power and

reverse power relay contact with LED indication. Standard load limiting inputs are

available, along with a new soft loading function which will allow isochronous loading and

unloading of an alternator parallel to an island or mains BUS with a base load facility.

2.3 Synchronizer Device

The analogue power controller has a full isochronous auto three phase synchroniser

incorporating frequency and phase correction with LED indication of frequency, phase,

capture angle and breaker closure. There is also a safety feature built into the synchroniser

that detects phase rotation and will only allow the breaker to close if the generator is up to

frequency, in phase (within a predetermined angle) and phase rotation in the correct

direction.

The generator voltage has to be adjusted using a seperate voltage

matching unit before synchronization, because the synchronizer device

can not influence the generator voltage.

Warning

2 Application

THESEUS Analogue AT 01 5

2.4 Load Ramp Device

This facility allows a genset to soft load after closing the generator breaker without the

island frequency deviating from the isochronous value. The load ramp is fully adjustable

and will allow an engine to load from zero to the rated load on the load share line and

unload down to either zero or a base load value. At the zero point, a relay contact closes,

indicating that the engine can come off line.

The load ramp facility is ideal for a single engine application parallel to the mains when

used in CHP mode. The base load can also be set to be equivalent to the rated load of the

engine and the ramp generator can ramp up to this rated load and ramp off again as and

when required.

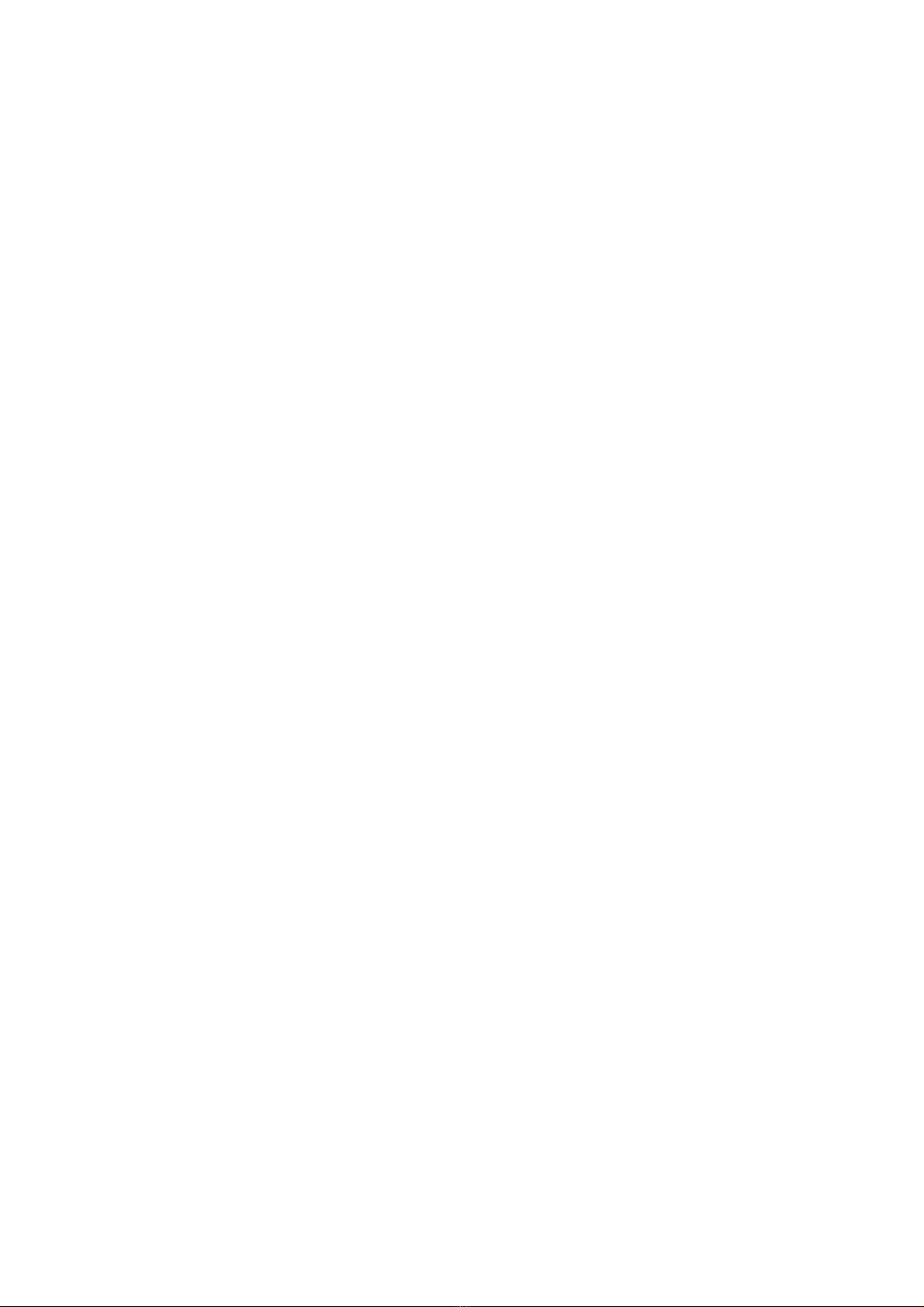

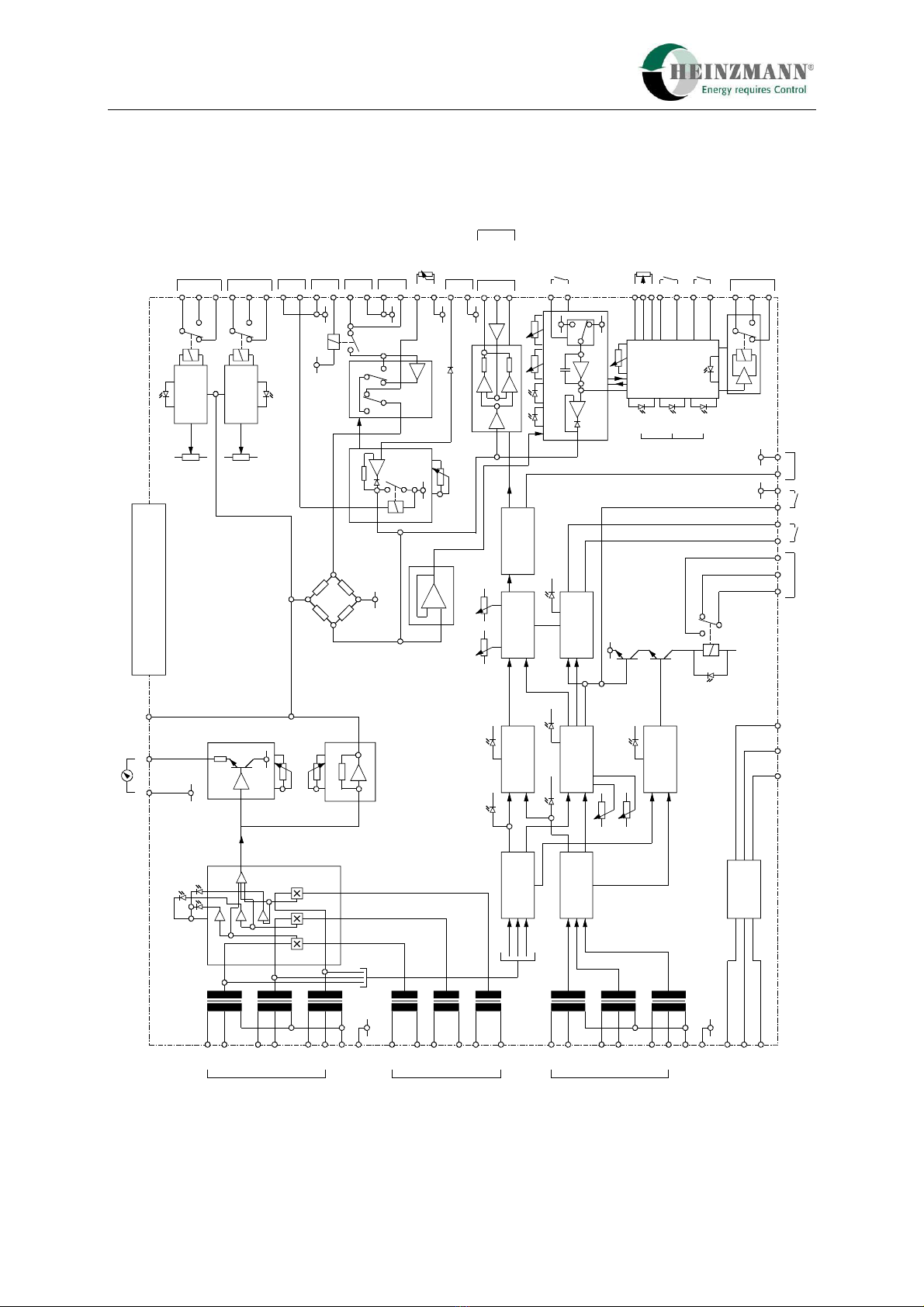

3 Block Diagram

6THESEUS Analogue AT 01

3Block Diagram

E

N

115

230

230

230

115

115

L1

L2

L3

Generator voltages

Analogue Theseus AT 01

1

2

14 16 13 54 55 56 37 38 35 36

52

53

51

28

27

30

29

25

24

23

32

31

4

6

39

5

40

20

21

12

11

9

8

42

41

44

43

46

47

45

49

50

48

18 17

33 34

15

Phase

rotaton

indicators

KW- meter

adjus.

Load share

line adjus.

Voltages

Voltages

Currents

Signal

processor

Signal

processor

Frequency

comparison

Phase angle

comparison

Phase

rotation o.k.

Insolated

supply

voltage

Angle

Delay

Rotation o.k.

in phase

Frequency

from bus

Frequency from

generator Frequencies

eaquel Gain Synchronizer time

Integrator Output

amplifier

Reset

circuit

locked

breaker

closed

+Synchron.

relay

-

+

0 V

Bridge

Generator

power

Reversed

power Reversed

power

Forward

power

0 V

+

0 V

0 V

0 V

Internal load

limitation

0 V

Control

logic

0 V 0 V

internal

base load

Base load on

Load

ramp

Max.

Min.

on/

off

up updown down

E

N

115

230

230

230

115

115

L1

L2

L3

Bus / mains

I1

I2

I3

Generator currents

0 V

+24 V

Supply

voltage

Synchronizer

relay

-10V0V+10V Sync.

on Relay

inhibit Group

sync.

Load at

minimum

Loadramp

on / off

Base load

on / off

External

Base load

Loadramp

up / down

Load sharing

0 V

Synchronizer

to governor

External load

limitation

Droop

Output

Loadshare line

Input

loadshare line

Generator

breaker

Mains

breaker

Forward power

relay

Reversed power

relay

Load control

unit

KW- indicator

Figure 1: Block Diagram of Analogue THESEUS AT 01

4 Mode of Operation

THESEUS Analogue AT 01 7

4Mode of Operation

4.1 General

Referring to the AT 01 block diagram, there are three sections incorporating load sharing,

synchronising and load ramping; these can be used independently of each other or in

combination.

The connection to the voltage and current inputs are made directly to the alternator outputs

and require a three wire, three phase signal with appropriate current transformer inputs

which can be specified to 1 A or 5 A CTs. The BUS voltage inputs on the secondary side

of the generator breaker are used for synchronising and a comparison is made between the

generator and the BUS frequencies and phases.

4.2 Load Measuring and Sharing Device

The three phase voltage inputs are conditioned and multiplied by the three phase current

inputs and are first compared for phase acceptance. LED’s indicate whether the phase of

the current to the voltage is correct. There is 180° reversing link for each current input that

can be changed when the engine is running, thus allowing easy reversal of current

transformers terminals K and L without shutting the generator down.

The load sharing device measures the output power of an AC generator (3 phase voltage

and current) and converts this to a DC voltage proportional to the generator load. This

voltage is connected to a bridge circuit. In parallel operation, these bridge circuits are

connected together by paralleling lines. If the power of the paralled generators are not

equal, there originates a little voltage difference between the bridges and then a small DC

current will flow in the paralleling leads. This will normaly cause a change in the speed

setting of the connected generators, but, as they are all coupled electrically by the rotary

field of the generators and have the same speed, their power output will be changed. When

the generators are sharing the total load correctly there will be no current in the paralleling

leads. This type of load sharing is very effective and can be accurate to within ±1% with

power factors between ±0.8.

The generator power proportional signal is also used for external meter indication and

forward/reverse power relay contacts. These contacts can be used for generator safety and

also starting and stopping generator sets, depending upon load level.

4 Mode of Operation

8THESEUS Analogue AT 01

4.3 Synchronizer Device

The auto synchronizer incorporates three phase voltage inputs which are conditioned and

compared for frequency and phase alignment. The unit first compares the frequency of the

BUS to the generator and gives an output signal to the governor speed that automatically

aligns the frequency. Once alignment is achieved, LED indication is given and the next

part of the circuit tries to align the phase. Once this is achieved, another LED confirms

alignment and an adjustable timer is then brought into operation before the breaker signal

is given. This delay time makes sure, that the generator breaker may be closed in constant

operating conditions only.

The device has a gain and a stability control for frequency and phase correction and also an

adjustable breaker delay and phase angle for optimum synchronisation time. The

synchronizer can normally close the breaker from diesel engine stop in approximately 8 -

12 seconds.

There is also a sync lock facility that allows the generator to be synchronised to a BUS, but

no breaker signal is given and is permanently synchronised in phase to a reference

frequency, ie, the BUS. This is very useful for checking phasing of transformers,

optimizing of parameters, etc, during commissioning or for stand-by synchronisation.

Under normal operation, once the breaker closure signal has been given, the unit is

automatically reset and disconnected from the governor after one second. Then the

synchronizer device is not controlling the speed of the engine anymore. Due to this fact,

there is no need for any interposing relay between the synchroniser and governor speed

input.

4.4 Load Ramp Device

The main function of the load ramp device is to soft load isochronously a single engine

after closure of the generator breaker.

The device can offer a standard load ramp from zero with adjustable time to rated load

equal to that of the paralleled engines offering a bumpless transfer and connection of load.

Isochronous unloading is also possible with a simple opening of a contact and the engine

will unload softly down to zero or a base load option which is internally or externally

adjustable. The time constants are adjustable seperatly.

There is also an enhanced feature of a minimum load relay which is set approximately to

3% of rated load which allows the generator breaker to be opened automatically once the

engine has ramped down to zero load. LED annunciation shows the state of the ramp

generator and relay functions.

5 Technical Data

THESEUS Analogue AT 01 9

5Technical Data

5.1 General

Input voltage 3 x 110 V or 415 V AC ±10%

phase to phase

Input current 0 - 5 A per phase max. 2 VA

or 0 - 1 A per phase max. 2 VA

select by resistor change

Current consuption 400 mA

Supply voltage 18 - 40 V DC 500 mA max.

Frequency range of generator 50/60 Hz

Temperature range 0 - 70° C

Protection grade IP 00

Weight 1.8 kg

5.2 Load Measuring and Sharing Device

Load measuring U x I x cosϕwith three phases

Load sharing up to 15 gensets in parallel

Output signal 6 V at 100% generator power,

adjustable

Output signal to kilowatt meter 0 - 1 V or 0 - 1 mA, adjustable

Forward power relay adjustable 0 - 80% load

indication with LED

contact load 30 V DC, 1 A

Reverse power relay adjustable from 20% power up to

30% reverse power

indication with LED

contact load 30 V DC, 1 A

Reverse power indication 1 LED per phase

Changeover of current transformer connections link changeover without shutting down

the engine

Load limitation internal or external adjustable, 0 - 100%

Generator breaker closure LED indication

5 Technical Data

10 THESEUS Analogue AT 01

Mains breaker closure LED indication

5.3 Synchronizer Device

Contact load of synchronizer relay 30 V DC, 2.5 A

Phase angle ±1 up to ±15°, adjustable

Synchronizer time 3 up to 15 sec. depends on plant,

adjustable

Gain adjustable

Output signal ±4 V

max. frequency correction ±2 Hz

Generator frequency o.k. LED indication

Bus frequency o.k. LED indication

Bus = generator frequency LED indication

Phase angle o.k. LED indication

Phase rotation o.k. LED indication

Synchronizer inhibit LED indication

Synchronizer relay closure LED indication

5.4 Load Ramp Device

Base load setting internal or external adjustable, 0 - 100%

Load ramp up ramptime adjustable, LED indication

Load ramp down ramptime adjustable, LED indication

Load at minimum relay

indication with LED

contact load 30 V DC, 1 A

Load at maximum indication with LED

6 Electrical Connection

THESEUS Analogue AT 01 11

6Electrical Connection

6.1 Table of Terminal Connections and their Functions

Terminal Function

1 0 V supply voltage

2 +24 V supply voltage

3 screen of lines on terminals 4, 5 and 6, 7

4 signal synchronizer output to governor

5 0 V synchronizer output to governor

6D signal load sharing output to digital governor

6A signal load sharing output to analogue governor

7 0 V load sharing output to governor

8 input signal of load share line

9 input 0 V of load share line

10 screen of load share lines

11 output 0 V of load share line

12 output signal of load share line

13 +10 V supply to load control unit and load setpoint potentiometer

14 -10 V supply to load control unit

15 output signal to load control unit

16 output 0 V to load control unit and load setpoint potentiometer

17 output signal to kilowatt meter, 0 - 5 V or 0 - 1 mA

18 output 0 V to kilowatt meter

19 0 V

20 input 0 V for droop

21 input signal for droop

22 screen of lines on terminals 23, 24 and 25

23 reference for external base load potentiometer

24 signal of external base load potentiometer

25 0 V for external base load potentiometer

26 0 V

27 switch input for load ramp close = on

28 0 V open = off

6 Electrical Connection

12 THESEUS Analogue AT 01

Terminal Function

29 switch input for base load close = on

30 0 V open = off

31 switch input to ramp up / down close = up

32 0 V open = down

33 switch input for synchronizer close = off

34 +12 V via 100 Ohm open = on

35 output for island / group synchronization

36 0 V

37 synchronizer relay inhibit close = inhibit

38 +12 V via 100 Ohm open = synch. possible

39 0 V 0 - 3 V or

40 external load limitation 10 kOhm potentiometer

41 0 V

42 generator breaker closed

43 0 V

44 mains breaker closed

45 Common forward power relay

46 N/C 30 V DC, 1.5 A

47 N/O

48 Common reverse power relay

49 N/C 30 V DC, 1.5 A

50 N/O

51 Common load at minimum relay

52 N/C 30 V DC, 1.5 A

53 N/O

54 Common synchronizer relay

55 N/C 30 V DC, 2.5 A

56 N/O

6 Electrical Connection

THESEUS Analogue AT 01 13

6.2 Connection of Bus Voltages and Current Transformers

AT 01

Generator

voltage

Earth

N

L1

L2

L3

Earth

N

L1

L2

L3

L3

L3

L2

L2

L1

L1

Bus

voltage

Generator

current

N

L1

L2

L3

Generator

PE

Bus

L1 L2 L3

NPE

Generator

breaker

Attention:

Take care that the right connections are made to

the high voltage phases on the AT 01!

The connections are shown as a generator power control with

synchronizer application.

When the unit is used as a group synchronizer and for controlled mains supply

a) the generator terminals are replaced by the island group (bus bar),

b) the bus bar terminals are replaced by the mains and

c) the generator breaker is replaced by the mains breaker.

Figure 2: Connection of Bus Voltages and Current Transformers

6 Electrical Connection

14 THESEUS Analogue AT 01

6.3 Connection with Control Unit of Series E 1 - F and E 2 - F

AT 01 KG 1-F/KG 2-F

456

LMG

0V

SyG

white

brown

blue

Accessory

Plug

Terminal

Strip

Cable 3 x 0,5 mm² with shielding

max. lenght 50 m

Shielding connected at control unit only

Figure 3: Connection with Control Unit of Series E 1 - F and E 2 - F

6.4 Connection with Control Unit of Series E 6 up to E 40

AT 01

LMG

0V

SyG

A3

KG 6 up to KG 40

Accessory

Plug

Terminal

Strip

456 B3E3

Cable 3 x 0,5 mm² with shielding

max. lenght 50 m

Shielding connected at control unit only

Figure 4: Connection with Control Unit of Series E 6 up to E 40

Table of contents

Other Heinzmann Recording Equipment manuals