Bitzer Group Lodam LMC341 DIWE User manual

Lodam Condensing Unit Controller

Modbus Interface

Version 2.0

LMC341 DIWE

Page 2

Contents

1. Read this first ................................................................................................ 4

1.1. Installation ........................................................................................ 4

1.2. Safety............................................................................................... 4

2. General ......................................................................................................... 5

3. Definitions..................................................................................................... 5

4. How to ... ...................................................................................................... 6

4.1. Connection samples......................................................................... 6

4.2. Communication recommendations.................................................. 6

5. Connections.................................................................................................. 7

5.1. Connections on the LMC341 DIWE controller..................................... 7

5.2. Cable specification .......................................................................... 7

5.3. Configuration................................................................................... 7

5.4. RS485 Repeater .............................................................................. 7

5.5. Recommended guidelines for cable routing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

6. Setup ............................................................................................................ 8

6.1. Modbus configuration....................................................................... 8

6.2. Data values, scaling and data types ................................................. 9

6.3. Modbus function codes ................................................................... 9

6.4. Modbus exception codes ................................................................. 9

7. Functions....................................................................................................... 10

7.1. Status information ............................................................................ 10

7.2. Inputs............................................................................................... 11

7.3. Outputs ........................................................................................... 12

7.4. Alarms ............................................................................................. 13

7.5. Control............................................................................................. 15

7.6. Modbus sample communication ...................................................... 16

8. Standards ..................................................................................................... 16

9. Trouble shooting ........................................................................................... 17

10. Index ........................................................................................................... 18

11. Notes............................................................................................................ 19

Modbus Interface manual LMC341 DIWE

Page 3

Page 4

1. Read this first

The contents of this manual are subject to change

without notice.

Lodam electronics holds the copyright to this user’s

manual. The user must follow any instructions given in this

user manual entirely and not only partly. Any non-follow-

ing of this user manual result in exclusion of all warranties,

guarantees, and liabilities.

Copyright© 2013 by Lodam electronics a/s. All Rights

Reserved.

Disposing of the parts of the controller:

INFORMATION FOR USERS ON THE COR-

RECT HANDLING OF WASTE ELECTRICAL

AND ELECTRONIC EQUIPMENT (WEEE)

In reference to European Union directive 2012/19/EU and

the related national legislation, please note that:

1. WEEE cannot be disposed of as municipal waste and

such waste must be collected and disposed of sepa-

rately;

2. The public or private waste collection systems defined

by local legislation must be used. In addition, the equip-

ment can be returned to the distributor at the end of its

working life when buying new equipment;

3. The equipment may contain hazardous substances:

the improper use or incorrect disposal of such may

have negative eects on human health and on the

environment;

4. The symbol (crossed-out wheeled bin) shown on the

product or on the packaging and on the instruction

sheet indicates that the equipment must be disposed

of separately;

5. In the event of illegal disposal of electrical and elec-

tronic waste, the penalties are specified by local waste

disposal legislation.

1.1. Installation

Before installation, the user should be thoroughly

familiarized with this technical manual, especially

with purposes, installation, settings and operation.

Special care should be taken when installing and con-

necting external equipment (sensor, high voltage etc.)

and handling the PCB’s correctly according to protection

against ESD.

Installation of the LMC341 DIWE Condensing Unit Control-

ler must be performed by authorized personnel only. All

warranties are excluded in case installation is performed

by unauthorized personnel or in case the LMC341 DIWE has

not been correctly installed.

Electrical plant failures are to be immediately solved, even

though no immediate danger exists; the LMC341 DIWE

must not be operating.

1.2. Safety

The LMC341 DIWE is not a safety component and

cannot be used in “medical” or “life support”

equipment.

The LMC341 DIWE is not a safety component according to

the Machinery Directive.

Before commissioning, the service technician shall ensure

that personal safety requirements are met in conformity

with the Machinery Directive based on safety estimations.

The LDH105 should not be apart when operating.

Fuses can only be replaced and NOT left out.

Operation sta must in detail be informed about operating

the LMC341 DIWE before operating the LMC341 DIWE.

Only use recommended parts/spare parts on the LMC341

DIWE. All warranties are excluded in case unoriginal part/

spare parts are installed.

Modbus Interface manual LMC341 DIWE

Page 5

2. General

Lodam’s Condensing Unit Controller, LMC341 DIWE enable

you to gain total control of your condensing unit to deliver

cooling to one or more evaporators – thereby optimizing

your system to save energy, time and money.

Remote control of the controller is via Modbus over a

RS485 connection and this document describes the

settings for this.

3. Definitions

BEST BEST software

HW Hardware/electronics

LMT Lodam Multi Tool (PC communication

tool for Lodam controllers)

Modbus Application-layer messaging protocol -

http://www.modbus.org/specs.php

RS485 Hardware communication standard

Page 6

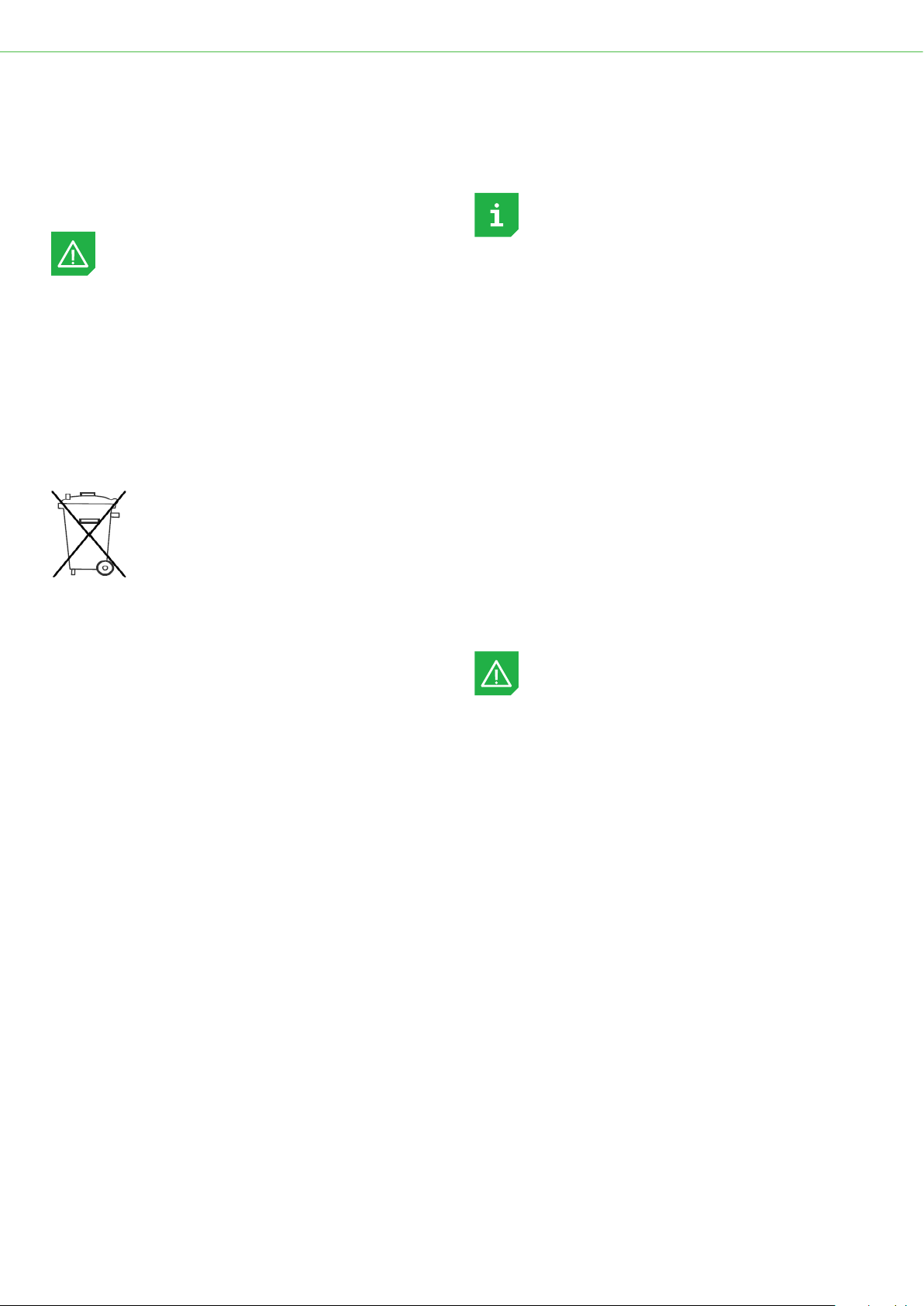

The end points, first and last controller on the string must

have a 120 ohm termination resistor.

All LMC341 DIWE controllers are grounded, the signal

ground is not needed as PE (Protective Earth) is used as

signal ground.

The following installation is not guaranteed to work!

Master

Controller

LMC341

DIWE

LMC341

DIWE

Modbus (RTU) via RS485

LMC341

DIWE

LMC341

DIWE

#1

#2

#3

#10

...

4.2. Communication recommen-

dations

The poll-interval setting in the master controller must be

considered. The processor of the LMC341 DIWE controller

can only handle a certain amount of requests per second.

Beyound this, request from the master controller will be

lost.

The data in the LMC341 DIWE controller don’t change very

rapidly so a poll interval of seconds will be sucient for

the monitoring purpose.

4. How to ...

4.1. Connection samples

• The Modbus communication is connected using a

shielded, 2-wired, twisted pair cable (RS485).The two

signal wires must be in the same pair of wires.

• The connection can be multi-drop with up to 10

LMC341 DIWE controllers on the same communication

line. For larger installations or from building to building, a

RS-485 repeater with galvanic isolation must be used.

• The cable must be installed as a string, not a star.

• The LMC341 DIWE is always the client (slave unit).

One master controller and one LMC341 DIWE.

Master

Controller

LMC341

DIWE

Modbus (RTU) via RS485 (2-wire)

120 ohm

Termination

resistor

120 ohm

Termination

resistor

One master controller and several LMC341 DIWE.

Master

Controller

LMC341

DIWE

LMC341

DIWE

Modbus (RTU) via RS485 (2-wire)

LMC341

DIWE

LMC341

DIWE

120 ohm

Termination

resistor

120 ohm

Termination

resistor

#1

#2

#3

#10

...

Modbus Interface manual LMC341 DIWE

Page 7

5. Connections

All LMC341 DIWE controllers have internally connected

signal ground and protective earth. The signal ground is

hence not needed as protective earth is used as signal

ground.

5.1. Connections on the LMC341

DIWE controller

Ethernet

2 x USB Host

RS485

1

2

3

4

+12V

Data+

Data-

GND

Data+

Modbus (RTU)

Data-

1 2 3 4

Terminal Description

CN32 - RS485 Modbus connection

GND: Do not use as all LMC341 DIWE controllers are

grounded(1).

Protective earth is used as signal ground.

Data- Inverted signal

Data+ Signal

+12V Power supply for RS485 connection.

Not used for Modbus communication!

Note (1): The LMC341 DIWE controller has internally

connected signal ground to PE (Protective Earth).

5.2. Cable specification

Communication is half duplex.

• Use shielded, tinned copper, twisted-pair cable – twisted

all the way to the controllers.

• Max 200 m cable length. Characteristic impedance

between 100 Ohm and 130 Ohm

• Foil or braided shield – shield grounded at the master

controller

• Shunt capacitance < 100 pF/m, AWG24, 2 * 120 Ohm

termination.

• Receiver impedance >= 12 kOhm.

5.3. Configuration

There can be up to 10 LMC341 DIWE controllers on the

same Modbus string.

If other equipment than LMC341 DIWE controllers are con-

nected on the same string, the maximum current sourcing

of the other equipment must be observed!

The network should be configured in sections, possible with

RS 485 repeaters between sections in large installations

and when connecting dierent buildings in one network. Up

to 3 repeaters may be used.

5.4. RS485 Repeater

The repeater should be an isolated (galvaniccally isolated)

RS485 repeater to separate the sections of the network.

The following products have been tested and verified to

work right out of the box:

• ICP CON 7510AR

• ICP CON 7510A

• Moxa TCC-120/120I

• BLACK BOX ICD202A

Other RS485 repeater brands and models should be tested

and verified before use in installations.

Page 8

5.5. Recommended guidelines for

cable routing

• Signal, control and communication cables should be

shielded with braided shielding and the shield connected

to the earth connection – preferrable at the master

controller.

• Signal, control and communication cables should

be routed so the influence from the power cables is

minimized. When crossing power cables, an 90 degrees

angle should be achieved

• Signal and power cables that run in parallel should be

separated by the largest possible appropriate clearance

distance, approx. 20 – 25 cm. A grounded shield plate or

grounded metal duct can be used instead.

• The cable shielding must not be interrupted.

• The cables should be kept as short as possible.

Route cables using grounded, metal cable trays or cable

ducts. Sections of cable tray or ducts must be connected

together with as large areas as possible.

• Communication cables should be twisted pair for the

data wires.

6. Setup

Communication with the LMC341 DIWE is via Modbus

(RTU). Configuration and reading of settings and readings

from the LMC341 DIWE is described in the following

sections.

Client Server

Initiate request

Perform the action.

Initiate the response

Receive the

response

Function code Data Request

Function code Data Response

6.1. Modbus configuration

Specification of the protocol:

Protocol:

Modbus (RTU mode)

See http://www.modbus.org/specs.php

Modbus node address:

LMC341 DIWE uses default address 1; can be

changed on the LUP200 display (option)

Baud rate:

Default 115200; 4800, 9600, 19200, 38400,

57600 are selectable

Number of data bits:

8

Parity:

Default Even; None and Odd parity are selectable

Number of stop bits:

Default 1; 2 (2 only if Parity is None)

Packet size:

Maximum 32 register in a row

Settings are configured on the LUP200 display of the

LMC341 DIWE controller in the Service->LOM MB config

menu.

Please observe that register numbers used in this manual

are zero-based as the LMC341 DIWE uses PDU telegrams.

Modbus Interface manual LMC341 DIWE

Page 9

6.2. Data values, scaling and data

types

Following is a description of used scaling and data types.

Scale 1, 10 and 100 refers to where the decimal point

is implied, as a decimal value can’t be transmitted via

Modbus.

Scale 1: The value is the exact value

Scale 10: To transmit a value it must be multiplied

by 10; i.e. 12.3 -> 123

A received value must be divided by 10;

i.e. 123 -> 12.3

Scale 100: To transmit a value it must be multiplied

by 100; i.e. 1.23 -> 123

A received value must be divided by 100;

i.e. 123 -> 1.23

uint8: Unsigned 8-bit integer

uint16: Unsigned 16-bit integer

sint16: Signed 16-bit integer

uint32: Unsigned 32-bit integer

sint32: Signed 32-bit integer

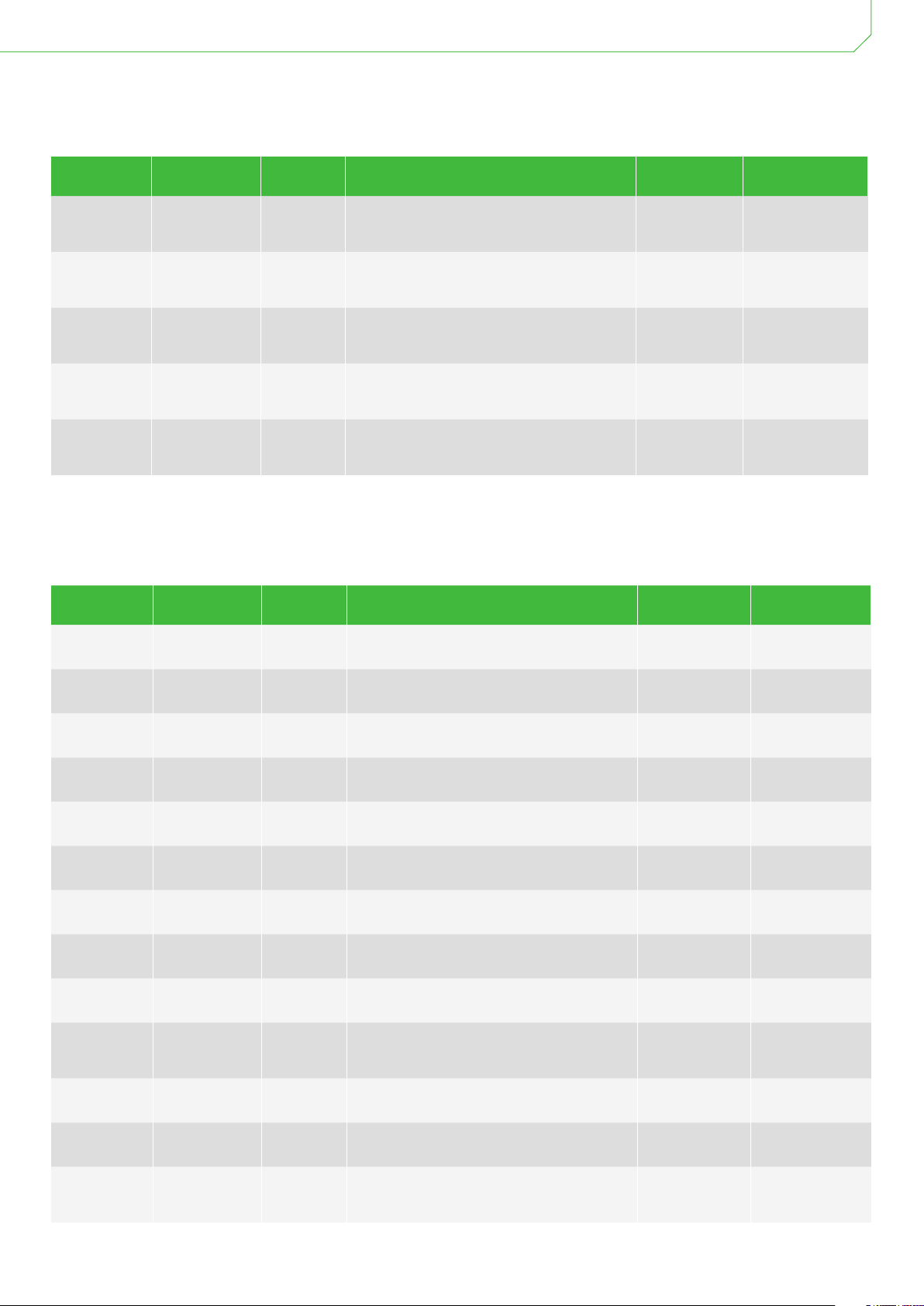

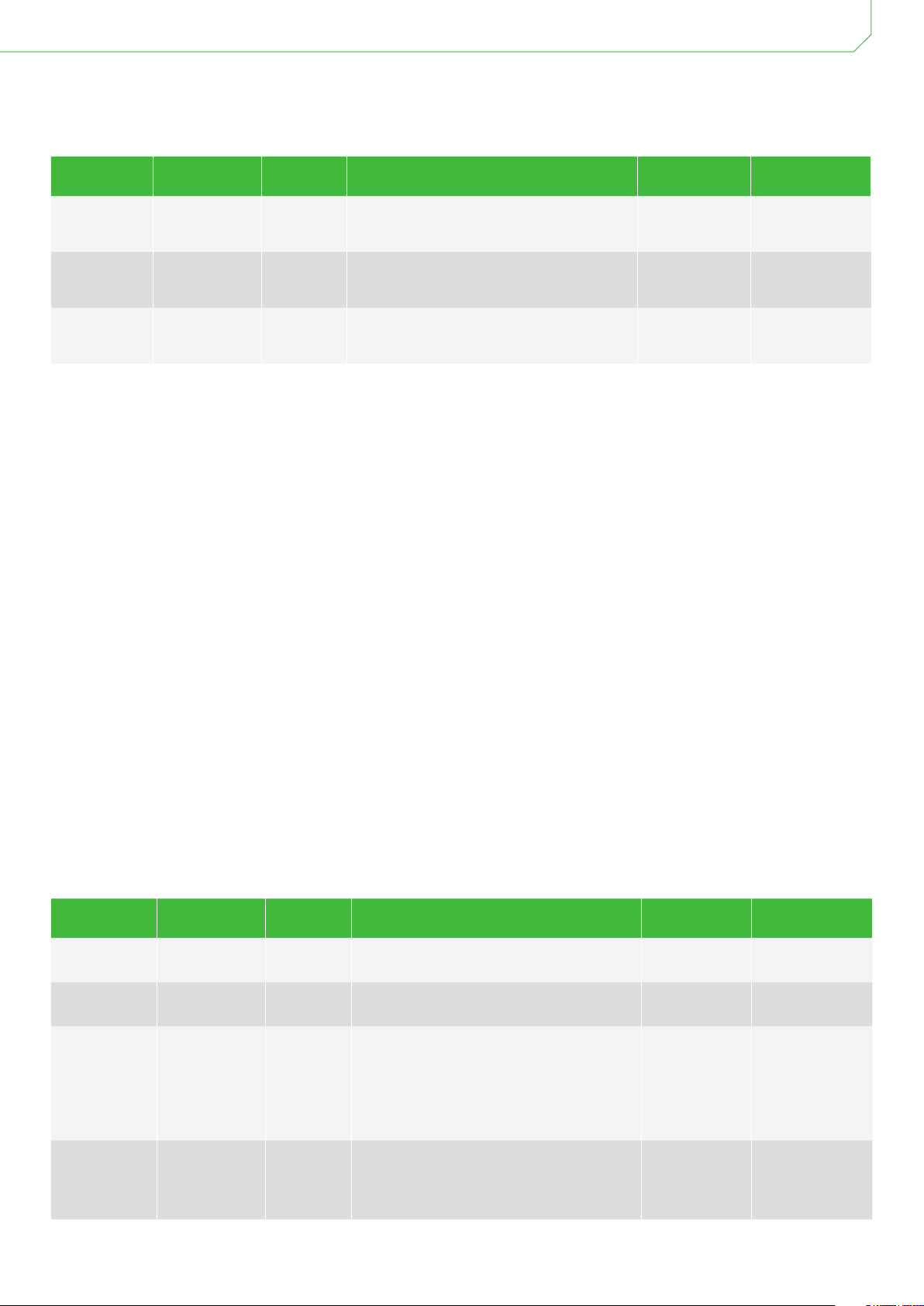

6.3. Modbus function codes

Function Code

(hexadecimal)

Code

(decimal)

Read Holding Registers 03 03

Read Input Register 04 04

Read/Write Multiple Registers 17 23

6.4. Modbus exception codes

Code Name Meaning

01 Illegal function The function code is not valid.

02 Illegal data address The specied register is not valid

03 Illegal data value The value is not allowed

Page 10

7. Functions

For all registers apply that a more specific description of

the parameters are to be found in the User manual for the

LMC341 DIWE.

The parameter names in brackets are the complete

parameter name as listed in LMT or BEST.

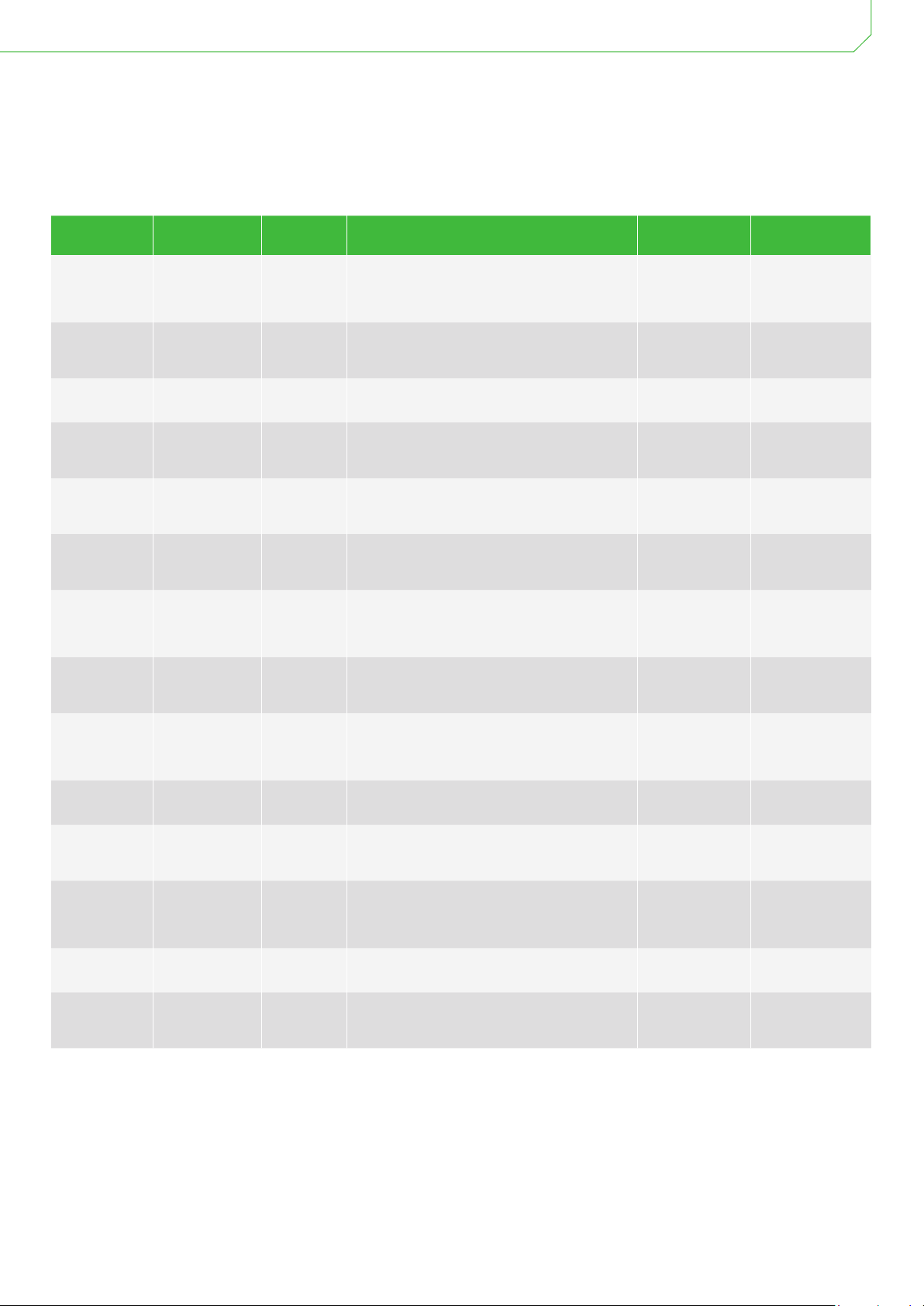

7.1. Status information

This section contains status information parameters.

Many are directly visible on the main menu of the LUP200

display (option).

Name Possible

Values Default Description Register

type Address

2ndSetp Unit None

Scale 1

unit8

0 2nd Setpoint is active

(Animation.2ndSetp)

0: Off

1: Active

Input register 1537

LowSound Unit None

Scale 1

unit8

0 LowSound fan mode is active

(Animation.LowSound)

0: Off

1: Active

Input register 1538

WinterStart Unit None

Scale 1

unit8

0 WinterStart is enabled

(Animation.WinterStart)

0: Off

1: Enabled

Input register 1539

HeatRecover Unit None

Scale 1

unit8

0 Heat recovery is enabled

(Animation.HeatRecover)

0: Off

1: Enabled

Input register 1540

SetPointSrc Unit None

Scale 1

unit8

0 What setpoint is used right now

(Animation.SetPointSrc)

0: User setpoint

1: 2nd Setpoint

2: Week program

Input register 1541

StatusIcon Unit None

Scale 1

unit8

0 Unit status - as on the displays main menu

(Animation.StatusIcon)

0: Normal

1: Min run

2: Min pause

3: Oil return

4: Stopped

5: Li m Tc

6: Lim Tdis

7: Lim Tfc

8: Lim dp

9: Lim Psuc

10: Lim Ifc

11: Off

12: Manual

13: Restarting

14: FC Emergency

15: Psuc Emergency

16: Critical Stop

Input register 1542

MinRun Unit None

Scale 1

unit8

0 Min. compressor run time is active

(Animation.MinRun)

0: Off

1: Active

Input register 1543

MinPause Unit None

Scale 1

unit8

0 Min. compressor pause is active

(Animation.MinPause)

0: Off

1: Active

Input register 1544

LimTc Unit None

Scale 1

unit8

0 TC limiter is active

(Animation.LimTc)

0: Off

1: Active

Input register 1545

Modbus Interface manual LMC341 DIWE

Page 11

7.2. Inputs

The section lists analogue and digital readings from the LMC341 DIWE controller.

Name Possible

Values Default Description Register

type Address

LimTdis Unit None

Scale 1

unit8

0 Tdis limiter is active

(Animation.LimTdis)

0: Off

1: Active

Input register 1546

LimT Unit None

Scale 1

unit8

0 Temp. FI limiter is active

(Animation.LimT)

0: Off

1: Active

Input register 1547

LimdP Unit None

Scale 1

unit8

0 dP limiter is active

(Animation.LimdP)

0: Off

1: Active

Input register 1548

LimPsuc Unit None

Scale 1

unit8

0 Psuc limiter is active

(Animation.LimPsuc)

0: Off

1: Active

Input register 1549

LimIFI Unit None

Scale 1

unit8

0 FI current limiter is active

(Animation.LimI)

0: Off

1: Active

Input register 1550

Name Possible

Values Default Description Register

type Address

T0 Unit °C

Scale 100

sint16

- Saturated suction temperature

(Input.T0)

-10000 °C – 12000 °C

Input register 1552

Troom Unit °C

Scale 100

sint16

- Room temperature

(Input.Troom)

-10000 °C – 12000 °C

Input register 1553

TC Unit °C

Scale 100

sint16

- Saturated discharge (condenser) temperature

(Input.TC)

-10000 °C – 12000 °C

Input register 1554

Tdis Unit °C

Scale 100

sint16

- Discharge temperature

(Input.Tdis)

-10000 °C – 12000 °C

Input register 1555

Tamb Unit °C

Scale 100

sint16

- Ambient temperature

(Input.Tamb)

-10000 °C – 12000 °C

Input register 1556

Tsuc Unit °C

Scale 100

sint16

- Suction temperature

(Input.Tsuc)

-10000 °C – 12000 °C

Input register 1557

Tsh Unit °C

Scale 100

sint16

- Suction superheat temperature

(Input.Tsh)

-10000 °C – 12000 °C

Input register 1558

TFC Unit °C

Scale 100

sint16

- Frequency inverter temperature

(Input.TFC)

-10000 °C – 12000 °C

Input register 1560

IFC Unit A

Scale 100

sint16

- Frequency inverter current

(Input.IFC)

000 A – 10000 A

Input register 1561

Ext_Ref Unit None

Scale 100

sint16

- External input offset

The offset range is set under capacity regulation

(Input.Ext_Ref)

-10000 °C – 10000 °C

Input register 1562

Psuc Unit bar

Scale 100

sint16

- Suction pressure

(Input.Psuc)

000 bar – 1300 bar

Input register 1563

Pdis Unit bar

Scale 100

sint16

- Discharge pressure

(Input.Pdis)

100 bar – 3300 bar

Input register 1564

Pressure

switch

input

Unit Boolean

Scale 1

uint8

- High pressure switch input

(Input.HP_Switch)

0: Off

1: Active

Input register 1565

Page 12

7.3. Outputs

Status of relay outputs.

Name Possible

Values Default Description Register

type Address

Oil_Sensor Unit Boolean

Scale 1

uint8

- Oil level failure

(Input.Oil_Switch)

0: Off

1: Active

Input register 1566

SE-B1 Unit Boolean

Scale 1

uint8

- Compressor overheated

(Input.Cpr_OH)

0: Ok

1: Failure

Input register 1567

Fan1_Fault Unit Boolean

Scale 1

uint8

- Fan1 failure

(Input.Fan1_OH)

0: Ok

1: Failure

Input register 1568

Fan2_Fault Unit Boolean

Scale 1

uint8

- Fan2 failure

(Input.Fan2_OH)

0: Ok

1: Failure

Input register 1569

DigIn1 Unit Boolean

Scale 1

uint8

- Digital input 1

(Input.DigIn1)

0: Off

1: Active

Input register 1570

DigIn2 Unit Boolean

Scale 1

uint8

- Digital input 2

(Input.DigIn2)

0: Off

1: Active

Input register 1571

ExtOnOff Unit Boolean

Scale 1

uint8

- External release input

(Input.ExtOnOff)

0: Off

1: Active

Input register 1572

SC_Cpr1 Unit Boolean

Scale 1

uint8

- Security chain for compressor 1

(Only valid in dual compressor mode)

(Input.SC_Cpr1)

0: Ok

1: Failure

Input register 1573

SC_Cpr2 Unit Boolean

Scale 1

uint8

- Security chain for compressor 2

(Only valid in dual compressor mode)

(Input.SC_Cpr2)

0: Ok

1: Failure

Input register 1574

Name Possible

Values Default Description Register

type Address

RE1 Unit Boolean

Scale 1

uint8

- Contactor K1 for frequency inverter /compressor

(Output.RE1)

0: Off

1: On

Input register 1584

RE2 Unit Boolean

Scale 1

uint8

- Liquid Line Valve / Oil Return signal

(Output.RE2)

0: Off

1: On

Input register 1585

RE3 Unit Boolean

Scale 1

uint8

- Crankcase heater

(Output.RE3)

0: Off

1: On

Input register 1586

RE4 Unit Boolean

Scale 1

uint8

- Power for ΔpII and SE-B1

(Output.RE4)

0: Off

1: On

Input register 1587

RE5 Unit Boolean

Scale 1

uint8

- Alarm relay

(Output.RE5)

0: Off

1: On

Input register 1588

RE6 Unit Boolean

Scale 1

uint8

- RI (Refrigerant Injection)

(Output.RE6)

0: Off

1: On

Input register 1589

Modbus Interface manual LMC341 DIWE

Page 13

7.4. Alarms

Alarm section with up to 16 alarms at a time. The alarms

are sorted with highest priority in Code1 parameter. When

an alarm becomes inactive the priority is less and it is

moved to a new parameter CodeNo > Code1.

An alarm number is coded, meaning status, severity level

and alarm number are encoded in the number in the

parameters Code1 – Code16.

Leftmost bit = Bit16; rightmost bit = Bit0.

Bit1 – Bit10:

Alarm number; 100 – 999. Code1 AND 1023dec =

alarm number.

Bit11 – Bit13:

Alarm level; 0 – 6 as listed for Level in the table

below.

Code1 AND 7168dec = level.

Bit16:

Alarm status; 1: Alarm active; 0: Alarm inactive.

Code1 AND 32768dec = status.

Name Possible

Values Default Description Register

type Address

RE7 Unit Boolean

Scale 1

uint8

- Fan 1

(Output.RE7)

0: Off

1: On

Input register 1590

RE8 Unit Boolean

Scale 1

uint8

- Fan 2

(Output.RE8)

0: Off

1: On

Input register 1591

RE9 Unit Boolean

Scale 1

uint8

- Compressor running for ΔpII

(Output.RE9)

0: Off

1: On

Input register 1592

Name Possible

Values Default Description Register

type Address

Count Unit None

Scale 1

uint16

0 Number of alarms in the list, active and inactive

(Alarm.Count)

0 - 16 alarms

Input register 1600

CountActive 0 Number of active alarms

(Alarm.CountActive)

0 – 16

Input register 1601

Level Unit None

Scale 1

uint16

0 Highest alarm level of the active alarms

(Alarm.Level)

0: None

1: Log

2: Event

3: Info

4: Warning

5: Critical

6: Fault

Input register 1602

Alarm Reset Unit None

Scale 1

uint16

- Alarm reset command variable

(Alarm.Reset)

Range 0 – 65535

100 – 999: Resets the specic alarm – if the alarm is

resettable

65535: Reset all resettable alarms

Holding register 1603

Page 14

Name Possible

Values Default Description Register

type Address

Code1 Unit None

Scale 1

uint16

0 Alarm number of most severe alarm

(Alarm.Code1)

0: No alarm

100 – 40935: Alarm number

Input register 1604

Code2 Unit None

Scale 1

uint16

0 Alarm number of less severe alarm

(Alarm.Code2)

0: No alarm

100 – 999: Alarm number

Input register 1605

Code3 Unit None

Scale 1

uint16

0 Alarm number of less severe alarm

(Alarm.Code3)

0: No alarm

100 – 999: Alarm number

Input register 1606

Code4 Unit None

Scale 1

uint16

0 Alarm number of less severe alarm

(Alarm.Code4)

0: No alarm

100 – 999: Alarm number

Input register 1607

Code5 Unit None

Scale 1

uint16

0 Alarm number of less severe alarm

(Alarm.Code5)

0: No alarm

100 – 999: Alarm number

Input register 1608

Code6 Unit None

Scale 1

uint16

0 Alarm number of less severe alarm

(Alarm.Code6)

0: No alarm

100 – 999: Alarm number

Input register 1609

Code7 Unit None

Scale 1

uint16

0 Alarm number of less severe alarm

(Alarm.Code7)

0: No alarm

100 – 999: Alarm number

Input register 1610

Code8 Unit None

Scale 1

uint16

0 Alarm number of less severe alarm

(Alarm.Code8)

0: No alarm

100 – 999: Alarm number

Input register 1611

Code9 Unit None

Scale 1

uint16

0 Alarm number of less severe alarm

(Alarm.Code9)

0: No alarm

100 – 999: Alarm number

Input register 1612

Code10 Unit None

Scale 1

uint16

0 Alarm number of less severe alarm

(Alarm.Code10)

0: No alarm

100 – 999: Alarm number

Input register 1613

Code11 Unit None

Scale 1

uint16

0 Alarm number of less severe alarm

(Alarm.Code11)

0: No alarm

100 – 999: Alarm number

Input register 1614

Code12 Unit None

Scale 1

uint16

0 Alarm number of less severe alarm

(Alarm.Code12)

0: No alarm

100 – 999: Alarm number

Input register 1615

Code13 Unit None

Scale 1

uint16

0 Alarm number of less severe alarm

(Alarm.Code13)

0: No alarm

100 – 999: Alarm number

Input register 1616

Code14 Unit None

Scale 1

uint16

0 Alarm number of less severe alarm

(Alarm.Code14)

0: No alarm

100 – 999: Alarm number

Input register 1617

Code15 Unit None

Scale 1

uint16

0 Alarm number of less severe alarm

(Alarm.Code15)

0: No alarm

100 – 999: Alarm number

Input register 1618

Code16 Unit None

Scale 1

uint16

0 Alarm number of least severe alarm

(Alarm.Code16)

0: No alarm

100 – 999: Alarm number

Input register 1619

Modbus Interface manual LMC341 DIWE

Page 15

7.5. Control

Parameters used to view and control operation of the LMC341 DIWE controller.

Name Possible

Values Default Description Register

type Address

Mode Unit None

Scale 1

uint8

0 Overall unit mode

(Control.PM_Mode)

0: Off

1: On

2: Manual

Holding register 1632

Control Mode Unit Boolean

Scale 1

uint8

0 Temperature control mode

(Control.CapMode)

0: Suction pressure

1: Room temp control mode

Holding register 1633

Runtime Hours Unit None

Scale 1

uint16

- Runtime in hours, wrap around after 7.5 years

(Control.RuntimeHours)

Input register 1634

MBExtOnOff Unit Boolean

Scale 1

uint8

0 Same function as Input.ExtOnOff, but for Modbus

(Control.MBExtOnOff)

0: Unit Stopped

1: Unit Released

Holding register 1635

TC Setpoint Unit °C

Scale 100

sint16

- Condenser TC setpoint

Only used if ambient compensation = Off

(Condens.TC_set)

000 °C - 8500 °C

Holding register 1636

Fan Mode Unit Boolean

Scale 1

uint8

0 Fan control mode

(Condens.Economy)

0: Eco

1: LowSound

Holding register 1637

Ambient

Comp.

Unit Boolean

Scale 1

uint8

1 Use ambient compensation or xed condenser

setpoint

(Condens.AmbComp)

0: Off

1: On

Holding register 1638

Setpoint Unit °C

Scale 100

sint16

- Capacity controller setpoint

Range depends on compressor and refrigerant

(Capacity.Tset)

-4500 °C - 3500 °C

Holding register 1639

2nd Setpoint Unit °C

Scale 100

sint16

- Secondary setpoint

Activated by a digital input

Range depends on compressor and refrigerant

(Capacity.2ndTset)

-4500 °C - 3500 °C

Holding register 1640

Act. Setpoint Unit °C

Scale 100

sint16

- Actual setpoint (read only)

(Capacity.ActTset)

-4500 °C - 3500 °C

Holding register 1641

Cap. Request Unit %

Scale 100

sint16

- Capacity request

Calculated capacity request

(Capacity.CapReq)

0 - 10000 %

Input register 1642

Cap. Actual Unit %

Scale 100

sint16

- Actual capacity

Actual capacity request – limiters might have reduced

the requested capacity

(Capacity.CapAct)

0 - 10000 %

Input register 1643

FI frequency Unit Hz

Scale 100

sint16

- Actual FI frequency in Hz

(Capacity.FrqAct)

0 - 10000 Hz

Input register 1644

Cpr. Running Unit Boolean

Scale 1

uint8

-Future use Input register 1645

Page 16

7.6. Modbus sample communica-

tion

Note: The following sample is a general Modbus commu-

nication sample and is not for the LMC341 DIWE!

Request: 0b041000000e75a4

Response: 0b041c0000095008b0e4a-

80014000b000108e108f1000f0002f39f8e

Request 0b03200000018f60

Response: 0b030200002045

8. Standards

The product is manufactured according to the following

standards.

RoHS 2002/95/EC

Low voltage 206/95/EC

EMC 2004/108/EC

61000-6-x Generic EMC

The following standards have been used:

EN 61010-1

Safety requirement for electrical equipment for

measurement and control.

EN 61000-6-2

Immunity standard for industrial environments.

EN 61000-6-3

Emission standard for residential, commercial and

lightindustrial environments.

CE approved.

Request (Input register)

0x0b Slave address 1 byte

0x04 Function code 1 byte

0x1000 Start addr 2 bytes

0x000e Quantity 2 bytes

0x75a4 CRC 2 bytes

Response

0x0b Address 1 byte

0x04 Function code 1 byte

0x1c NB bytes of data 1 byte

0xffff Value1 2 bytes

0x0000 Value2 2 bytes

0x0950 Value3 2 bytes

0x08b0 Value4 2 bytes

0xe4a8 Value5 2 bytes

0x0014 Value6 2 bytes

0x000b Value7 2 bytes

0x0001 Value8 2 bytes

0x08e1 Value9 2 bytes

0x08f1 Value10 2 bytes

0xffff Value11 2 bytes

0x000f Value12 2 bytes

0x0002 Value13 2 bytes

0xfff3 Value14 2 bytes

0x9f8e CRC 2 bytes

Request (Holding register)

0x0b Slave address 1 byte

0x03 Function code 1 byte

0x2000 Address 2 bytes

0x0001 Quantity 2 bytes

0x8f60 CRC 2 bytes

Reponse

0x0b Slave address 1 byte

0x03 Function code 1 byte

0x02 Quantity 1 byte

0x0000 Value1 2 bytes

0x2045 CRC 2 bytes

Modbus Interface manual LMC341 DIWE

Page 17

9. Trouble shooting

•Check if there is power to the LMC341 DIWE,

range 15 - 30 VDC/12 – 24 VAC.

•Check if Data+ and Data- wires have been switched.

•Check if the communication node

adress setting matches the selected.

Note: Node address should be between 1 and 247, both

included.

•Check if the communication speed matches the selected.

•Check if communication is running.

The LUP200 display will show readings and commands.

Page 18

10. Index

A

Alarms 13

C

Cable routing 8

Control 15

D

Data types and scaling 9

Definitions 5

Disposing 4

F

Functions 10

G

General 5

I

Inputs 11

Installation 4

Internally connected 7

M

Master controller 6

Modbus configuration 8

Modbus exception codes 9

Modbus function codes 9

Modbus sample communication 16

O

Outputs 12

S

Safety 4

Setup 8

Standards 16

Status information 10

Modbus Interface manual LMC341 DIWE

Page 19

11. Notes

Innovative and energy saving

climate control

When it comes to climate control Lodam is one of the most experienced you can turn to. For

more than four decades we have developed, produced and implemented electronic solutions

dedicated to optimising applications like:

• Compressors

• Condensing units

• Heat pumps

• Air conditioning

• Refrigerated truck and trailer

• Reefer containers

We know the importance of reliable, energy-ecient operation – and constantly push techno-

logical boundaries to bring you the most innovative and forward-thinking solutions.

As part of the BITZER Group we are backed by one of the world’s leading players in the

refrigeration and air conditioning industry. This alliance provides us with extensive network and

application knowhow and allows us to stay at the forefront of climate control innovation. And

to help ensure comfortable surroundings for humans and reliable protection of valuable goods

anywhere in the world.

Lodam electronics a/s

Kærvej 77

6400 Sønderborg

Denmark

Tel. +45 7342 3737

Fax +45 7342 3730

lodam@lodam.com

For more information visit:

www.lodam.com

17-04-2018 Contents are subject to change without notice.

Table of contents