Helios Power Solutions DCW300 User manual

User Manual

DC/ DC Converters

DCW300 / DCW500

300 / 500 watts

REV --1

Contents

1 General

2 Input Voltage options

3 Output Voltage options

4 Output Voltage adjustment

5 Over Voltage protection ( OVP )

6 Over Current protection ( OCP )

7 Cooling

8 Operating temperature

9 Connections

10 Single Unit operation

11 Parallel Operation of two units

12 Series connection

13 Safety

14 Production Specifications & Mechanical details

1: General:

The DCW300 & DCW500 Series product is a range of dc/dc converters, designed for use in industrial

( fixed ) applications. They are designed to step up or step down dc voltages.

2: Input Voltage options:

These units are offered with a range of “standard” input voltages, as illustrated in the general product data

sheet table, but can also be manufactured to customer’s special input voltage.

3: Output Voltage options:

These units are offered with a range of “standard” output voltages, as illustrated in the general product data

sheet table, but can also be manufactured to customer’s special input voltage.

4: Output Voltage Adjustment:

The output voltage is user adjustable via a trim pot on the side of the unit.

The output adjustment is typically 0% ~ 15%, but can be customised to suit customer requirements.

Warning: If the output voltage is adjusted too high, the unit will shut down to protect the load connected to it.

Should this occur, turn the input power off, wind back the voltage trim pot to approximately where it should

be and turn the power back on after approximately 30 seconds.

5: Over Voltage Protection ( OVP )

Overvoltage protection is by way of double regulator loop, which will shut down the output voltage.

Should this occur, turn the input power off, for approximately 30 seconds and then turn power back on. If the

unit fails to power up, it needs to be returned to service department for investigation.

6: Over Current Protection ( OCP )

The DCW300 / 500 employ a constant current with hiccup mode ( over load / short circuit ) protection.

At approximately 60% of the output voltage, the unit operates in constant current mode and then enters

hiccup mode for short circuit protection.

7: Cooling:

Cooling by way of conduction ( to customer chassis ) and natural convection. …NO fans.

For reliable operation the power supply should be mounted such that: -

There isno obstruction toconvected air forunits cooledby natural convection.

Air temperature does not exceed maximum rated ambient.

8: Operating Temperature:

Figure 8-1 is a typical illustration of the derating

required if the unit operates in high ambient

environments.

Fig 4-1.

Fig: 8-1

9: Connections:

Positive output: The standard units are designed with built-in isolation diode. This allows the connection of two units in

parallel for N+1 Redundancy applications..

10: Single Unit Operation:

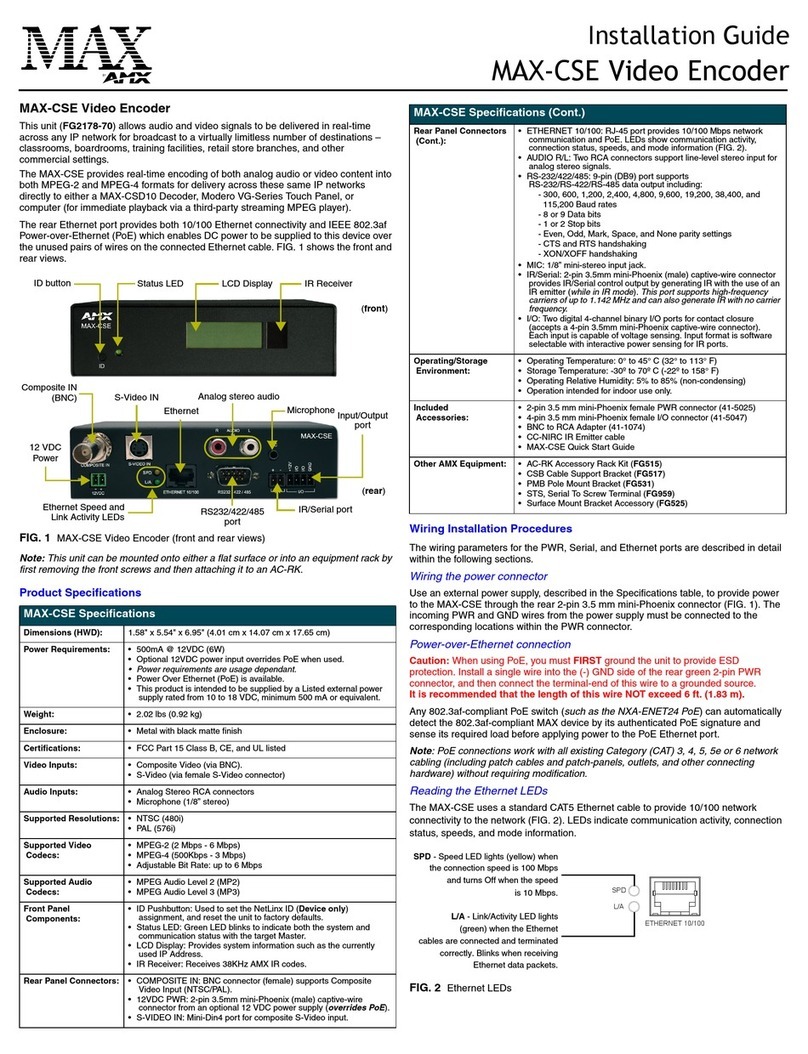

The connection details illustrated in Fig 9-1 is of a

typical standard model and it may vary from unit to unit

and or design.

DC Input:+ - & Earth

Alarm: The units are supplied with a Power Fail

Alarm. This will operate if the Input power is lost, or the

output voltage fails. The alarm is by way of “voltage

free” change over contacts. User can select to use

FAIL OPEN or FAIL CLOSE in reference to COM.

Negative Output: - - load connection for –VE output. Fig 9-1

+ -

Load

Alarm

DC Input

Fig 10-1

Note:

•The terminals are rated at 25A each. In some input / output

configurations, where the current is above 20A, all the –VE & +VE

terminals should be used.

•Input and output cables should be separated from one another for minimum

interference and continued safety.

•Cables should be short and of adequate cross section to minimise voltage

drop and resistive heating. Source and return cables should be run together

for minimum pickup and radiation.

11: Parallel Operation of two units:

The DCW300 / 500 units have built-in output isolation diodes that allow two units ( maximum ) to be

connected in parallel for N+1 Redundancy applications. This ensures that the output power to the load is

available, in the event one of the units should fail. +VE Connection to be made via the Redundant

terminals.

Note: Units are not to be connected in parallel for increase power

The two alarms can be connected in series or parallel to provide one common alarm if required.

+ -

Load

Alarm

DC Input

Fig 11-1

12: Series Operation of two units:

The DCW300 / 500 units can be connected in series as per Fig 12.1.

This allows for example two 24V output models to be connected in series for 48V output.

Output diodes to prevent reverse voltage applied to each unit under certain conditions.

13. Safety:

In general these units are designed to be built into customer equipment and are therefore often of an open frame construction.

Hazardous voltages and surface temperatures are therefore accessible on the printed circuit boards and exposed components.

The user must ensure that these are not accessible after installation.

These hazards may still be present for a period of time after input disconnection. Therefore access to exposed unit should not

be attempted until at least 2 minutes after disconnection and then only by qualified personnel.

The input voltage, requirements are specified on the unit rating label. Failure to operate within these ratings may result in a

safety hazard, and the unit may be permanently damaged.

For continued protection against electric shock user must not allow units to operate in high moisture environments (see product

specification for humidity rating). If exposed to such, remove supply voltage and allow to dry out before further use

Fuses: Most units will have an on-board input fuse.

WARNING: Should this fuse blow, DO NOT replace the fuse. The units needs to be returned to a qualified service technician

for investigation, before fuse is replaced.

For continued protection against fire hazard replace fuses only with correct type and rating (fast 'F' HRC). See label for fuse

rating.

Environment

Fire hazard may occur if power supply is operated in atmospheres designated explosive or highly corrosive, or atmospheres

containing a high level of abrasive dust, or in extremes of temperatures outside specified limits (see product specification), or

environments unprotected from severe impact.

Fig 12-1

+

48 / 24V -

+

48 / 24V

-

Input: 48vdc

48VDC

Load

DCW300-500 SERIES

DC/DC Converters Single Output: 300 ~ 500 Watts

Wide range of input / output voltage combinations

300 and 500 watt power options

Convection cooled: No fans

N+1 redundancy : standard

Output Fail alarm: standard

Fully isolated input – output

Over voltage & short circuit protection

MTBF > 200,000hrs

Specials input / output combinations on request.

Any output from 12vdc ~ 120vdc possible

Input Voltage 24VDC ( 20 ~ 29 )

48VDC ( 38 ~ 60 )

110VDC ( 88 ~ 135 )

Other voltages on request

Input Protection Reverse polarity protection.

Inrush current limiting

Thermal Fuse

Isolation Input - Output 1500 vdc

Input – Chassis 1500 vdc

Output – Chassis 500 vdc

Other options on request

Efficiency Model dependent , typically 80%

Switching Freq. 50kHz

Output voltage Any voltage from 12 to 120VDC

Output Power DCW300: 300 watts

DCW500: 500 watts

Voltage

adjustment -0% ~ +15% ( other options on request )

Parallel

Operation Built-in isolation diode allows maximum two

units to be connected in parallel for N+1

redundancy .

Line Regulation ±1% over input range

Load Regulation ±2% from no load to full load.

Output

Protection

Over voltage protection

Current limiting with hiccup mode.

Thermal protection

Short Circuit

Protection Current limiting with hiccup mode

EMI EN55022 class A

Immunity EN61000-4

Output Ripple &

Noise 1% pk-pk maximum of output voltage setting

Operating

Temp. 0°C to +50°C at full load.

Derate 2.5% per °C from 50° -70°C.

Humidity 10-95% non-condensing

( Conformal Coating optional )

Cooling Conduction cooled or Convection cooled.

Output Alarm Built-in Voltage free relay contacts

Terminals Screw- type terminal block

( other options on request )

Dimensions &

Weight DCW300: 290 x 132 x 62mm 2Kg

DCW500: 352 x 132 x 62mm 2.5Kg

Model Input

V Output

V A Power

W

DCW300-24-12FT 24V 12V 25A 300W

DCW300-24-15FT 24V 15V 20A 300W

DCW300-24-24FT 24V 24V 12.5A 300W

DCW300-24-48FT 24V 48V 6.2A 300W

DCW300-24-110FT 24V 110V 2.7A 300W

DCW300-48-12FT 48V 12V 25A 300W

DCW300-48-15FT 48V 15V 20A 300W

DCW300-48-24FT 48V 24V 12.5A 300W

DCW300-48-48FT 48V 48V 6.2A 300W

DCW300-48-110FT 48V 110V 2.7A 300W

DCW300-110-12FT 110V 12V 25A 300W

DCW300-110-15FT 110V 15V 20A 300W

DCW300-110-24FT 110V 24V 12.5A 300W

DCW300-110-48FT 110V 48V 6.2A 300W

Model Input

V Output

V A Power

W

DCW500-24-12FT 24V 12V 40A 480W

DCW500-24-15FT 24V 15V 33A 500W

DCW500-24-24FT 24V 24V 20A 500W

DCW500-24-48FT 24V 48V 10A 500W

DCW500-24-110FT 24V 110V 4.5A 500W

DCW500-48-12FT 48V 12V 40A 500W

DCW500-48-15FT 48V 15V 33A 500W

DCW500-48-24FT 48V 24V 20A 500W

DCW500-48-48FT 48V 48V 10A 500W

DCW500-48-110FT 48V 110V 4.5A 500W

DCW500-110-12FT 110V 12V 40A 500W

DCW500-110-15FT 110V 15V 33A 500W

DCW500-110-24FT 110V 24V 20A 500W

DCW500-110-48FT 110V 48V 10A 500W

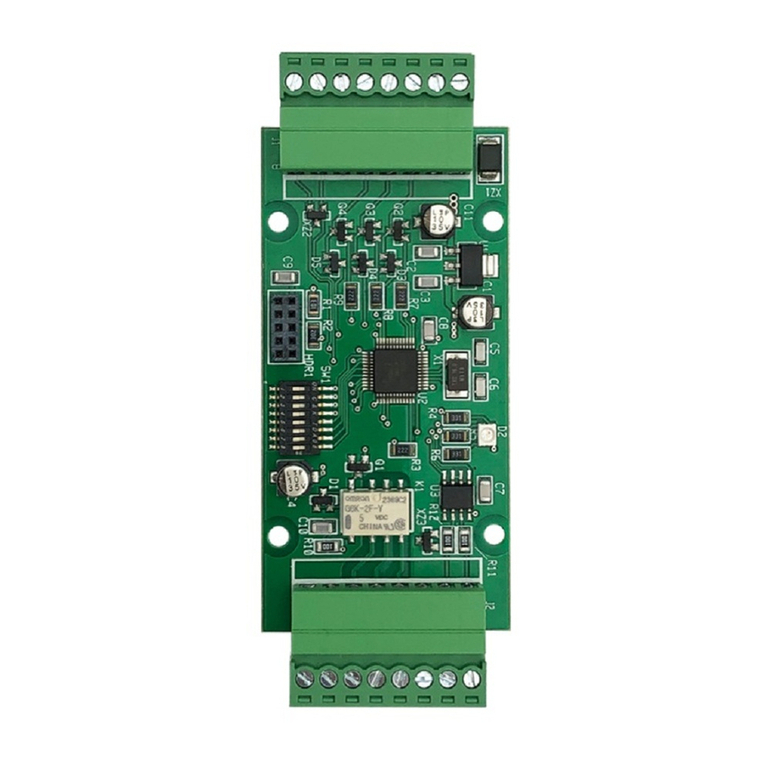

19in Rack Mount option

Standard model

DIN Rail mounting option

Specifications

Features

REV (20-03-19 )

www.heliosps.com.au

279.4

114.3132.1

289.6

5.4 QTY: 4

5.4 QTY: 4

351.1

129.5

341

114.3

61.6

3.2

61.6

3.2

DCW300

DCW500

DCW300-500 SERIES

DC/DC Converters Single Output: 300 ~ 500 Watts

www.heliosps.com.au

This manual suits for next models

1

Table of contents

Popular Media Converter manuals by other brands

YOKOGAWA

YOKOGAWA JUXTA VJB3 user manual

Kathrein

Kathrein EBX 520 quick start guide

Albalá Ingenieros

Albalá Ingenieros PDC3002C01 manual

Dedicated Micros

Dedicated Micros DV-IP Decoder Setup guide

Harman Kardon

Harman Kardon SC6 owner's manual

SignaMax

SignaMax OAM Managed Dual Rate Converter Series user guide

Sonero

Sonero X-AVT100 instruction manual

IS5 COMMUNICATIONS

IS5 COMMUNICATIONS iSC2F user manual

Kenwood

Kenwood DEM-999D instruction manual

Clarion

Clarion DVH940 owner's manual

METRObility Optical Systems

METRObility Optical Systems twister 2131-34-01 Installation & user guide

Baumer

Baumer HUBNER BERLIN HOG 11 Mounting and operating instructions