Siemens AG 3

1 Basicrequirements

1PM4 hollow shaft motors conform with:

-98/37/EC MachineDirective

-73/23/EEC Low Voltage Directive and

-89/336/EEC ElectromagneticCompatibilityDirective.

Ensure that your end product conforms to all currently valid

legal requirements. Follow the compulsory national, local

and installation-specific regulations.

Starting up the motors is not permitted until the end product

conforms to this stipulations of the named guidelines.

ObservetheSIEMENSProjectPlanningInstructionsfor1PM4

motors.

The safety instructions must be observed during the

transport, storage, assembly, disassembly and operation

of the hollow shaft motors!

Failure to observe the instructions can lead to serious personal

injuries or property damage.

All activities (transport, storage, assembly, disassembly

of the hollow-shaft motors) must be performed by

qualified, skilled workers who are aware of the specific

dangers and who observe the stipulations of the present

operating instructions.

Maintenance (replacement of the gear encoder or bearing) may

only be performed by the manufacturer or authorized SIEMENS

service centers.

Mechanical hazards

Appropriate tools etc. are used for transport and assembly work

Lifting devices, ground conveyors and lifting tackle must

correspond to the valid regulations, e.g.:

EUDirectiveforMachines98/37EEC,appendix1

Regulations of the statutory industrial accident insurance institution

BGVD6, BGV D8,BGV D27, VBG9a ecc.

There is an injury hazard in the vicinity of the rotating motor.

The manufacturer of the end product is responsible for

protection against accidental contact with the rotating

motor.

Do not wear any additional clothing, jewelry or allow long

hair to hang freely.

Electricalhazards

The electrical connection to the hollow shaft motors is made as

described in the operating instructions.

All electrical work only must be performed by qualified

electricians and always with the equipment electrically

dead.

Requirements of qualified electricians according to

EN50110-1:1996(DINVDE0105-100):

- Knowledge of electrical engineering

- Experience of electrotechnical work

- Knowledge of the plant / machine

- Knowledge of the hazards and safety measures

- Ability to decide upon a safe working sequence.

Hollow-shaft motors are only driven with configured converters.

Any other connection can lead to their destruction.

Never connect the motors directly to an external three-

phase mains! The correct phase sequence is vital!

The temperature sensor and encoder system including electronics

contain electrostatically endangered components (EEC).

Do not touch the connections with your hands or with tools

which could be electrostatically charged!

Thermal hazards

The surface temperature of the motors may exceed 80oC (176oF).

Do not touch hot surfaces!

Temperature-sensitive components (electric lines, electronic

components) must not touch hot surfaces.

IntendedUsage

The motors correspond to the harmonized standards of the

EN60034(VDE0530)series.

They are intended for industrial or commercial plants.

Special case: More stringent requirements must be taken into

consideration during the configuration and assembly for use in non-

commercialplants.

Usage for the intended purpose includes observing all the

specifications in the operating instructions.

Ambienttemperatures:-15oCto+40oC(5oFto104oF)

The motors must be protected against frost if water is used as a

coolant.Site altitude: up to1000ma.s.l.

The conditions at the location of use must correspond to all the

informationon the rating plate.

It is forbidden to use them in areas at risk of explosion.

The operating instructions are part of the scope of delivery and shall

be kept in an accessible place.

The technical details of special versions and design variants of the

motors can vary.

Please contact the manufacturer or a SIEMENS service center if you

have any questions regarding the use or operational characteristics

of the motors.

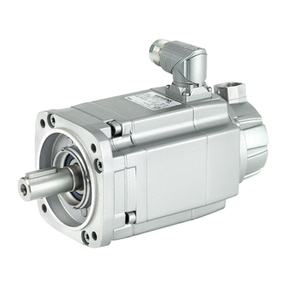

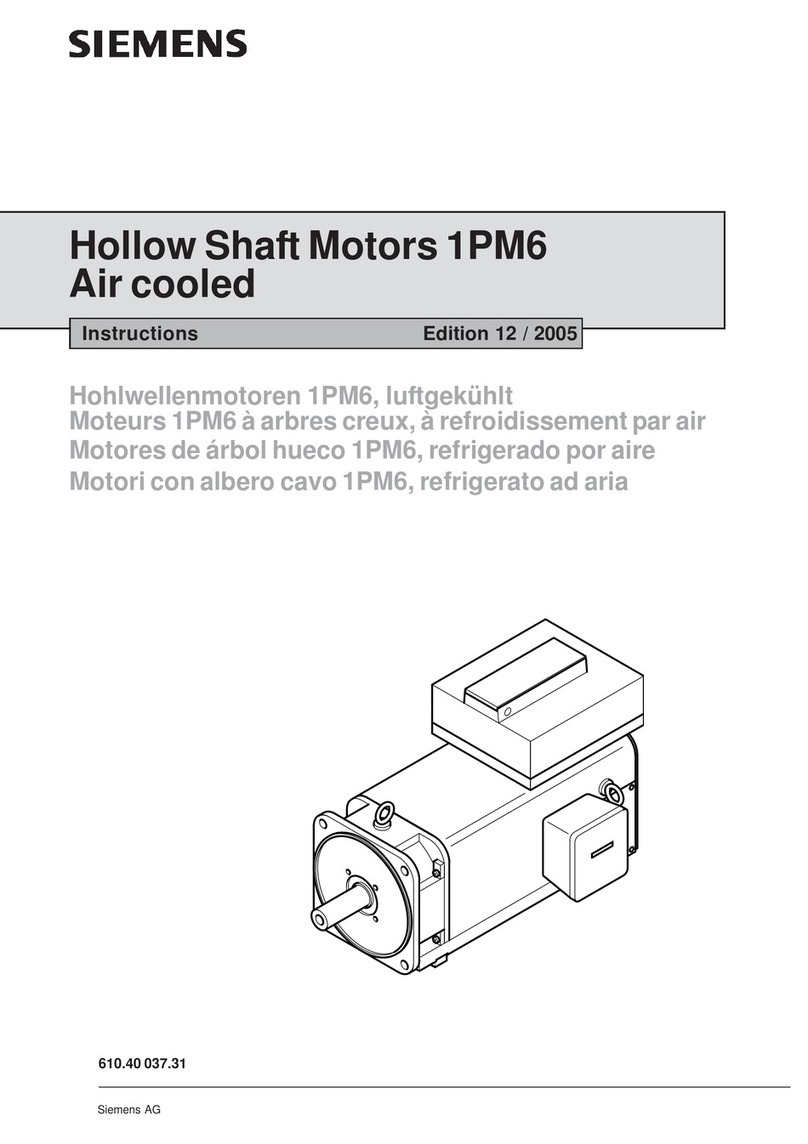

2 Productinformation

2.1 Application range

The hollow shaft of the motor serves for the supply of cooling

lubricant or the insertion of collets. The motors are used if

-the environmental conditions are unsuitable for air cooling,

-theenvironmentmustnotbethermallypollutedor

-the motor has to have a high power density in a restricted

mounting space.

Application cases: Milling machines with full encapsulation, turning

lathes with driven tools or counterspindles.

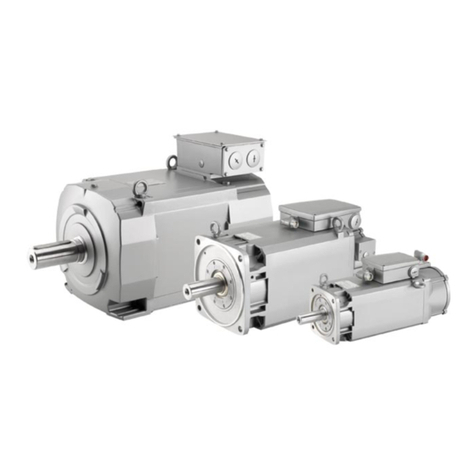

Types of construction: see Fig. 1 of the appendix

2.2 Technical parameters

Motor types 1PM4101,103,105, 107

1PM4133, 135, 137

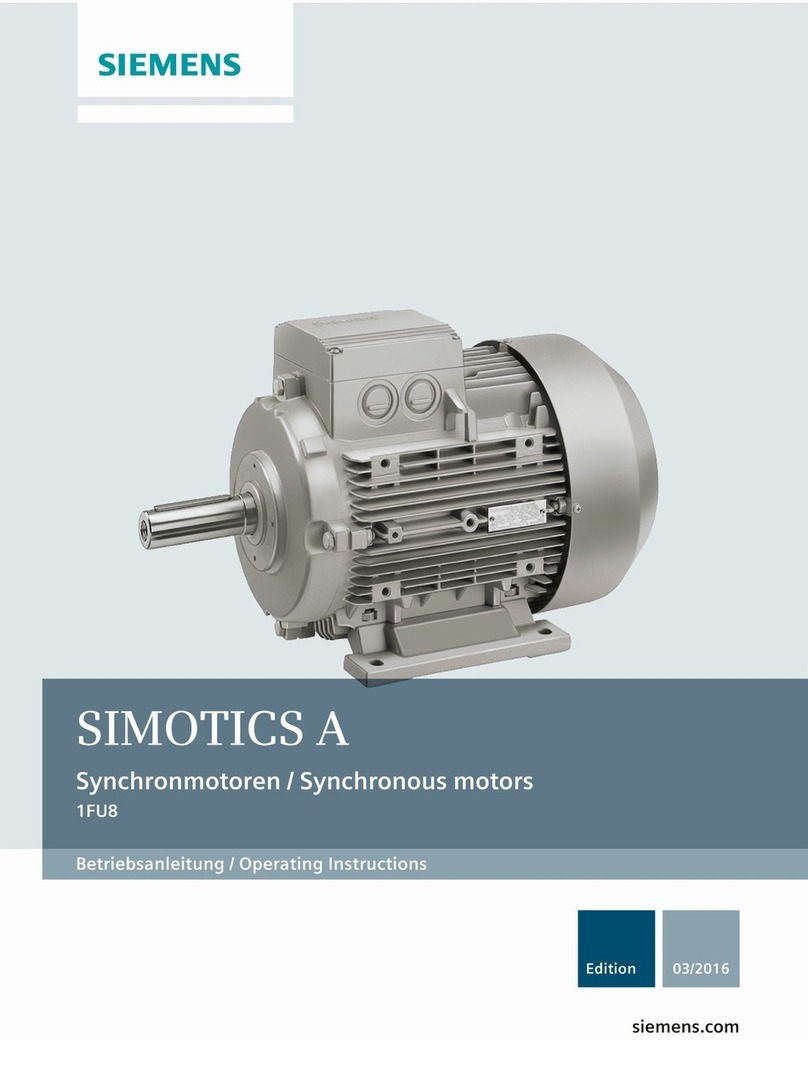

Types of construction Fig.1

Standard protection class IP65(attheshaftentry IP55)

Coolanttemperatureatinlet oil:0oCto+10oC(32 to 500F)

water: 5°C to 25°C (41 to 770F)

Other coolants or temperatures on request

Ambient temperature max.40oC

Protect from frost if water-cooled!

Measuring-surface sound-pressure level (EN 21 680 Part 1)

1PM410. to 1PM413. approx. 69 dB(A);

72 dB(A) with L37

Balancing(EN60034-14) vibration severity grade SR

The bearings are designed for high speeds:

Motor types Standard L37

1PM4101...105 12.000min-1 18.000min-1

1PM4107 12.000min-1 15.000min-1

1PM4133 10.500min-1 15.000min-1

1PM4137 10.500min-1 13.000min-1

1PM4138 10.500min-1 12.000min-1

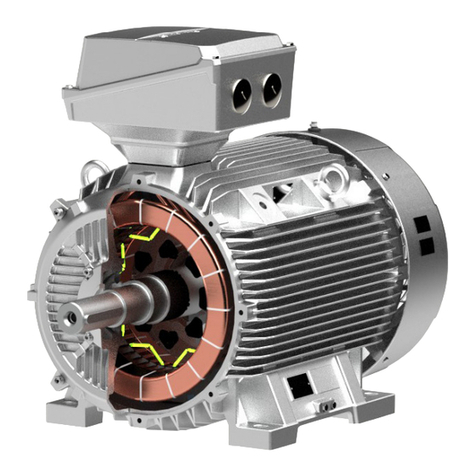

2.3 Mode of operation and design

Motors of the 1PM4 series are water-cooled, four-pole

asynchronous motors. The squirrel-cage rotor (rotor) has a hollow

shaft.

- Core-and-winding assembly:

Temperature sensor for temperature measurement and

regulation, and to protect against overheating, fitted in the stator

winding (a second sensor as a reserve).

- Encoder system

Incremental encoder sin/cos (I-256) for measuring the motor

speed and the relative change in the rotor position (installed at the

ND-end).

ENGLISH