HELWIG CARBON BPK Probe User manual

Page 1 of 8 BPPI 6.19

BPK-Probe

Shaft Voltage Detection Device

Operating Guide

Page 2 of 8 BPPI 6.19

BPK Probe™ Important Safety Information

You must understand all of the safety statements in this manual prior to operating the BPK

Probe™.

The WARNING designation indicates a potentially hazardous situation that, if not

avoided, could result in death or serious injury.

The BPK Probe™ is designed to be in direct contact with rotating motor shafts. Rotating

motion can be dangerous; even smooth, slowly rotating shafts can grip clothing, and

mere skin contact can force an arm or hand into a dangerous position. Injuries due to

contact with rotating parts can be severe.

All power sources for machines are potential sources of danger. When using electrically

powered or controlled machines, the equipment as well as the electrical system itself

must be properly grounded. High pressure systems, too, need careful inspection and

maintenance to prevent possible failure from pulsation, vibration, or leaks. Such a

failure could cause, among other things, explosions or flying objects.

While never a substitute for appropriate machine guards, personal protective equipment

must always be worn around rotating motor shafts. It is important to note that

protective clothing and equipment can create hazards. For example, a protective glove

can become caught between rotating parts, or a respirator facepiece can hinder the

wearer’s vision.

Do not use the BPK Probe™ in explosion proof or otherwise hazardous environments.

Follow all safety precautions when working with rotating equipment.

The BPK Probe™ should be used by qualified, trained personnel ONLY.

Page 3 of 8 BPPI 6.19

Purpose of the BPK Probe™

The BPK Probe™ measures motor shaft voltage. It also demonstrates the effectiveness of a

bearing protection kit (BPK) if a BPK is installed.

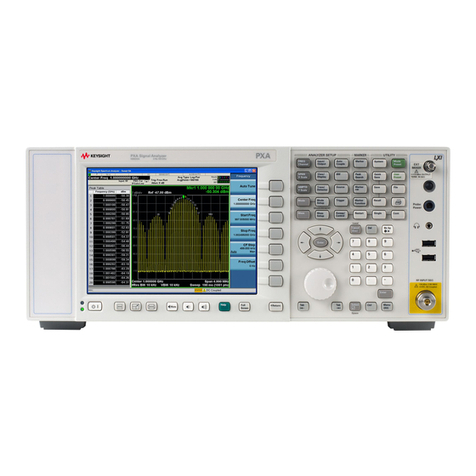

Components

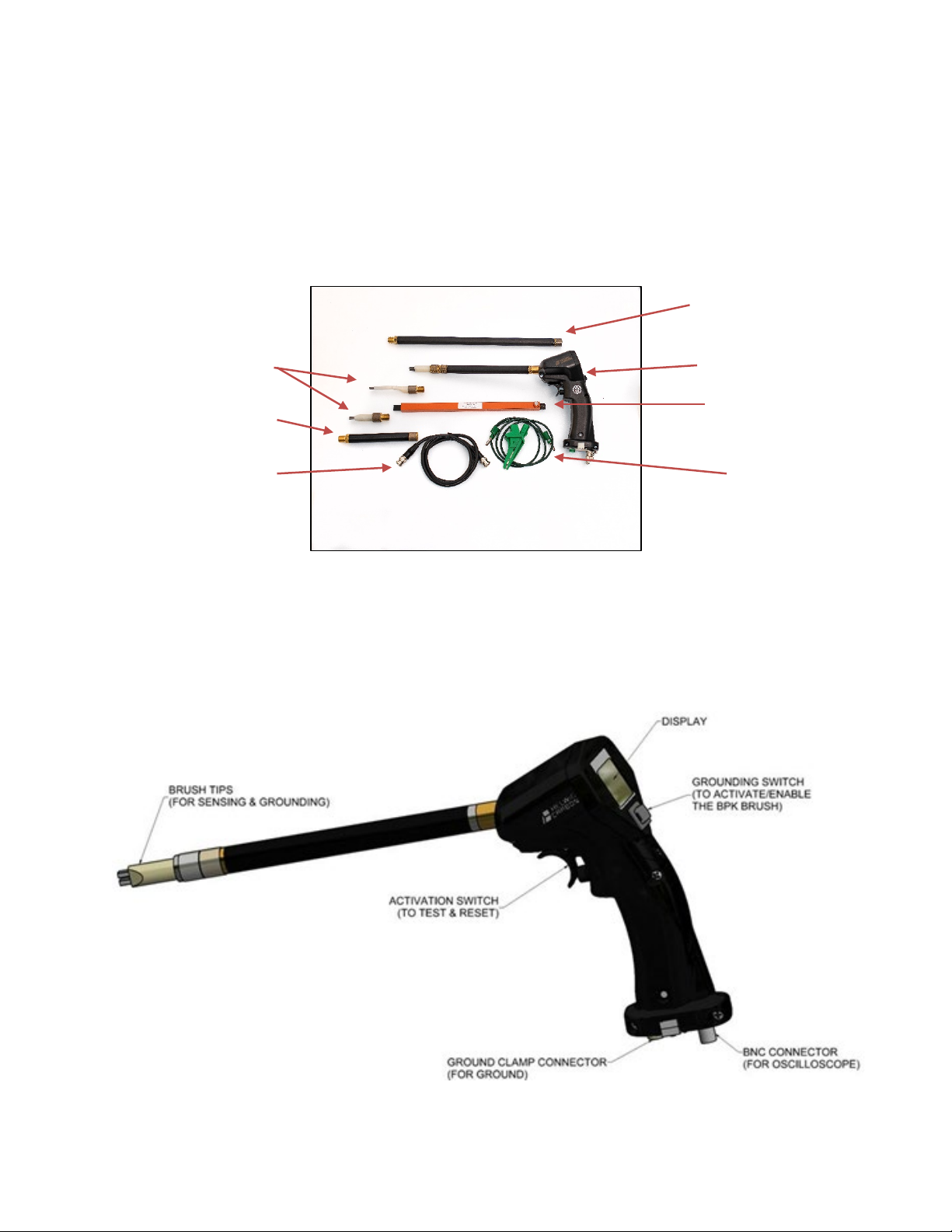

BPK Probe™ Assembly Features

4” Extension Tube

Spare Tips

BNC Cable

Ground Wire &

Clamp

Probe Preparation Tool

BPK Probe™ Assembly

12” Extension Tube

Page 4 of 8 BPPI 6.19

BPK Probe™ Instructions for Use

Step 1: Prepare the BPK Probe™

Follow all safety precautions when working with rotating equipment.

The BPK Probe™ comes with a variety of tips and accessories. The assembly comes with the

6” extension tube and standard tip already mounted. Different extension tubes and tips can be

quickly and easily changed. In addition, the BPK Probe™ assembly has a BNC connector and

cable for connecting an oscilloscope if needed.

a) Verify the motor shaft contact area is clear of debris, oils and contamination.

b) Using the rubber flap side of the Probe Preparation Tool (Figure 3), identify a contact area

on the shaft for measurements.

c) Verify the contact area is clean and not in line with a key, keyway, set screw, or anything

that can obstruct or damage the sensor tip brushes.

d) If required, use the Probe Preparation Tool’s cleaning stone (Figure 3) to remove rust,

debris, and oil from from the contact area (Figure 4).

e) Select the best tube and tip for your application.

Figure 4: Use the Probe Preparation

Tool’s cleaning stone to clean contact

area.

Figure 3: The Probe Preparation Tool

has two ends

: a cleaning stone to

clean the shaft surface and a

rubber

flap to detect for keyways.

Cleaning Stone

Rubber Flap

Page 5 of 8 BPPI 6.19

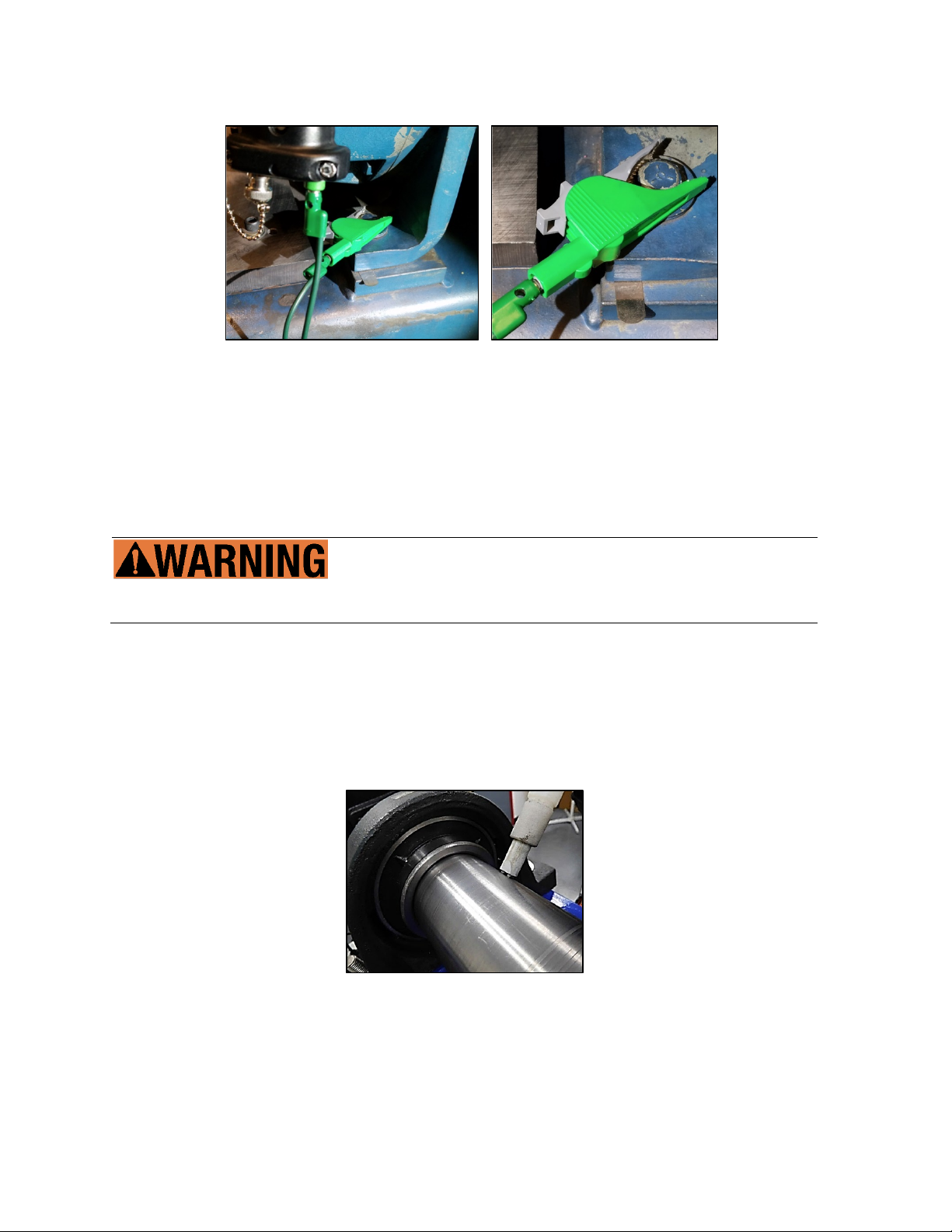

f) Attach the ground wire to the BPK Probe™ (Figure 5).Locate a clean, paint-free ground

source and secure the ground clamp (Figure 6).

g) Ensure the ground or optional BNC cable cannot be entangled with rotating or stationary

equipment, guards, etc.

Step 2: Test Motor Shaft Voltage

Follow all safety precautions when working with rotating equipment.

a) With the ground clamp safely secured, verify the rocker switch is off (LED not lit). This

disables the embedded grounding brush.

b) Remove the protective sensor tip cover and keep nearby.

c) On a suitable and properly prepared surface, carefully place the sensor tip against the

rotating shaft (Figure 7).

d) Ensure both sensor tip brushes are firmly and squarely against the contact surface.

e) Press the probe tip onto the shaft until about 1/8” of the spring-loaded brushes are exposed.

Figure 5: Attach ground wire to probe.

Figure 6: Locate a ground source

and secure the ground clamp.

Figure 7: Place the sensor tip against

the rotating shaft.

Page 6 of 8 BPPI 6.19

f) Perform the test. With the BPK Probe™ brushes pressed against the motor shaft, press and

hold the trigger switch throughout the test. As the test starts, the Helwig Carbon logo will

show (Figure 8).

g) Next, a SAMPLING SHAFT VOLTAGE message will appear (Figure 9). Continue to hold the

trigger switch with the tip of the probe against the motor shaft. When complete, the screen

will show a real-time test result (Figure 10).

h) Carefully remove the probe from the motor shaft, note the results, and release the trigger.

Remove the ground clamp and replace the protective tip cover. The test is complete.

i) The shaft voltage test can be repeated with and without

engaging the embedded grounding brush. To enable the

grounding brush, press the rocker switch on the face of the

probe handle. The embedded grounding brush is enabled

when the green LED on the switch is lit. Testing with the

grounding switch enabled shows the effectiveness of the

Helwig grounding solution (Figure 11).

Figure 8: As the test starts, the Helwig

Carbon logo will show.

Figure 9: A SAMPLING SHAFT

VOLTAGE message will appear.

Figure 10: Test results for unprotected

motor

.

Figure 11: Test results with

grounding switch enabled.

Page 7 of 8 BPPI 6.19

Step 3: Battery Status and Replacement

a) The BPK Probe™ is powered by a 9v battery. To check battery status, press and release

the probe trigger. The display will show the Helwig Carbon logo and then go to a ready

screen. The battery status will appear in the upper right corner of this screen (Figure 12).

b) If the battery is too low to operate the probe, you will get a flashing LOW BATTERY

message (Figure 13). The probe will not allow testing until the battery is changed.

c) To change the battery, loosen the retaining screw on the bottom of the probe handle (Figure

14). Remove the battery cover plate and slide the battery from the probe handle. Replace

battery (Figure 15). Insert cover plate and tighten the retaining screw.

Figure 12: Battery status in

upper right corner

.

Figure 13: LOW BATTERY

message

.

Figure 14: Loosen retaining

screw and remove cover plate.

Figure 15: Replace battery.

Page 8 of 8 BPPI 6.19

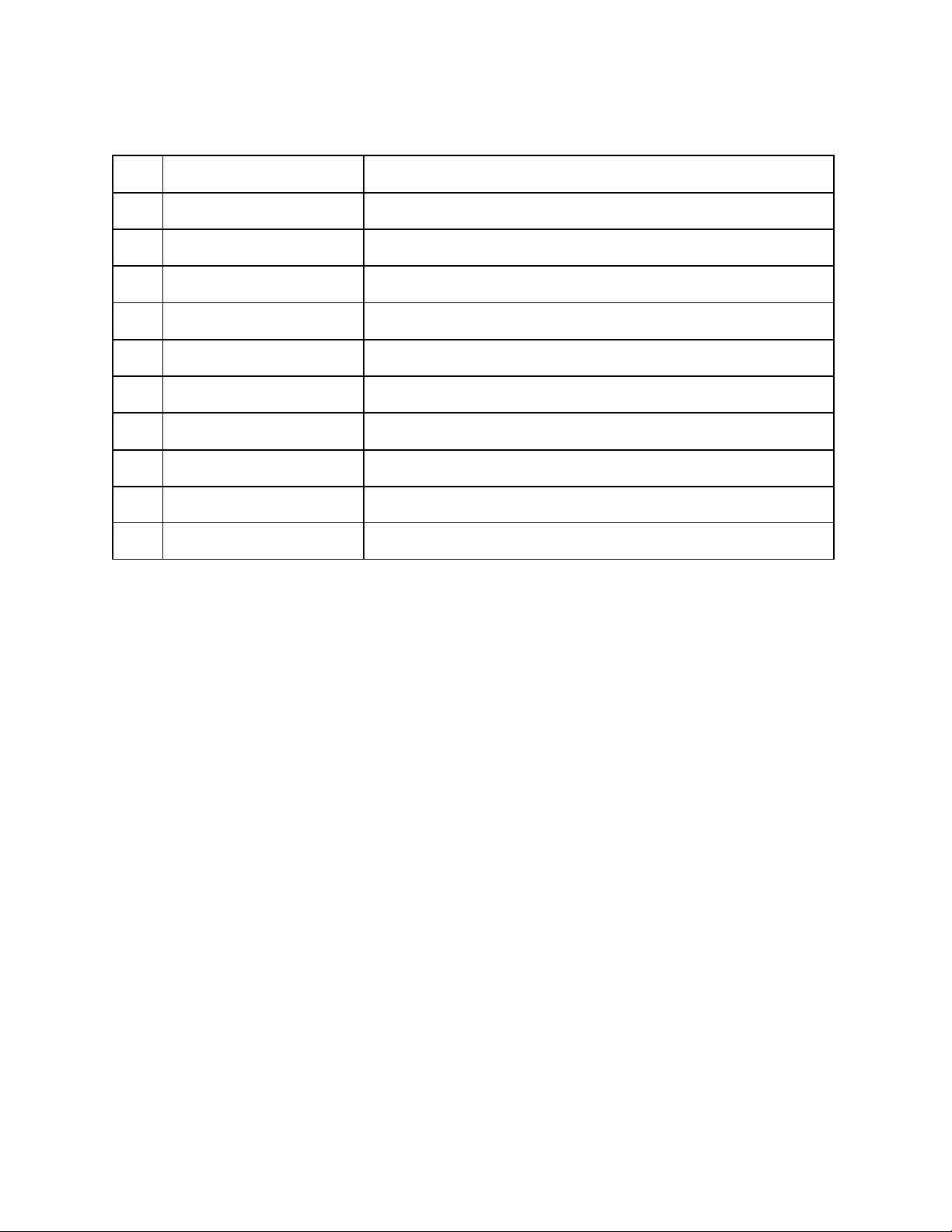

BPK-Probe Accessory Part Numbers

Item

Part Number

Description

1

P2017.01.07

PROBE PREPARATION TOOL

2

BKCT2392A-5-ND

GROUND CLAMP

3

501-1377-ND

GROUND WIRE

4

ACX1813-ND

BNC CABLE

5

PTE.04

PROBE TIP EXTENSION, 4"

6

PTE.06

PROBE TIP EXTENSION, 6"

7

PTE.12

PROBE TIP EXTENSION, 12"

8

PT.01

PROBE TIP ASSEMBLY, STANDARD

9

PT.T01

THIN PROBE TIP ASSEMBLY

10

10181262027702

REPLACEMENT BRUSH TIPS

Table of contents

Other HELWIG CARBON Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

Keithley

Keithley 616 instruction manual

RR Mechatronics

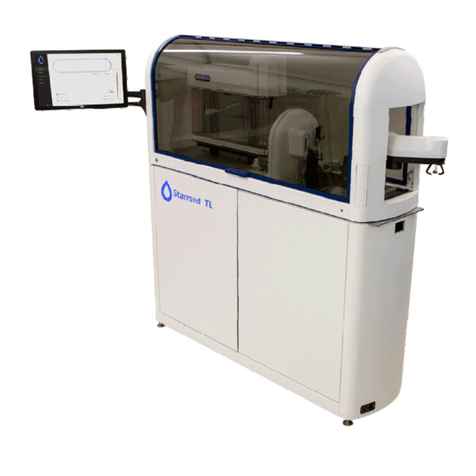

RR Mechatronics STARRSED TL Instructions for use

ASELSAN

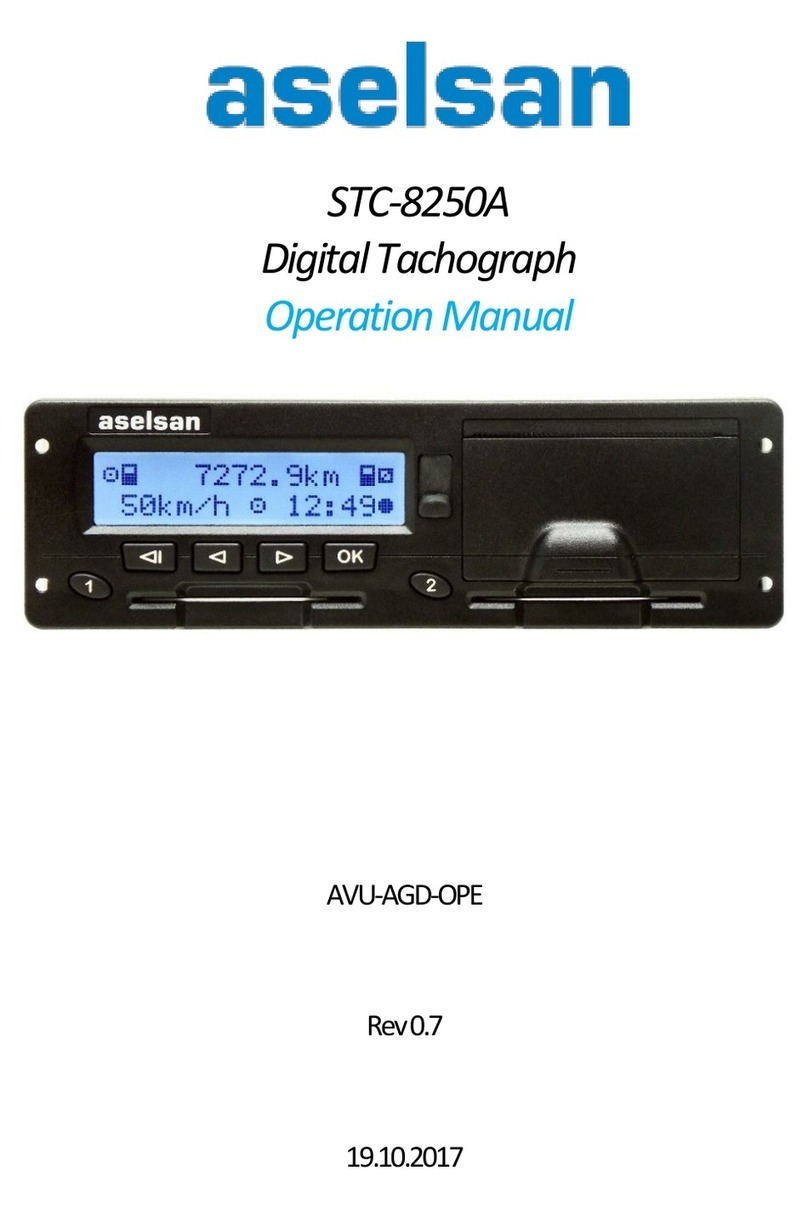

ASELSAN STC-8250A Operation manuals

Keysight Technologies

Keysight Technologies MXA Series Installation note

Endress+Hauser

Endress+Hauser Prosonic M FMU40 Brief operating instructions

Adash

Adash A3716 user manual