10.3.1 - - Replace bacterial filters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

10.3.2 - - Fill-nozzle O-ring replacement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

10.3.3 - - Fill and clean procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

10.3.4 - - Replace needle O-ring and check needle. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

10.3.5 - - Cleaning Liquid sensor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

10.4 - - Pump tubes replacement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

10.5 - - Reagents replacement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

10.6 - - Cleaning Touch screen display. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

11 - Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

11.1 - - General error procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

11.2 - - Flushing liquids. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

11.3 - - Reagents. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

11.3.1 - - Reagents alarm. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

11.4 - - Separator error. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

11.5 - - Fill time-out error. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

11.6 - - Hazy reports. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

11.7 - - Leaking pipettes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

11.8 - - Liquid level sensor not sensing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

11.9 - - Sampling and results troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

11.10 - - Robot arm error - general procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

11.11 - - Air bubbles. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

11.11.1 - - Pipette looks like zebra crossing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

11.11.2 - - Foam in column. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

11.11.3 - - One air bubble about 5 mm under meniscus. . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

11.11.4 - - One air bubble rising in pipette. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

11.11.5 - - Small air bubbles rising in pipette. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

11.11.6 - - Random air bubbles in pipette. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

11.12 - - Quality control troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

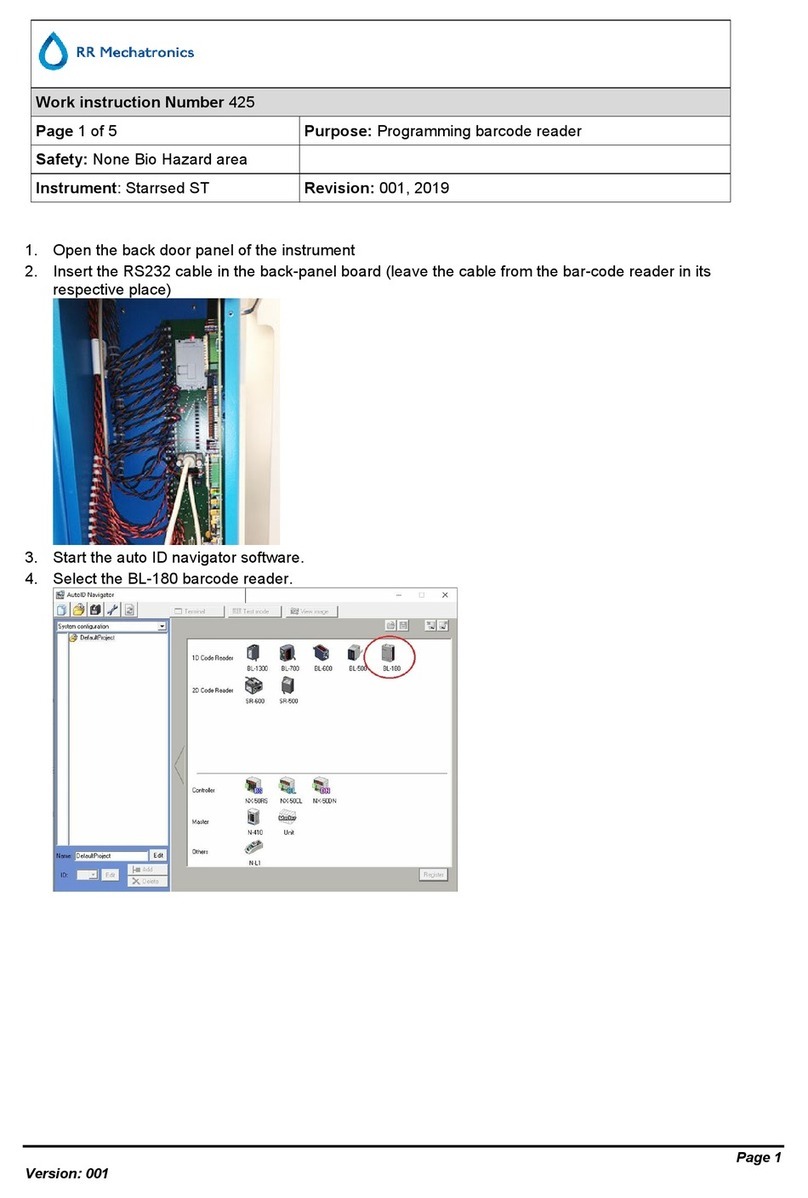

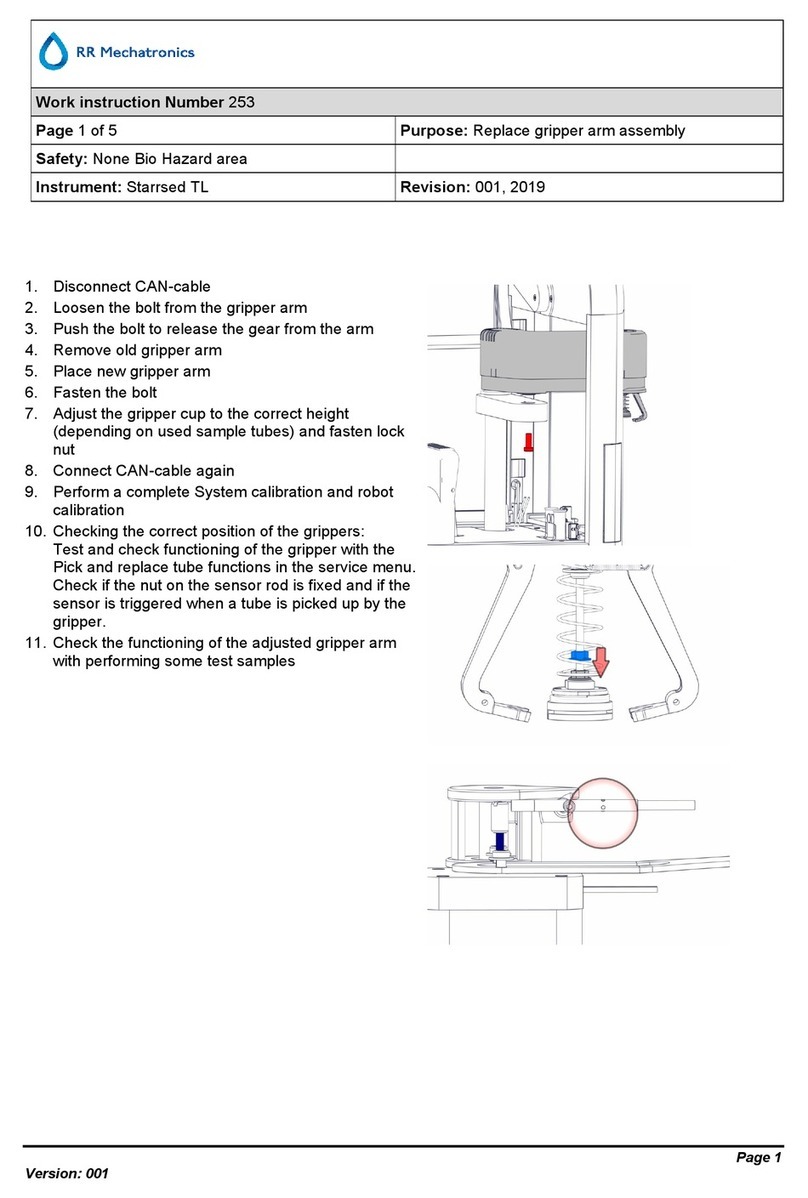

12 - Work instruction Interrliner. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

13 - Appendix for Interrliner. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

13.1 - - Appendix - Maintenance schedule . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

13.2 - - Spare part list Starrsed TL. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

13.3 - - Appendix - Error list Interrliner. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 126

13.4 - - Appendix - List of supported tube types Interrliner. . . . . . . . . . . . . . . . . . . . . . . . . . . 134

14 - Glossary of Terms. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 135

Contents

6MRN-164_2-EN Version 1.08 Starrsed TL