HELWIG CARBON BPK-Probe User manual

Page 1of 7

BPK –Probe™

Shaft Voltage Detection Device

Page 2of 7

Operating Guide

BPK-Probe™ Important Safety Information

You must understand all the safety statements in this manual prior to operating the BPK-Probe™

The WARNING designation indicates a potentially hazardous situation that, if not

avoided, could result in death or serious injury.

The BPK-Probe™ is designed to be in direct contact with rotating motor shafts. Rotating

motion can be dangerous; even smooth, slowly rotating shafts can grip clothing, and

mere skin contact can force an arm or hand into a dangerous position. Injuries due to

contact with rotating parts can be severe.

All power sources for machines are potential sources of danger. When using electrically

powered or controlled machines, the equipment as well as the electrical system itself

must be properly grounded. High pressure systems, too, need careful inspection and

maintenance to prevent possible failure from pulsation, vibration, or leaks. Such a

failure could cause, among other things, explosions or flying objects.

While never a substitute for appropriate machine guards, personal protective equipment

must always be worn around rotating motor shafts. It is important to note that

protective clothing and equipment can create hazards. For example, a protective glove

can become caught between rotating parts, or a respirator facepiece can hinder the

wearer’s vision.

Follow all safety precautions when working with rotating equipment.

The BPK-Probe™ should be used by qualified, trained personnel ONLY.

Page 3of 7

Purpose of the BPK-Probe™

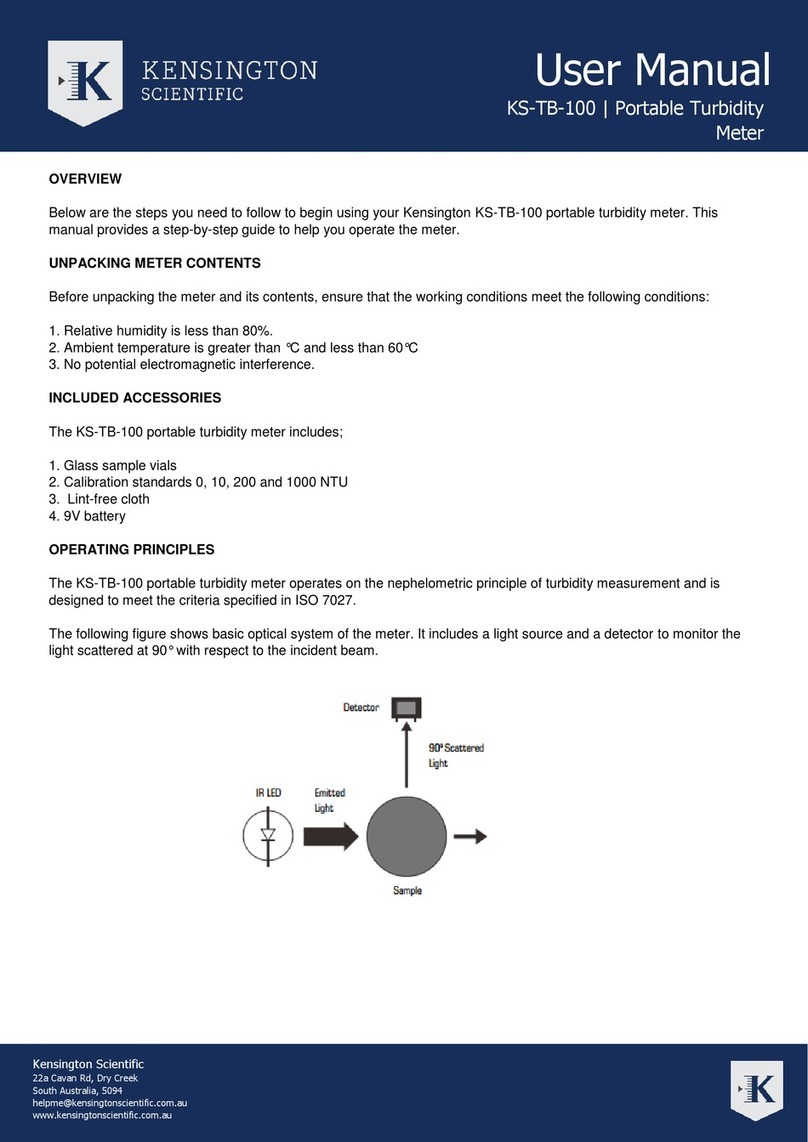

The BPK-Probe™ is a complete kit including everything you need to determine risk to your motor

from damaging bearing discharges. It also demonstrates the effectiveness of a Bearing Protection

Kit (BPK) and allows for test data to be stored in on-board memory and/or on an oscilloscope.

Each kit includes everything you need to test and document the risk to your motor from

damaging Bearing Discharges.

BPK-Probe™ Features

Enhansed color LCD screen with with Probe status icons and real time visual test results.

On-Board memory stores test data plus the Probe includes a BNC output for closer analysis of

captured test data on an included Tablet Oscilloscope.

Thin Sensor Tip design for ease of accessability with field replaceable Sensor Tips

Two quick exchange Extension Tubes for hard to access motor shafts.

USB Memory Stick and Micro SD Card and Reader for downloading test results from the Probe or

oscilloscope –including captured video.

Memory stick includes Operator manuals for both the BPK-Probe and the Tablet oscilloscope.

All cables needed to download data and charge the batteries on the BPK-ProbeTM and oscilloscope

A durable hardshell case with custom foam to protect your investment.

Page 4of 7

BPK-Probe™Instructions for Use

Step 1: Prepare the BPK-Probe™

Follow all safety precautions when working with rotating equipment.

The BPK-Probe™ kit comes with everything you need to complete and document a bearing

discharge test in the field or back at the shop. The LCD screen includes Probe and test-status

ICONS and displays/stores test results for immediate on-site feedback. A unique feature allows the

user to test the motor as-is, without protection then again test the motor but this time with Helwig’s

embedded Bearing Protection Kit™(BPK) enabled. With the embedded BPK enabled the user can

measure the effectiveness of the grounding solution. In addition, the BPK-ProbeTM has an on-board

micro SD card for recording/downloading test results. For a more detailed analysis of the data

captured by the BPK-Probe™ it includes a BNC output and cable that are easily connected to the

included tablet oscilloscope.

To Start

a) Verify the motor shaft contact area is clear of debris, oils and contamination.

b) Using the rubber flap side of the Probe Preparation Tool (Figure 3), identify a contact area on

the shaft for measurements.

c) Verify the contact area is clean and not in line with a key, keyway, set screw, or anything that

can obstruct or damage the sensor tip brushes.

d) If required, use the Probe Preparation Tool’s cleaning stone (Figure 3) to remove rust, debris

and oil from from the contact area (Figure 4).

Figure 4: Use the Probe Preparation

Tool’s cleaning stone to clean contact

area.

Figure 3: The Probe Preparation Tool

has two ends: a cleaning stone to

clean the shaft surface and a rubber

flap to detect for keyways.

Cleaning Stone

Rubber Flap

Page 5of 7

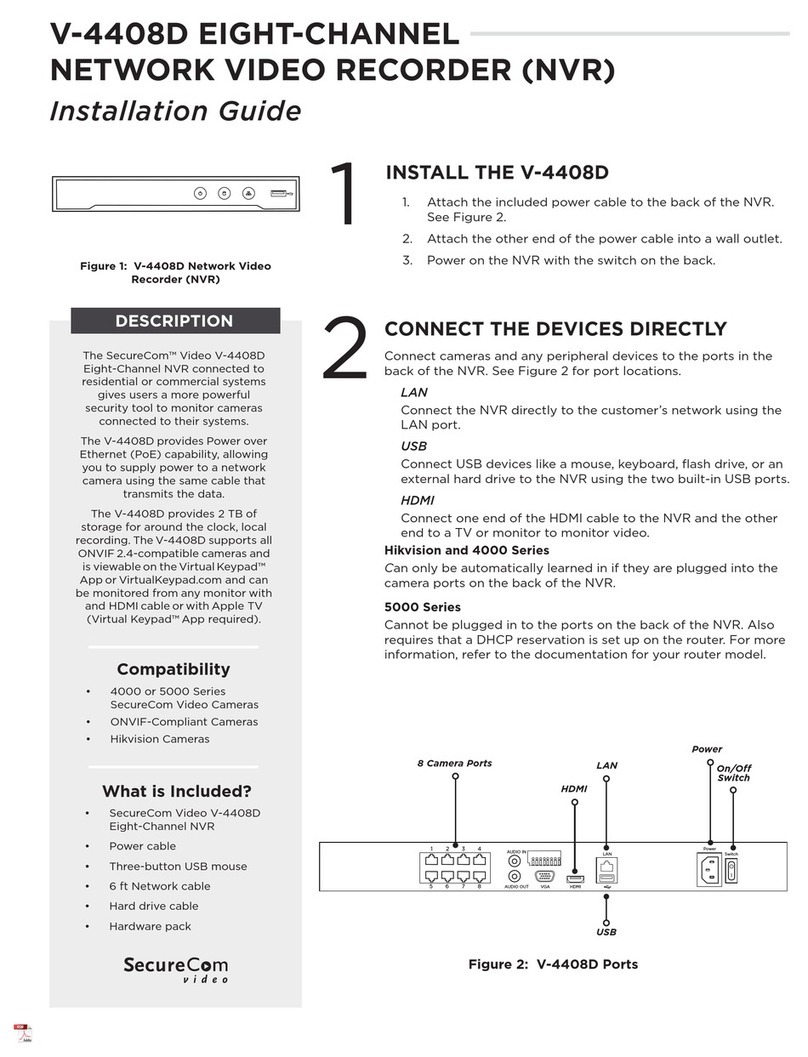

e) Attach the ground wire to the BPK-Probe™ (Figure 5). Locate a clean, paint-free ground source

and secure the ground clamp (Figure 6).

f) Ensure the ground or BNC cable if used, cannot be entangled with rotating or stationary

equipment, guards, etc.

Step 2: Test Motor Shaft Voltage

Follow all safety precautions when working with rotating equipment.

To Test

a) With the ground clamp safely secured, press and release the Trigger Switch to activate the

Probe. Verify the rocker switch is off, LED not lit, and there is no Ground ICON displayed at the

top of the screen. This disables the embedded grounding brush (Figure 7). To capture test

data, ensure the SD ICON is active.

b) Note; The BPK-Probe will automatically shut off after 30 seconds of idle time. To reactivate

press and release the Trigger Switch.

Figure 7

Figure 5: Attach ground wire to probe.

Figure 6: Locate a ground source

and secure the ground clamp.

Page 6of 7

c) Remove the protective sensor tip cover and keep nearby.

d) On a suitable and properly prepared surface, carefully place the sensor tip against the rotating

shaft (Figure 8).

e) Ensure both sensor tips are squarely and firmly against the contact surface. Press both spring-

loaded sensor tips onto the shaft until about 1/8” is exposed (Figure 9).

Figure 8 Figure 9

f) With the BPK-Probe™sensor tips against the motor shaft, press and hold the trigger switch.

The Helwig Carbon logo will show (Figure 10). Next a sampling screen will appear (Figure 11),

continue to hold the trigger switch. When sampling is complete the screen will show a real-time

test result (Figure 12). Release the trigger.

Figure 10 Figure 11 Figure 12

g) Carefully remove the probe from the motor shaft, note the displayed results. Test results are

also stored on the included micro SD card if installed. Remove the ground clamp and replace

the protective tip cover. The test is complete.

Page 7of 7

Step 3: Re-Test Motor Shaft Voltage with Ground Protection

To Retest with Embedded Grounding Solution

a) The shaft voltage test can be repeated both with and without engaging the Probe’s embedded

Bearing Protection Kit™(BPK). To enable the embedded grounding kit, press and release the

trigger switch, the Helwig Logo screen will appear (Figure 12). Next, toggle the rocker switch

until the switches green LED is lit and the ground ICON shows at the top of the screen (Figure

13). Repeat testing procedure with the embedded grounding brush enabled to show the

effectiveness of the Helwig grounding solution (Figure 14).

Figure 12 Figure 13 Figure 14

b) If, when testing with the embedded Ground Switch enabled, green LED lit, the result is a

Grounding Error (Figure 15) please verify the ground wire and clamp are properly and securely

connected to a ground source. If the Grounding Error persists, have a qualified electrician verify

the motor and motor drive grounds are properly bonded to a ground source.

Figure 15

Video Tutorial

The video tutorial is not a substitute for reading the BPK-Probe™Important Safety

Information and Instructions for Use.

For a video tutorial of the BPK-Probe™, visit Helwig Carbon Products on YouTube at

www.youtube.com/user/Helwigcarbon (Insert Helwig contact information)

Table of contents

Other HELWIG CARBON Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

Marcador

Marcador CAFE RACER 69 mm Instruction

horiba

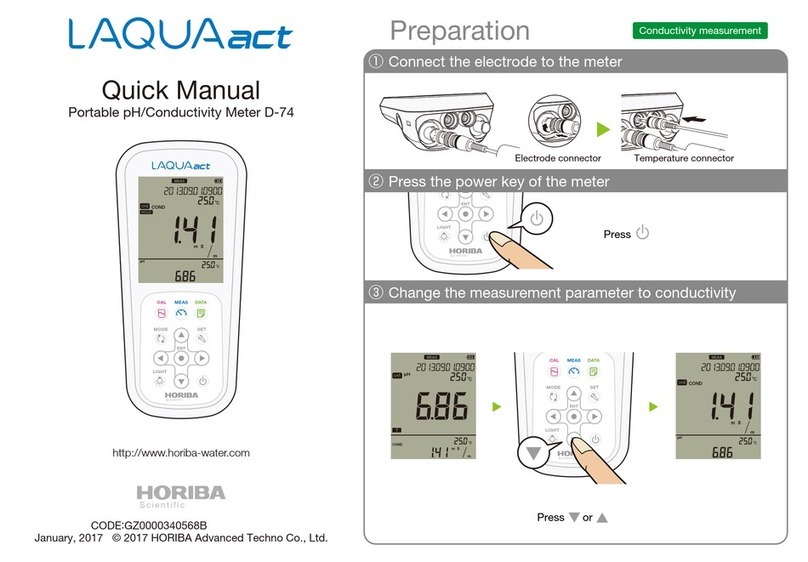

horiba LAQUAact D-74 Quick manual

PCB Piezotronics

PCB Piezotronics IMI SENSORS M626B01 Installation and operating manual

Mobeye

Mobeye WaterGuard-FS CM2300FS user manual

Hunter

Hunter HC Flow Meter quick start guide

GE

GE DigitalFlow GF868 Programming manual