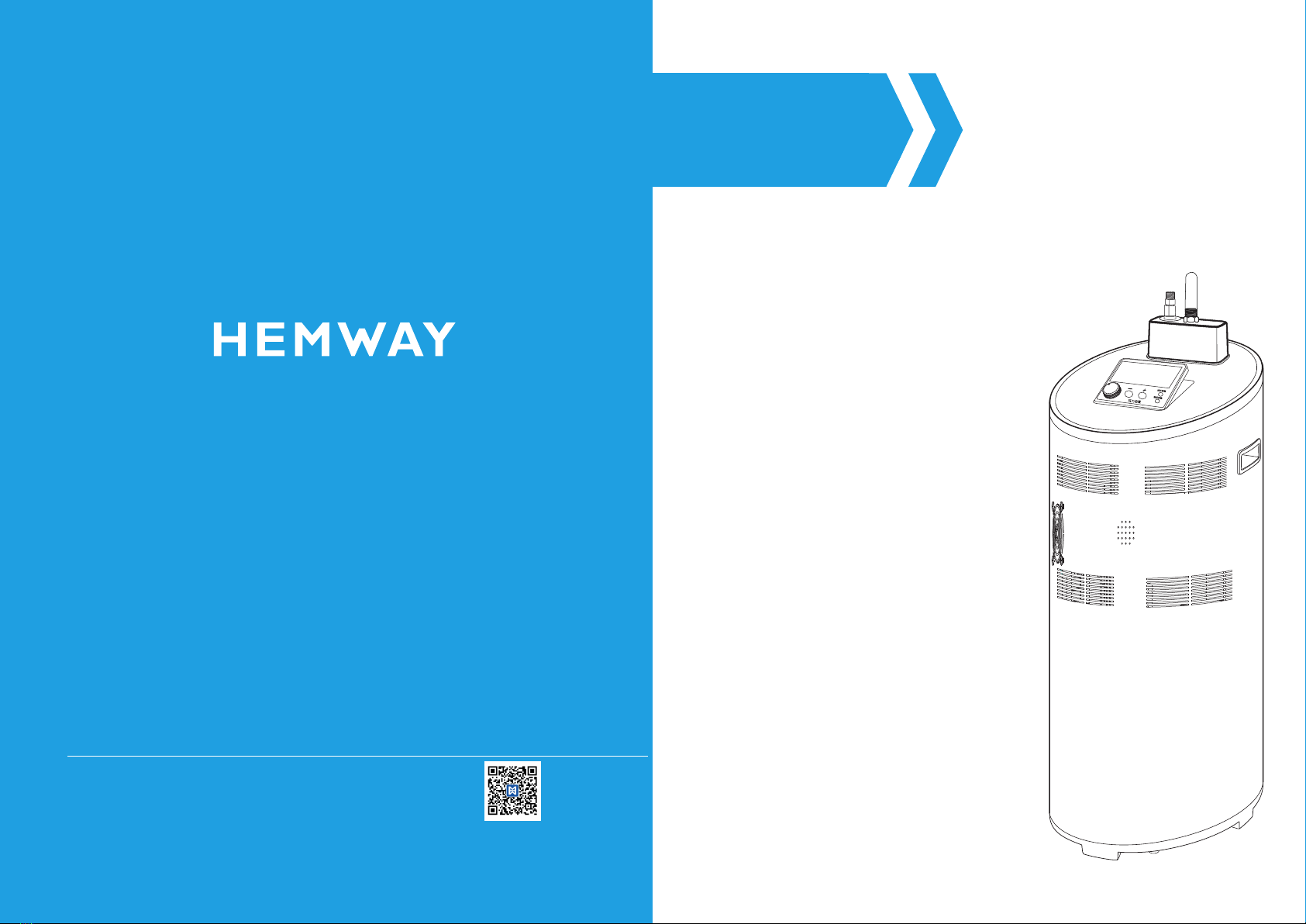

HEMWAY YUNBA H98V3 User manual

YUNBA

Smart ironing steam generator

H98V3

INSTRUCTIONS

SHENZHEN HANMINGWEI SMART EQUIPMENT CO., LTD

Add:

Building 3B, 8 Cichang Road, Henggang, Longgang District, Shenzhen

Tell:0755-8467 9158 Fax:0755-2377 3276 htpp://www.hemway.com.cn

hemway@hemway.com.cn

I. Product Introduction

II. Installation Guidance

III. Operating Method

III. Operating Method

01

01

02-03

04-06

07

08

09

10-11

12

STATEMENT

SHENZHEN HEMWAY SMART DEVICE CO.,LTD

All right reserved.

Without the express written permission of SHENZHEN HEMWAY SMART DEVICE

CO.,LTD, no unit or individual may act arbitrarily to reproduce, reproduce or translate part

or all of the contents of this instruction.

Shall not be used in any form or by any means (electronic, mechanical, photocopying,

recording or otherwise) for the dissemination of commodities or for any commercial or

profit-making purposes.

If there are any changes in the product structure and appearance, please refer to the

real product.The product specifications and information mentioned in this instruction are

for reference only and are subject to change without notice.Check out our website at any

time:

http://www.hemway.com.cn

The product works under high temperature and high pressure environment. Non-pro-

fessional maintenance personnel are not allowed to disassemble the product without

permission. Please refer to our warranty card for warranty.

Outside the warranty period, we also provide services. If you need to replace the

parts, we will charge a certain amount for the parts.

Unless otherwise agreement, this instruction is used only as a guidence and all

statements, information, etc. in this book do not constitute any form of warranty.

Product Introduction

Technical Parameters

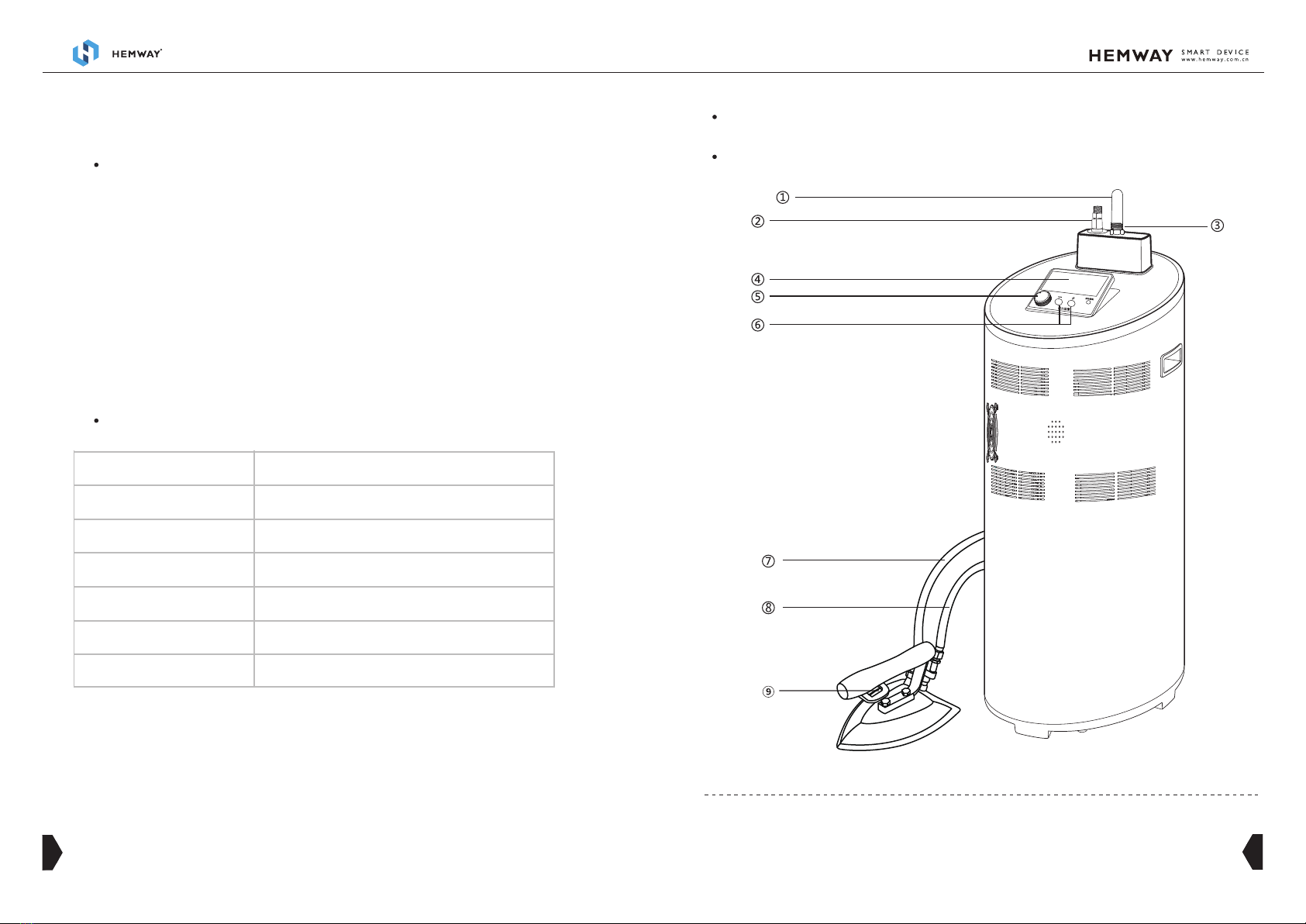

External Product Structure

Product Installation Standards

External Product Structure

IV. Maintenance and Maintenance Methods

V. Fault Analysis and Troubleshooting

VI. After Service

INDEX

Name

External product structure

Front Side of the product

I. PRODUCT INTRODUCTION

Product Introduction

Technical Parameters

YUNBA H98V3 smart ironing steam generator is a garment ironing product

independently developed by our company and obtained a number of national patents. The

product has the functions of automatic water adding, frequency conversion heating,

automatic drainage , discharging and intelligent scale removal. At the same time, it has the

characteristics of adjustable pressure, intelligent dormancy, voice reminder and fault code

reminder. The steam capacity of the product is sufficient to meet the requirements of small

ironing, medium ironing , big steam ironing and other industries .

This product is suitable for all kinds of clothing factories, clothing finishing centers,

home textile stores, curtain stores, laundry rooms, etc. It can remove wrinkles and finalize

the design of various fabrics, achieve ideal ironing effect, and meet the steam supply of

other equipment.

Product Model

Heater Rated Power

Rated Voltage

Working Pressure

Product Weight(Gross Weight)

Size of Host

YUNBA (Smart ironing machine all in one)

1. Steam control switch 2. Water return pipe joint 3. Steam pipe joint 4. Display screen

5. status switch 6. Pressure setting button 7. Steam pipe 8. Water return pipe

9. Iron steam control switch

H98V3

4.8 kW

380V

1.5~4.2Kg/cm²

23 Kg

680x350x260mm

2

1

The power supply must use 16A socket, grounding line end in the socket must reliably grounding.

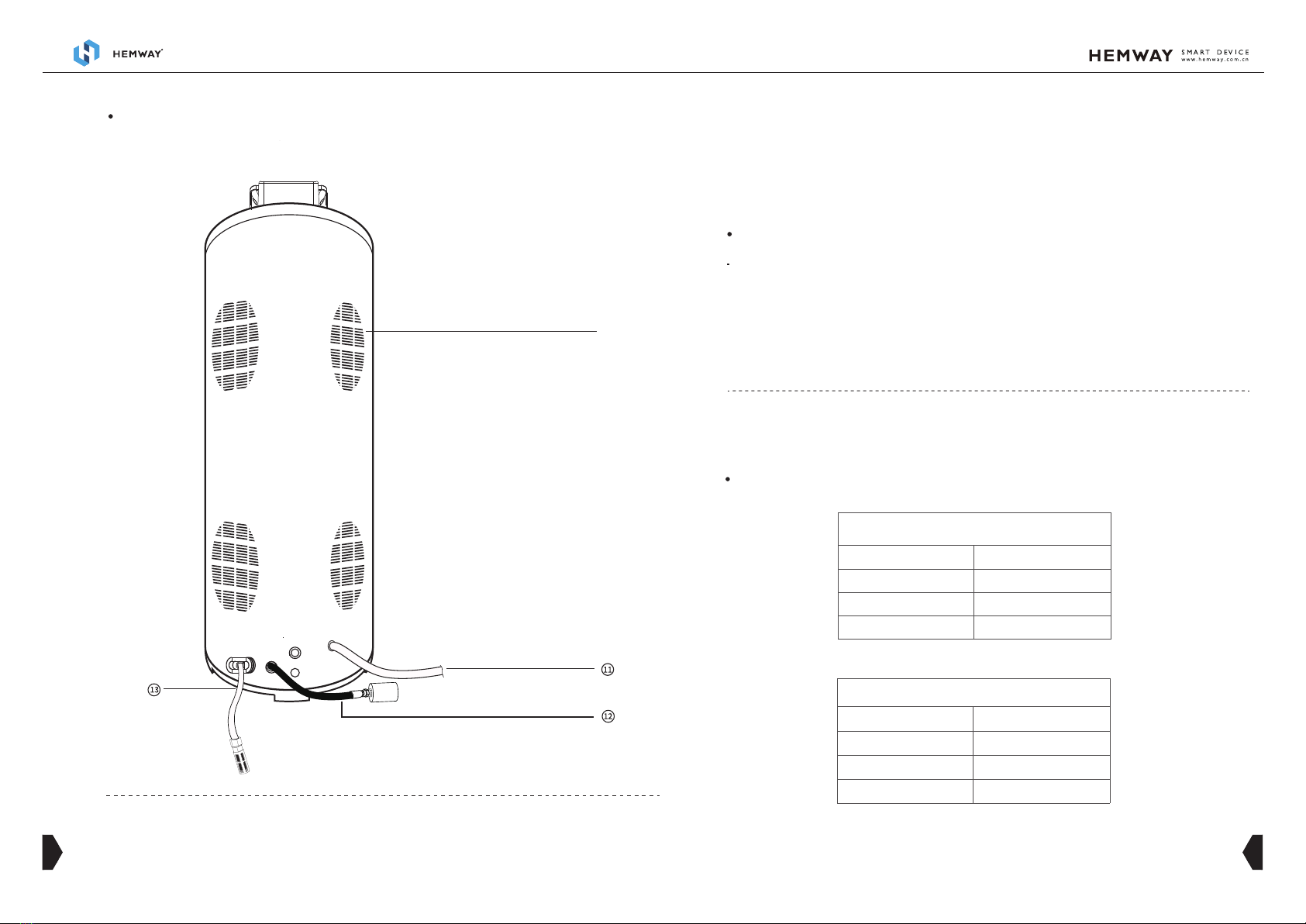

Back side of product

Tip: disconnect the power supply and turn off the steam control switch

before installation.

II. INSTALLATION GUIDANCE

10. Heat emission hole 11. Descaling switch 12. Power Line 13. Water inlet pipe

Produc t Installation Standards

Circuit installation

(Note: only when the equipment is supplied at the voltage of 220V can it work normally, and the

current of the supply line is no less than 20A.

Please use the corresponding power supply line to avoid overload of the circuit caused by the

equipment being energized.)

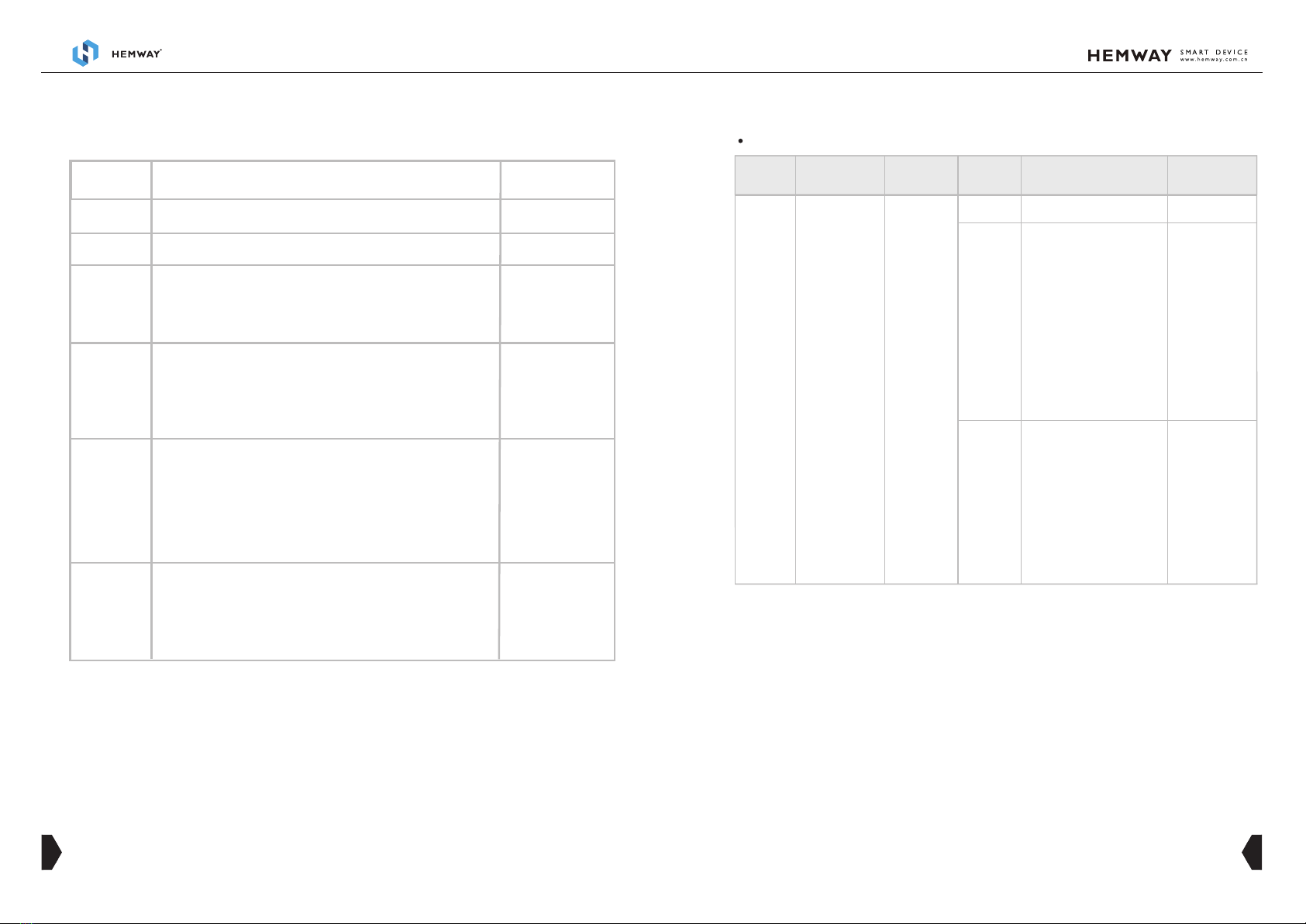

Power supply load standard

AC220V single-phase electric power

supply line reference table

1 set 4.0mm² copper wire

6.0mm² copper wire

10.0mm² copper wire

16.0mm² copper wire

2 sets

3 sets

4 sets

External transformer load comparison table

1 set

2 sets

3 sets

4 sets

5KVA

10KVA

15KVA

20KVA

⑩

4

3

Descaling switch

Power Line

Water inlet pipe

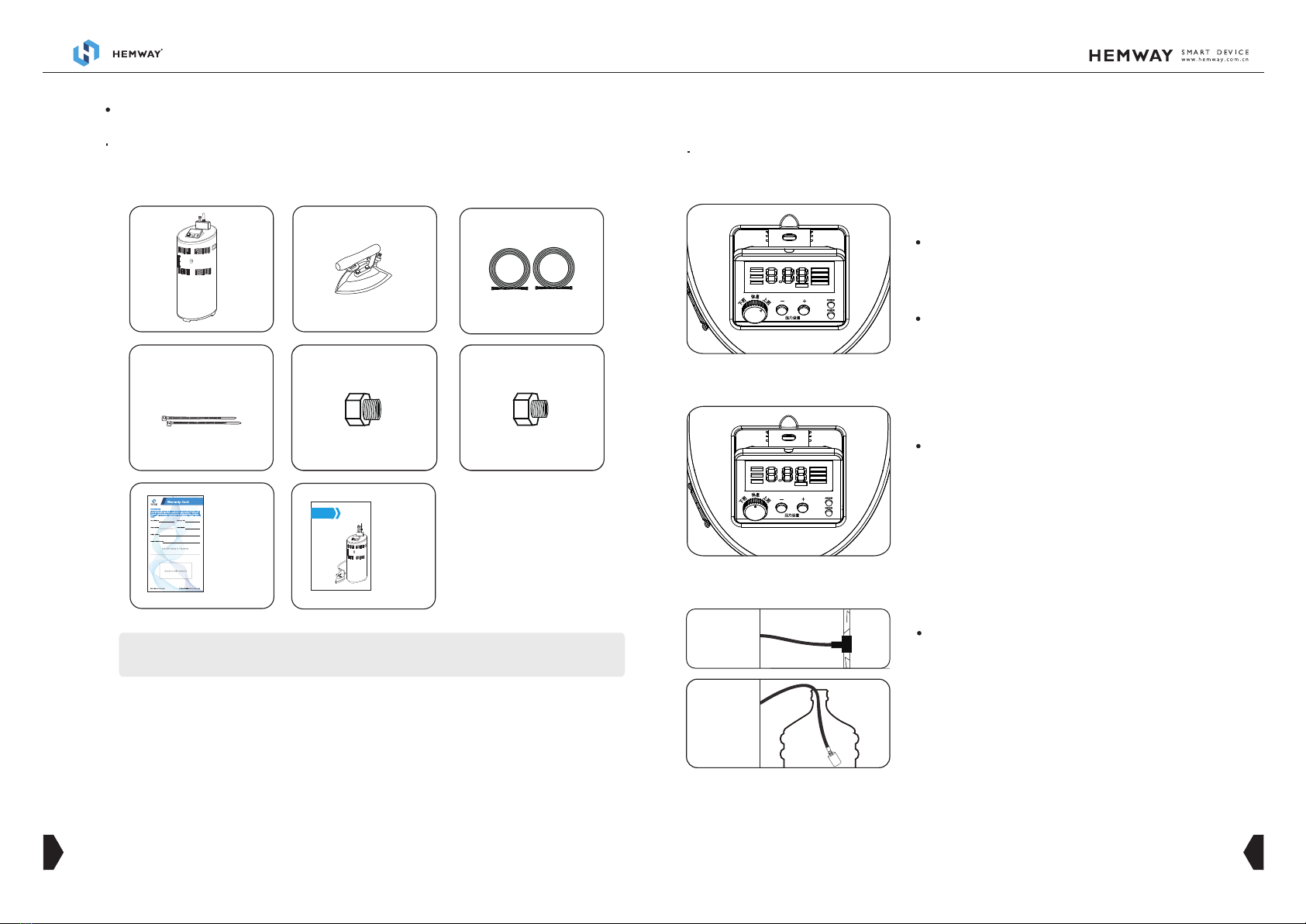

Iron installation

Equipment Installation

Device pipeline installation

Connect the host to the iron. Install the steam pipe and water return pipe of the iron

on the corresponding wiring port on the host panel as shown in the figure below and

lock them tightly.

( Note: please disconnect the power when installing and disassembling here.)

Recommend installation method

Connect the water inlet connector to the

water inlet main pipe.

Connect the main drainage pipe (14) to

the drainage main pipe.

Tip: Please use filtered water

Water pressure requirements: less

than 1Kg/cm2

Drainage pipeline requirements standard

Quantity of equipment Tube

3sets

5sets

10sets

3/4”tube

1”tube

1.5”tube

Material:【Recommend】304 stainless steel,【Optional】galvanized pipe, PPR pipe

Optional installation methods

(Not Recommend)

When the workshop does not install the water

inlet main pipe and drainage main pipe, the

water inlet and drainage problems can be

solved in the following ways

Put the water inlet tube into the inlet bucket

Tighten the connection between the

drainage pipe and drainage head of the

equipment and put it into the drainage

container.

(Disclaimer: Hemway will not be responsible

for any consequences arising from the failure

to operate as required.)

Water inlet bucket Drainage bucket

Water inlet pipe

Drainage pipe

Water return pipe joint

Steam control switch

Steam pipe joint

6

5

Note: when opening the outer packing, please read the instructions carefully and keep the

relevant certificates properly.

Packing list

Host Iron

Ribbon Drainage adapter X1 Water inlet adapter X1

Guarantee card Specification

Note: if there is a shortage or damage of parts, please contact the local dealer or call our

service hotline: 400-882-5552.

III. OPERATATION METHODS

Note: please carefully check whether all parts are installed in place before use to ensure that the interface is locked

and firm.

When start working

When break

When off work

Turn the status switch to the working position, the

corresponding indicator light on the control panel,

and the system enters the working state, accompa-

nied by a voice prompt: the device is started and can

be used later.

To adjust the steam pressure, please press “+” or “-”

in the pressure setting area of the control panel.

During the noon break, turn the status switch to the

break position, and the corresponding indicator light

will be on, the device will enter the standby state.

Arrange two minutes in advance to turn the status

switch to the position of off duty after work, and the

equipment enters the drainage status. Please ensure

that the drainage pipe is connected in the following

way before drain:

Mode A: please ensure that the drainage pipe is firmly

connected to the main drainage pipe;

Mode B: please ensure that the drainage pipe is firmly

connected to the drainage device and put the

drainage pipe into the drainage bucket;

Note: the drainage process takes about two minutes,

during which time do not switch off the power.

(When drain, will cause bigger airflow roar voice, it is

normal phenomenon)

Mode A:

Connect the

main drainage

pipe

Mode B:

Connect the

drainage

device

Control panel

Control panel

Drainage pipe

Drainage pipe

Water return pipeSteam pipe

YUNBA H98V3

Smart ironing steam generator

INSTRUCTIONS

78

IV. MAINTENANCE AND MAINTENANCE METHOD V. FAULT ANALYSIS AND TROUBLESHOOTING

Item

Drainage

Content

Filter head

Please drain after work

If there is no connection of soft water and water pipe supply equipment,

please clean the filter head regularly

Maintain

frequency

One time per day

One time per week

Drainage pipe One time per month

Please check the drainage pipe interface regularly, and tighten it with

wrench if there is any loose;Periodically check the drainage pipe for

dirt removal. If it is blocked, please clean it in time to avoid affecting

the drainage function

③Please clean the cooling fan filter regularly

Deeply

Descaling

Please clean the residual scale in the boiler innerface regularly, and

remove the water level detector and use sandpaper to clean the scale

on the surface;Clean the heater and boiler innerface regularly (many

scale accumulates on the innerface of the heater used for a long time,

which will reduce energy efficiency and increase power consumption.

It is recommended to replace it)

One time per half year

Vent inspection One time per month

One time per month

①Please check the air outlet of the cooling fan regularly for foreign

matter and shielding (timely cleaning)

②Please check regularly whether the cooling fan is rotating normally

(with or without wind power), and maintain in time if any abnormality

is found.

①Check if the pump is working

normally (there is slight vibration

and sound when working

normally)Water will come out of

the drainage pipe within 5

seconds after starting the machine

①Check if the voltage at the

power supply end of two position

three-way solenoid valves is

normal (DC24V), which is

combined with crisp sound under

normal circumstances.No sound

absorption means that the water

return valve is broken.

②When there is no vibration,

check whether the pump power

supply end voltage is normal

(DC24V), normal means the water

pump is broken

Circuit

Please check regularly whether the air switch and electric leakage

protection function is normal, whether the electric leakage protection

switch is loose, fire traces, if abnormal, please use a screwdriver to

tighten or replace

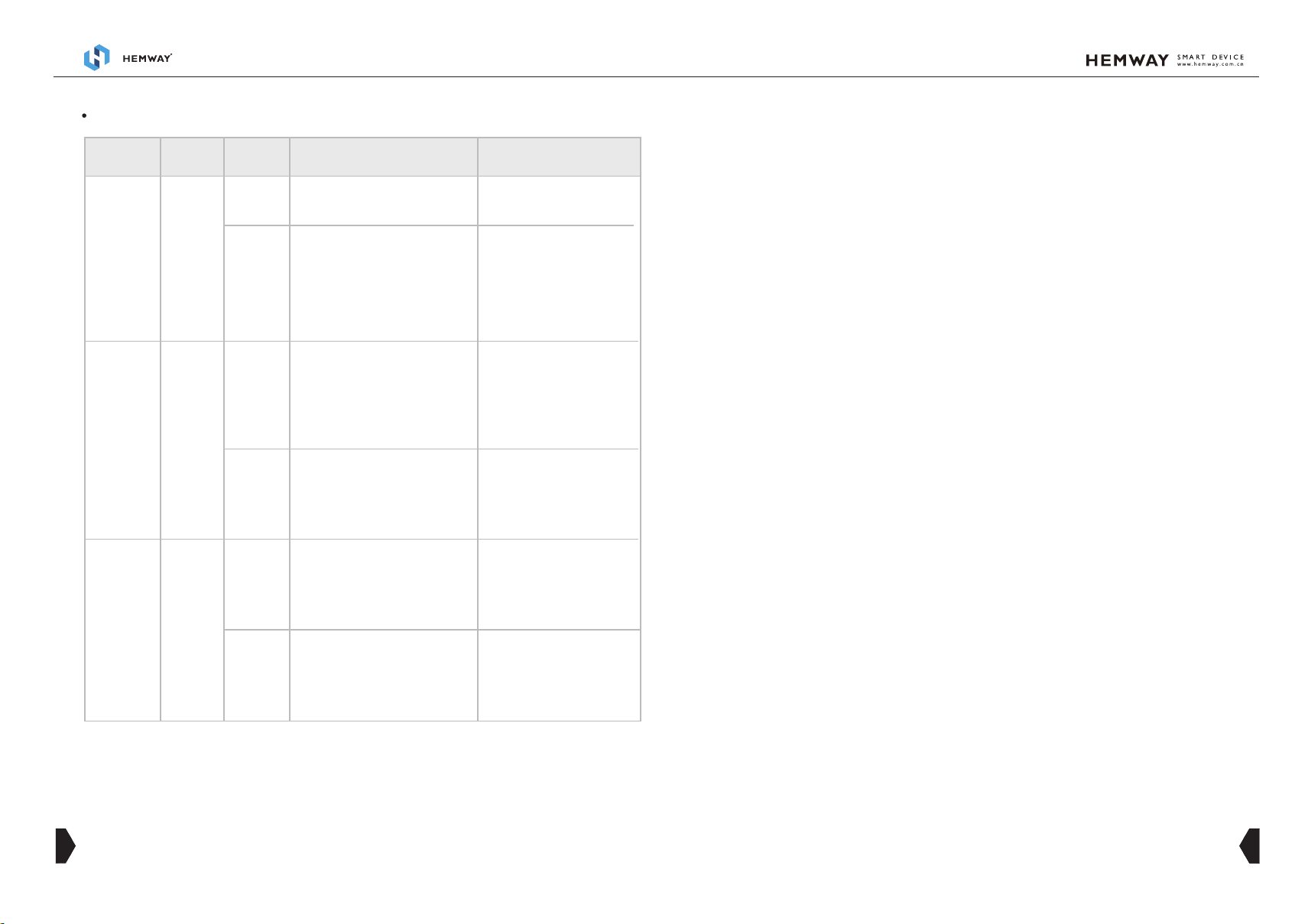

Fault code analyses:

Fault code Fault

character

Fault

phenomenon Fault point check and

confirm methods Handling method

Water source Check if water is blocked Clean the blockage

③No drain when vibration, check

whether the voltage at the power

supply end of the pump is normal

(DC24V), otherwise the pump is

broken.

Replace water pump

Water pump

Two position

three way

solenoid

valve

Replace water retrun

valve or clean the

Abnormal water

adding system

Abnormal time for

adding water and

replenishing water

(when the water is

added for more

than 6 minutes

and none stop, or

when the water is

replenished for

more than 4

minutes and is not

replenished)

F02

②Under normal circumstances,

suction but no water, it means that

the pipeline or one-way valve

blocked

10

9

11

VI. AFTER SERVICE

①Replace main control board

②Check the water level line

and water level grounding port

If you have any quality problems or other problems after buy Hemway products, please contact the

local dealer or call the service hotline: 400-882-5552 for consultation.

To apply for a warranty must be in accordance with the below conditions:

(1)Please operate the machine strictly according to the manual when it is first started up and used.

(2)Only parts from HEMWAY can be used.

(3)Please refer to the warranty card for other terms..

Other fault analysis:

Fault

phenomenon

Fault

character

Fault

point

Check and confirm

methods

Handling method

Iron serious

spraying

water

Abnormal

water level

control

Water level

sensor scale

Main control

board

damaged

After drain, disassemble the

equipment to check if the water

level probe is scaling

After drain, check if the voltage

between the water level probe and

the hardware plate where the probe

is located is AC12±1v;After the

equipment is filled with water, check

if the voltage between the water level

probe and the hardware plate where

the probe is located is AC0±1V.

Clean water level probe

The screen

does not

display and

the power

indicator does

not light

Abnormal

power

supply

Electric

leakage

protection

switch

Transformer

Check whether the electric leakage

protection input voltage is normal; if

the voltage is normal, check the

output voltage; if there is no voltage

at the output end, then the electric

leakage protection switch is

damaged.

Check if the transformer input

voltage is normal (AC220V), if the

voltage is normal, check if the

transformer output voltage is positive

(AC24V);If the voltage is abnormal,

then the transformer is broken

Replace electric leakage switch

Replace transformer

Pressure

setting

failure

Pressure

setting

system

abnormal

Pressure

setting key

Main control

board

Disconnect the power supply, open

the side cover of the device, press

the pressure setting key, and test the

two ends of the key with the multime-

ter. Failure to connect means the key

is broken.

Disconnect the power supply, open

the side cover of the equipment,

press the pressure setting key, and

test with multimeter. If it is connect-

ed, the main control board is broken

Replace the keys

Replace main control board

12

11

Table of contents

Popular Steam Cleaner manuals by other brands

Samsung

Samsung DF60A8500CG user manual

cecotec

cecotec HydroSteam 1030 Active instruction manual

VAPamore

VAPamore MR-750 OTTIMO Instruction book and users guide

Silvercrest

Silvercrest SDM 1500 C2 operating instructions

BLACK DECKER

BLACK DECKER HGS400-LA use and care manual

Silvercrest

Silvercrest SDM 1500 A1 operating instructions