HENAN HANWEI ELECTRONICS CO., LTD WD6200 User manual

HENAN HANWEI ELECTRONICS CO., LTD

WD6200

Fixed gas detector

Operation manual

Read this manual carefully before using the device

Ver:HWWM161229CG

SAFETY INFORMATION

Before using this product, please read the following safety instruction

carefully and comply with related operation regulation strictly.

Please don't use defective detector. Before using, please check if there is

crack or spare part missing. If yes, please contact to the seller.

WD6200 detector had been calibrated in manufacturer’s factory,

however, it is still suggested to calibrate it at your working spot before

using it.

In order to assure the user’s safety and assure the detector work

normally, the users are suggested to do impact test on the detector with

high concentration level-known gas (put the detector into the target gas

whose concentration is higher than the high alarm level) If the displayed

value is exceeding the correct range, please calibrate the detector.

Please don't expose the device to the gas whose concentration is

exceeding the range. Otherwise, it will influence the accuracy and

shorten the sensor life.

Please cut off power supply before open the detector. Please don’t open

the detector or replace the sensor in the places where danger gas

possibly exists.

Installation must abide by the national and local regulations.

The detector must be earthed, so as to avoid RF interference.

Please don’t paint the detector.

Please use the specified spare parts during maintenance and repairing.

Please don’t put the gas sensor into organic solvent or flammable

solution.

Please don’t expose the detector to high concentration gas which is

exceeding the detection range. Otherwise, it will shorten the sensor life.

Please don't expose the device to electric shock, strong magnetic field or

serious continuous mechanic shocking.

1

Table of content

1. BRIEF INTRODUCTION.................................................................................. 2

2. TECHNICAL SPECIFICATION .......................................................................... 2

3. STRUCTURE.................................................................................................. 4

4. INSTALLATION.............................................................................................. 5

4.1 INSTALLATION POSITION .....................................................................................5

4.2 INSTALLATION DIMENSION..................................................................................5

4.3 INSTALLATION METHOD......................................................................................6

5. WIRE CONNECTION...................................................................................... 9

6.POWER ON.................................................................................................. 12

7.MENU OPERATION ...................................................................................... 13

7.1 REMOTE CONTROLLER .....................................................................................13

7.2LOW ALARM SETTING.......................................................................................15

7.2 HIGH ALARM SETTING .....................................................................................15

7.3 ZERO TRANSLATION.........................................................................................15

8.CALIBRATION .............................................................................................. 16

9. SENSOR REPLACEMENT.............................................................................. 17

10. TROUBLE SHOOTING GUIDANCE............................................................... 19

2

1. Brief introduction

WD6200 adopt high quality gas sensor and MCU technology, has good

repeatability and stability. It is widely used in the fields of oil processing

plants, chemical factories, metallurgy, power plants etc. With 4-20mA signal

output, it can be connected with the control panel of KB2160.

Main features:

High sensitivity, stable performance, long life span;

4-20mA signal output;

Relay output of low alarm, high alarm and fault alert;

High quality LCD screen can work in -40℃environment.

Setting through remote controller, easy for operation;

Specific installation rack, easy for the installation;

Sensor module design, easy for maintenance and replacement;

Indication functions of re-calibration remind and sensor overdue.

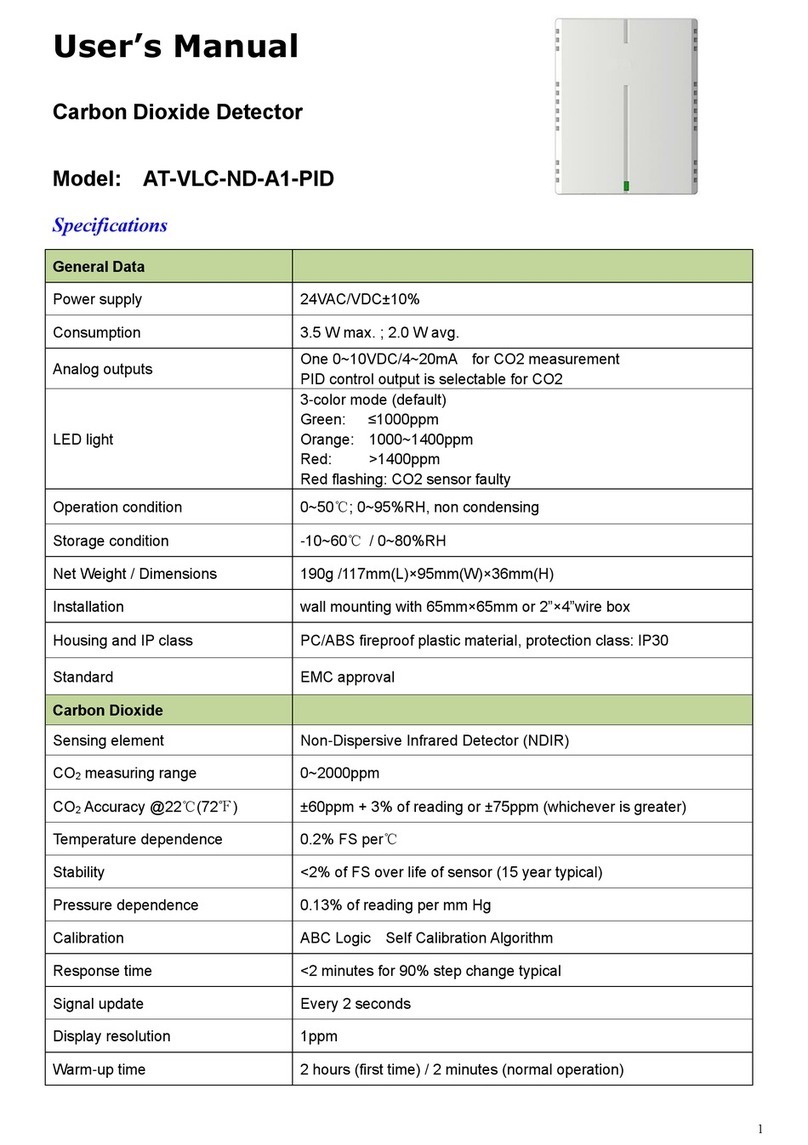

2. Technical specification

Sensor type: Catalytic or electrochemical or infrared

Gas sampling: Natural diffusion

Working voltage: DC 24V±6V Consumption: ≤5W

Accuracy: ≤±5%F.S

Status indication: Yellow LED: Fault Red LED: gas leak alarm

Response time (t90): ≤30s (LEL)/ ≤60s (Toxic gas / O2)

Temperature: -40℃~70℃(LEL) / -20℃~50℃(toxic gas / O2)

Humidity: ≤95%RH

Explosion-proof: ExdⅡCT6Gb

Ingress protection: IP65

Environment pressure: 86kPa~106kPa

Signal output: 4-20mA output Relay output

3

Screw thread: G3/4

Cable requirement: 3-line, ≥1.5 mm2,

Cable outer diameter between 6mm and 12mm

Distance to the panel: ≤1000m

Sensor life:

Catalytic 3 years; Electrochemical: 2 years; Infrared: ≥ 5 years

Dimensions and weight: 293 mm×263mm×108mm

Weight: about 2.7kg

Target gas

Detection range

Resolution

Standard gas flow

CH4

0~100%LEL

0~5%VOL

0~100%VOL

1%LEL

0.1%VOL

500ml/min

C3H8

0~100%LEL

1%LEL

500ml/min

H2

0~100%LEL

1%LEL

500ml/min

C4H10

0~100%LEL

1%LEL

500ml/min

CO

0~1000ppm

1ppm

200±50ml/min

H2S

0~100ppm

1ppm

200±50ml/min

O2

0~30%VOL

0.1%VOL

300±50ml/min

NH3

0~100ppm

1ppm

400±50ml/min

SO2

0~500ppm

1ppm

600ml/min

NO2

0~20ppm

1ppm

1000±50ml/min

4

3. Structure

NO.

Name

NO.

Name

1

Top thread

9

Front cover

2

Earth nut

10

Installation rack

3

Thread connector

11

Top thread

4

adaptor

12

Sensor assembly

5

Cable protector

13

Name plate

6

ALARM indicator

14

chains

7

Remote control receiver

15

LCD screen

8

FAULT indicator

WD6200 Structure schematic drawing

5

4. Installation

4.1 Installation position

1) For petrol gas, oil gas and alcohol gas etc. which is heavier than the air,

the position is 0.3m-0.6m higher than the ground.

2) For natural gas, CH4 etc which is lighter than the air, the position is

0.5m-2m higher than the gas source.

Note: Gas density more than 0.97kg/CBM, then it's heavier.

3) Gas density less than 0.97kg/CBM, then it's lighter.

4) Choosing suitable position should first consider the air flow speed and

direction, relative position to the potential leakage source and air

ventilation. The installation be convenient for maintenance and

calibration.

5) The position should be far away from shocking, shattering, strong

electromagnetic interference. Around the position, there should be at

least 0.5m empty place.

6) There should not be fast air blow. Otherwise, it will influence the testing

result.

4.2Installation dimension

Installation rack

6

4.3 Installation method

When installing the detector, the sensor head should be downwards, so as to

avoid dust or rain falls onto the sensor and assure the target gas can be better

detected

According to the working place situation, the user can choose a suitable

method of the following 3 methods.

Wall mounted type installation

1). Drill suitable screw holes on the wall according to the installation rack.

2). As shown in the below picture, assemble the installation rack and tighten

them by the M5 screws. Please remember to add the light spring washer onto

the screws.

Unit: MM

WD6200 Dimension

7

3) Fix the installation rack assembly tightly on the wall through M6

expansion bolts.

4) Hang the detector onto the rack. Please make sure the hanging is firm and

steady. Then fix both the detector and the rack by using 2pcs of M5 screws.

1 fixed mount

2 Installation rack

3 light washer

4 screws

1 WD6200 detector

2 hanging accessories

3 fixing mount

4 installation rack

5 M5 screws(2pcs)

6 wall

8

Horizontal / vertical pipe installation:

On the installation spot, if there is horizontal or vertical pipe whose diameter

is not more than 75mm, the user can first assemble the installation rack set,

then fix rack set on the pipe. Details as shown on the following picture:

Hang the detector onto the rack. Please make sure the hanging is firm and

steady. Then fix both the detector and the rack by using 2pcs of M5 screws

9

5. Wire connection

Warning:

Before connecting the wires, please cut off the power supply.

Please make sure the detector is earthed.

Steps of wire connection:

1. Screw off the front cover and take out the PCB by pulling the pull-tab.

1 Front cover

2 PCB

3 pull tab

10

2. Take out the rotary union, washer and rubber sealing plug, and then pass

the wire through the rotary union, washer and rubber sealing plug as

shown on the below picture.

3. All the wires should be connected to the terminals inside the detector.

Below is the terminal drawing and instruction.

1 Washer

2 rubber sealing plug

3 rotary union

4 cable protector

11

If L-alarm relay output is configured to active voltage output, then there is

changes on the terminals as follows:

NO.

Mark

Function

12

COM

Cathode of

voltage output

13

NC

Voltage Anode

NC output

14

NO

Voltage Anode

NO output

4. After all the wire connection is ok, please pull out the useless wire and

then screw on the rotary union, tighten the rubber sealing plug and the

wire.

Note: The outer diameter of the wire between the control panel and

detector should not be less than 6mm.

5. Install PCB, screw on the front cover.

Note: According to the spot situation, the user can first install the

NO.

mark

function

NO

.

mark

function

1

NC

Fault relay NC

8

To earth

2

NO

Fault relay NO

9

Iout

4-20mA output

3

CO

M

Fault relay COM

10

24-

power

4

NC

High alarm relay

NC

11

+24

power

5

NO

High alarm NO

12

COM

low alarm relay

COM

6

CO

M

High alarm COM

13

NC

Low alarm relay NC

7

14

NO

Low alarm relay NO

12

detector and then connect the wire; or first connect the wire and then

install the detector.

6.Power on

Note:The working voltage of the detector is DC 24V±6V. Voltage over

30V may damage the detector irremediably.

Power on

1) Connect the detector with the power source.

The screen displays all the icons. Then in turns it will display the

software version number (such as V1.01) and the sensor module

software version number (“○

S” icon on the top right corner ).

2) Detector starts warm up, wait until the warm up is completed. (the time

depends on the sensor type).

3) After warm up, the screen displays the gas level and detector status and

sends relative signals to the control panel. Detailed display is shown

like the below picture.

13

4) Different working status as different display shown in below table.

Status

LED

LCD

Relay

Normal

Off

Gas

level

—

L-alarm

Red alarm LED

flickers twice per

second

Gas

level

L-alarm relay

closed

H-alarm

Red alarm LED

flickers 5 times per

second

Gas

level

H-alarm and

L-alarm relays

closed

Calibration data

wrong

Yellow fault LED on

E-01

Fault relay closed

Sensor fault①

Yellow fault LED on

E-02

Fault relay closed

Communications

fault

Yellow fault LED on

E-03

Fault relay closed

Sensor not

calibrated

Yellow fault LED on

E-05

—

High

concentration

protection②

—

FULL

All the relays

closed

Note: ①/②: These 2 functions only available for combustible type.

7.Menu operation

7.1 Remote controller

1) All the settings and calibration are operated through the remote

controller IR03.

2) The remote controller must be operated within 1 meter near the detector

14

and the operation angel is±15°(based on the middle line of the screen.)

3) If not used for long time, please take out the batteries.

4) Below is the picture of the remote controller IR03

5) In power off situation, press for 1~2s to open the remote controller,

and then again press for 1~2s will close the remote controller. If

there is no any button been pressed down in 6 minutes, the remote

controller will power off automatically.

6) If you press both the button and , the remote controller will

change between IR03 mode and IR05 mode, WD6200 detector require

to be operated within IR03 mode.

There are totally 4 menu options which can be shown on WD6200 screen.

The below table will give you a detailed explanation.

Menu

Function

Description

F--1

L-alarm setting

Set the low alarm level

F--2

H-alarm setting

Set the high alarm level

F--3

Zero translation

Translate zero point

F--4

Calibration

Calibration

15

7.2Low alarm setting

1) In normal status, press “ ” once and it will display [F--1]. Then

press “ ”, it will display the pre-set low alarm level.

2) You can change this figure by pressing “ ” or “ ”.

3) After setting completed, press “ ” to save the setting. If the screen

display “OK”, then the setting will be effective.

4) After above operation, press “ ” to continue the other settings. Or,

press “ ” to return to the normal working status.

7.2 High alarm setting

1) In normal status, press “ ” twice and it will display [F--2]. Then

press “ ”, it will display the pre-set high alarm level.

2) You can change this figure by pressing “ ” or “ ”.

3) After setting completed, press “ ” to save the change. If the screen

display “OK”, then the setting will be effective.

4) After the above operation, press “ ” to continue the other settings. Or,

press “ ” to return to the normal working status.

7.3 Zero translation

After the detector have been used for some time, if you reinstall it and put it

in a new environment, it may not display “0”in clean air, this is called zero

drift. Zero drift usually happens due to great change of temperature and

humidity of the detecting environment, it can be corrected by zero

translation.

1) Make sure the detector is put in clean air environment, after the detector

works over 10 minutes, operate with remote controller and press the

button for three times, the detector will display [F--3], then press

the button , the screen will show indication “OK?”, then press

16

to execute zero translation.

2) During zero translation, the screen will show the current A/D value.

How long does it take depend on the sensor type and how much the

sensor drifted. For small drift, zero translation can be done immediately.

3) After zero translation is done, the detector will go back to show [F--3],

you can press to continue other setup or press to go back to

normal working situation.

Note: Zero translation cannot correct the sensitivity deviation which caused

due to long time use, it is normally used when zero calibration is

inconvenient to proceed. Even though you have done zero translation, it is

highly suggested to do calibration once every 180 days.

8.Calibration

WD6200 has calibration remind function, if less than 30 days left for next

calibration, the detector will display flashing“○S”in normal working status,

press can check how many days left for next calibration, if it shows

“D020”, it means 20 days left for next calibration. Please calibrate the

detector within 20 days.

Calibration steps:

1) After the detector works over 10 minutes, press the button for four

times, the screen will show [F--4], then press the button .

2) On the screen it shows default calibration concentration, press the

button or to change the figure to be same with the

concentration of your calibration gas, then press the button .

3) Input the calibration gas, keep the input gas flow steady and

continuously, and it should last for 2~3 minutes.

4) The screen shows the current A/D value, and the figure is changing,

after the figure is steady, press to confirm the value, the detector

will remember the current A/D value and calibration will be effective

17

immediately.

5) After calibration is done, the screen display [F--4], you can press

to continue other setup or press to go back to normal working

status.

Note: It is suggested to do Zero calibration first, and then do Span

calibration. And you can calibrate more than one point.

9. Sensor replacement

In normal working status, if the mark of “○

S”display on the screen(not

flashing), it means the sensor is about to lose effect, please replace the sensor

on time. Press button for twice, you can see how many days left for

sensor overdue. For example,“E020”means the sensor will lose effect after

20 days.

To replace the sensor, open the cover of the main body is not necessary, only

Table of contents