Henan Liangyi U2 User manual

0

Henan Liangyi Mechanical and Electronic Technology Co.,Ltd

3D Printer--U2 User Manual

1

Legal Notice

We’re entitled to amend the relevant content without

notification. We are irresponsible for any damage while

manipulating according to this manual,caused by including

misprinting and other publishing errors. Nobody is allowed to

amend,copy or translate. The manual is copyrighted and the

final interpretation is reserved.

2

Contents

1. Introduction

1.1 How to use the manual.......................................................................................................3

1.2 Precautions......................................................................................................................... 3

2.Brief Introduction............................................................................................................................. 4

2.1 Appearance............................................................................................................................ 4

2.1.1. Lateral View.............................................................................................................. 4

2.2 Axis.....................................................................................................................................5

2.1.3. Accessories................................................................................................................ 6

2.1.4.Tools........................................................................................................................ 6

2.2 Printer Specifications............................................................................................................ 7

2.3 Work environment.................................................................................................................8

3. Machine Inspection......................................................................................................................... 9

3.1 Printer Installation Preparation..................................................................................................... 9

3.1.1 Packaging inspection..................................................................................................9

3.1.2 Machine Inspection.................................................................................................... 9

3.2 Filament Installation..............................................................................................................9

3.3 Install the Cura.................................................................................................................... 14

3.4 Cura operation.................................................................................................................. 17

4. Remove the model.........................................................................................................................20

5. Remove the support.......................................................................................................................20

6. Troubleshooting.............................................................................................................................20

3

1. Introduction

1.1 How to use the manual

It includes 4 parts: Introduction,Overview,Operation and Common Troubleshooting.

Please read this manual carefully before installing and manipulating the machine just

for your information.

1.2 Precautions

Please read this chapter carefully before using.

1.2.1 Safety

Don’t touch the printed model or the nozzle when it’s working or just fishing,just in case of the

scald and the damage of the printed model.

Plastic nippers and a pair of goggle are advised when you try to remove the support

part.

There will be a less-pleasant odor when it’s printing,so that is why we advise a

well-ventilated environment. In addition, please keep the printer away from strong

airflow which may effect the quality of printing.

Tips: Please keep well-ventilated because some irritant odor will be released when

ABS is melting.

1.2.2 Protective Measures

--Please don’t spoil any water or drinks inside the cabinet which may cause the

damage of circuit.

--Please don’t power off or plug out the SD card or the USB cable,or it may damage

the date of the model.

--Please keep a proper distance, like10mm or above, between the nozzle and the

heating bed when you do the testing. If not,it may cause nozzle jam when the filament

flows out from the nozzle after heating.

4

2.Brief Introduction

Simplicity and stability is the design concept of U2.

It’s easy to manipulate and make whatever you like with a few buttons even for

amateurs. The working principle is extruding the melting ABS/PLA and fast

solidification after shaping to accomplish the 3D printing

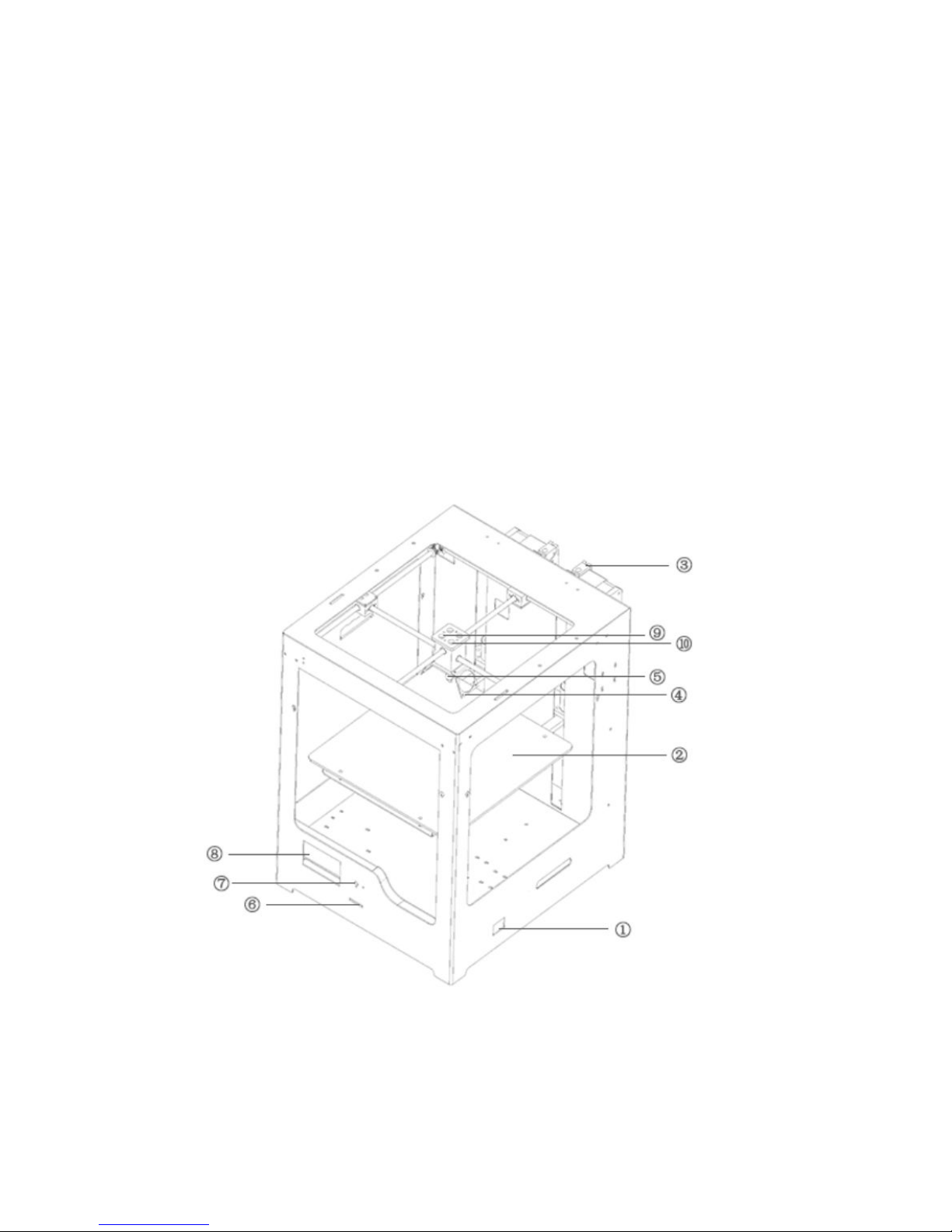

2.1 Appearance

2.1.1. Lateral View

①Power ⑥SD Slot

②Heating bed ⑦Menu Button

③Extruder ⑧LCD Screen

④Fan ⑨A1 Filament-in A1

⑤Nozzle ⑩A2 Filament-in A2

5

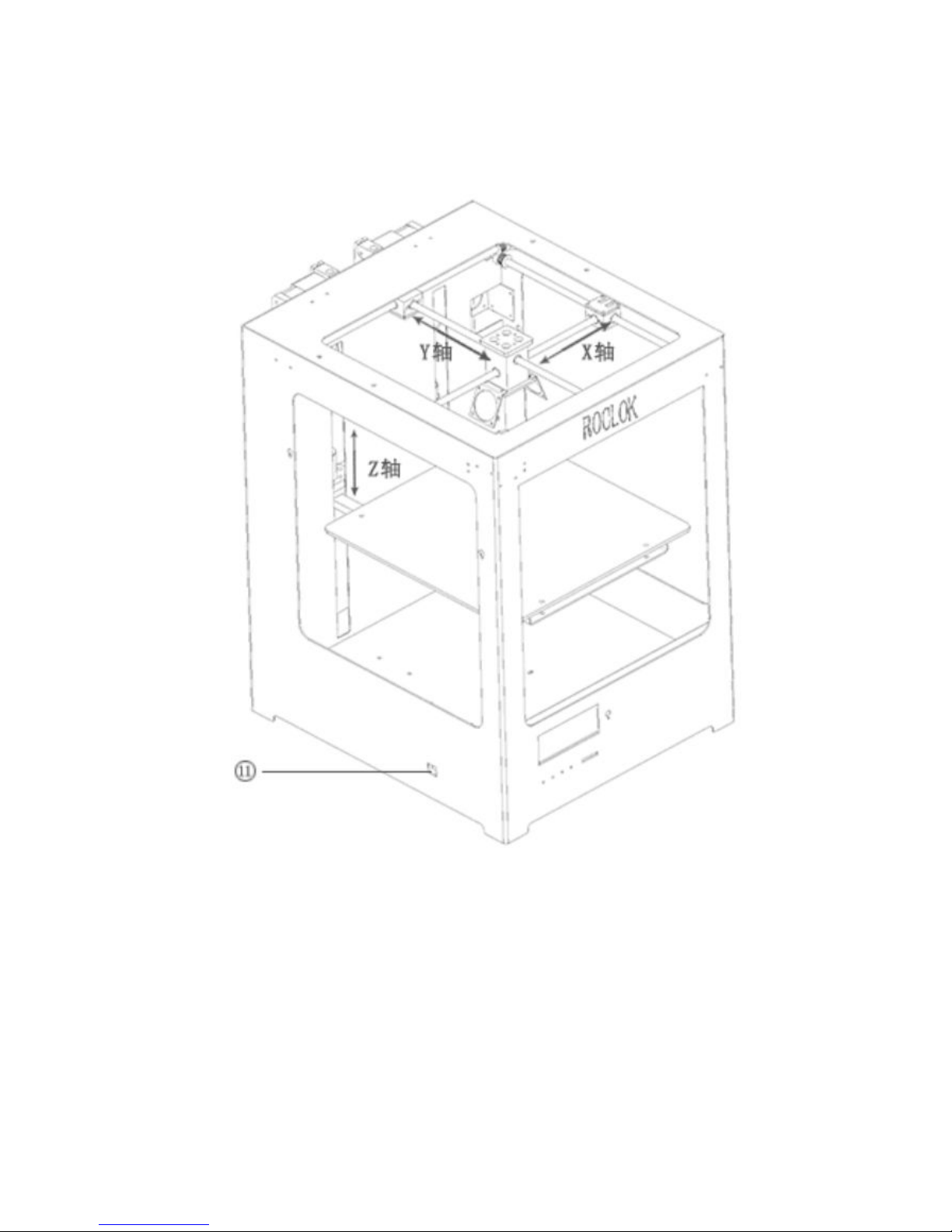

2.2 Axis

⑪USB Slot

6

2.1.3. Accessories

2.1.4.Tools

7

2.2 Printer Specifications

Forming

Technology:

Fused Deposition Modeling(FDM)

Technical

Parameters:

Nozzle Quantity:single nozzle\dual nozzle

Molding size:250*250*300mm

Positioning accuracy:X.Y Axis10Micron,Z

Axis1.5Micron

Minimum print thickness:0.06mm

Nozzle diameter:0.4mm(0.3 Optional)

Maximum air-way speed:250mm/s

Maximum print speed:150mm/s

Maximum extrusion temperature:250 degree

Highest temperature hot bed:120 degree

Highest Feeding speed:100mm/s

Filament:

Support filament:ABS、PLA、PVA、PS、PC

Filament filament:150~250 filament

Filament color:black、white、red、yellow、green、blue and so

on

Hardware:

Controller:Arduino ATmega2560 R3 Microcontrollers

Control board:RUMBA control board

Stepper motor:X、Y 42*48 Stepper motor,1.2A

Stepper motor:Z axis42*48 Stepper motor,1.5A

8

Stepper motor:E axis42*48 Stepper motor,1.8A

Input Power:110~220V,1.5A

Output Power:Special Switching Power Supply,24V,10.5A

Software:

Operating System:XP、Vista、Win7、Win8, LINUX,OS

Input File:STL、OBJ、GCode

Slice Software:Cura、Slic3r、kisslicer

Upper computer software:Cura、Printrun、RepetierHost

Machinery:

Bare metal Dimensions:38*47*57cm

Package Dimensions:44*54*61cm

Net weight:24.5kg

Gross weight:about 32kg

2.3 Work environment

Relative humidity 20%--90%

Room temperature 10℃--35℃

9

3. Machine Inspection

3.1 Printer Installation Preparation

3.1.1 Packaging inspection

3.1.1.1 Please check the integrity of the package

When you receive the product.

3.1.1.2 Please reject the product once any damage.

3.1.2 Machine Inspection

3.1.2.1 Please open the package carefully to check the machine;

3.1.2.2 Any damage found, please take picture and contact the manufacturer in time.

3.2 Filament Installation

3.2.1 Check the glass to see if it’s loose or not,Adjust the glass locker and aluminum plate.

3.2.2 Insert the filament to the tube with tools in tools bag (No12 wrench) in A1 hole.

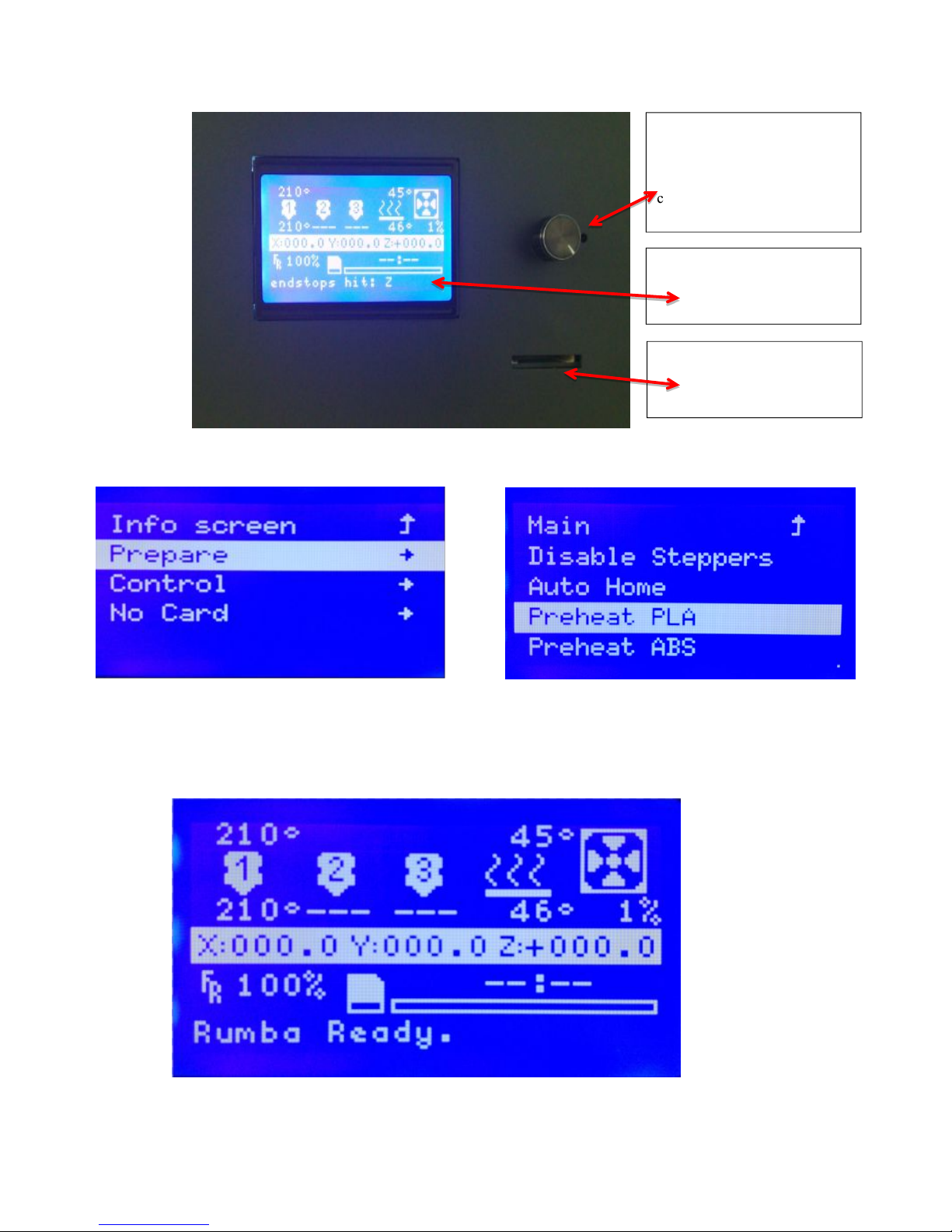

3.2.3 Preheat(PLA filament)

Power switch

Power jack

10

PLA filament can be installed before the nozzle temperature is up to 210 centigrade.(Adjusting

the distance between nozzle and bed is necessary before installing the filament)

Menu knob

Rotate to choose and press to

confirm operation

SD card slot

Menu

11

Auto Home

Adjust the bed and nozzle distance and watch the flowing of the filament from the nozzle.

12

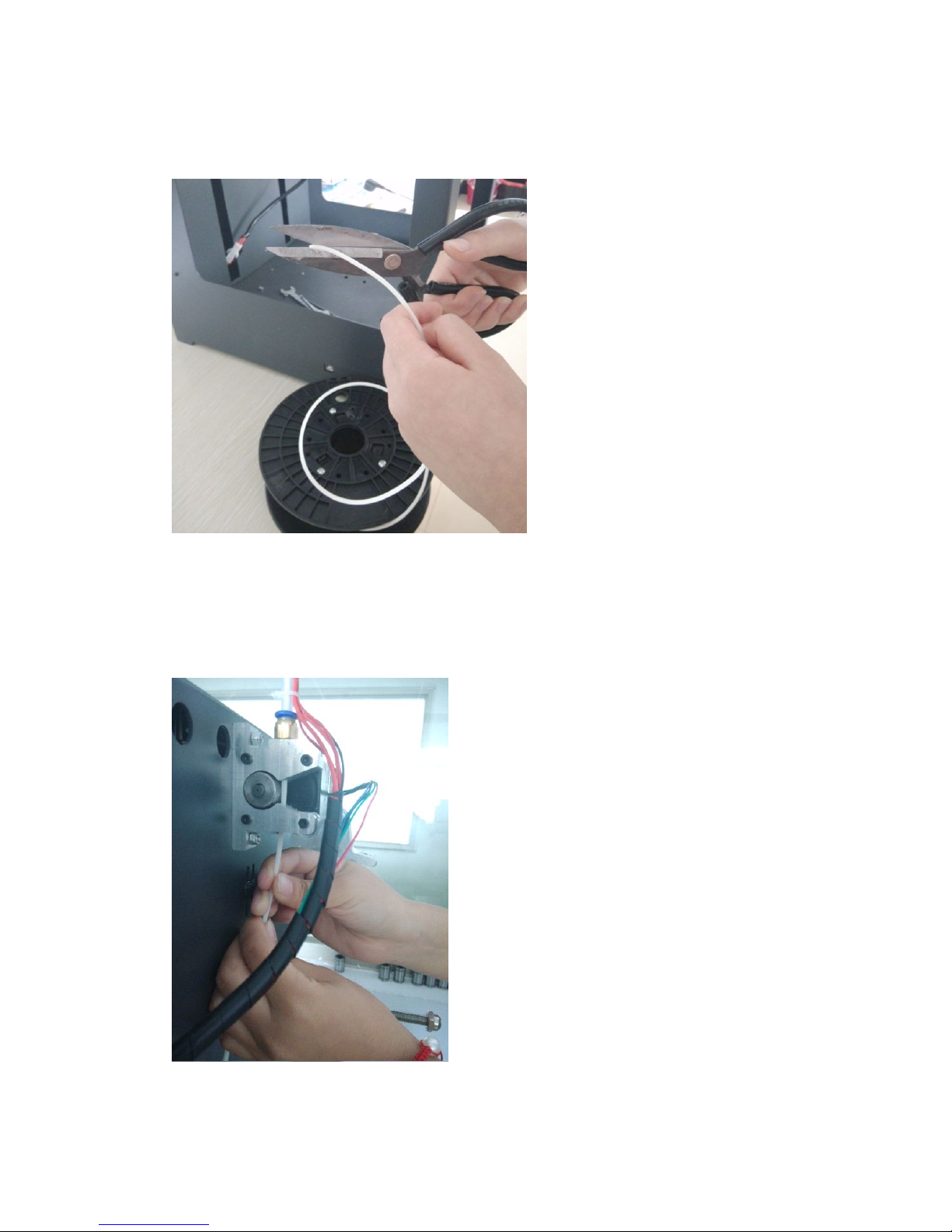

Use scissors to trim the material into a conical.

Insert the filament through the tube until it flows out of the nozzle.

13

Fix the screw and spring with the hex wrench.

Detailed procedure of adjustment:

Auto home-prepare-Disable stepper

Then,place a piece of paper between the nozzle and the bed to adjust the distance between them by

fasten or loosen the screw under the bed.(If you need,I can provide you a video of this part)

14

3.3 Install the Cura

This software is already in the SD memory card or you can download online.

3.3.1 Process of installation Cura

15

1.Choose Other

2.Click Next

16

17

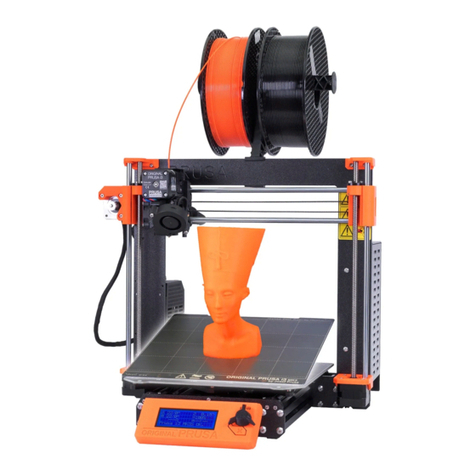

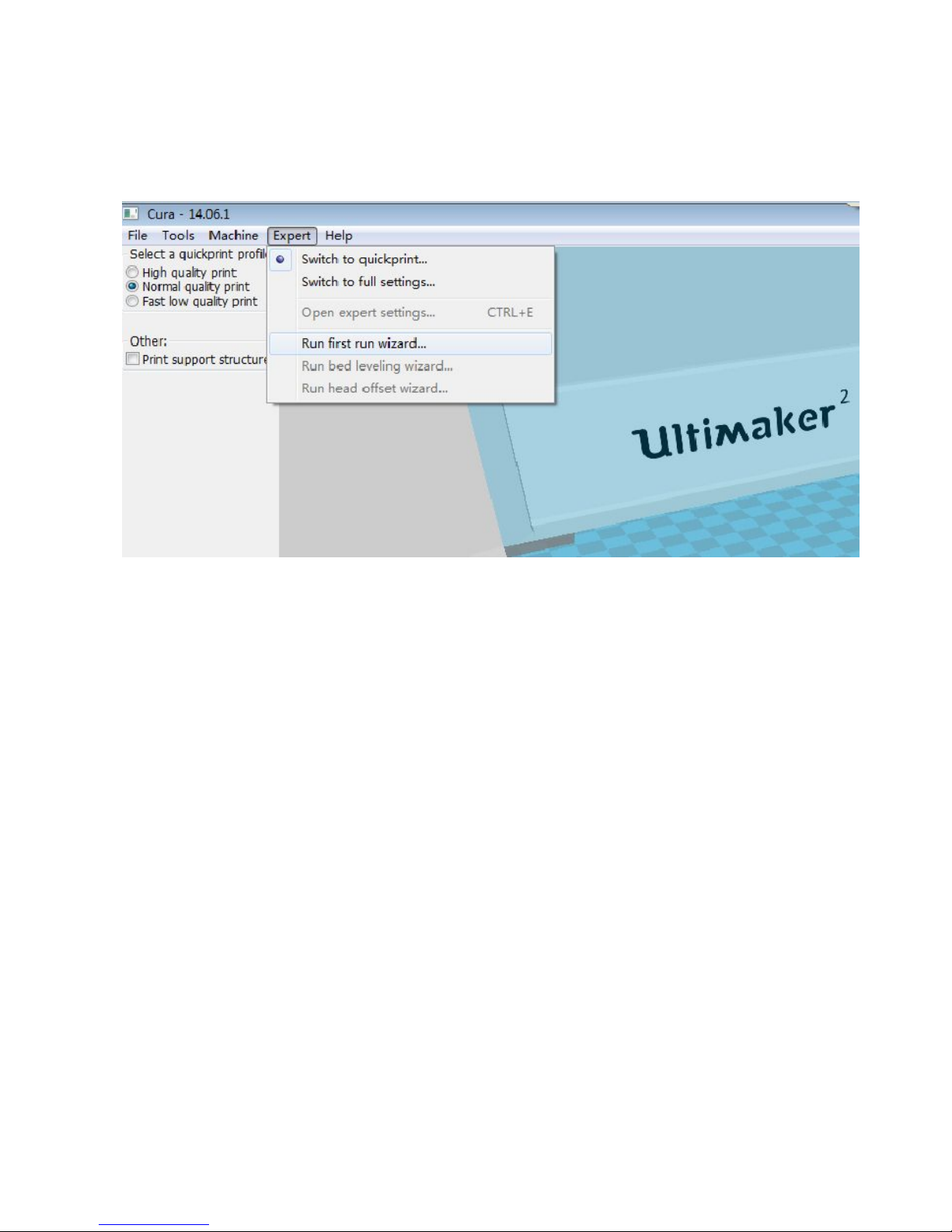

3.4 Cura operation

Use Cura to turn .stl into .gcode . Save .gcode into SD card, and print.

3.4.1 Cura “Advanced” Interface

18

3.4. 2 Cura “Advanced” Interface

3.4.3 Cura main parameters

(1)Layer height :every layer thickness usually is 0.2 mm,If you want a higher precision,

Please set a smaller value.The higher accuracy it is, the longer time it takes.

(2)Wall thickness :Especially the hollow objects,

wall thickness should be Integer times the diameter of the nozzle.

(3)Bottom/Top thickness: should be Integer times the wall thickness (suggest 3-5 times) .

(4)Fill Density :10-20% is ok ,if u need harder object ,set 30-40%。

(5) Print Speed:suggest 30---80.

(6)Printing Temperature :PLA 190℃-230℃; ABS 220℃--240℃.

(7)Support Type:TOUCHING BUILDPLATE \ VERYWHERE \ NONE.

(8)Add raft:the machine will print one layer under object , to make object easy to stick together

with the building plate.

(9)Diameter :usually 1.75 or 2.9 mm。And you can measure the diameter of the filament.

(10)Packing Density:PLA is 1.00;ABS is 0.85.

3.4.4 .GCODE made and use

3.4.4.1 move the STL or OBJ into Cura, choose the right parameter , and save the GCODE into

SD card, insert the SD card into machine and print

19

3.4.5 Insert SD card to the machine ,turn on the power,press down the knob and select the

Print From SD,choose the .gcode,press down the knob,wait for printing 。

LCD

Knob

SD Card

Table of contents