7

EN

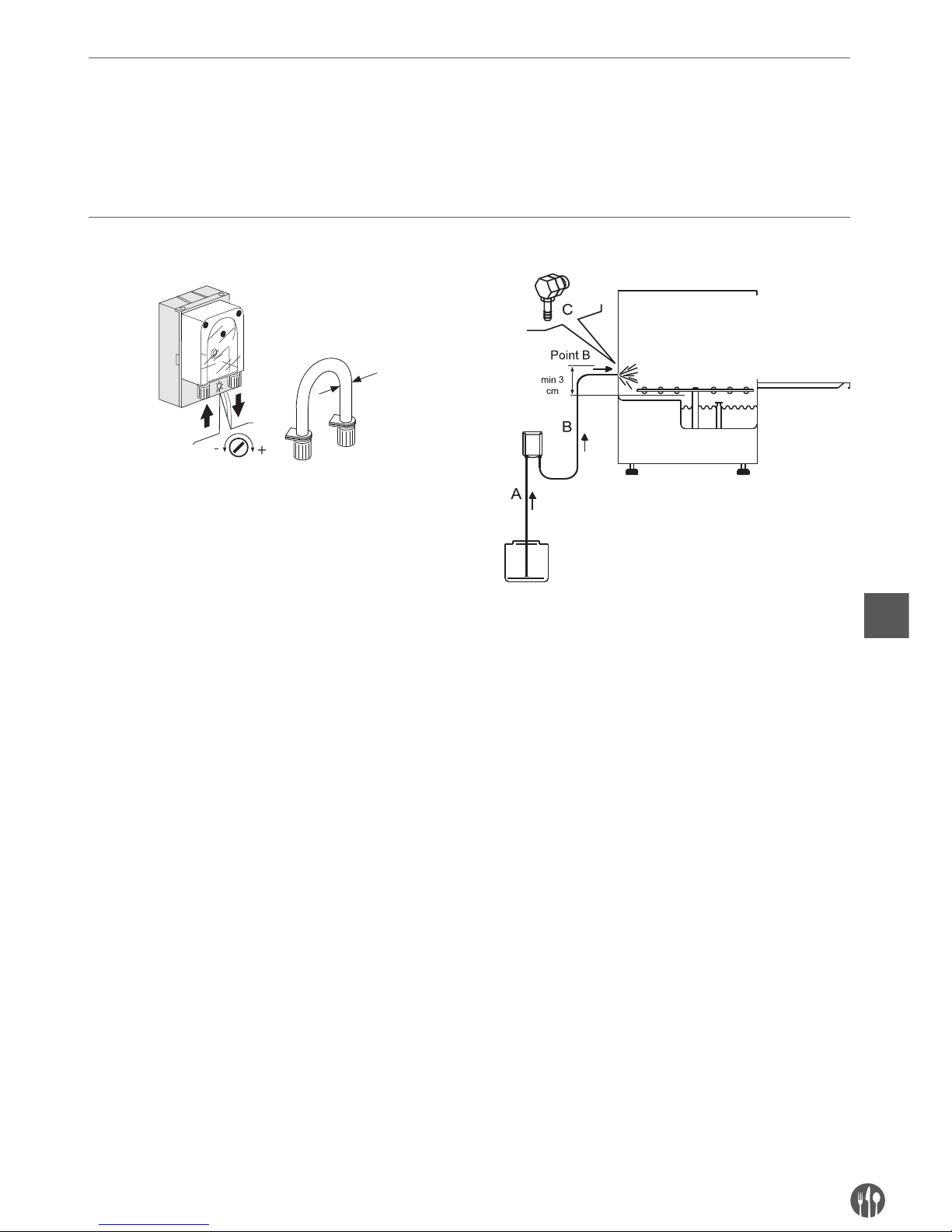

Connect the machine’s water supply with an inter-

rupt valve capable of quickly and completely shut-

ting off water intake.

Make sure that the water supply pressure comes

within the values given in the Table 1.

If it is less than 2 bar dynamic pressure (200 kPa)

an external pressure pump must be installed to

guarantee optimal machine operation.

If, however, the water supply pressure is greater

than 400 kPa, a pressure reducing device must be

installed.

For water with average hardness greater than 8°f.,

a water softener must be used. This will result in

cleaner dishes and longer life of the appliance.

Note: All damages caused by the hydraulic lime-

stone (calcareous water higher-up than 8°f and

without watersoftner) are not are not covered by

warranty.

In order to ensure the optimum performance, the

water supply temperature must come within the

range given in table 1.

Each machine is provided with a rubber tube with

a ¾” threaded attachment for water filling.

Connect the emptying tube, supplied with the ap-

pliance, to the union elbow located under the tub

so that water flows freely. If it is not possible to

empty the water at a level lower than the drain of

the appliance, it is advisable to install an emptying

pump, which can be provided by request.

The emptying tube should always be connected to

a siphon to prevent odor back-up from the screen.

1.3 ELECTRICAL CONNECTION

The electrical connection must be made accord-

ing to current technical standards. Ensure that the

mains voltage corresponds to the value given on

the machine dataplate.

A suitable omni-polar one-way switch shall be

installed and sized according to the absorption

provided, in order to completely guarantee the

disconnection from the supply mains, under “cat-

egory III” overvoltage conditions.

This switch shall be included in the power net-

work solely and exclusively used for this purpose

and installed in the immediate vicinity of the ma-

chine. Always turn the machine off via this switch.

This is the only model of switch that guarantees

a total electrical power disconnection.

Make sure that the facility is equipped with

efficient ground connection.

WARNING: check very carefully if the “ground con-

nection” of the machine, is properly sized and fully

efficient, and that not too many units are connected

on it. An undersized or poor “ground connection”

might lead to corrosion and/or pitting effect on the

stainless steel plates, even to perforation.

On the back of the appliance there is a terminal

marked with the symbol , which is provided for

equipotential connection between different ap-

pliances (see electrical safety standards).

Feed cable: the retailer - importer - installer must

ensure that the feed cable complies with the cable

insulation category of the workplace, in conformity

with current Technical Standards.

code mm Nr of cycles kW V kg

230831, 230732, 230749, 231531 400x495x(H)585 1 (120 s) 2.59 230, 50 Hz 28

230848, 230756, 230763, 231548 450x535x(H)700 1 (120 s) 2.59 230, 50 Hz 37

230855, 230794, 230800, 231555 590x600x(H)850 1 (120 s) 3.2 230, 50 Hz 56.5

231579 590x600x(H)850 2 (120 and 180 s) 5.15 400, 50 Hz 56.5