Henko 671 User manual

Operating Manual

Henko 671 Brush Machine

Henko A&T B.V.

Graafschap Hornelaan 184, 6004 HT Weert,

The Netherlands

Tel: +31 (0)495 63 30 10, Fax: +31 (0)495 58 67 35

[email protected], www.henko-at.nl

© Henko A&T B.V.

Rev. 18-8-2014

Page 2 of 33 18-8-2014 Henko A&T B.V.

Introduction

Dear reader,

This operating manual provides all information for

safe operation of the Henko 671 Brush Machine.

The Henko 671 Brush Machine has been designed and built in

accordance with the state of the art and recognised safety rules

and regulations. Nevertheless dangers for personnel or objects

can occur, because not all danger zones can be avoided if the

functionality is to remain intact. However you can prevent

accidents due to these dangers by complying with the

instructions in this operating manual. Moreover you will then be

able to use the Brush Machine to its full capacity and avoid

unnecessary disturbances.

CAUTION!

There is danger of injury and danger of material damage

when assembling, operating, and maintaining the Brush

Machine. Therefore:

First read this operating manual carefully, prior to assembly

and operation of the Brush Machine. Always comply with the

instructions and information contained herein, particularly the

safety instructions.

If the operating manual is lost or in poor condition, request a

new copy from the manufacturer (the same applies for parts of

the operating manual).

This operating manual only applies for the Brush Machine

specified on the cover sheet and at the end of every page.

Compare this information with the information on the type plate

of the Brush Machine.

After you have read the entire operating manual thoroughly for

the first time, take good care of the operating manual over the

entire service life of the Brush Machine, so that you can look up

something later.

If you sell the Brush Machine, give this operating manual to

the new owner.

All information, illustrations and dimensions in this operating

manual are non-binding. No claims whatsoever can be derived

from this information, illustrations or dimensions.

Introduction

Henko A&T B.V. 18-8-2014 Page 3 of 33

Reprinting or duplication of any type, including excerpts,

requires the written permission of the manufacturer.

Conversion of, or changes to the Brush Machine are only

permitted with the manufacturer's written consent.

Unauthorised conversion voids any liability on the part of the

manufacturer, as well as the guarantee.

Only use original spare parts and accessories that are

approved by the manufacturer. Otherwise the design-specified

characteristics of the Brush Machine, the functionality or the

safety can be impaired. Consequently the use of other parts

voids the liability for the ensuing consequences.

Contact your specialist dealer to order spare parts or

accessories.

In addition comply with the instructions in the operating manual

of the motor manufacturer. This is included in the sub-package

for the Brush Machine.

Henko A&T B.V. assumes no liability for the content of the

operating manual provided by the motor manufacturer.

Explanation of symbols, signs and direction indications

For better understanding, the following conventions are used for

this operating manual:

1.

To emphasise important information, the following types of

special notices are used:

DANGER!

There is an imminent dangerous situation that results in death

or serious injury if it is not avoided.

WARNING!

There is a possible dangerous situation that can result in death

or serious injury if it is not avoided.

Introduction

Page 4 of 33 18-8-2014 Henko A&T B.V.

CAUTION!

There is a possible dangerous situation that can result in

minor injury or material damage, if it is not avoided.

ATTENTION!

...indicates a possible dangerous situation that can result in

material damage, if it is not avoided.

NOTE

...indicates useful tips and recommendations, as well as

information for efficient and trouble-free operation.

...refers to important information in other sections and documents.

2.

Many texts serve a particular purpose. These texts are marked

as follows:

Listings.

Instructing text, e. g. a sequence of activities.

3.

In the text the sides of the Brush Machine are cited (left, right,

front, rear). Left or right refers to the side that the operator of

the machine sees viewed from the direction of travel. The Brush

Machine of the machine is mounted in front, the steering arm is

mounted in the rear.

Introduction

Henko A&T B.V. 18-8-2014 Page 5 of 33

Table of contents

Introduction . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . 2

Table of contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1 Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.1 Intended use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.2 Non-intended use . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

1.3 Product observation . . . . . . . . . . . . . . . . . . . . . . . . . . 8

1.4 Requirement imposed on the operator or personnel . 9

1.5 Danger zone . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1.6 Work clothing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

1.7 Safety devices and protective devices . . . . . . . . . . . 11

1.7.1 Safety switch . . . . . . . . . . . . . . . . . . . . . . . . . 11

1.7.2 Brush Machine deck . . . . . . . . . . . . . . . . . . 11

1.7.3 Protective cover . . . . . . . . . . . . . . . . . . . . . . . 11

1.8 Safety regulations and accident

prevention regulations . . . . . . . . . . . . . . . . . . . . . . . 12

1.9 Disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

1.10 Safety signs on the Brush Machine . . . . . . . . . 14

2 Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

2.1Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

2.2Technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

3 Commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

3.1 Unpacking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

3.2 Making the steering arm operational . . . . . . . . . . . . 19

4 Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

4.1 Preparatory activities . . . . . . . . . . . . . . . . . . . . . . . . 23

4.1.1 Adjusting the height of the Brush Machine . . 24

4.1.2 Checking the motor oil level . . . . . . . . . . . . . . 24

4.1.3 Filling fuel . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Table of contents

Page 6 of 33 18-8-2014 Henko A&T B.V.

4.2 Sweep operation . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

4.2.1 Starting the motor . . . . . . . . . . . . . . . . . . . . . . 25

4.2.2 Stopping the motor . . . . . . . . . . . . . . . . . . . . . 26

4.2.3 Switching the traction drive on and off . . . . . . 26

4.2.4 Switching the Brush Machine drive

on and off . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

4.2.5 Side adjustment of the Brush Machine . . . . . 27

5 Maintenance and repair . . . . . . . . . . . . . . . . . . . . . . . . . . 28

5.1 Safety guidelines for maintenance and repair . . . . . 28

5.2 Regular maintenance tasks . . . . . . . . . . . . . . . . . . . 29

5.2.1 Maintenance schedule . . . . . . . . . . . . . . . . . . 29

5.2.2 Maintenance records . . . . . . . . . . . . . . . . . . . .30

5.2.3 Checking the Bowden cables

for ease of movement . . . . . . . . . . . . . . . . . . . 30

5.2.4 Checking the air pressure in the tyres . . . . . . .31

5.2.5 Cleaning the Brush Machine . . . . . . . . . . 31

5.2.6 Checking and cleaning the air filter . . . . . . . . . 31

5.3 Maintenance and repair verifications . . . . . . . . . . . . 32

6 Decommissioning and preservation . . . . . . . . . . . . . . . 33

7 Faults and fault correction . . . . . . . . . . . . . . . . . . . . . . . . 33

Table of contents

Henko A&T B.V. 18-8-2014 Page 7 of 33

1 Safety

The basic prerequisite for safe and trouble-free operation of the

Brush Machine is knowledge of the safety instructions and

safety regulations.

Consequently read this chapter carefully all the way through

and comply with the specified instructions and warnings.

The safety instructions and warnings that you find at the

appropriate point in the text of the following chapters must be

complied with. The manufacturer cannot be made liable if the

instructions and warnings are not complied with.

In addition to the instructions contained in this operating

manual, the statutory regulations, particularly the safety and

accident prevention regulations, must also be complied with.

1.1 Intended use

The Henko 671 Brush Machine may only be used to brush

artificial grass, clean paths and surfaces that are paved with

concrete, asphalt, paving stones or slabs outside of closed

rooms.

Intended use also includes compliance with all the instructions

in the operating manual.

DANGER!

If the Brush Machine is used for a use other than the use

described above, dangerous situations can occur for people or

material damage can occur.

Therefore:

Only use the Brush Machine for its intended purpose.

Always comply with all the instructions in this operating

manual.

Particularly refrain from the uses of the sweeping machine

listed in section 1.2. They are considered non-intended use.

Safety

Page 8 of 33 18-8-2014 Henko A&T B.V.

1.2 Non-intended use

Any use that deviates from that described in section 1.1, is

considered non-intended use.

For example, non-intended use of the Brush Machine

occurs when

it is used to clean unpaved surfaces e.g. gravel paths,

it is used to clean roofs or flat roofs,

it is used in enclosed spaces, e.g. halls, or barns,

it is used to transport persons or objects,

it is used to move or carry objects or vehicles,

it is operated in faulty condition or with safety-relevant

faults,

it is used without the safety cladding elements that are

installed as standard equipment,

unsuitable personnel are assigned to operate the sweeping

machine.

1.3 Product observation

Notify us without delay if faults or problems occur when

operating your Brush Machine, or if accidents occur or nearly

occur.

Together with you we will find a solution to the problem and

allow the knowledge gained to flow into our subsequent work.

Safety

Henko A&T B.V. 18-8-2014 Page 9 of 33

1.4 Requirements imposed on the operator

or personnel

Handling the Brush Machine is only permitted for persons,

who are at least 16 years old,

who are physically and mentally suited to do so,

who have read and understood this operating manual, and

from whom it is expected that they responsibly perform the

tasks assigned to them.

Commissioning, maintenance, repair and disposal of the Brush

Machine may only be executed by the specialist dealer or by

persons with appropriate technical training and experience.

1.5 Danger zone

The danger zone is the area in which the safety or the health of

persons is jeopardised. Consequently no one should be in this

area when the Brush Machine is in operation.

WARNING!

For persons in the danger zone there is danger of injury due to

collision with the Brush Machine and due to thrown up

sweepings.

Therefore:

Only operate the Brush Machine if no one is in the danger

zone.

Carefully observe the danger zone and stop the sweeping

machine if persons enter the danger zone.

The danger zone is shown in the sketch (see Fig. 1, on the next

page):

A top view of the Brush Machine is shown. The shaded area is

the danger zone.

The danger zone on the right side and left side is determined

through the width of the Brush Machine. Toward the front side

of the Brush Machine the length of the danger zone is 5 m in

front of the Brush Machine.

Safety

Page 10 of 33 18-8-2014 Henko A&T B.V.

NOTE

When swinging the Brush Machine to the right or left this change in

direction also applies for the danger zone.

Safety

A

Fig. 1:

Danger zone

2.5 m

5 m ahead of the Brush Machine

Henko A&T B.V. 18-8-2014 Page 11 of 33

1.6 Work clothing

WARNING!

Unsuitable, loose work clothing, bandanas, ties, and scarves

can be caught by the Brush Machine and pulled in.

Severe injuries are the result.

Therefore:

When operating the Brush Machine, and for maintenance

and repair tasks, always wear suitable tight-fitting work

clothing.

Special protective clothing is not necessary for work with the

Brush Machine. However always wear tight-fitting work clothing

that cannot get caught in the Brush Machine, and that is

appropriate for the respective weather, as well as sturdy shoes.

For commercial use the owner must ensure that suitable work

clothing is selected and also worn.

1.7 Safety devices and protective devices

1.7.1 Safety switch

The switch levers for traction drive and rotation of the Brush

Machine are designed as safety switches. By pressing down

the switch levers on the steering arm handles, the traction drive

and the rotation of the sweeping broom will be switched on.

To bring the Brush Machine to a standstill, it suffices to

release the switch levers.

1.7.2 Brush Machine deck

The Brush Machine deck is mounted like a protective sheet

metal element above the sweeping brushes and prevents

operating personnel from being hit by thrown up sweepings.

1.7.3 Protective cover

The belt drives in the interior of the Brush Machine are

considered danger zones and are protected against access by

the front protective cover and the housing.

Safety

Page 12 of 33 18-8-2014 Henko A&T B.V.

1.8 Safety regulations and accident prevention

regulations

Comply with the following instructions to avoid injury and material

damage. In addition, for commercial use comply with the safety

and accident prevention regulations issued by the Employers

Liability Insurance Associations.

Only operate the Brush Machine with properly mounted

safety devices and protective devices (see section 1.7).

These devices may only be dismounted for maintenance and

repair tasks. After concluding these tasks the safety devices

and protective devices must be immediately remounted.

Otherwise there is significant danger of injury.

Only use the Brush Machine for its intended use, otherwise

dangerous situations can occur with serious or fatal injuries

as the result (intended use: see section 1.1).

Due to poor lightning conditions during operation a number of

dangers can occur. Only operate the Brush Machine if there

is adequate lighting.

For sweeping tasks along walls there is danger of hand

scrape injuries. Avoid touching the walls with your hands and

wear protective gloves.

Maintenance and repair tasks may only be executed by the

specialist dealer or by specialised personnel.

High voltage on the ignition cable and spark plug connector!

Always switch the sweeper off with the fuel control lever,

before performing tasks on the ignition cable or spark plug

connector.

Comply with the instructions on the safety stickers that are

located on the Brush Machine. Safety stickers must not be

removed. If they have become illegible or have been lost,

they must be replaced (meaning of the stickers: see section

1.10). Contact your specialist dealer to order new stickers.

Wear tight-fitting clothing. Long hair must be tied back.

Safety

Henko A&T B.V. 18-8-2014 Page 13 of 33

Do not operate the Brush Machine in faulty condition;

significant injury hazards can occur. If faults occur switch off

the Brush Machine and initiate the repair.

Execution of the specified maintenance and repair tasks is

part of intended use of the Brush Machine; intended use

particularly includes compliance with the maintenance

intervals. If you do not execute these tasks, faultless

function cannot be ensured. Dangers for personnel and

objects can occur. We recommend that you keep

maintenance logs.

Switch off the Brush Machine prior to performing repair

tasks, including cleaning tasks. Ensure that no other person

can restart the Brush Machine (e. g. pull off the spark plug

connector). Otherwise there is danger of injury.

Only use original spare parts and accessories that are

approved by the manufacturer. The use of other parts voids

the liability for the ensuing consequences.

1.9 Disposal

After its service life, only have qualified specialists dispose of

the Brush Machine. The manufacturer assumes no liability for

damage that occurs due to improper disposal.

Safety

Page 14 of 33 18-8-2014 Henko A&T B.V.

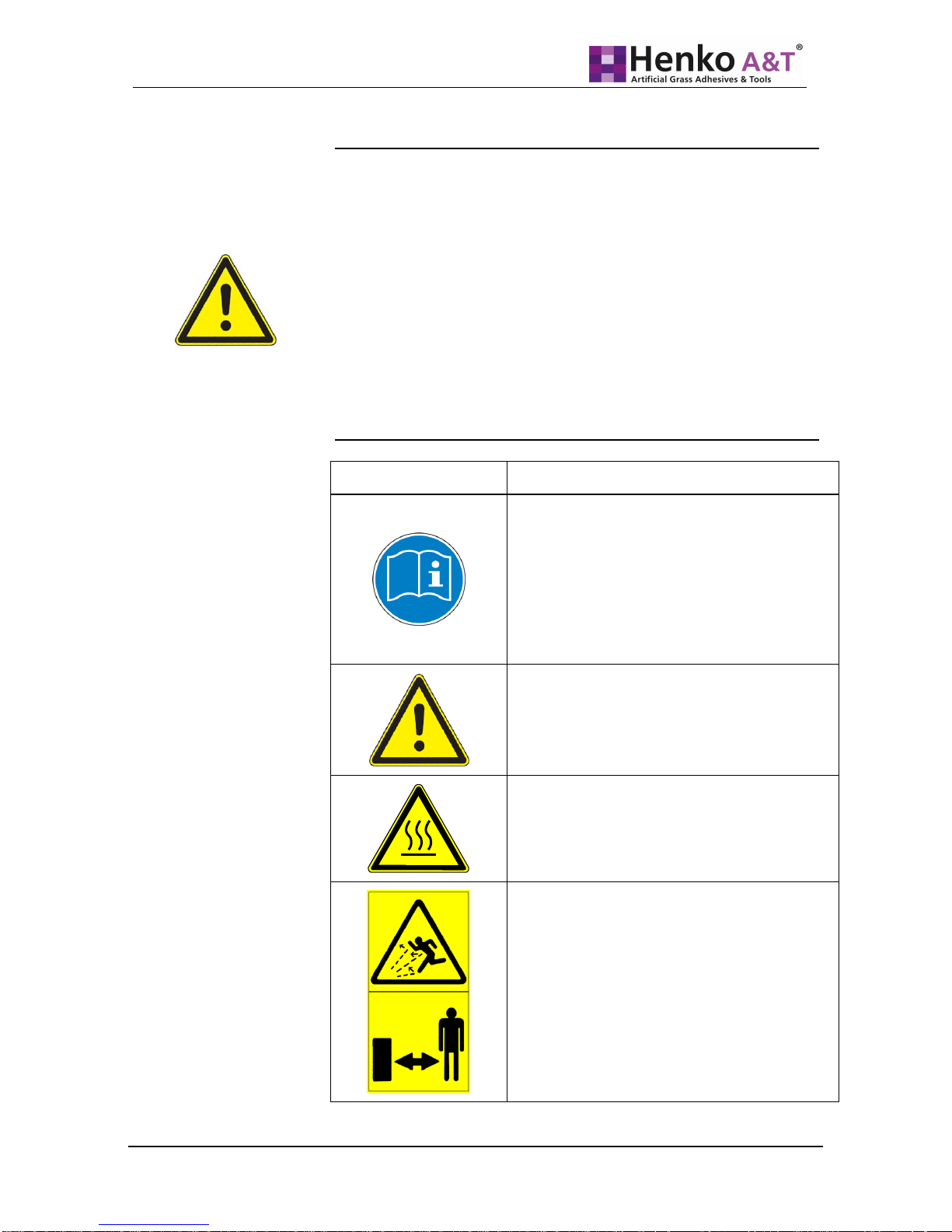

1.10 Safety signs on the Brush Machine

Warning!

Danger of injury due to ignorance of the danger zones.

The stickers attached on the Brush Machine contain warnings of

specific dangers as well as instructions for correct operation. The

stickers supplement the instructions specified in this manual.

Therefore:

Always comply with the warnings affixed on the sweeping

machine.

Do not remove any warning stickers

Replace warning stickers that come off of the machine or that

have already been lost.

Stickers

Meaning

Before using the Brush Machine, the

operating manual must be read. All

information contained in the operating

manual must always be complied with.

Position: On the rear of the machine in the

operator’s field of vision.

Warning - general dangers.

Position: On the rear of the machine in the

operator’s field of vision.

Warning - hot surface.

Position: On the motor.

Warning - thrown up sweepings.

Maintain distance.

Position: On the rear of the brush deck.

Safety

Henko A&T B.V. 18-8-2014 Page 15 of 33

2 Description

Description

The brush on this engine driven device is for brushing artificial

grass both for installation and maintenance and has been

especially designed and made to our own specifications.

The special fibers in the brush prevent any damage to the

artificial grass fibers in the turf while still performing the proper

cleaning and comb action.

It will make the seams less visible, remove debris, comb the

fibers, and brush the infill (if applicable).

The 4-stroke petrol engine requires little maintenance and is

very economical. Wide handle- bars give good directional

control and good grip.

Replacement brushes can also be ordered at Henko A&T B.V.

Page 16 of 33 18-8-2014 Henko A&T B.V.

2.2 Overview

Fig. 3: Components and operating elements

Switch lever –

traction drive

Switch lever –

brush drive

Trunnion

(Side adjustment

–Brush Machine)

Accessory

receptacles

Brush Machine deck

Sweeping brush

Support

wheel

Drive wheel

Fuel control lever

and motor stop

Description

Steering arm

Knob

(Locking

mechanism for

side adjustment of

the sweeping

brush)

Protective cover

Henko A&T B.V. 18-8-2014 Page 17 of 33

2.3 Technical data

Dimensions, weight, travel speed, motors

Work width

70 cm

Brush diameter

25 cm

Weight

45 kg

Travel speed

3.3 km/h

Motor

Honda GCV 135 or

Briggs & Stratton DOV

Hand/arm vibrations on the Brush Machine

Vibration total value

(Honda motors)

ahwd = 3.5 m-2

Vibration total value

(Briggs & Stratton motor)

ahwd = 3.3 m-2

Noise emission value of the Brush Machine

Sound power level

(Honda motor)

LWAd = 95 dB(A)/1pW

Sound power level

(Briggs & Stratton motor)

LWAd = 94 dB(A)/1pW

Sound pressure level

at the operator’s ear

(Honda motor)

LpAd = 84.5 dB(A)/20µPa

Sound pressure level

at the operator’s ear

(Briggs & Stratton motor)

LpAd = 84 dB(A)/20µPa

Description

Page 18 of 33 18-8-2014 Henko A&T B.V.

3 Commissioning

CAUTION!

Danger of injury and danger of material damage due

to improper assembly of the Brush Machine.

Therefore:

The completion and all necessary adjustments, incl. trial

run are included in the scope of delivery and must be

executed by the specialist dealer prior to transfer to the

customer!

We recommend that two people assemble the Brush

Machine.

3.1 Unpacking

Place the packed Brush Machine on a level floor

Open the box on the top

Cut open the 4 corners of the box to the floor.

Mount the drive wheels (see the assembly instructions

for the drive wheels included as a separate sheet in the

box, or at the end of this page)

Set up the steering arm in accordance with section

3.2 and roll the Brush Machine out of the packaging.

Dispose of the packaging in accordance with the waste

disposal regulations issued by your municipal

administration.

Wheel

Here

hinged pin

Freewheel /

tappet

Washer

Commissioning

Fig. 4:

Assembly –drive wheels

Henko A&T B.V. 18-8-2014 Page 19 of 33

3.2 Making the steering arm operational

The Henko 671 Brush Machine has an adjusting possibility for

the height of the steering arm handles. A medium height that

most users perceive as comfortable has been specified in the

factory. The steering arm is folded forward for transport. To

establish operational readiness the steering arm must be

straightened up and bolted to a support bracket.

CAUTION!

Danger of injury and danger of material damage when raising the

steering arm.

When lifting up the steering arm there is a crush hazard between

steering arm and motor.

Bowden cables can be pinched and damaged when lifting up the

steering arm.

Therefore:

Carefully lift up the steering arm.

When lifting up the steering arm pay attention to the Bowden

cables.

Behind the rear wheel a support bracket is bolted onto the

housing; it extends around the rear and has a bore that is

aligned flush with a bore in the lower steering arm crossmember

(see Fig. 5).

Commissioning

Task to be performed by the specialised workshop!

Fig. 5:

Steering arm fastening –

lower

Support bracket

Bolt here

Page 20 of 33 18-8-2014 Henko A&T B.V.

Use the pre-mounted M6 screw to fasten the steering arm on

the support bracket. Washers must be placed under the

screw head and under the stop nut.

See Fig. 6.

Commissioning

Fig. 6:

Correct installation –

steering arm / support

bracket

Table of contents

Popular Lawn And Garden Equipment manuals by other brands

Sunforce

Sunforce SOLAR user manual

GARDEN OF EDEN

GARDEN OF EDEN 55627 user manual

Goizper Group

Goizper Group MATABI POLMINOR instruction manual

Rain Bird

Rain Bird 11000 Series Operation & maintenance manual

Cub Cadet

Cub Cadet BB 230 brochure

EXTOL PREMIUM

EXTOL PREMIUM 8891590 Translation of the original user manual

Vertex

Vertex 1/3 HP Maintenance instructions

GHE

GHE AeroFlo 80 manual

Land Pride

Land Pride Post Hole Diggers HD25 Operator's manual

Yazoo/Kees

Yazoo/Kees Z9 Commercial Collection System Z9A Operator's & parts manual

Premier designs

Premier designs WindGarden 26829 Assembly instructions

Snapper

Snapper 1691351 installation instructions