HENNING WeightWatcher Beam User manual

Operating Manual

WeightWatcher Beam

Service-Hotline: +49 2336 9298-232

©Copyright 2014 by Henning GmbH & Co. KG

Rev. 1.1 09/2014

2

Content

1. Connection Diagram.......................................................................................................... 3

2. Alarm Relays..................................................................................................................... 4

3. HOLD-Function ................................................................................................................. 4

4. How to Access a Parameter.............................................................................................. 4

5. How to Adjust a Parameter................................................................................................ 5

6. Scheme of Menu............................................................................................................... 6

7. How to Calibrate the Load Measuring................................................................................ 7

8. Alarm Limits....................................................................................................................... 8

9. How to Adjust the Display.................................................................................................. 9

10. Electric Characteristics.................................................................................................... 9

15. Installation des WeightWatcher Beam...................................................................... 10-13

16. Operation Instructions in Brief ........................................................................................14

Henning GmbH & Co. KG

Industriegebiet S5

Loher Str. 4

58332 Schwelm (Germany)

Tel.: +49 2336 9298-0

Fax.: +49 2336 9298-100

Service-Hotline: +49 2336 9298-232

www.henning-gmbh.de

©Copyright 2014 by Henning GmbH & Co. KG

Rev. 1.1 09/2014 3

1. Connection Diagram

Wire configuration

Farbe

Abk.

Belegung

Red

RD

Supply voltage 24 V DC

Blue

BU

Ground

White

WH

+ Hold input

Brown

BN

- Hold input

Green

GN

NO contact AL-1

Yellow

YE

NC contact AL-1

Grey

GY

COM contact AL-1

Pink

PK

NO contact AL-2

Black

BK

NC contact AL-2

Violet

VT

COM contact AL-2

©Copyright 2014 by Henning GmbH & Co. KG

Rev. 1.1 09/2014

4

2. Alarm Relays

AL-1 (change-over contact)

Changes state as soon as the load limit adjusted by is exceeded.

AL-2 (change-over contact)

Changes state as soon as the load limit adjusted by is exceeded.

3. HOLD-Function

The HOLD input responds for alternating and direct voltages between 12 V to 230 V.

During the elevator travel the measured loads can heavily fluctuate (friction in the rails

etc.). As long as a voltage (e. g. the travel signal) between 12 to 230 V is applied at the

HOLD input the alarm output through the alarm relays does not take place. If during an

elevator ride a signal is presented to the HOLD input or if no signal is presented when

the elevator is at standstill, the system automatically carries out a compensation of the

rope weight in case of elevators with multiple suspensions as well as a compensation of

the weight of a possibly existing compensation chain.

Slack Rope Alarm

There is a possibility to create negative switching thresholds by setting the first digit to

minus. Slack rope situations can be detected because the measured weight is below the

weight of the car.

4. How to Access a Parameter

The unit is provided with a menu offering access to the adjustable parameters.

This key is pressed to browse through the menu items. After selecting a menu

item, it is used to navigate through the sub-menu. For parameters, it helps you set

the parameter-value desired.

This key is pressed to select a menu item displayed, or to apply the value set for

a parameter.

This key is pressed to quit the current menu item or parameter without applying

the set value. By repeatedly pressing this button, you will return to displaying the

current total load in the car.

Attention:

The unit automatically returns to its home-position displaying the current total load in

the car, and will do that after one minute without any push of a button, regardless of

which menu-item had been selected beforehand.

After ten minutes without any push of a button it changes into the energy-saving

mode, i.e. the display goes off for being reactivated by the next push of a button.

©Copyright 2014 by Henning GmbH & Co. KG

Rev. 1.1 09/2014 5

5. How to Adjust a Parameter

1.) Press button to navigate through the parameters until the one to be

adjusted is displayed.

2.) Press button to select this parameter.

3.) Press button to navigate to the value desired for the currently flashing

digit. Press button to change to the next digit.

4.) After setting the last digit, press button again. After that the whole figure

will be flashing.

5.) Press button once more to apply the adjusted parameter.

©Copyright 2014 by Henning GmbH & Co. KG

Rev. 1.1 09/2014

6

6. Scheme of Menu

current total load

(4 digits in the menu-item selected)

calibrating of WeightWatcher Beam

(cali)

zero point adjustment

(tara)

state-changing thresholds of alarm-relays

(alar)

weight unit

(unit)

version number

(Program-Version)

©Copyright 2014 by Henning GmbH & Co. KG

Rev. 1.1 09/2014 7

7. How to Calibrate the Load Measuring

Leaving the pre-adjusted menu-item unchanged means that the loads

are to be entered in terms of percent of the nominal load, such as for example

100% for full load and 105% for overload.

Take the following steps to calibrate the WeightWatcher Beam

1. Mount the rope-sensor to the upper belt

2. Connect WeightWatcher Beam to a power supply ranging between 12V and

28V DC Calibrate the WeightWatcher Beam both under full load and zero-load

conditions

a. How to Calibrate Zero Load

Purpose of this function is to compensate the weight of the empty

cabin. Take the following steps:

i. By navigate to menu-item and select it by pressing

. Then navigate by to menu-item and select it

by pressing . The standard value (refer to ) is

(0% load, i.e. empty cabin). As soon as you will have adjusted

the last digit, the whole figure will be flashing.

ii. Apply it by pressing . After that a countdown will be running

from to . At the current weight of the car

will be measured. It goes without saying that at that moment

there must not be anything in the cabin or on the car roof that

does not belong there under normal operation conditions (tools!),

and that there must not stay any person in the cabin or on the

car roof in order not to warp the zero load parameter.

b. How to Adjust Full load

Take the following steps:

i. By navigate to menu-item and select it by pressing

. Then navigate by to menu-item and select it

by pressing . After that adjust on the display an arbitrary load

to be loaded into the cabin. Unless you changed the standard of

menu-item enter this load in terms of a percentage of the

nominal load, i.e. 100% (), if you are loading the nominal

load, or 75% () if you are going to load ¾ of the nominal

©Copyright 2014 by Henning GmbH & Co. KG

Rev. 1.1 09/2014

8

load only. As soon as you will have adjusted the last digit, the

whole figure will be flashing.

ii. Apply it by pressing . After that a countdown will be running

from to . At the current weight of the car

including load will be measured. It goes without saying that at

that moment there must not be anything additional in the cabin or

on the car that does not belong there under normal operation

conditions (tools!), and that there must not stay any person in the

cabin or on the car roof in order not to warp the full load

parameter.

iii. As from now on calibration of the rope-sensor is completed and

in effect.

8. Alarm Limits

Alarm limit: a designation that corresponds to the load limit in the cabin, which –if

exceeded –will change the state of the alarm relay. After changing the state of the

alarm-relay, the corresponding status-LED will be luminating.

AL-1 (freely programmable load)

Changes its state, if the load limit adjusted by parameter is exceeded.

AL-2 (freely programmable load)

Changes its state, if the load limit adjusted by parameter is exceeded.

How to Adjust the Alarm Limits:

1. By navigate to menu-item and then press .

2. Now –in the same manner –navigate to the alarm limit to be adjusted

(, ) and select it by pressing .

3. By navigate to the desired value of the currently flashing digit and select it

by pressing . This will at the same time make the next digit flash.

4. After having adjusted the last digit and accordingly pressed , the whole

figure will be flashing.

5. Press once more to apply the parameter.

6. You can quit this menu-item at any time by pressing .

©Copyright 2014 by Henning GmbH & Co. KG

Rev. 1.1 09/2014 9

Attention:

Unless you changed the standard setting of menu-item the alarm limits

are to be adjusted in terms of percentage, i.e. 100% for full load and 105% for

overload.

9. How to Adjust the Display

Menu-item offers two options. Weights and alarm limits will be displayed

according to the option you choose.

- (Percentage) Weights are all displayed in terms of percentage.

(preset standard)

Full load equals 100%

Empty cabin equals 0%

(Load) Weights are displayed in tons.

The function sets the gross weight to zero;

after that, only the net weight of the cabin shown.

10. Electric Characteristics

WeightWatcher Beam

Supply Voltage

12 V –28 V DC

Power Consumption

< 1 W at 12 V DC

Fuse

1 A mT

HOLD-Input

0,8 W

Relay outputs

2

max. switching voltage

250 V AC / 220 V DC

max. starting current

2 A

max. continuous load current

30 V DC 1 A

125 V AC 0,3 A

max. switching capacity

(resistive load)

62 VA

max. switching capacity

(inductive load)

62 VA

min. switching load DC

10 mV DC 0,01 mA

©Copyright 2014 by Henning GmbH & Co. KG

Rev. 1.1 09/2014

10

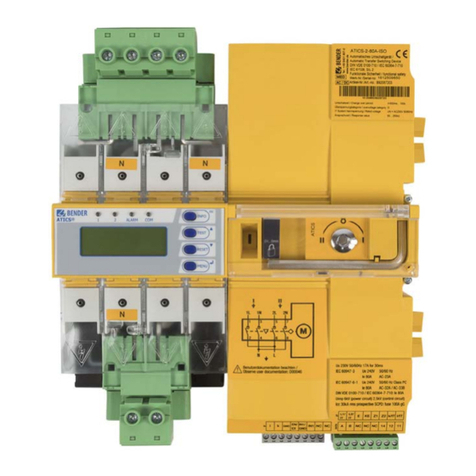

11. WeightWatcher Beam Installation

The sensor has to be mounted on the upper belt of the frame (see Fig. Sketch).

It is important to ensure that the

sensor has to be placed

centered on the upper U-profile.

The surfaces of the U-profile

must be smooth, so that

complete contact with the

sensor is guaranteed. The

sensor must not wobble or do

not tilt when tightening.

The ratchet fittings are to be

used! Unfortunately, standard

screws are unsuitable for this

installation.

In version 1, The sensor is to

be positioned so, that the

adjustable foot of the sensor

body is brought in line with the

outer edge of the cable plate,

and is fitted to the U-profile.

In version 2, The sensor body

can only be placed in front of

the plate. In this case, please

ensure that the cable always

runs away from the centre. This applies to both versions. This applies to both

versions. Pulleys are supplied.

The sensors are to be fitted at various distances (see table) to their respective

profiles. Two holes (minimum diameter - 11mm) must always be drilled at a distance

of 179 mm apart. This applies to all three WeightWatcher Beams.

Version 1

Version 2

©Copyright 2014 by Henning GmbH & Co. KG

Rev. 1.1 09/2014 13

12. Operation Instructions in Brief

1.) Install the unit at an appropriate place.

2.) Calibrate with empty cabin

By navigate to menu-item select sub-item and confirm by

. The preset standard (see ) is (0% cabin load, i.e. empty

cabin). After setting the last digit, the whole figure will be flashing until you

confirm it by pressing . After that a countdown will be running from

to . At the current weight of the cabin will be

measured. At that moment there mustn’t be anybody in the cabin or on the car

roof , in order not to warp the measurement. Furthermore make sure that you

didn’t leave any tools in the cabin or on the car roof, nor any other things that

don’t belong there during normal operation.

3.) Calibrate with loaded cabin (nominal load)

By navigate to menu-item select sub-item and confirm by

. Now you can adjust on the display an arbitrary load that you will load into

the cabin. Unless you changed the preset menu-item , you will have to

enter the load in terms of percentage, i.e. 100% (), if you load the

nominal load, or 75% (), if you load ¾ of the nominal load for example.

After setting the last digit, the whole figure will be flashing until you confirm it by

pressing . After that a countdown will be running from to . At

the current weight of the cabin (including load!!) will be measured. At

that moment there mustn’t be anybody in the cabin or on the car roof , in order

not to warp the measurement. Furthermore make sure that you didn’t leave any

tools in the cabin or on the car roof, nor any other things that don’t belong there

during normal operation, except the load for calibration.

4.) Adjust the alarm limits (see item 10)

By navigate to the alarm limit and confirm by . Scroll by to the

value desired, then press to adjust the state-changing limit. Press 2

times to confirm the adjustment.

5.) Connect the control lines to the lift controller and make sure that you

accordingly choose the make- resp. break-contact.

©Copyright 2014 by Henning GmbH & Co. KG

Rev. 1.1 09/2014

14

Table of contents

Other HENNING Measuring Instrument manuals