HER CHEE ATV-320 U User manual

SERVICE MANUAL

ATV-320 S/U

2002/24

JUNE 30, 2007

High Power Liquid Cooled Engine

HER CHEE INDUSTRIAL CO., LTD.

F-2

Foreword

This service manual contains information on servicing ATV-320(S/U)

This manual is written for use as a guideline only. It is recommended that any

mechanic, with or without sufficient experience, thoroughly read through the manual

and only attempt to service those areas that are fully understood in accordance with

the guidelines provided by this manual. For fully qualified mechanics, this manual

supplies service data necessary for repairs and maintenance. It is highly

recommended that a qualified mechanic, regardless of technical level, should study

the service manual in full before attempting service on ATV-320

All the data and diagrams provided in this service manual are valid at the time of

publication. Information may be updated without notice due to improvements or

upgrades.

No quotation, reproduction, or reprint of the service manual, as a whole or in part, will

be permitted without the express written consent from ADLY Motor sports.

F-3

CONTENTS

General Information & Lubrication

General Information --------------------------------------- F-4

Information for Preparation ------------------------------ F-5

Lubrication --------------------------------------------------- F-7

Chapter 1 Engine, Transmission & Gear

Engine Removal & Installation ------------------------- I-2

Cylinder Head & Valve ----------------------------------- I-5

Cylinder & Piston ------------------------------------------ I-20

Crankcase & Crankshaft --------------------------------- I-27

Cooling System -------------------------------------------- I-33

Transmission & Gear ------------------------------------- I-38

Chapter 2 Fuel System & Carburetion

Carburetor -------------------------------------------------- II-3

Fuel Tank ---------------------------------------------------- II-7

Air Cleaner -------------------------------------------------- II-10

Exhaust System -------------------------------------------- II-12

Chapter 3 Ignition and Starting System

Ignition System ---------------------------------------------- III-1

Starting System --------------------------------------------- III-4

Recoil Backup Starting System ------------------------- III-7

Chapter 4 Frame & Cover

Frame & Cover --------------------------------------------- IV-2

Chapter 5 Wheel, Tyres & Brakes -----------------------------------

Handlebar & Steering ------------------------------------- V-2

Front & Rear Wheel --------------------------------------- V-6

Suspension System --------------------------------------- V-9

Hydraulic Brake -------------------------------------------- V-14

Chapter 6 Electrical Equipment

Alternator & Starter Gear--------------------------------- VI-2

Electrical Equipment ------------------------------------- VI-10

Wire Diagram ---------------------------------------------- VI-13

F-4

General Information

MODEL IDENTIFICATION

The frame serial number is stamped on the

lower front right side of frame.

The VIN (Vehicle Identification Number) is

attached to the lower front right side of frame

behind the frame number.

The engine serial number is stamped on the

upper rear right crankcase.

The carburetor identification number is

stamped on the right side of the carburetor.

VIN No.

Frame No. Engine No.

Carburetor Identification No.

F-5

Information for Preparation

ATTENTION ON OPERATION

zAll washers, oil rings, clamp rings, opening pins shall be duly replaced by a new item when

dismounted.

zLocking of all screws, nuts, cross screws shall be performed in the order of first the large screws

and then the small ones and from inside to outside in opposite angles by tightening the torque

locks.

zAll items must use original parts, pure oil and greases.

zAll service shall use special tools and general tools to repair.

zAll dismounted items requiring for checks shall be duly cleaned and for assembly, all items shall be

duly lubricated.

F-6

Information for Preparation

ATTENTION ON OPERATION

zCertified lubricants in cans shall be used on all the elements to be lubricated.

zAfter assembly, performance of all elements shall be duly checked and the locking shall be duly

verified.

zIn case of an operation is performed by over 2 people, the assignment shall be conducted in

coordination and safety shall be the first priority.

zDefinition of signs:

The sign given in the Service Manual shall refer to the operation methods and observation.

OIL: Lubrication by designated lubricant.

GREASE: Lubrication by grease

Special Tool: Parts on which special tools shall be used

General Tool: General tools shall be used

New: Replace by new items after dismounting

Attention

Dangerous and important operations

F-7

Lubrication

GENERAL

The maintenance of the oil pump and engine oil can be done with the engine install in the frame.

When removing and install the oil pump, use care not to allow dust or dirt to enter the engine and oil

line.

SPECIFICATION

ITEM STANDARD mm (in) SERVICE LIMT mm (in)

Rotor tip clearance 0.15 (0.006) 0.20 (0.008)

Body clearance 0.15-0.20 (0.006-0.008) 0.25 (0.010)

Oil pump

Rotor end clearance 0.04-0.09 (0.002-0.004) 0.12 (0.005)

TORQUE VALUES

Oil drain plug 20-25 N.m (15-18 ft-lb)

Oil filter screen cap 18-22 N.m (13-16 ft-lb)

Transmission oil check bolt 10-15 N.m (7-11 ft-lb)

Transmission oil drain bolt 10-15 N.m (7-11 ft-lb)

Troubleshooting

Oil level too low

◦External oil leaks

◦Worn valve guide or seal

◦Worn piston rings

Oil contamination

◦Oil not changed often enough

◦Head gasket faulty

◦worn piston rings

Low oil pressure

◦Oil level too low

◦Clogged oil filter, oil passage, and or oil pipe

◦Faulty oil pump

F-8

Engine Oil

OIL LEVEL

Warm up the engine.

Stop the engine and park the vehicle on level

ground.

Check the oil level through the oil window.

If the level is near the lower of the window, fill to

the middle level with the recommended engine oil.

OIL CHANGE

NOTE

◦Drain the oil from the crankcase while the engine

is warm.

This ensures complete and rapid draining.

Place the oil pan under the engine.

Remove the oil filler cap and oil drain plug and

drain the engine oil.

Remove the oil filter screen cap, spring and filter

screen, and clean the filter screen.

After the oil has been completely drained, be sure

the O-ring on the filter screen cap is in good

condition and install the filter screen with the

closed end facing out.

Install the spring and cap.

Torque: 18-22 N.m (13-16ft-lb)

Make sure that the sealing washer is in good

condition, install the drain plug and tighten it.

Torque: 20-25 N.m (15-18 ft-lb)

Fill the engine with recommended engine oil

through the oil filler hole.

ENGINE OIL CAPACITY:

0.8 Liter (0.85 US qt.) at change

Reinstall the oil filler cap and start the engine and

let it idle for a few minutes.

Recheck the oil level.

Check that there are no oil leaks.

Min. Level

Filter Screen

Oil Filler Cap

F-9

Oil Pump

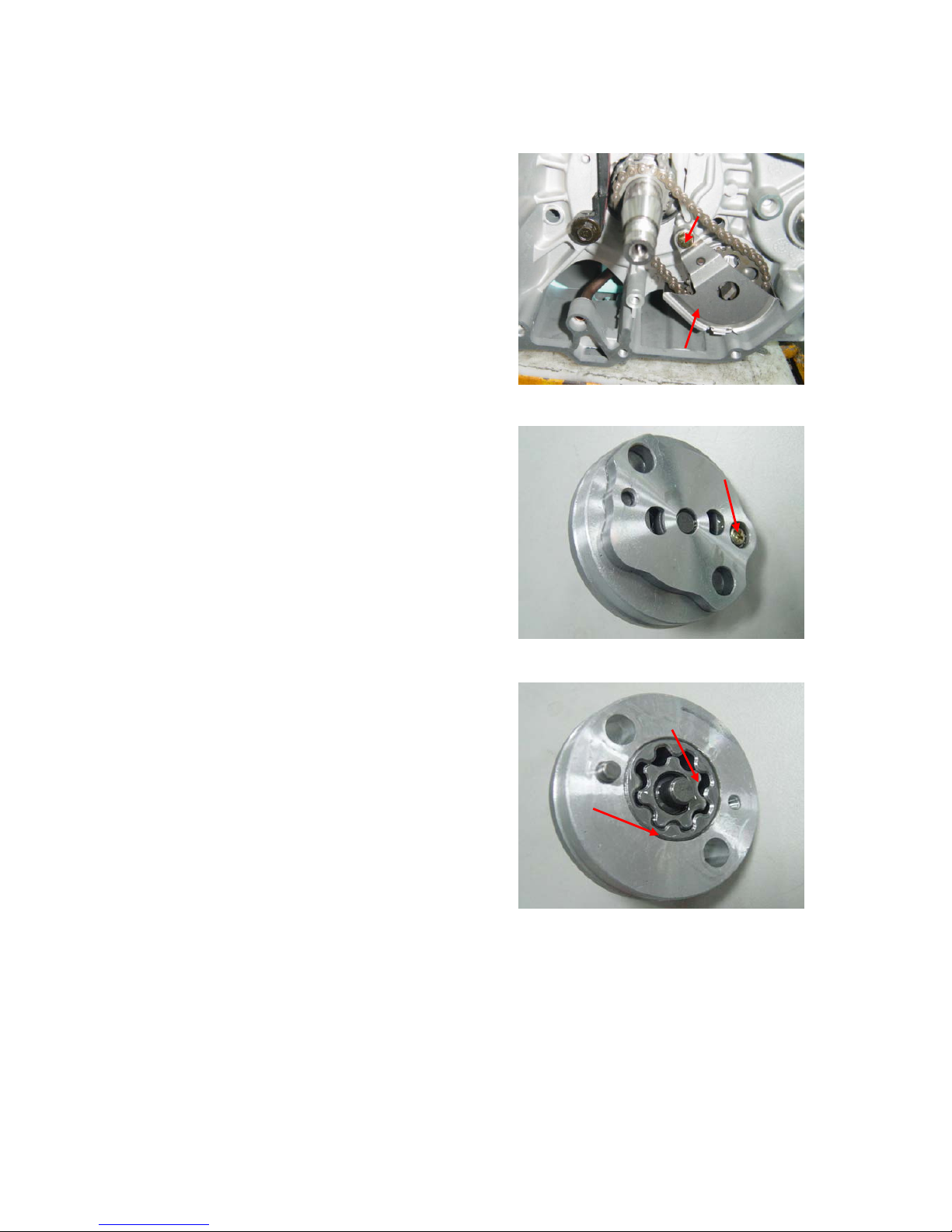

OIL PUMP REMOVAL

Remove the right crankcase cover.

Remove the flywheel and starter idle and driven

gears.

Remove the attaching bolt and oil separator cover.

Remove the circlip, then remove the oil pump

drive chain and driven sprocket.

Remove the two oil pump mounting bolts and

remove the oil separator and oil pump.

OIL PUMP DISASSEMBLY

Unscrew the pump cover attaching screw and

disassemble the oil pump.

OIL PUMP INSPECTION

Measure the pump body-to-outer rotor clearance.

Service Limit: 0.25 mm (0.010 in)

Measure the outer rotor-to inner rotor tip

clearance.

Service Limit: 0.20 mm (0.008 in)

Check the rotor-to pump body clearance.

Service Limit: 0.12 mm (0.005 in)

OIL PUMP ASSEMBLY

Install the outer and inner rotor into the pump

body.

Insert the pump shaft by aligning the flats of the

shaft and inner rotor.

Install the dowel pin.

Install the pump cover by aligning the hole of the

cover with the dowel pin.

Tighten the screw.

Make sure that the pump shaft rotates freely

without binding.

Bolt

Oil Separator Cover

Attaching Screw

Max. 0.25mm

Max. 0.20mm

Chapter 1 Engine, Transmission & Gear

I-1

Contents

Engine Removal & Installation

Cylinder Head & Valve

Cylinder & Piston

Crankcase&Crankshaft

Cooling System

Transmission&Gear

GENERAL SAFETY

WARNING

If the engine must be running to do some work, make sure the area is well-ventilated. Never run

the engine in a closed area. The exhaust contains carbon monoxide gas that may cause loss of

consciousness and lead to death.

WARNING

Gasoline is extremely flammable and is explosive under certain condition. Do not smoke or allow

flames or sparks in your working area.

WARNING

The battery electrolyte contains sulfuric acid. Protect your eyes, skin and clothing. In case of

contact, flush thoroughly with water and call a doctor if electrolyte gets in your eyes.

WARNING

The battery generates hydrogen gas which can be highly explosive. Do not smoke or allow flames

or sparks near the battery, especially while charging it.

SERVICE RULES

1. Use genuine ADLY or ADLY-recommended parts and lubricants or the equivalents. Parts that

do not meet ADLYs’ design specifications may damage the vehicle.

2. Use the special tools designed for this product.

3. Use only metric tools when service the vehicle. Metric bolts, nuts and screws are not

interchangeable with English fasteners. The use of incorrect tools and fasteners may

damage the vehicle.

4. Install new gaskets, O-ring, cotter pin, lock plates, etc. when reassembling.

5. When tightening a series of bolts or nuts, begin with large-diameter or inner bolts first and

tighten to the specified torque diagonally, unless a particular sequence is specified.

6. Clean parts in clean solvent upon disassembly. Lubricate any sliding surfaces before

reassembly.

7. After reassembly, check all parts for proper installation and operation.

Chapter 1 Engine, Transmission & Gear

I-2

Engine Removal/Installation

GENERAL

A floor jack or other adjustable support is required to support and maneuver the engine.

SPECIFICATION

Engine dry weight 32 kg (72 lb)

Oil capacity Engine 1.0 liter (1.06 US qt.) at disassembly

0.8 liter (0.85 US qt.) at change

Transmission 0.6 liter (0.74 US qt.) at disassembly

0.5 liter (0.63 US qt.) at change

Coolant capacity Engine and radiator 1.1 liter (1.16 US qt.)

Reserve tank 0.3 liter (0.31 US qt.)

Total 1.4 liter (1.47 US qt.)

TORQUE VALUES

Engine upper hanger plate 18 – 24 N.m (13 – 16 ft.lb)

Engine mounting nut 40 – 55 N.m (29 – 40 ft.lb)

Step bar rear bolt 40 – 55 N.m (29 – 40 ft.lb)

Step bar front bolt 18 – 24 N.m (13 – 16 ft.lb)

Chain cover bolt 10 – 14 N.m (7 – 10 ft.lb)

Chapter 1 Engine, Transmission & Gear

I-3

Engine Removal & Installation

ENGINE REMOVAL

Park the vehicle on the level ground and

pull parking lever to park the vehicle.

Disconnect the battery ground (-) cable.

Remove left and right floor panel and step bar.

Remove foot brake pedal.

Remove front chain cover then disconnect drive

chain.

Disconnect gear selection rod then remove

muffler ass’y.

Disconnect coolant hose.

Disconnect spark plug and generator wire

connector and coupler

Disconnect blow-by tube at cylinder head cover

and crankcase.

Disconnect carburetor on intake manifold and

vacuum tube.

The engine is held in the frame by three point,

two at bottom an on at rear upper.

Loosen the all nuts on fixing studs and move all

studs.

Remove the front engine bracket.

Slightly raise the engine and pull it toward front

frame then pull out the engine thru right side.

Front engine bracket

Chapter 1 Engine, Transmission & Gear

I-4

ENGINE INSTALLATION

Move the engine into the frame

Insert the front engine bracket to correct position

then insert the bolts.

Insert all other engine mounting bolts and tighten

the nuts by following steps.

A. Rear lower engine mount

Torque value: 40 – 55 N.m (29 – 40 ft.lb)

B. Front engine mount

C. Front engine bracket

Torque value: 40 – 55 N.m (29 – 40 ft.lb)

D. Rear upper hanger plate

Torque value: 18 – 24 N.m (13 – 16 ft.lb)

E. Rear engine mount.

Torque value: 40 – 55 N.m (29 – 40 ft.lb)

Install the removed parts in the reverse order of

removal.

Refill coolant to specified volume and connect

battery terminals.

NOTE

◦Checked all connect points and oil level before

restarttheengine.

D

D

E

A

B

C

Chapter 1 Engine, Transmission & Gear

I-5

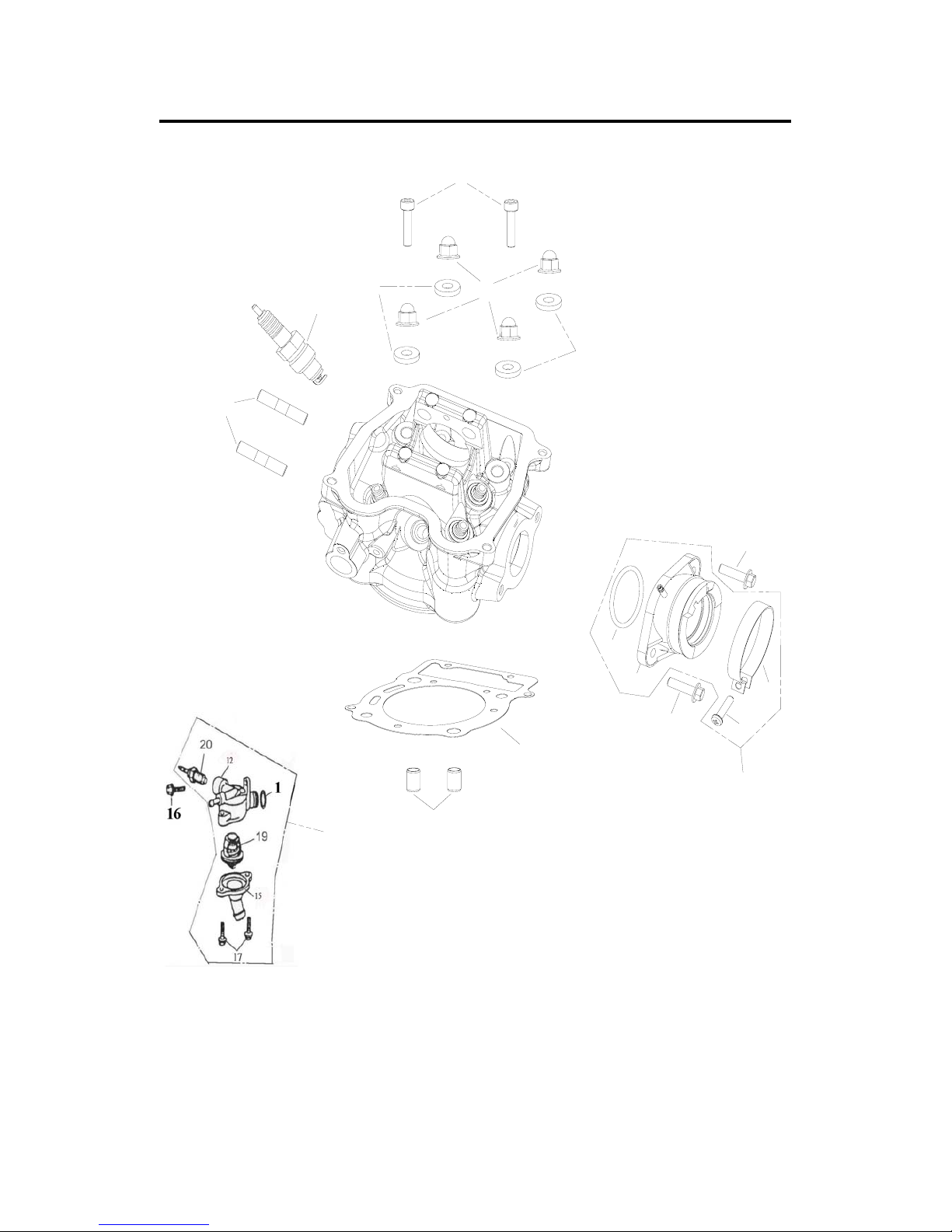

Cylinder Head Cover

1

5

2

3

7

6

4

8

11

10 95

5

5

9

Chapter 1 Engine, Transmission & Gear

I-6

Cylinder Head

2

3

4

4

5

6

7

8

9

11

10

12

12

13

14

18

Chapter 1 Engine, Transmission & Gear

I-7

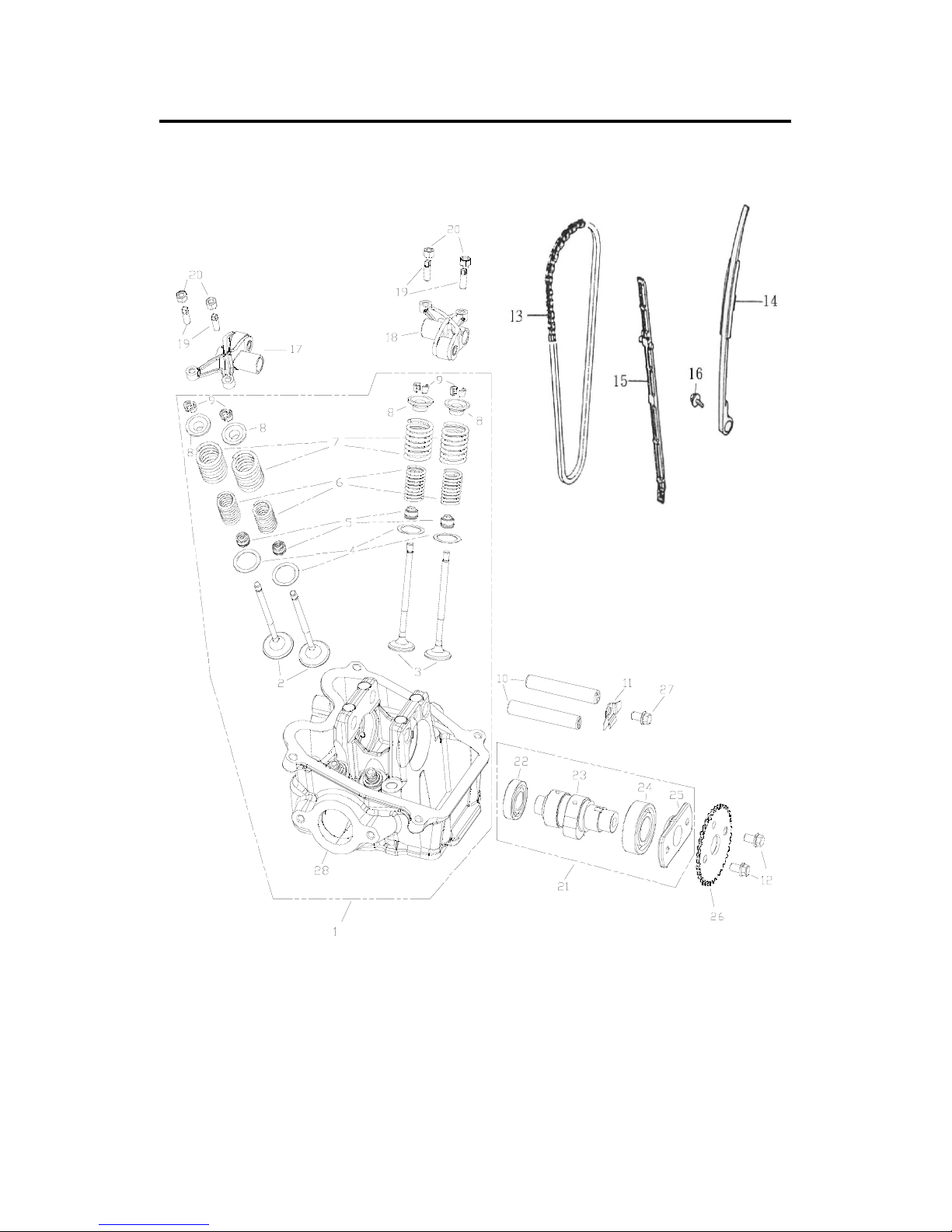

Camshaft / Valve / Cam

Chapter 1 Engine, Transmission & Gear

I-8

Cylinder Head/Valves Service Information

GENERAL

This section covers maintenance of the cylinder head, valves, camshaft and rocker arms.

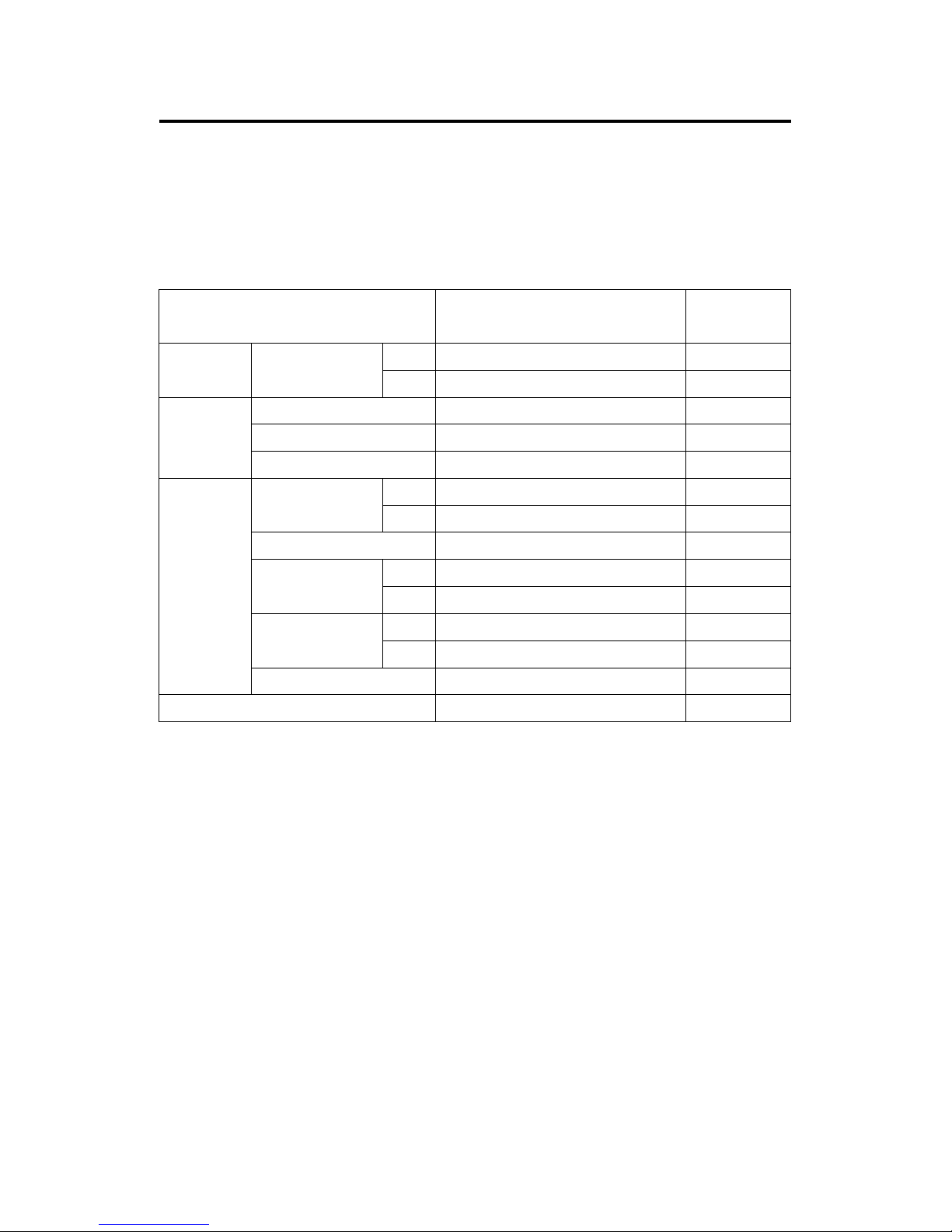

SPECIFICATION

Item Standard mm (in) Service Limit

mm (in)

IN 34.590-34.34.700 (1.3618-1.3661) 34.54 (1.3598)

Camshaft Cam height

EX 34.460-34.680 (1.3567-1.3654) 34.41(1.3547)

Rocker arm I.D. 11.000-11.018 (0.4330-0.4337) 11.10 (0.4370)

Shaft O.D. 10.966-10.984 (0.4318-0.4324) 10.91 (0.4295)

Rocker arm

Roller O.D. 17.00 (0.6693) 16.95 (0.6673)

IN 4.975-4.970 (0.1959-0.1965) 4.90 (0.193)

Valve stem

EX 4.955-4.970 (0.1951-0.1957) 4.90 (0.193)

Valve guide I.D. 5.00-5.012 (0.1969-0.1973) 5.03 (0.198)

IN 0.010-0.037 (0.0004-0.0015) 0.08 (0.003)Stem-to-guide

clearance EX 0.030-0.057 (0.0012-0.0022) 0.10 (0.004)

Inner 28.7 (1.13) 27.5 (1.08)Valve spring free

length Outer 32.0 (1.26) 30.4 (1.20)

Valve

Valve seat width 1.1 (0.04) 1.8 (0.07)

Cylinder head warpage - 0.05 (0.002)

TORQUE VALUES

Cylinder head cover screw 3.5-5.0 N.m (2.5-3.6ft.lb) Apply a locking agent

Cylinder cover bolt 8-12 N.m (6-9 ft.lb)

Cylinder head cap nut 22-28 N.m (16-19 ft.lb)

Camshaft holder bolt 8-12 N.m (6-9 ft.lb)

Cam chain tensioner sealing bolt 8-12 N.m (6-9 ft.lb)

Oil pipe bolt: 8 mm 8-12 N.m (6-9 ft.lb)

Exhaust pipe stud bolt 7-11 N.m (5-8 ft.lb)

Spark plug 15-20 N.m (11-15 ft.lb)

Chapter 1 Engine, Transmission & Gear

I-9

Troubleshooting

Engine top problems usually affect engine performance. These can be diagnosed by a

compression test, or by tracing noises with a sounding rod or stethoscope.

Low Compression

◦Valves

—Incorrect valve adjustment

—Burned or bent valves

—Incorrect valve timing

—Broken valve spring

◦Cylinder head

— Leaking or damaged head gasket

—Warped or cracked cylinder head

◦Cylinder and piston

Compression Too High

◦Excessive carbon build-up on piston or combustion chamber

Excessive Noise

◦Incorrect valve adjustment

◦Sticking valve or broken valve spring

◦Damaged or worn camshaft

◦Loose or worn cam chain

◦Worn or damaged cam chain tensioner

◦Worn cam sprocket teeth

◦Worn rocker arm and/or shaft

Chapter 1 Engine, Transmission & Gear

I-10

Cylinder Head Cover

CYLINDER HEAD COVER REMOVAL

Remove blow-by hose on cylinder head cover.

Remove four cylinder head cover bolts.

Camshaft

CAMSHAFT REMOVAL

Remove the cam chain adjuster sealing bolt and

spring.

Remove the two cam sprocket holder bolts.

NOTE

。Be careful not to drop the bolts into the

crankcase

Derail the cam chain from the cam sprocket teeth

and remove the cam sprocket.

NOTE

。Suspend the cam chain with a piece of wire to

keep it from falling to the crankcase.

Remove rocker arm/cam shaft bearing holder

plate mounting bolt and holder plate.

Remove rocker arm shaft by using a M6 bolt

screw in shaft then pull out the shaft.

Remove rocker arm.

Remove the cam shaft from cylinder head.

CAMSHAFT INSPECTION

Check each cam lobe for wear or damage.

Measure the intake and exhaust cam lobe

height.

Service Limit: 34.54 mm (1.3598 in)

Turn the outer race of each camshaft bearing

with your finger.

The bearing should turn smoothly and quietly.

Replace the camshaft assembly if the races do

not turn smoothly or quietly.

Holder plate

Holder bolt

Holder bolt

Intake lobe

Exhaust lobe

Blow-by tube

Head cover bolts

Chapter 1 Engine, Transmission & Gear

I-11

Rocker Arm

ROCKER ARM REMOVAL

Remove rocker arm/cam shaft bearing holder

plate mounting bolt and holder plate.

Remove rocker arm shaft by using a M6 bolt

screw in shaft then pull out the shaft.

Remove rocker arm.

ROCKER ARM INSPECTION

Measure the rocker arm shaft O.D.

Service Limit: 16.96 mm (0.6677 in)

Measure the rocker arm bore I.D.

Service Limit: 17.04 mm (0.6709 in)

Turn the outer race of each rocker arm roller with

your finger.

The roller should turn smoothly and quietly.

Replace the rocker arm assembly if the races do

not turn smoothly or quietly.

Measure the rocker arm roller O.D.

Service Limit: 16.95 mm (0.6673 in)

17.04mm

16.96mm

Roller

This manual suits for next models

2

Table of contents

Other HER CHEE Offroad Vehicle manuals