HER CHEE SS-50 User manual

SERVICE MANUAL

SS-50/100

March, 2008

High Power Engine

HER CHEE INDUSTRIAL CO., LTD.

Preface

The Service Manual in reference is provided as the technical information for

checking and preparation of ADLY SS-50/100 scooter and the edit description is

given in diagrams with " Operation Sequence ", " Highlights " and " Checking

Arrangement " for reference of the service staffs.

The information, illustrations or contents included in this manual may be

different with the actual scooter in case specifications are changed. Your

understanding will be appreciated.

HER CHEE INDUSTRIAL CO., LTD.

I N D E X

Information of preparation 1

CheckandAdjust 2

Engine-

InstallationofLubricant

3

FuelInstallation 4

Engine dismounting/disassembling 5

Cylinder head, Cylinder and Piston 6

Starter / Driving Disc / Clutch / Transmission 7

FinalTransmissionMechanism 8

Crankcase, Crankshaft and Transmission box 9

Chassis-

Frontwheel,Brake,Suspension 10

Rear heel, Brake, Suspension

11

Electricaldevices 12

Wiringdiagram 13

ADLY MOTO 1-1

INFORMATION FOR PREPARATION

Attention on Operation

zAll washers, oil rings, clamp rings, opening pins shall be duly replaced by a new item

when dismounted.

zLocking of all screws, nuts, cross screws shall be performed in the order of first the large

screws and then the small ones and from inside to outside in opposite angles by tightening

the torque locks.

zAll items must use original parts, pure oil and greases.

zAll service shall use special tools and general tools to repair.

zAll dismounted items requiring for checks shall be duly cleaned and for assembly, all

items shall be duly lubricated.

ADLY MOTO 1-2

INFORMATION FOR PREPARATION

Attention on Operation

zCertified lubricants in cans shall be used on all the elements to be lubricated.

zAfter assembly, performance of all elements shall be duly checked and the locking shall

be duly verified.

zIn case of an operation is performed by over 2 people, the assignment shall be conducted

in coordination and safety shall be the first priority.

zDefinition of signs:

The sign given in the Service Manual shall refer to the operation methods and observation.

OIL: Lubrication by designated lubricant.

GREASE:Lubrication by grease

Special Tool: Parts on which special tools shall be used

General Tool: General tools shall be used

New: Replace by new items after dismounting

Attention

Dangerous and important operations

ADLY MOTO 1-3

INFORMATION FOR PREPARATION

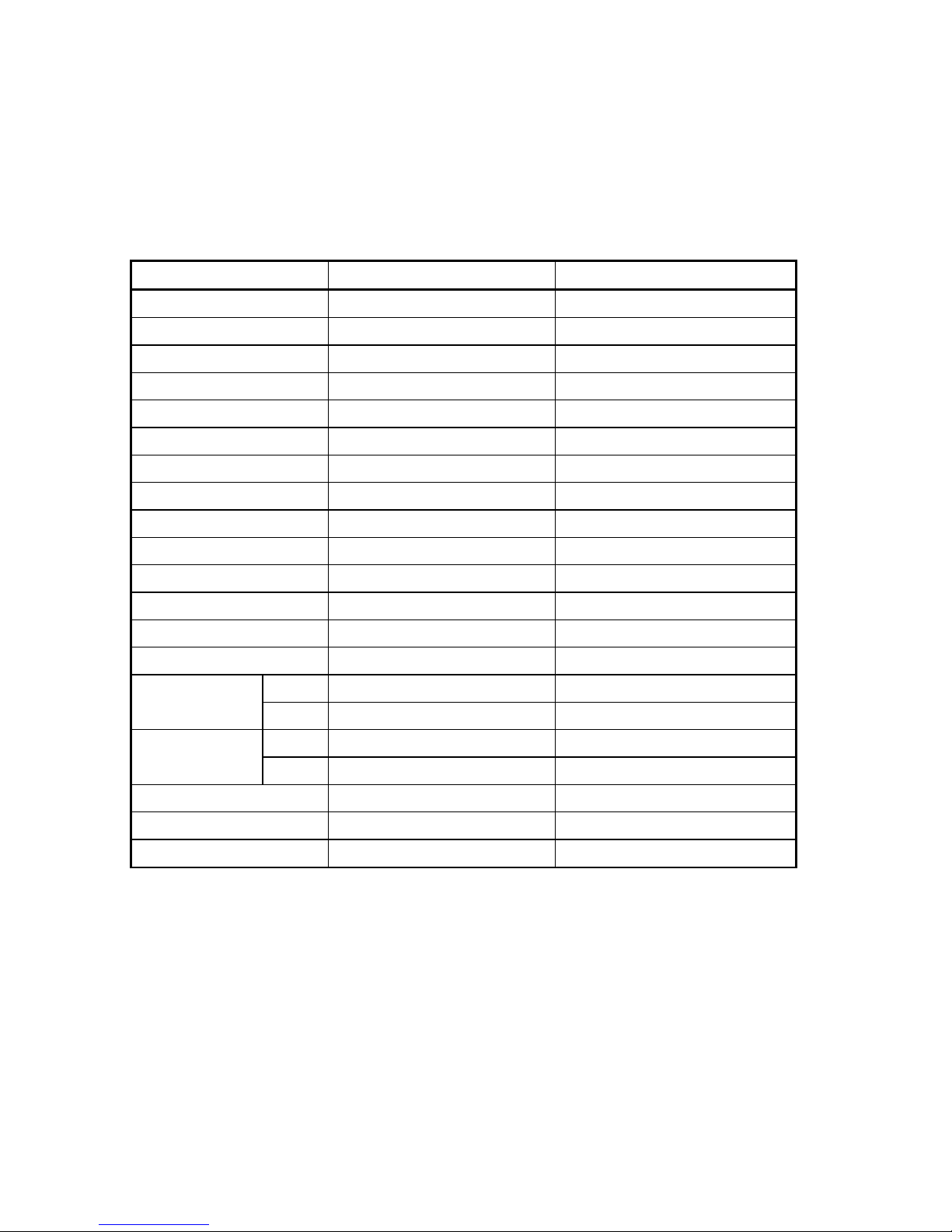

SPECIFICATION

TYPE SS-50Ⅰ/Ⅱ SS-100Ⅰ/Ⅱ

LENGTH 1780 mm 1780 mm

WIDTH 675 mm 675 mm

HEIGHT 1160 mm 1160 mm

WHEEL BASE 1250 mm 1250 mm

NET WEIGHT 75 kg 75 kg

ENGINE TYPE 4-STROKE, Single Cylinder 4-STROKE, Single Cylinder

COOLING AIR COOLED AIR COOLED

DISPLACEMENT 49.26 C.C. 95.57 C.C.

BORE×STROKE 40.0×39.2 52×45

COMPRESSION RATIO 7.2:1 5.8:1

IGNITION C.D.I C.D.I

STARTER ELECTRIC / KICK ELECTRIC / KICK

SUSPENSION Hydraulic Shock Absorber Hydraulic Shock Absorber

TRANSMISSION AUTOMATIC AUTOMATIC

SS (Ⅰ) 120/70-12 (Front & Rear) 120/70-12 (Front & Rear)

TIRE

FRONT/REAR SS (Ⅱ) 120/70-12 120/70-12

SS (Ⅰ) Disc Disc

FRONT BRAKE SS (Ⅱ) Double Disc Double Disc

REAR BRAKE Drum Drum

MAX. POWER 2.8Kw / 5500 rpm 5.26kw / 7000 rpm

MAX. TORQUE 4.75N-m / 5500 rpm 7.4N-m / 6500rpm

ADLY MOTO 1-4

INFORMATION FOR PREPARATION

LOCKING TORQUE

Adopt the standard torque locking for the item unlisted.

STANDARD TORQUE:

Type Locking Torque (kg-m)

5 mm Screw 0.4

6 mm Screw 1.0

6 mm Hex Washer Face Bolt / Nut 1.2

8 mm Hex Washer Face Bolt / Nut 2.7

10 mm Hex Washer Face Bolt / Nut 4.0

CHASSIS:

Locking Place Quantity Dia. (mm) Locking Torque (kg-m)

Spanner Nut of Handle Steering Steam 1 25 7.0

Front Wheel Axle Nut 1 10 4.5

Rear Axle Nut 1 14 11

Rear Brake Arm Screw 1 5 0.6

Upper Screw of Rear Shock Absorber 1 10 4.0

Lower Screw of Rear Shock Absorber 1 8 2.7

Engine Mounting Bracket 1 8 6.0

ENGINE:

Locking Place Quantity Dia. (mm) Locking Torque (kg-m)

Screw of Cylinder Cap 4 6 1.0

Flywheel Nut 1 10 3.8

Clutch Jacket Nut 1 11 3.8

Driving Disc Nut 1 28 5.5

Nut of Transmission Disc 1 10 3.8

Oil-check Screw 1 8 1.3

Joint Screw of Exhaust Manifold 2 6 1.2

Exhaust Pipe Support Screw of Muffler 2 6 1.2

Spark Plug 1 14 1.4

Bolt of Crank Shaft Case 6 6 10

Bolt of Engine Installation 1 8 5.0

ADLY MOTO 1-5

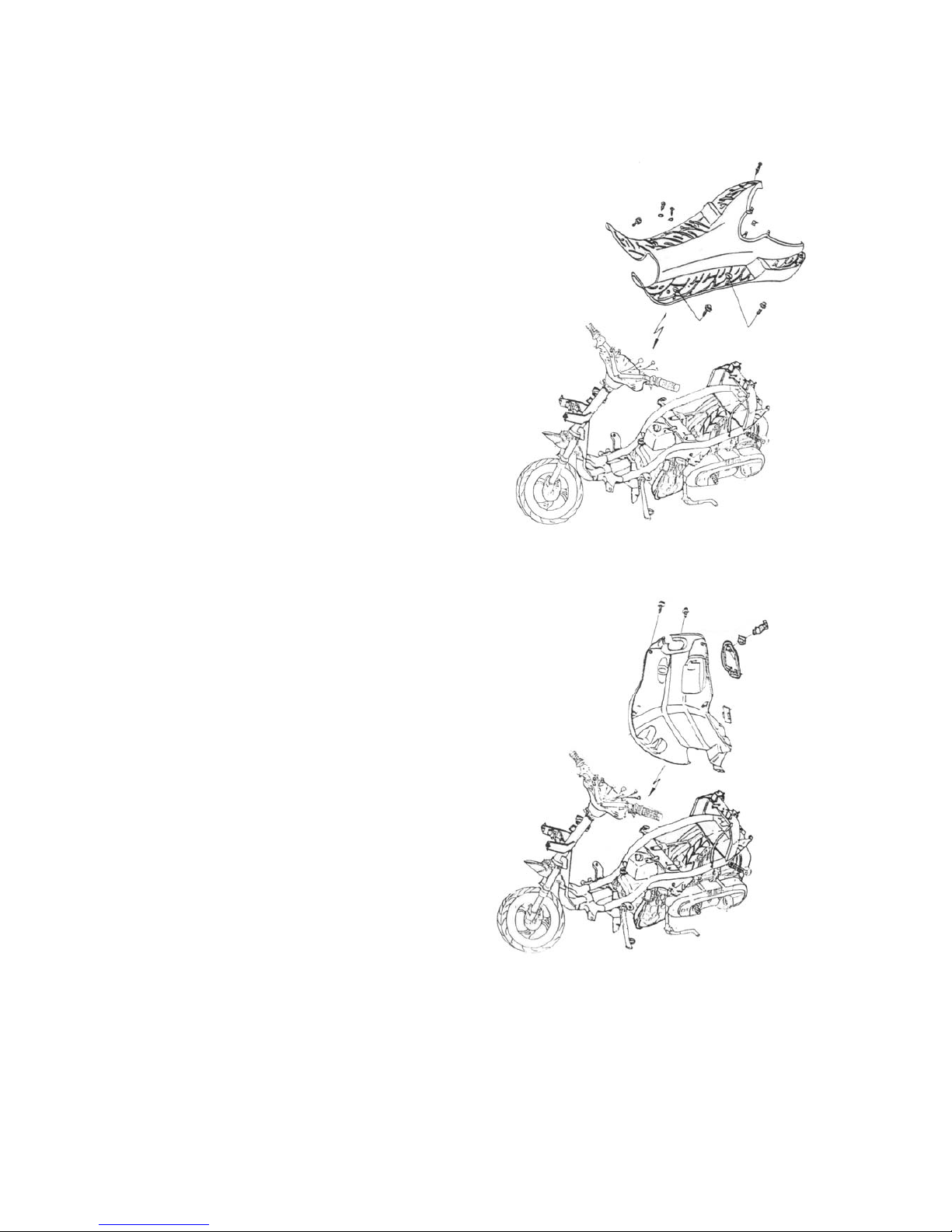

INFORMATION FOR PREPARATION

The following drawing that shows the disassembling situation of the cover parts

for SS50/100 scuuter.

ADLY MOTO 1-7

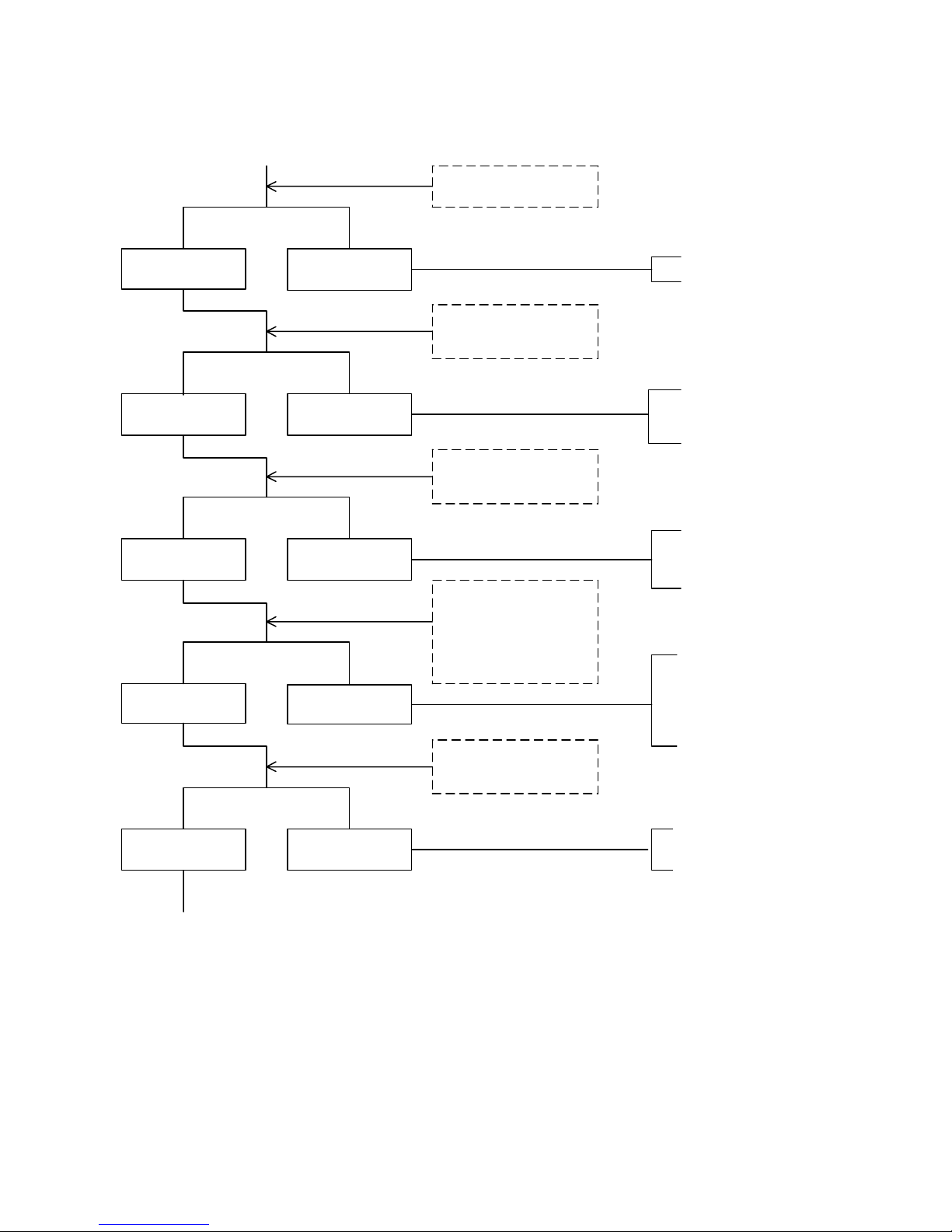

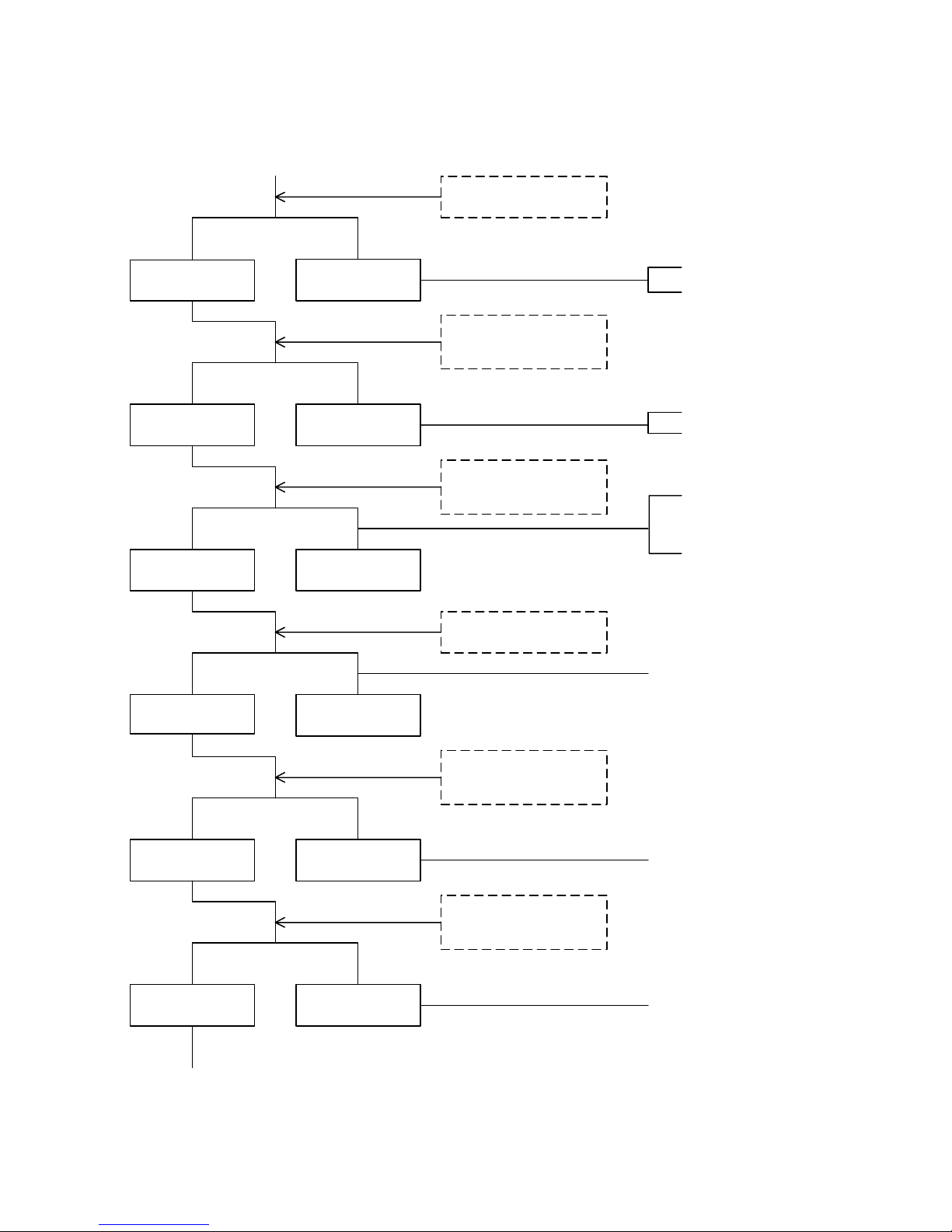

fuel supply to

carburetor is

sufficient

no fuel supply to

carburetor

loose the fuel release

screw of caruretor and

check if the fuel is inside

of carburetor ?

sparking no sparking or

weak

compression

pressure

is normal

compression

pressure too low

or no pressure

engine can not

ignite engine can ignite

but can not start

spark plug is dry spark plug is wet

loosen the spark plug,

connect with the spark

cap and contact with the

frame, check the spark

plug sparking ?

test the compression

pressure

follow the standard

stat-up procedure and

test again

loosen the spark plug

and test

Diagnose

Check and Adjuster Reason of Trouble

fuel tank without gasoline

tubing to carburetor blocking

float chamber tubing of carburetor blocking

fuel filter blocking

fuel cup blocking

air hole of fuel tank blocking

spark plug grimy or damage

C.D.I damage

main switch damage

ACG fulser coil damage

high tension coil damage or no gap

ACG lighting coil damage

valve set damage

cylinder, piston, piston ring damage

cylinder gasket leakage

valve burn

valve timing is not correct

valve gap is too tight or no gap

start clutch damage

ignite timing is not correct

fuel adjuste screw of carburetor isn't correct

intake manifold sucking air

auto. plunger starter is damage

fuel level of carburetor is too high

auto. plunger starter is damage

throttle open angle is too wide

DIFFICULT START OR CANN'T START

continue

INFORMATION FOR PERPARATIO

N

ADLY MOTO 1-8

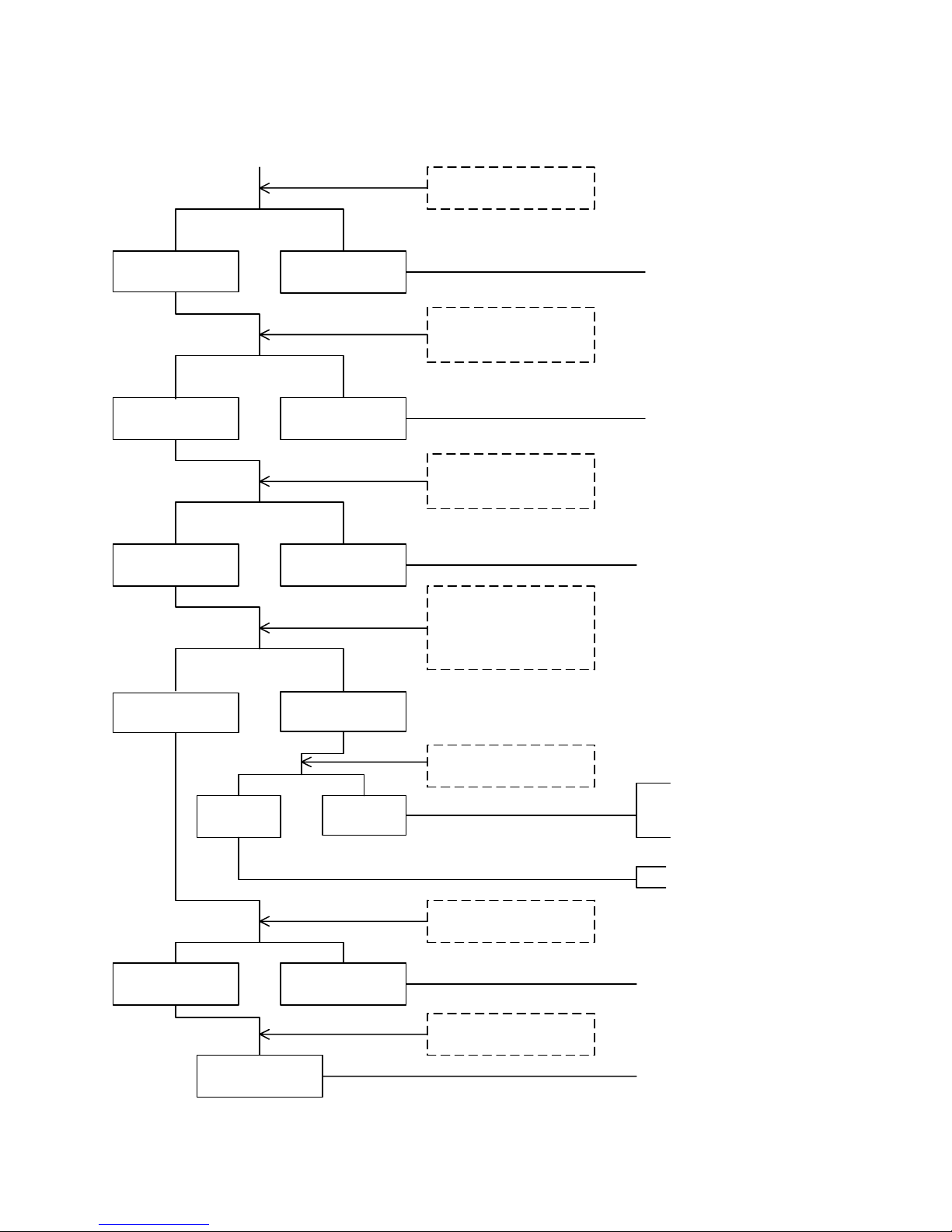

engine speed go up engine speed can't

go up fully

ignite timing is

correct ignite timing isn't

correct

valve gap is correct valve gap

isn't correct

compression pressure

is normal

compression

pressure

is too low

no blocking blocking

spark plug normal spark plug stain

oil quantity

is normal oil quantity is

too rich

normal abnormal

normal over heat

no knocking knocking

INFORMATION FOR PREPARATION

REVOLUTION NOT SMOOTH , LOST POWER

Diagnose

start engine and

go up speed slight

adjusting ignite

timing

adjusting valve gap

is not correct

testing compression

pressure

check carburetor

blocking ?

loosen spark plug

and check

check the oil

quantiity of

crankcase is too

rich or dirty?

check cylinder head

lubricating ?

engine over heat

increase engine

speed or continue

turning at high

speed

Check and Adjust

air cleaner blocking

fuel supply isn't smooth

air hole of air tank blocking

exhaust pipe blocking

auto.plunger starter damage

film of carburetor damage

fuel cup damage

C.D.I damage

pulser coil damage

valve gap adjusting isn't correct

valve set over abrade

valve set damage

cylinder, piston abrade

cylinder gasket leakage

valve timing isn't correct

cleaning carburetor

cleaning the stain

spark plug type isn't correct

oil flowing is too rich

oil flowing is too lean

oil doesn't circulate

oil tubing blocking

oil supply is too lean

cylinder, piston abrade

mixutre gases is too lean

carbon residue in combustion chamber

is too more

igniting time is too earily

fuel isn't good

clutch sliding

mixutre gases is too lean

carbon residue in combustion chamber

is too more

igniting time is too earily

fuel isn't good

Reason of Trouble

continue

ADLY MOTO 1-9

normal abnormal

INFORMATION FOR PREPARATION

REVOLUTION NOT STABLE (LOW R.P.M.)

Diagnose Check and Adjust

adjusting is correct adjusting isn't

correct

no sucking air sucking air

sparking normal sparking abnormal

normal abnormal

ignition timing adjusting

adjust the carburetor fuel

adjuste screw

carburetor sucking air

loosen spark plug,

connecct with spark cap

and contract with frame,

check the spark plug

sparking ?

check A.C.G

end

Reason of Trouble

C.D.I damage

pulser coil damage

mixture gases too lean

(loosing screw)

mixture gases too rich

(locking screw)

spark damage or stain

C.D.I damage

A.C.G damage

coil damage

spark plug cable damage odr short

main switch damage

A.C.G damage

air hole damage or blocking

(-) pressure tube damage

gasket damage

the screw of carburetor is

loosen

(-) pressure tube broken

ADLY MOTO 1-10

normal abnormal

INFORMATION FOR PREPARATION

REVOLUTION NOT SMOOTH(HIGH SPEED)

Diagnose

Check and Adjust

normal abnormal

normal abnormal

no blocking blocking

valve timing is

correct valve timing isn't

correct

adjusting ignite timeing

adjusting valve gap

check fuel cup supply

normal ?

carburetor blocking

check and adjust valve

timing

Reason of Trouble

C.D.I damage

ACG pulse coil damage

fule filter blocking

air hole of fuel tank blocking

fuel cup damage

fuel of tank is too less

camshaft gear mark position is not

correct

normal spring broken or

elastic deformation

end

check the spring of valve

adjusting isn't correct

valve set damage

cleaning

spring damage

ADLY MOTO 1-11

voltage of battery

can't go up voltage of battery

is normal

INFORMATION FOR PREPARATION

CHARGE ABNORMAL

Diagnose

Check and Adjust

normal measure value

too high

battery have voltage battery have not

voltage

normal abnormal

start engine and measure

voltage of the two

terminal for battery

measure the resistance of

ACG coil

check the regulator

check socket of regulator

loosen ?

Reason of Trouble

battery damage

coil damage

terminal damage

YL wire damage

R wire damage

regulator damage

socket damage

ACG damage

(over charge)

main switch at ON

the battery have

voltage

main switch at ON

the battery have no

voltage

normal socket loosen

GR wire broken

regulator damage

socket damage

check the socket of

regulator

check the voltage between

regulator and frame

ADLY MOTO 1-12

no sparking or

weak sparking strong

INFORMATION FOR PREPARATION

SPARK PLUG NO SPARKING

Diagnose

Check and Adjust

loosen no loosen

normal abnormal

normal abnormal

normal abnormal

change spark plug and

check again

check spark plug, cap,

ignition coil loosen?

check C.D.I unit socket

loosen ?

check the terminal of

C.D.I unit unimpeded?

measure resistance

check relate spare parts

Reason of Trouble

the previous spark plug damage

spark plug cap loosen

main switch damage

pulser coil damage

coil damage

lighten coil damage

the previous C.D.I unit damage

socket damage

normal abnormal

main switch damage

socket, joint connect abnormal

change CDI unit

abnormal

change ignition coil

the previous coil damage

ADLY MOTO 2-1

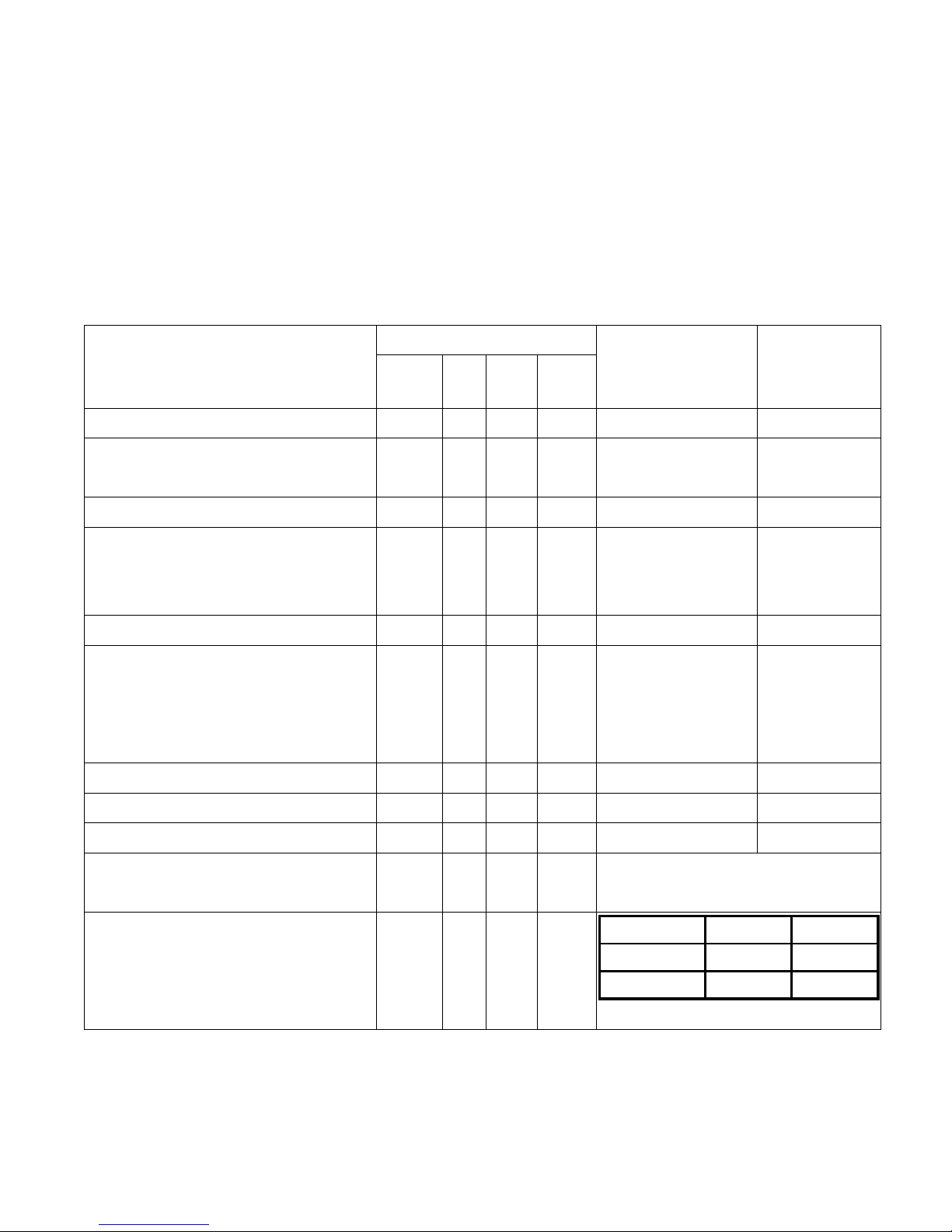

CHECK AND ADJUST

Way of Check & Adjustment

1. Mark “○” is checking time.

2. Mark “☆” is the regular exchange of service items.

This exchange time is just for general riding of the majority not for the special use , please

arrange with this principle according to the difference of the riding condition.

Service Time (month)

Service Items Before

riding 1 st each 6 each 12 Judgement Standard Remarks

Operating Device

Handle- Play, loose/tight

Operation

○

○

Wheels- Right/left turn round angle ○

Front Fork-Damage

Installationofshaft

ShaftGap

○

○

○

○

○

Direction Post

Direction Post

Brake Device

Brake- Play

Trytorun

Correct brake

○

○

○

○

○

○

○

○

○

Play

Handle , handle front

10-20 mm

Wires- Loose / tight and damage ○ ○ ○

Gap of casing & brake ○○

Wore of brake & operating parts ○Direction

Wore & Damage of casing

○

Standard diameter 110 mm

Limitation 110.5mm

Riding Device

Tires-Air pressure of tires

○

○

○front rear

air pressure 1.5 kg/cm 1.75 kg/cm

tire 120/70-12 120/70-12

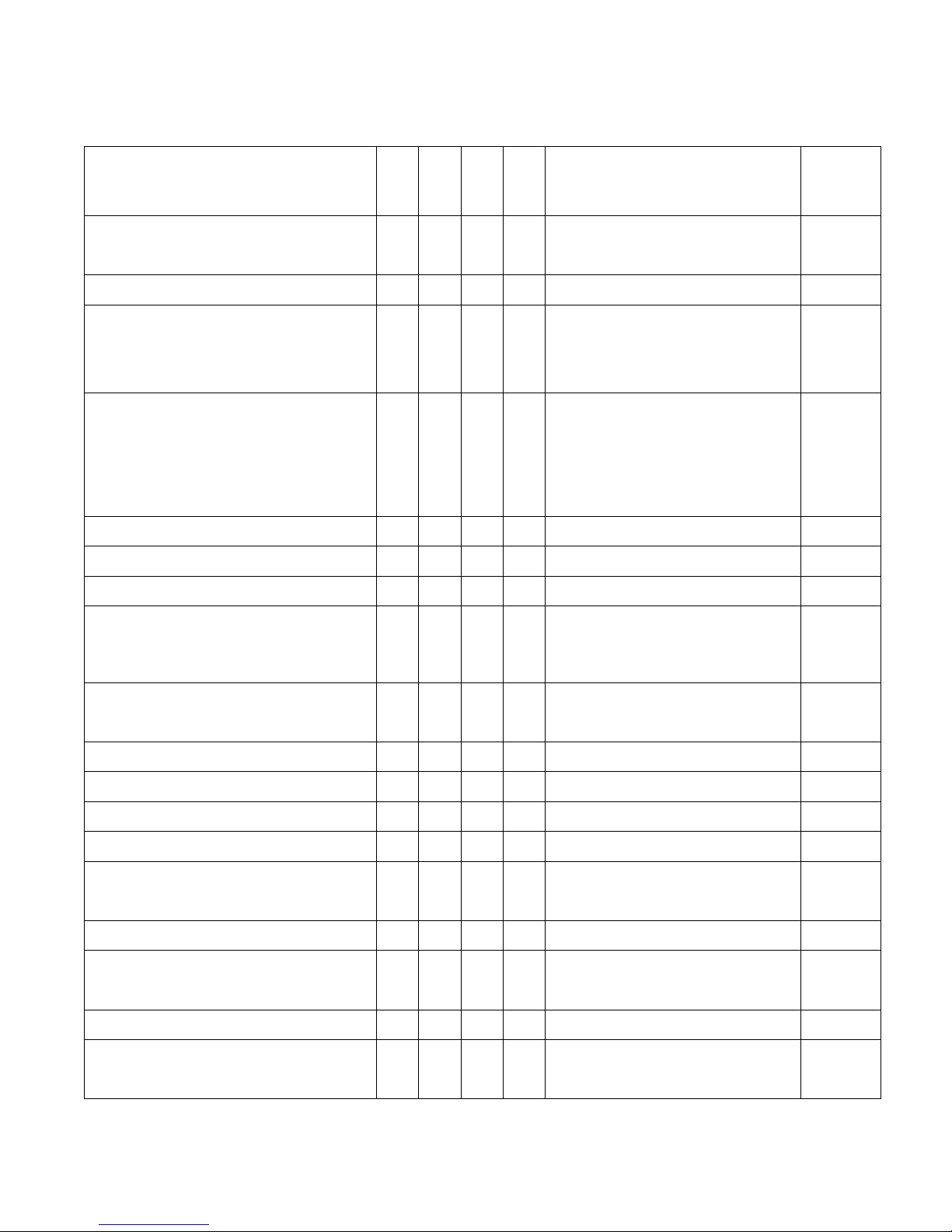

ADLY MOTO 2-2

Riding Device

Tire

Check & damage of tires ○○ ○ Ditch-front wheel till 0.8mm

Rear wheel till 0.8 mm

Abnormal & ditch in tires ○○ ○

Bolt & nut of tires locking

○

○

Flocking torsion

Front wheel – 4.0~5.0 kg-m

Rear wheel –10~12 kg-m

Damage of felly ,side ring , disc ○ ○

○

Vibration of felly, in edge of felly

Front wheel – horizontal under 2.0

mm

vertical under 2.0 mm

Rear wheel – horizontal under 2.0 mm

vertical under 2.0 mm

Tightness of front bearing ○

Tightness of rear bearing ○

Buffer device

Spring -damage ○Spring of

shock

absorber

Suspension arm – damage of joint gap

&arm

○

Buffer -oil leakage or damage ○

Tightness of installation ○

Power transmission device

Clutch -action ○○○

Transmission

○ ○ Level : way of direction hole , oil

fill to the mark of the hole

It’s rear

Gear case

Electril device

Ignition device -condition of ignition

spark plug

○ ○ Gap of spark plug 0.6~0.7 mm

Battery -connection of terminal ○

Wiring of electrical appliance – damage

or loose in connection place

○

ADLY MOTO 2-3

Check Items Before

riding 1 st

M

6

M

12

M

Judged standard remarks

Engine

Body – starting & abnormal noise

low speed & accelerating

exhaust

air filter

○

○

○

○

○

○

○

○

○

Idle : 1800±100 rpm

Lubrication device

Oil and oil filter ○ ○ Warning light lighting

Oil leakage ○ ○

Oil level ○

Fuel installation

Gasoline filter is dirty ○

Leakage of fuel ○ ○

Throttle gate & choke ○

Fuel filter is clogged ○

Oil level ○

Alteration of pipes 9each 2 years

Lights & direction lights

Action

○ ○

On/off normal , dirty , damage ○

Rear mirror – view ○

○

Reflector & license tag –dirty & damage

Instrument –action ○

Exhaust pipe & muffler

Installation loosed or damage ○

Function of muffler ○

Frame & body –loose or damage ○

Abnormal from previous day –confirm

normal

○

Others - greasing of each part ○ ○

Cleaning combustion chamber , exhaust

pipe , and carbon muck in muffler

○

ADLY MOTO 2-4

CHECK AND ADJUST

Disassembly of External Parts

•Remove the external parts for check

and adjustment.

•Remove 4 hex washer face bolts,

4 space tubes , and then remove

luggage carrier.

•Remove 12 self-tapping screws and 2

pan flat bolts.

•Remove central cover ,L/R side cover,

decoration strip and cowling.

•Install with the reverse sequence.

WARNNING:

6Do not break the union of body and

pedal.

6Before locking screws , please

confirm the matching correct of all

parts.

•Front cover.

•Remove 3 pan flat bolts , 1 hex bolt.

•Remove 12 self-tapping screws.

•Disconnect the light connectors.

•Install with the reverse sequence.

WARNNING:

6Do not damage & break the joint of

inner body and front damper.

6Before locking screws , please

confirm the matching correct of all

parts.

ADLY MOTO 2-5

CHECK AND ADJUST

Disassembly of Pedal

•Remove L/R body cover.

•Remove 4 bolts, 6 self-tapping screws

2 pan flat bolts.

•Separate the joint with luggage case

(claw & groove)and remove the pedal

•Install with the reverse sequence.

WARNNING:

6Installing to the luggage box after

composing confirming the pedal with

the joint of luggage case correctly.

Disassembly of Luggage Case

•Remove front fender.

•Disconnect the light connectors.

•Remove power switch cap.

•Remove edge nut on luggage case.

•Install with the reverse sequence.

WARNNING:

6Going on the installation operation

after jointing correctly the luggage

case and front fender.

ADLY MOTO 2-6

CHECK AND ADJUST

Rear Light Assembly

•Remove 2 hex bolts.

•Remove 3 L/R sides body cover.

•Disassembly the connection head of

wireness rear light.

•Assembly with the sequence in

reverse of disassembly.

WARNNING:

6Ensuring the joint of tail light hole

correct with the bulge of truck.

Handle Covering

•Remove 4 self-tapping screws ,

separate the joint with speedometer.

•Remove the handle covering.

•Assembly with the sequence in

reverse of disassembly.

WARNNING:

6Aim handle covering correctly the

handle covering back’s joint.

This manual suits for next models

1

Table of contents

Other HER CHEE Scooter manuals

Popular Scooter manuals by other brands

Tomoloo

Tomoloo Two Wheels Folding Electric Scooter manual

Ignite

Ignite ESC01 user manual

Peg-Perego

Peg-Perego DUCATI DESMOSEDICI IGED1033 Use and care

Yamaha

Yamaha AEROX NS50 owner's manual

Jamara

Jamara KickLight 460495 instruction manual

Mart Cart

Mart Cart 280-3700 Owner's manual and technical documentation