Heraeus Soluva Air M10 User manual

Instructions

Soluva® Air M10

UV-C Air Disinfection System

IPS_Man 20003302000 en 12.20

Keep for future reference

Heraeus Noblelight

Soluva® Air M10

UV-C Air Disinfection System

Page 2 of 38 IPS_Man 20003302000 en 12.20

IPS_Man 20003302000 en 12.20 Page 3 of 38

Table of contents

1 Introduction.............................................................................................. 4

1.1 Risk assessment................................................................................ 6

2 Product description................................................................................. 7

2.1 Intended use ...................................................................................... 9

3 Safety instructions .................................................................................. 10

3.1 List of the symbols used .................................................................... 10

3.2 Target group, personnel qualifications............................................... 11

3.3 Basic safety instructions .................................................................... 12

4 Transport.................................................................................................. 15

5 Installation................................................................................................ 16

6 Control...................................................................................................... 21

7 Maintenance............................................................................................. 24

7.1 Replacement parts............................................................................. 30

8 Disposal.................................................................................................... 31

8.1 UV lamps ........................................................................................... 31

8.2 Device................................................................................................ 31

9 EC Declaration of Conformity ................................................................ 32

10 Liability and quality agreement.............................................................. 32

11 Annex........................................................................................................ 32

11.1 Technical description ......................................................................... 33

11.2 Installation instruction fischer concrete screw ULTRACUT FBS II .... 36

Page 4 of 38 IPS_Man 20003302000 en 12.20

1 Introduction

Heraeus Noblelight GmbH

Heraeusstraße 12-14

63450 Hanau, Germany

Phone: +49 6181 35-5522

Mail: [email protected]

www.heraeus-noblelight.com

Available language versions of the operation manual

www.heraeus-noblelight.com/soluva-manuals

Heraeus Noblelight GmbH retains all rights to this operation manual.

IPS_Man 20003302000 en 12.20 Page 5 of 38

The text, information and illustrations in this manual must not be reproduced,

distributed or disclosed to third parties or used without authorisation for pur-

poses of competition.

This operation manual was prepared with great care. However, should you de-

tect an error in it, we would appreciate if you let us know.

Service

If you have any questions regarding repairs, spare parts, installation or initial

operation, please contact our service team:

Europa/EMEA/

Rest of world

( +49 6181 35-5522

Americas ( +1 301 990-8700

Japan ( +81 (0) 3/6902-6633

China/Taiwan ( +86 (21) 3357-5335

Korea ( +82 (31) 270 9449

èGlue the type plate sticker here.

Page 6 of 38 IPS_Man 20003302000 en 12.20

Vorwort

This operation manual provides instructions for the use and care of the product.

This operation manual is for use by personnel operating and servicing the

product.

èRead this operation manual prior to initial operation.

èObserve the instructions given in the operation manual.

èEnsure that this operation manual is available to all persons

handling the product.

èMake sure the operation manual can be consulted without a

problem at any time during the service life of the product.

NOTICE!Heraeus Noblelight cannot be held liable for any damage or dis-

turbance of operations caused by non-compliance with the instructions

given in this operation manual.

The proper function of the product is guaranteed only if

uthe product is operated in accordance with the instructions; and

uthe operation manual and maintenance recommendations are observed.

Text markup

The markups used in the text indicate the following:

uBold = important information

uItalics = reference to a chapter, or a menu item

uè = instruction; something needs to be done

1.1 Risk assessment

Heraeus Noblelight offers powerful light sources that are optimised for the spe-

cific application and hence have a high ultraviolet (UV), visible (VIS) and in-

frared (IR) radiation capacity, depending on lamp type, which may be a risk to

the user (artificial optical radiation (AOR)).

Various sources of information, in the form of harmonised standards and tech-

nical rules, together with European Directives and national laws, are available

to facilitate the safe use of these lamps and systems, or the devices and ma-

chines in which they are incorporated. These documents contain requirements

and guidelines for risk group classification, AOR risk assessment, technical

design, technical control, marking and possible safety precautions for users.

IPS_Man 20003302000 en 12.20 Page 7 of 38

èSee, e.g., the standards EN 62471, IEC/TR 62471-2, EN 12198-1 and EN

14255-1/-2.

EU Directive 2006/25/EC on the minimum health and safety requirements re-

garding the exposure of workers to risks arising from artificial optical radiation

provides that employers must assess whether and to what extent harmful op-

tical radiation, including UV and IR radiation, is emitted by the product and what

the exposure risks are for workers in the vicinity, e.g. foreseeable duration of

exposure and foreseeable accessible distances. This is a legal obligation of the

employer with respect to health and safety at the workplace and not a product-

related legal obligation of the manufacturer.

The employer can use the end-product manufacturer's operation manuals to

help it assess the exposure risk at the workplace but they do not release the

employer from its legal obligation to perform a risk assessment itself because,

in particular, the hazards from artificial optical radiation caused by the use of

the product at the workplace can be assessed only under the final user condi-

tions. Based on the results of the workplace risk assessment, the employer

must take appropriate measures to protect the user against hazards, including

risks from artificial optical radiation. The risk assessment shall include, without

limitation, the following areas:

uThe effect of the artificial optical radiation generated by the product on the

materials and users in the vicinity if the product is used as intended.

uThe fire hazard that may arise due to the product being a source of heat if

used as intended

uThe requirements regarding adequate ventilation and/or extraction if used

as intended.

uAmbient conditions under which the product is to be operated or stored,

such as temperature and relative air humidity.

uSafe working practices for working with the product.

uIn addition to the operation manual, all applicable legal and other regula-

tions regarding accident prevention and protection of the environment must

be observed.

2 Product description

Soluva® Air M10 is a product of Heraeus Noblelight for the disinfection of air in

closed rooms.

This product allows dry disinfection without chemicals.

The UV lamps contained in the device destroy the structure of the microorgan-

isms' DNA by using highly disinfectant UV light of the wavelength 254 nm

(ozone-free).

Page 8 of 38 IPS_Man 20003302000 en 12.20

Optimising the disinfection effect

The disinfection effect of the Soluva® Air M10 depends on good air circulation

in the room.

èExamples of arrangement in the room see chapter Mounting.

Reduction of the risk of infection in dependence on air circulation and

room size

The higher the air circulation rate with disinfected air in the room, the lower the

risk of infection.

Air circulation rate (1/h) 1 2 3 4

Risk of infection -25 % -42 % -52 % -59 %

[J.L. Jimenez, COVID-19 Aerosol Transmission Estimator, https://tinyurl.com/

covid-estimator, 23/11/2020]

This mean, an air circulation rate of 3 per hour can more than halve the risk of

infection:

uExample (general): A room with 4m x 7m = 28m² floor area and a height

of 2.4 m has a room volume of 28m² x 2.4m = 67m³.

To obtain an air circulation rate of 3 per hour, a device should have an air-

flow rate of 3 x 67m³/h = 200m³/h.

uOne Soluva® Air M10 with 1,100m³/h airflow rate is suitable for a room of

367m³. For a ceiling height of 3.5m, the corresponding floor area would be

105m².

uWith two devices, you can either double the air circulation rate in a room

(and hence further reduce the risk of infection) or disinfect a room of double

the size at the same air circulation rate.

Scope of supply

The Soluva® Air M10 consists of:

uHousing with side covers for air inlet and outlet.

u2 UV lamps (NNI 370/77 XL HR) for air disinfection.

uIntegrated control unit.

uLED strip light for visualising the operating states.

uConnecting cable 15 m with plug with earthing contact (detachable).

IPS_Man 20003302000 en 12.20 Page 9 of 38

Fig.1: Main dimensions

èAdditional technical data see Annex.

2.1 Intended use

Soluva® Air M10 is intended exclusively for the disinfection of ambient air in lar-

ger rooms or halls with a minimum ceiling height of 3.00 m.

Reasonably foreseeable misuse

The following exclusions apply, among others:

uDo not use to expose humans or animals to radiation.

uDo not use outside of the permitted ambient conditions.

uManipulation or bypassing of a safety device

uDo not use for general lighting purposes.

uDo not use outdoors.

uDo not use in explosive or combustible atmospheres.

DANGER

Explosion hazard

èUse in explosion hazard areas is prohibited.

Page 10 of 38 IPS_Man 20003302000 en 12.20

3 Safety instructions

èObserve the safety instructions.

ðNon-observance of the safety instructions causes hazards to per-

sons, the environment and the product.

More information about the handling of UV radiation is provided at www.her-

aeus-noblight.com/UVSafety

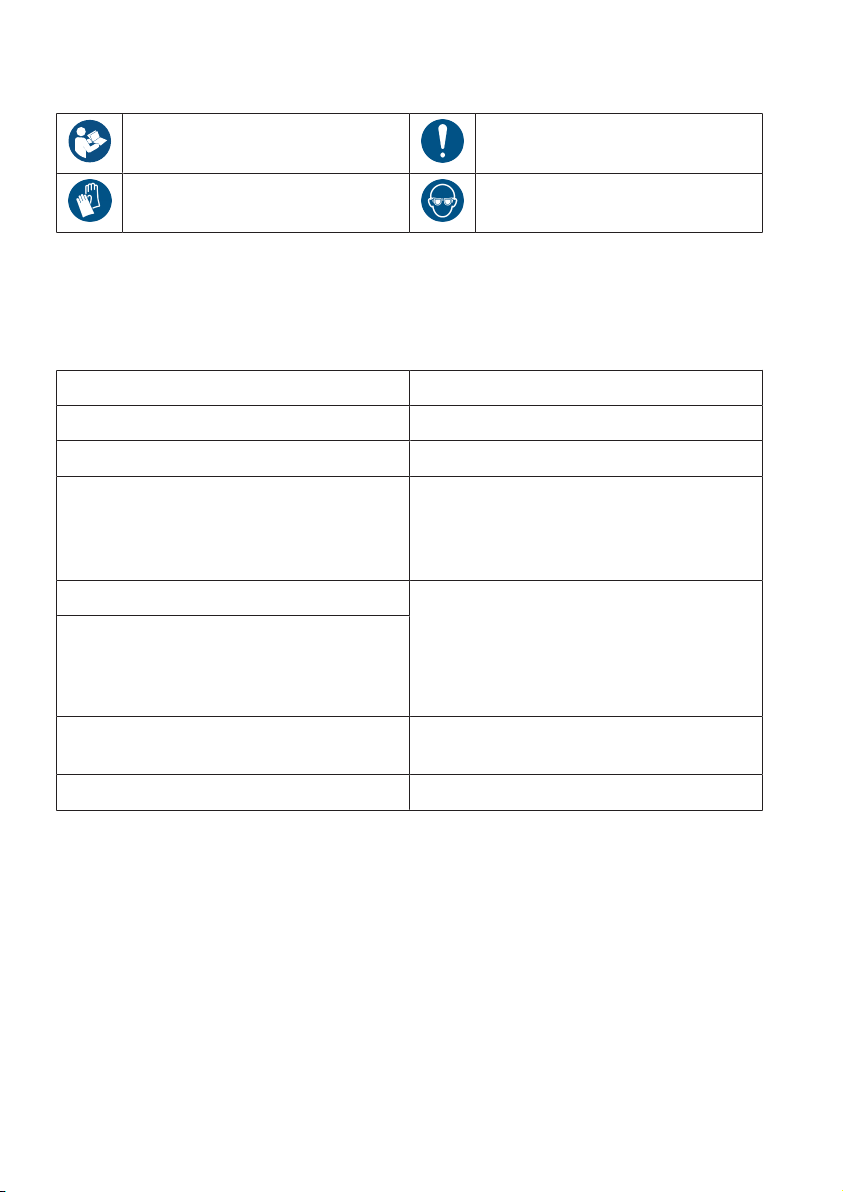

3.1 List of the symbols used

Various symbols are used in this operation manual to identify the remaining

risks of the different hazard levels. The symbols help the user detect and mem-

orise risks.

Signal words

The signal word "DANGER" indicates a high-risk hazard which, if not avoided,

will cause death or severe injury.

The signal word "WARNING" indicates a medium-risk hazard which, if not

avoided, may cause death or severe injury.

The signal word "CAUTION" indicates a low-risk hazard which, if not avoided,

may cause minor or moderately severe injury.

Warning signs

Risk of electrical shock Explosion hazard

Generic warning Warning of optical radiation

hazard

UV radiation

Fire hazard Warning of hot surface

Warning of injury to hands

(crushing)

Warning of injury to hands

(cutting)

IPS_Man 20003302000 en 12.20 Page 11 of 38

Mandatory action symbols

Read the instruction manual. Notes regarding optimal use.

Wear hand protection. Wear safety glasses.

3.2 Target group, personnel qualifications

Any work on or with the product must be carried out only by persons demon-

strably qualified for the respective task.

Task Qualification

Transport Technical qualification

Installation Technical qualification

Electrical connection If a ready-made cable provided by

the customer is used, electrical con-

nection must be made by a qualified

electrician.

Operation Only by persons aged 16 or older.

The persons must have appropriate

physical, sensory and mental abilit-

ies and have read and understood

the operation manual.

Maintenance work (cleaning or repla-

cing UV lamps)

Electrical work (control cabinet main-

tenance)

Qualified electrician

Other repair and maintenance work Technical qualification

Page 12 of 38 IPS_Man 20003302000 en 12.20

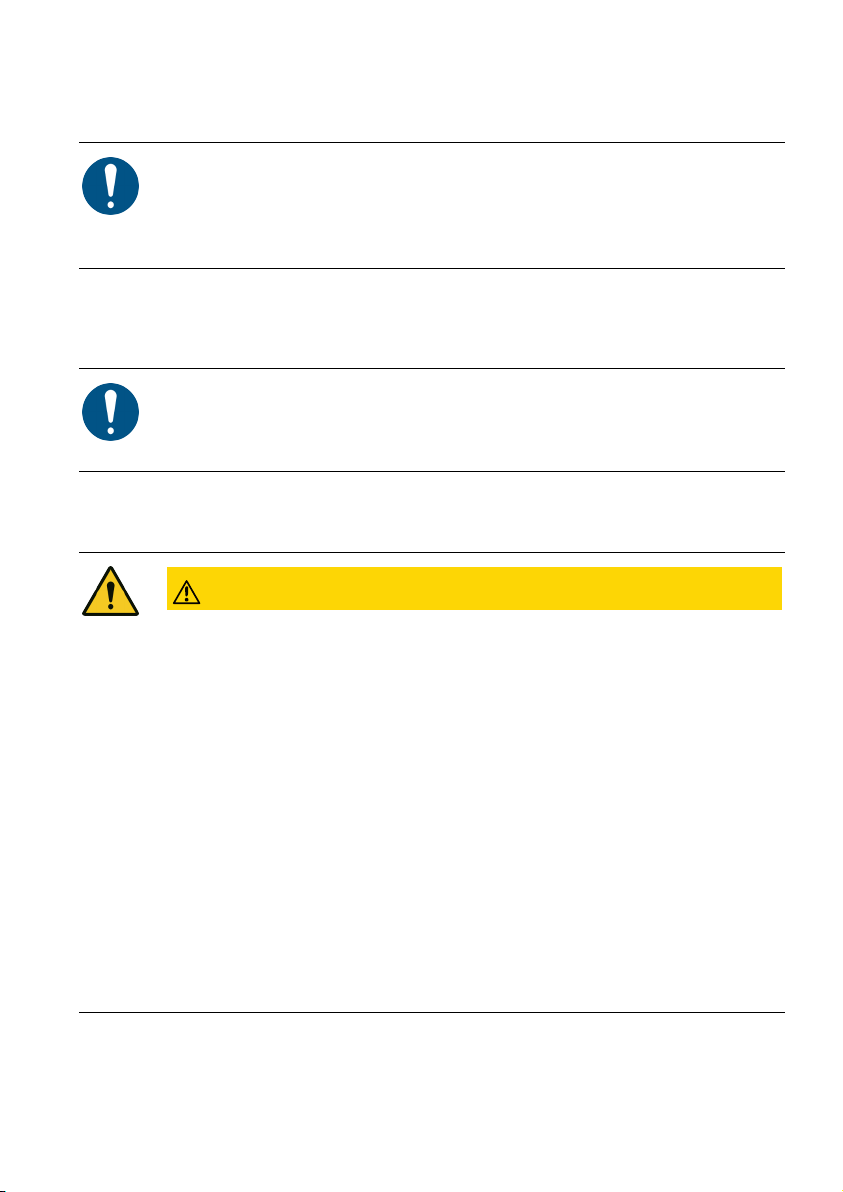

3.3 Basic safety instructions

Personal protective equipment

èThe following personal protective equipment must be worn when

handling the UV lamps (cleaning/maintenance):

ðCut-resistant gloves

ðSafety goggles

Explosion hazard

DANGER

Explosion hazard

In operation, the UV lamp's surface temperature is about 100°C. The

lamp electrode temperature is about 1,200°C.

Danger of ignition at the UV lamp.

èUse in explosion hazard areas is prohibited.

Risk of electrical shock

DANGER

Dangerous voltage

Risk of electric shock when working on live components. Danger to

life.

èDe-energise the product.

èSecure against restarting.

èCheck the product is de-energised.

IPS_Man 20003302000 en 12.20 Page 13 of 38

Danger to eyes and skin

WARNING

Ultraviolet radiation by this product

This product is classified in risk group 3 (high risk) in accordance with

EN 62471 (Photobiological Safety of Lamps and Lamp Systems).

UV radiation damages eyes and skin.

èWithin the danger zone in risk group 3, prevent exposure of eyes

and skin. Consider reflection of the radiation.

èWear appropriate personal protective equipment (depending on

length of stay in the risk group, shown in the diagram).

èCover exposed skin on arms, legs and neck.

èDo not look into the radiation during operation. This may cause

damage to your eyes.

Danger zone of the artificial optical radiation

Danger zone of the artificial optical radiation DIN EN 62471

Risk groupe 3

Risk groupe 2 (max. 30 min/8 h day)

Risk groupe 1 (max. 5,5 h/8 h day)

Distance from the device (m)

Hight (m)

Maintenance side

(Air outlet)

The diagram describes the situation at the lowest recommended installation

height (lower edge of the device 2.70 m above floor).

The maximal lengths of stay apply to persons without protective clothing and

were calculated using the exposure limits in the "ICNIRP GUIDELINES", pub-

lished in HEALTH PHYSICS 87(2):171-186; 2004.

èConsider the area of the risk groups when positioning the Soluva® Air M10.

Page 14 of 38 IPS_Man 20003302000 en 12.20

èPersonnel within the danger zone must be informed accordingly and be pro-

tected against the hazards.

Persons must not stay within the radiation area of risk group 3.

èPrior to maintenance work at the device itself or other installa-

tions on the ceiling, switch off the Soluva® Air M10 or equip per-

sons with appropriate protective clothing.

Danger to surrounding materials

Ultraviolet radiation alters materials which are not UV-resisting.

èAppropriately shield off UV radiation to protect materials not to be

exposed.

Health hazard

CAUTION

Mercury

The UV lamps contain mercury due to the process. The mercury may

be released if the UV lamps are mechanically destroyed. Mercury is

regarded as hazardous to health acc. to Regulation EC/1271/2008

and the California Proposition 65 (www.P65Warnings.ca.gov).

èDo not inhale released vapours. Clear the danger zone. Appropri-

ately ventilate the working rooms.

èAvoid any contact with mercury.

èDo not allow mercury to reach the sewage system or ground wa-

ter.

èDispose of according to regulations. Either pick up mercury

beads with special mercury tongs or bind them with a special

mercury absorbent. After that, put them into a lockable plastic

container and dispose of in accordance with the applicable legal

regulations regarding the disposal of hazardous substances.

IPS_Man 20003302000 en 12.20 Page 15 of 38

Risk of burns

WARNING

Hot surface

The lamp and surfaces exposed to radiation can get very hot during

operation. The radiation heats the housing and surrounding compon-

ents. Contact with the hot surface will cause burns.

èDo not touch hot surfaces.

èAllow the product to cool down (approx. 10 minutes).

èWear protective gloves.

4 Transport

CAUTION

Risk of crushing

The product may be dropped when it is handled. Crushing injury may

occur.

èProtect the product against being dropped.

èWear personal protective clothing.

NOTICE!Improper handling of the device and the packaging may cause in-

jury. Take appropriate precautions.

èProtect the product against damage.

èAvoid vibrations and impact.

èUse aids suitable for the weight, e.g. fork-lift trucks, slings.

Slings must not chafe.

èCheck that the packaging of the product is not damaged.

Any damage to the packaging may be the cause of a subsequent

malfunction.

Page 16 of 38 IPS_Man 20003302000 en 12.20

Packaging materials

èWe recommend storing the packaging material for later shipping or trans-

port.

Otherwise, dispose of in an environmentally compatible way (carton: paper/

cardboard, padding material: residual waste).

5 Installation

Selecting optimal place of installation

èConsider the zones of the risk groups when positioning the device. See Fig.

"Danger zone of the artificial optical radiation" in chapter Basic safety in-

structions [}12].

èDo not operate sources of heat or vapour in the vicinity of the device.

èDo not mount the device near a door.

èMake sure no objects that reflect UV radiation, such as windows or metallic

surfaces, are located in the direction of the two openings.

èMake sure no objects sensitive to UV radiation are located in front of the

two openings.

èConsider the length of the connecting cable.

Make sure there is an appropriate power socket within the defined distance.

èPosition the Soluva® Air M10 in such a way that the recommended min-

imum clearances to ceiling and floor will be observed.

IPS_Man 20003302000 en 12.20 Page 17 of 38

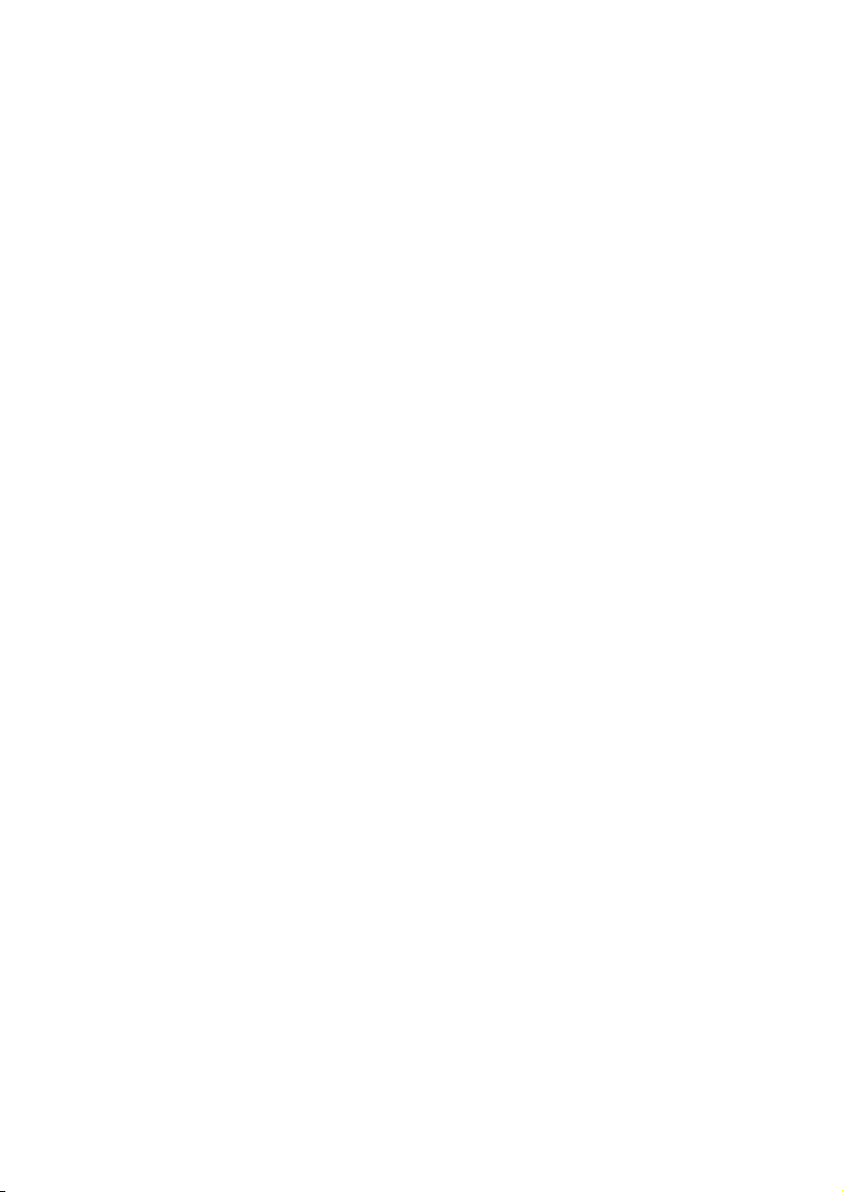

Ceiling

Floor

>= 1,500 mm

Air flow

>= 1,000 mm

NOTICE!The shown minimum clearance to the ceiling can be obtained

only by using a special suspension fixture to mount the device, which is

not included in the delivery.

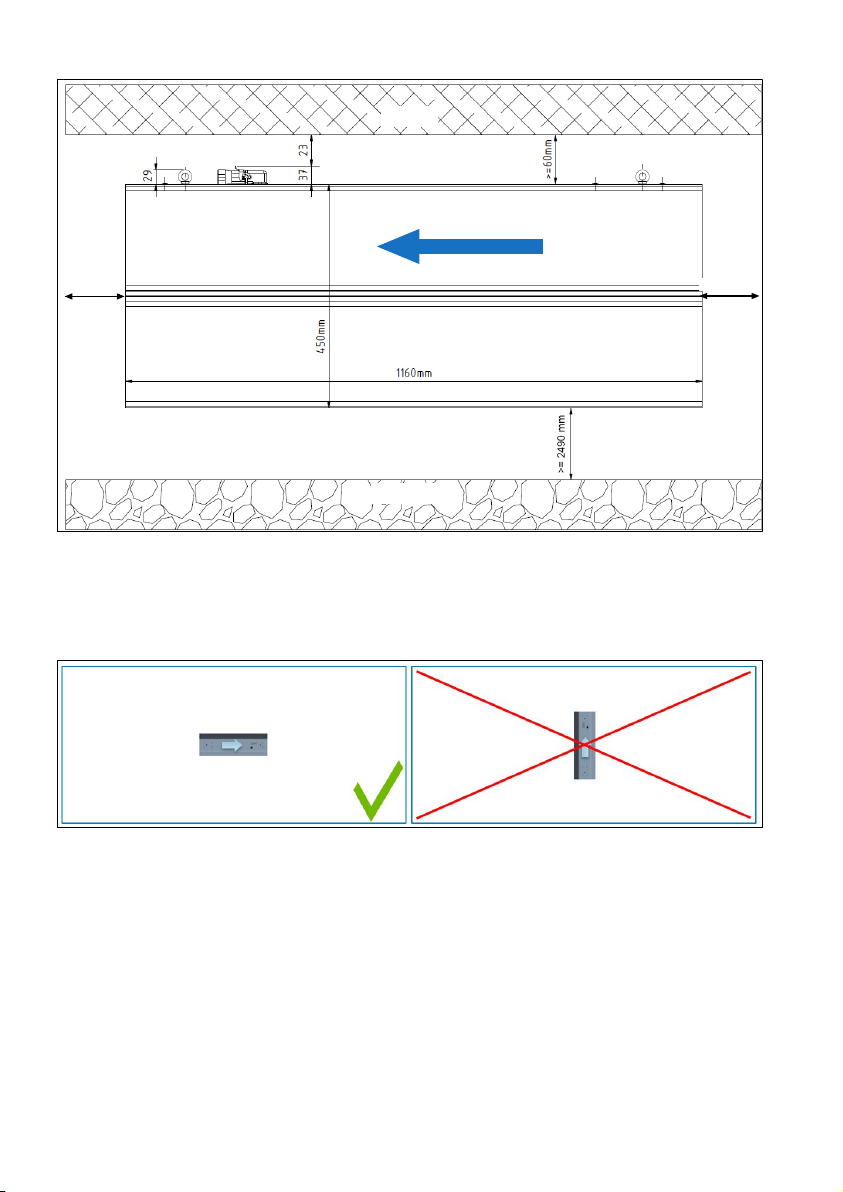

Location within the room

Page 18 of 38 IPS_Man 20003302000 en 12.20

èIf more than one device shall be suspended in the room, the following ar-

rangement must be observed.

Suspending the device

èDo not use nails.

èDo not use screws without suitable plugs to fasten interior

devices to gypsum plasterboards, sheets of drywall, gypsum

boards, tiles, plywood or similar materials.

èA minimum of two persons is required to safely position and suspend the

device.

èFence off the danger zone until it is ensured that the device is securely

mounted to the ceiling.

èFor concrete ceilings, use the enclosed mounting kit.

èProvide appropriate suspension points (two) at the ceiling or a girder.

The minimum load-bearing capacity per suspension point must be 500 N.

IPS_Man 20003302000 en 12.20 Page 19 of 38

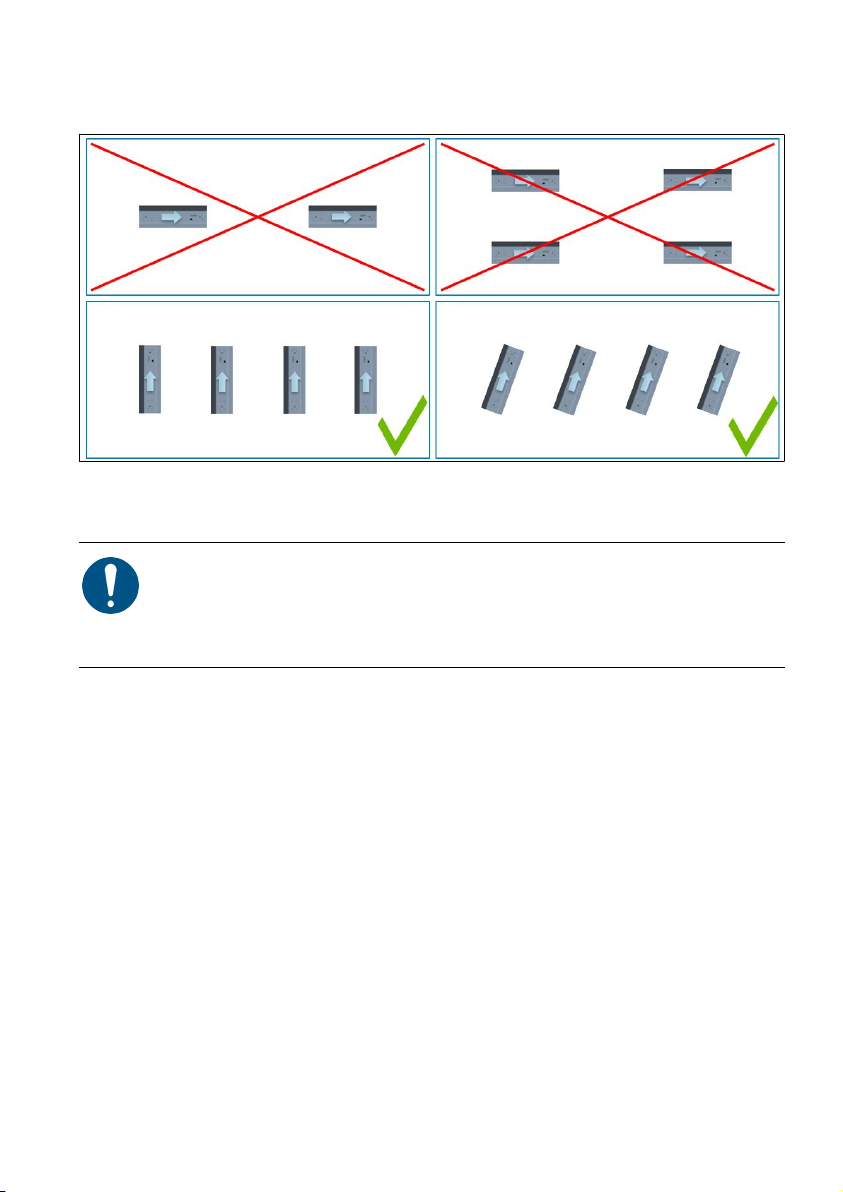

Suspension points

(ring bolts)

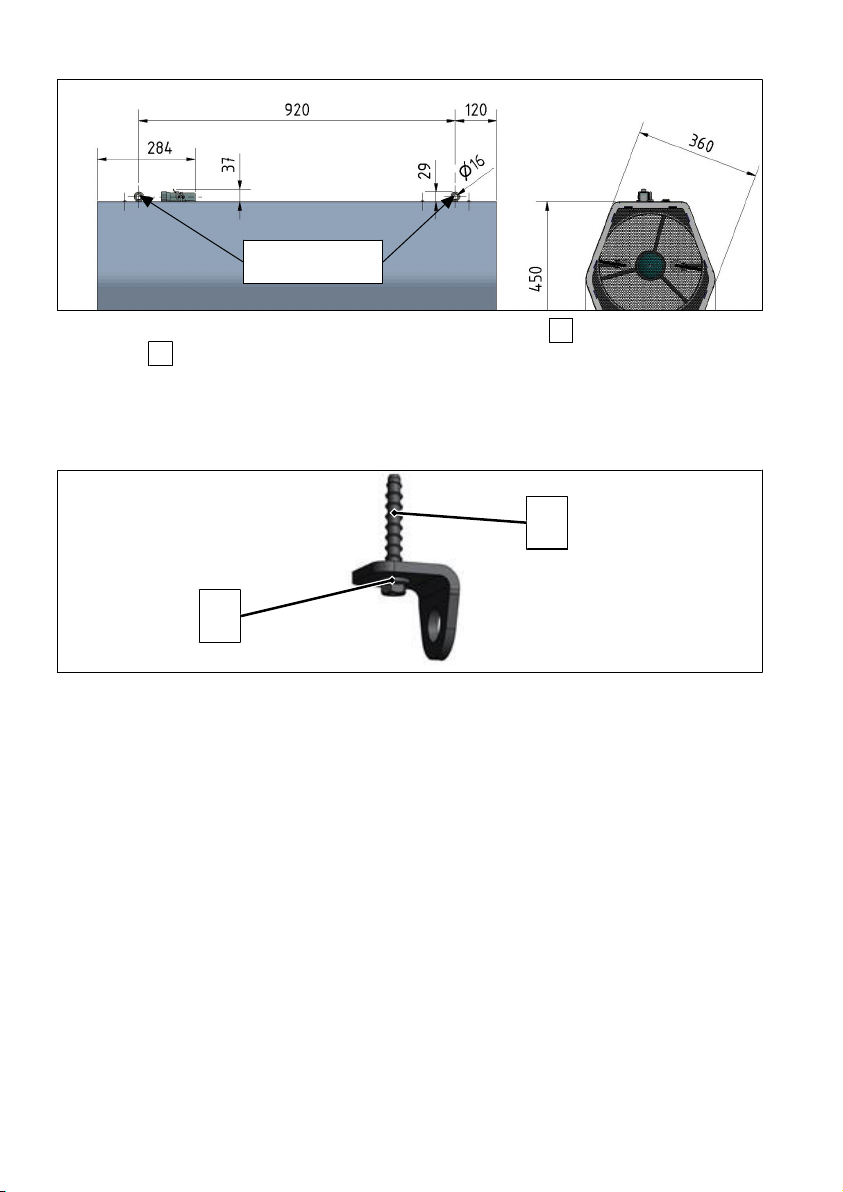

èDrill appropriate holes and fasten mounting bracket 1 to the ceiling using

screw 2 . Observe the mounting instructions for "fischer Betons-

chrauben" [fischer concrete screws] in the Annex [}32] (Plugs are not

used, screw is screwed in directly into the borehole.)

Borehole spacing (center-to-centre) 864 mm to 976 mm, depending on the

orientation of the mounting brackets.

2

1

èDefine the operating height.

Suspend the Soluva® Air M10 in such a way that the lower edge of the

device is located at a height of not less than 2.70 m.

èAdjust/cut an appropriate suspension rope to the final operating height.

Page 20 of 38 IPS_Man 20003302000 en 12.20

20 mm

Rope overlap approx. 100 mm

Tightening torque of the M5 nuts: 2 Nm

Retighten after approx. one hour and again after three

hours.

The screwed connection should be checked again after

one month and after six months.

After that: regular checking every six months

Place clamping brackets always

on the non-loaded rope section.

Maximal total length of the suspension rope (incl. snap hooks) approx. 3.8 m

Minimal total length of the suspension rope (incl. snap hooks) approx. 0.26 m

èSecurely connect the suspension rope to the ring bolts of the Soluva® Air

M10 through the snap hooks and suspend it at the mounting brackets using

additional snap hooks.

èNote: The air inlet and outlet openings must remain unobstructed.

The intake air must not be hotter or colder than specified in the

technical data.

èDo not cover the LED strip lights.

Establishing electrical contact

èPlug the connecting cable into the device and into a suitable power socket.

Observe the connection data shown on the type plate.

èIf an extension cable is needed, it must have the following specifications:

ð16 A

ðMin. cross-section 1.5 mm2

èContact Heraeus Noblelight Service if you have any questions.

Table of contents

Popular Accessories manuals by other brands

SEVERIN

SEVERIN TURBOBÜRSTE TB 9070 Dimensions

Aroma-Zone

Aroma-Zone ZÉPHYR instruction manual

Invacare

Invacare Personal Seat VF Installation and operating instructions

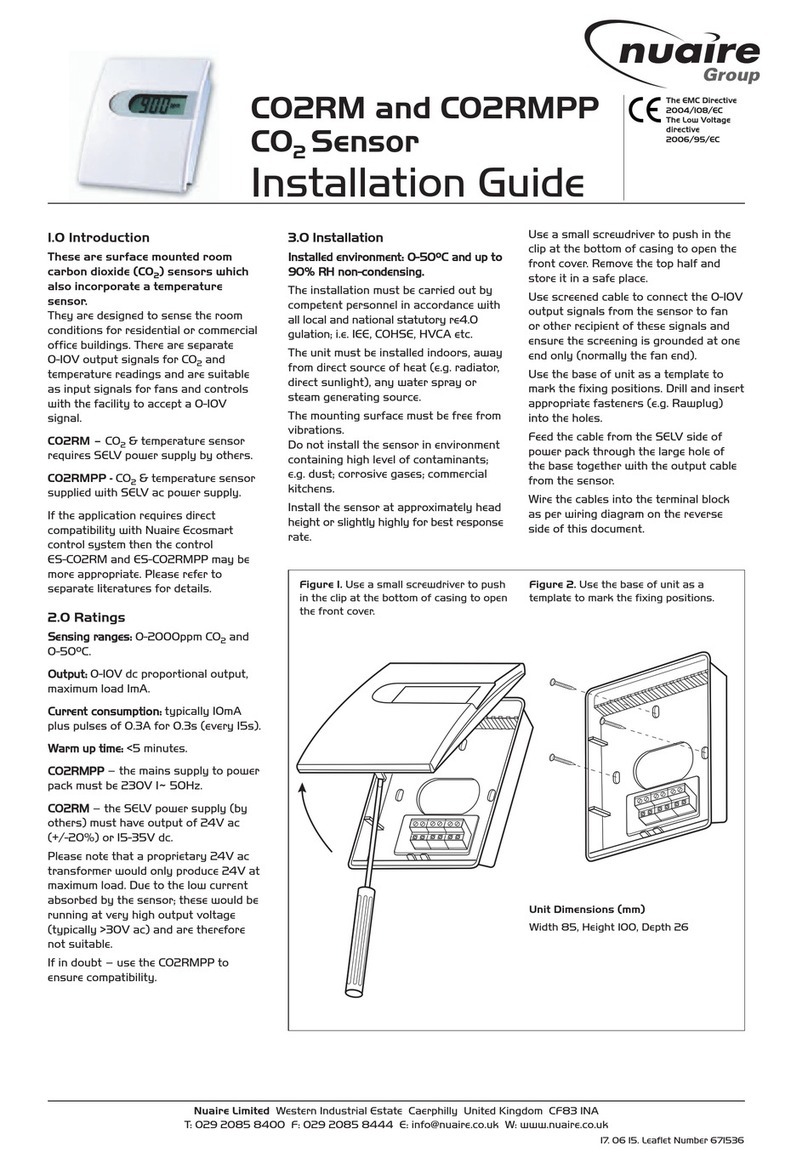

Nuaire Group

Nuaire Group CO2RMPP Installation guide / instruction manual

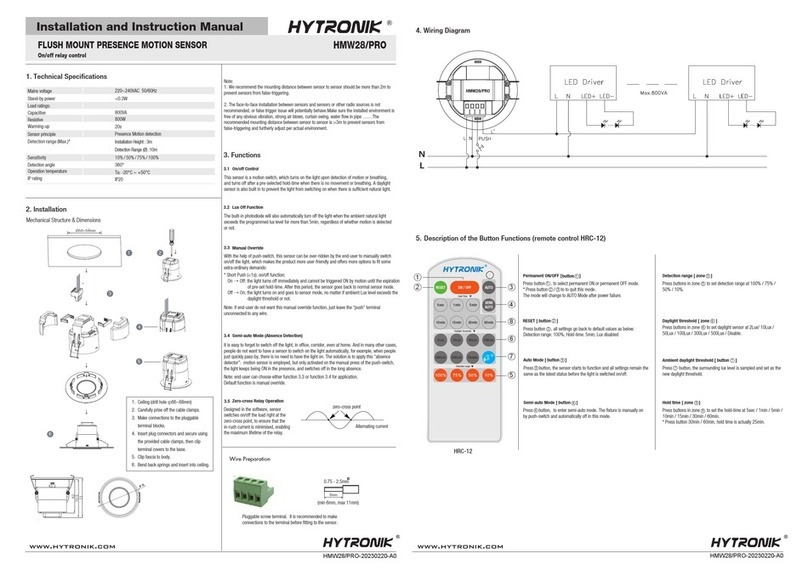

Hytronik

Hytronik HMW28/PRO Installation and instruction manual

Festo

Festo Sorting Station Inline operating instructions