2

Contents

1 Preliminary note���������������������������������������������������������������������������������������������������3

2 Safety instructions �����������������������������������������������������������������������������������������������4

3 Functions and features ����������������������������������������������������������������������������������������4

4 Function���������������������������������������������������������������������������������������������������������������5

4�1 Operating modes (ModE) ������������������������������������������������������������������������������5

4�2 Select medium (MEdI) �����������������������������������������������������������������������������������6

4�3 Define the internal pipe diameter (diA) ����������������������������������������������������������6

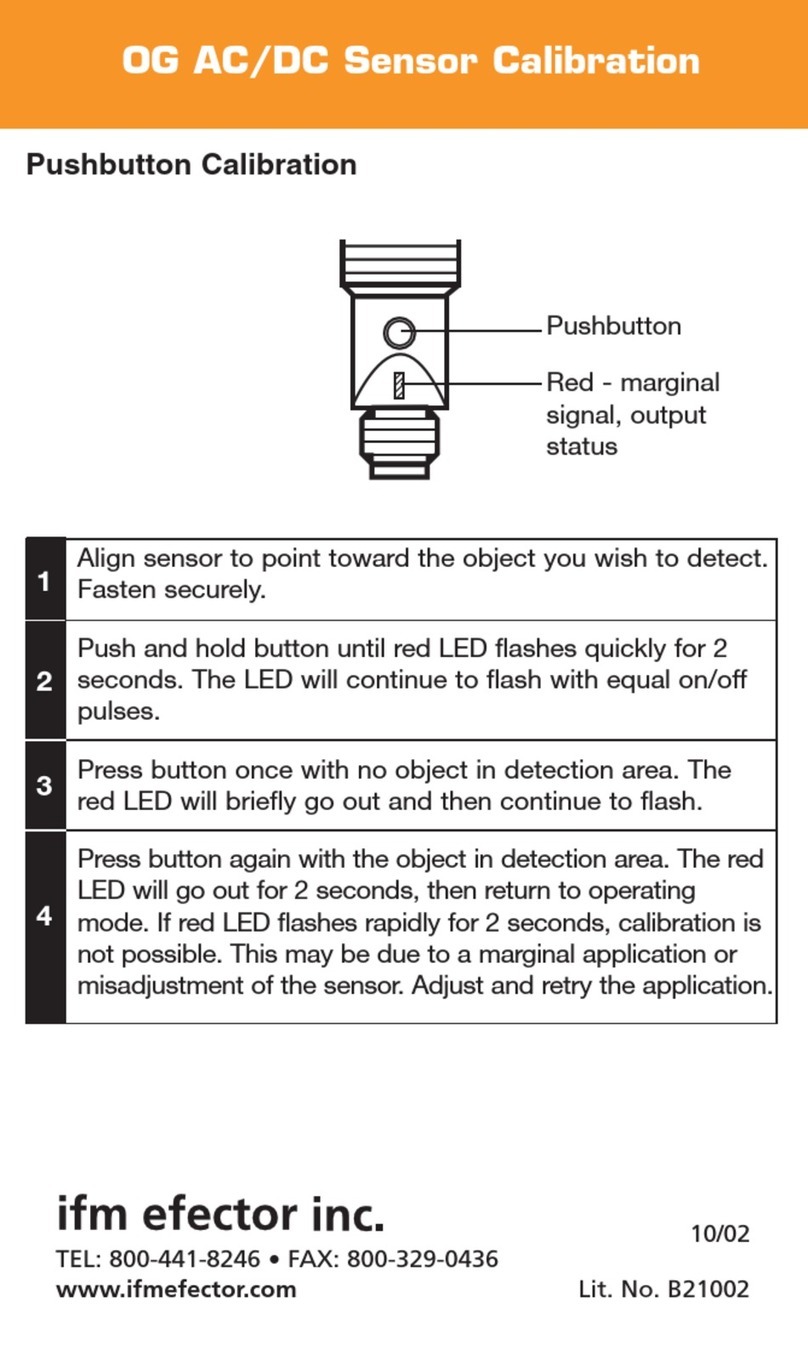

4�4 Customer-specific calibration (CGA) �������������������������������������������������������������6

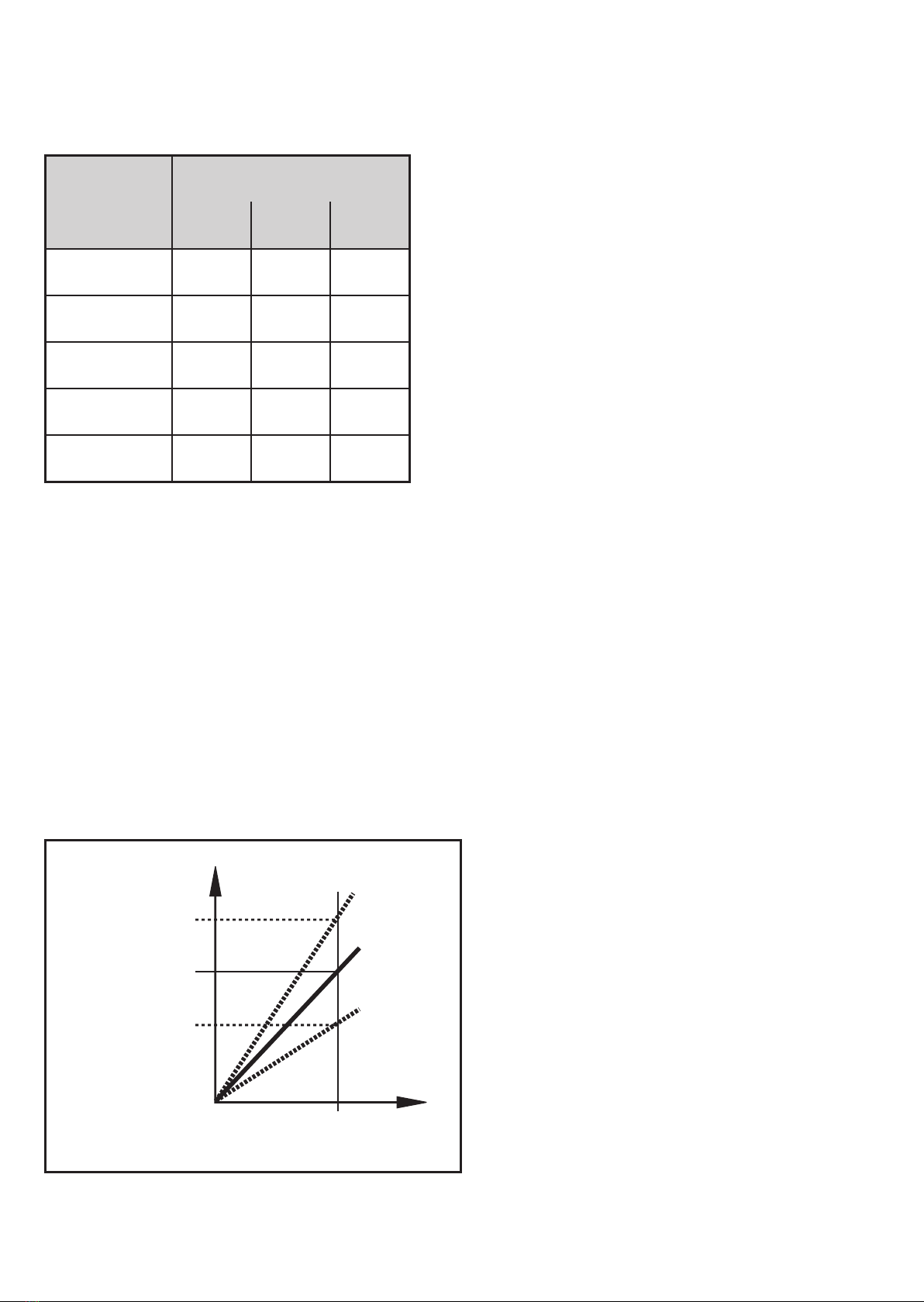

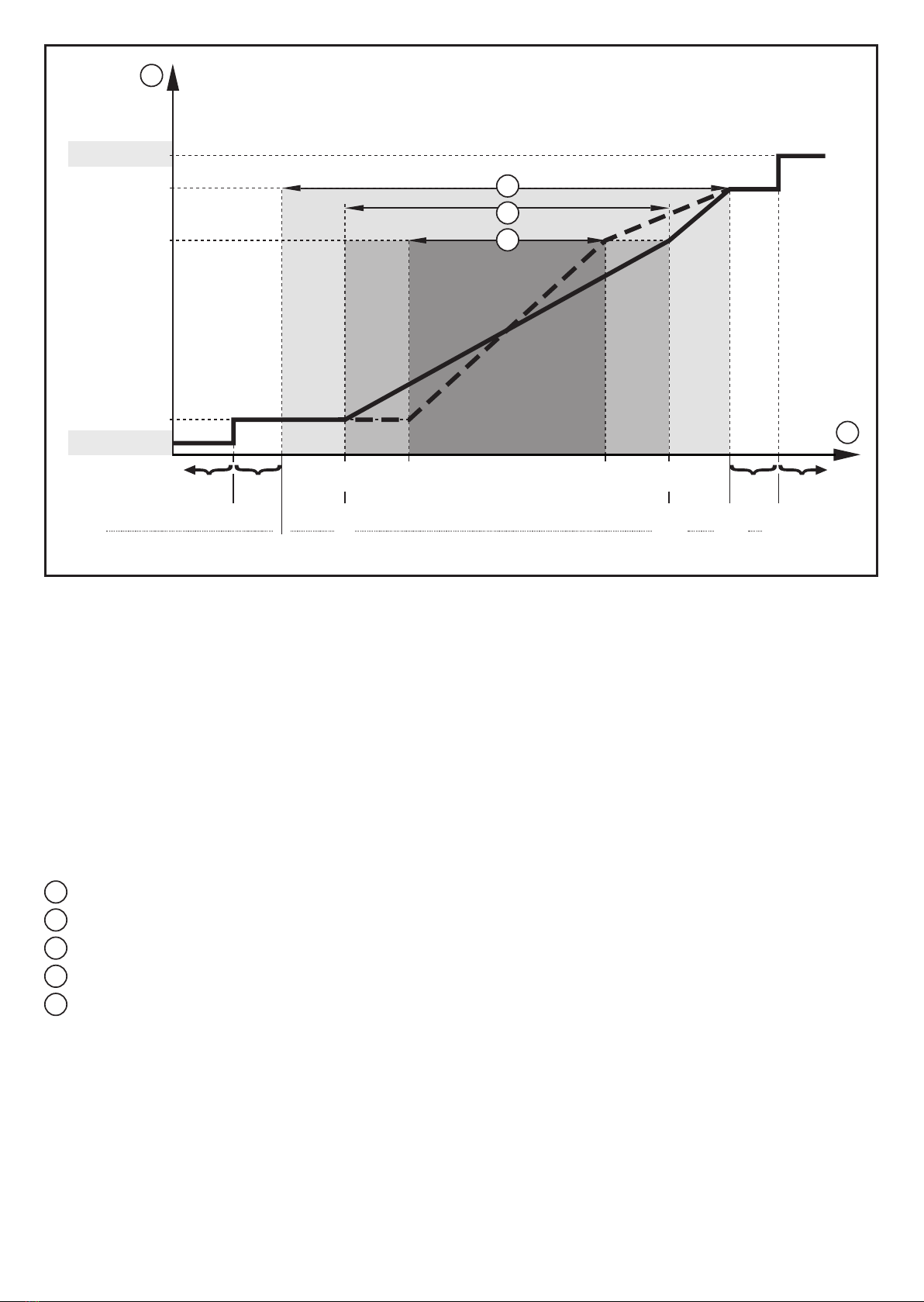

4�5 Analogue function ������������������������������������������������������������������������������������������7

4�6 Measured value damping (dAP) ��������������������������������������������������������������������8

4�7 IO-Link �����������������������������������������������������������������������������������������������������������9

5 Mounting��������������������������������������������������������������������������������������������������������������9

5�1 Installation position ��������������������������������������������������������������������������������������10

5�2 Interference in the pipe system �������������������������������������������������������������������12

5�3 Alignment�����������������������������������������������������������������������������������������������������12

6 Electrical connection������������������������������������������������������������������������������������������13

7 Operating and display elements ������������������������������������������������������������������������14

8 Menu������������������������������������������������������������������������������������������������������������������15

9 Set-up ����������������������������������������������������������������������������������������������������������������17

10 Parameter setting ��������������������������������������������������������������������������������������������18

10�1 Parameter setting in general ���������������������������������������������������������������������18

10�1�1 Switch between the menus���������������������������������������������������������������19

10�1�2 Change to the process value display (RUN mode) ��������������������������19

10�1�3 Lock / unlock�������������������������������������������������������������������������������������19

10�1�4 Timeout���������������������������������������������������������������������������������������������19

10�2 Settings for volumetric flow monitoring������������������������������������������������������20

10�2�1 Define the operating mode ���������������������������������������������������������������20

10�2�2 Define the internal pipe diameter������������������������������������������������������20

10�2�3 Configure the analogue output for flow (OUT2)��������������������������������21

10�2�4 Carry out the flow adjustment�����������������������������������������������������������21

10�3 Settings for temperature monitoring ����������������������������������������������������������22

10�3�1 Analogue output for temperature (OUT1) �����������������������������������������22