Heraeus Ut 6 P User manual

(GET)INSTRUCTIONMANUAL

Heraeus

INSTRUMENTS

LaboratoryAirCirculationOvens

ModelsUT6 P,UT12P,UT20P

ComplywiththeoperatinginstructionsandkeepthismanualinthevicinityoftheunitI

Issue:May,1994

50042750

HeraeusInstrumentsGmbH

Heraeusstrafie12-14

D-63450Hanau

DD

Nationalsales

Internationalsales

Technicalsupport

Nationalsales

Internationalsales

Technicalsupport

Spareparts

++(06181)35-300

++(06181)35-4 22

++(06181)35-5305

++(06181)35-5973

++ (06181)35-749

++(06181)35-880

++(06181)35-667

OHeraeusInstrumentsGmbH.63450Hanau,Germany

functionline*isa registeredtrademarkofHeraeusInstrumentsGmbH

TheGermanversionofthisInstructionmanualappliesintheeventofanydeviationsinthetranslation

Nominalcharge

Thisinstructionmanualappliesforthefollowingmodels:

OrderNo.

50042298

50042300

SO042306

50042312

Model

UT6P

UT6P

UT12P

UT20P

Equipment

Aircirculationoven,programmedcontroller,1/PEAC,230V;50/60Hz

Aircirculationoven,programmedcontroller,1/PEAC,120V;50/60Hz

Aircirculationoven,programmedcontroller,1/PEAC,230V;50/60Hz

Aircirculationoven,programmedcontroller,1/PEAC,230V;50/60Hz

Theseheatingcabinetsmustbeoperatedinaccordancewiththeinstructionmanualand

mayonlybeusedfortheirintendedapplicationsinordertoensurethesafetyofperson-

nel,theenvironmentandtheprocesseditemsandmaterials.

Readtheinstructionmanualcarefullybeforeusingtheequipmentandcomplywiththein-

structionsthatitcontainstoavoidmakingmistakesandtopreventanypersonalinjuryor

damagetoproperty.

2/3450042750Issue:May,1994

CONTENTS

1.GENERALSAFETYINSTRUCTIONS4-6

Explanationoficons4

Generalinformation5

Operatinginstructions5

Fieldofapplication5

Safelyinstructions6

2.SETUPANDINSTALLATION7-9

Transport7

Unpackingtheunit7

Installation7

Roomventilation8

Mainsconnection8

Noiseinsulation8

Connectingtoanairextractionsystem9

3.UNITSPECIFICATION10-17

Overviewofthecontrolelements10

Switchgearunit10

On/ Offswitch10

Overtemperatureprotectiondevice10-11

Fresh-airflapcontrol11

Automaticcontrolunit12

Signallamps,statusfunction12

Basicfunctions:temperaturecontrol,timeswitch,airspeedadjustment12

Added-featureprogrammingfunctions,fixedprograms13

Fixedprogramsegments14

Compilationofa fixedprogram14

Exampleofa fixedprogram15

Programmedcontrollerfunction16

Terminationcommands16

Exampleofa temperature/timeprogram,definitions16

WhathappensIf...? 17

4.OPERATION18-28

Startingupwith

Basicfunctions- temperaturecontrol,timeswitch,blowerspeedadjustment18-19

Added-featureprogrammingfunctions,example20-21

Programmedcontrollerfunctions,example22-27

Operatingguidelines28

Loading28

Shutdown28

5.MAINTENANCE29-30

Decontamination/ disinfection29

Cleaning29

Servicing30

Tests30

Repairs30

Approvedspareparts/ accessories30

6.TECHNICALDATA31-34

Issue:May,1994500427503/34

GENERALSAFETYINSTRUCTIONS

EXPLANATIONOFICONS

Thissymbolmarkschaptersandsectionsofthisinstructionmanualwhichareparticularly

relevantlosafety.

Whenattachedtotheunit,thissymboldrawsattentiontotherelevantsectionofthe

instructionmanual.

Marksinformationaboutoptimumutilizationoftheunitintheinstructionmanual.

Warnsofhotsurfaces.

setI Keyfortemperatureselection,time-switchfunctionandtoconfirmenteredinformation

prog

Keyfortheprogrammingfunction,limeselectionandtoconfirmenteredinformation

vent

Keytosettheairspeedandtoconfirmenteredinformation

Valueadjustmentkey,INCREASEVALUE

Valueadjustmentkey,REDUCEVALUE

Informationaboutproperdisposal/ recycling

Overtemperatureprotectiondevice

:resh-alrflapcontrol

Continuousadjustmentfromminimumtomaximumvalues

Quickreferenceguidetooperation

oSelectthestatusofthecontrolunit(enabled/disabled)

(T)

Temperaturecontrolfunction,selecttemperature

Time-switchfunction,seltheoperatingtimes

Programmingfunction

Blowerfunction

4/34 50 042750Issue:May,1994

GENERALSAFETYINSTRUCTIONS

A

Generalinformation

Theunitfulfilsthefollowingsafetystandards:

DINEN61010-1/03.94.VDE0411Part1 / 03/94,E DINVDE0411Part111.

DIN12880Part1 /11.78andDINEN60335-1,VDE0700Part1

DINEN55011Part3,DINVDE0875Part11/ 07.'92

"Q' Alwaysquotethedataontheratingplatewhenrequestinginformationororderingspare

parts

Operatinginstructions

Theoperatormustprovideanybodyworkingonorwiththisequipmentwithwritteninstructionsfor

anyoperationstobeperformed.Suchinstructionsmustbeeasytounderstandandmustbe

availableinthelanguageoftherespectivepersonnel(FRG:UWVBG1 § 7 (2)).

•Logbook

Werecommendthata logbookiskept,whichrecordsanytestsandcalibrationoperations

performedontheunitandanyotherwork(repairs,modificationsetc.).

Fieldofapplication

Theunithasbeendesignedasanitemoflaboratoryequipmentfortechnicalapplications.

•Heattreatmentofsamplesormaterialswithoperatingtemperaturesofbetween

roomtemperature+ approx.20*Cand250'C,

e.g.fordrying,ageing,analysis,fusing,burningIn,oxidizing,reducing,preheating,etc.

•Hot-airsterilization,sterilizationbyheatingthearticleuptoa temperatureofatleast160'C

(FRG:alsorefertoDIN58947).

Note.Th«ilerillzationtemperatureusuallyrequiredinIhefleWofmedicallaboratoryworkl>110*C.

Theunithasbeendesignedforinstallationandoperationinthefollowingfields:

•Laboratories,e.g.inthecommercialorindustrialsector,schools,universities,hospitalsand

biology

Theunitisequippedwithanindependentovertemperatureprotectiondevice,whichmeansthatit

doesnotrequireconstantsupervision.

Theheatingunithasbeendesignedforcontinuoususe.

Makesurethatanadequateclearanceismaintainedbetweentheinsidewallsoftheinner

compartmentandtheloadedarticles,andbetweenthevariouslayersofloadedarticles,to

preventunevenheatingofthematerials.

Protectivegloves,gogglesetc.mustbemadeavailabletotheoperatorbecauseofthe

potentiallyhighoperatingtemperatures.

Theunitmustnotbeusedtodryorheatsubstanceswhichmayreleasecombustible

gasesorvapoursintotheatmosphere,whichcouldbumorexplodewhenmixedwithair.

Theheatingunitisequallyunsuitablefortheheattreatmentofcombustibledustsor

fibrousmaterials.

Issue:May,1994500427505/34

1GENERALSAFETYINSTRUCTIONS

Safetyinstructions

ComplywiththeInstructionsinthismanualandkeepitInthevicinityoftheunit.

TheseunitsmustbeoperatedinaccordancewiththeInstructionmanualandmayonlybeused

fortheirIntendedapplicationsinordertoensurethesafetyofpersonnel,theenvironmentandthe

processeditemsandmaterials.

ReadtheInstructionmanualcarefullyandcomplywiththeinstructionsthatitcontainstoavoid

makingmistakesandtopreventanyperonalinjuryordamagetoproperly.

Unitmustbeoperatedbyinstructedpersonnel.

Keepunitoutofreachofchildren.

ApartfromtheInstructionsinthismanual,therespectivenationalregulationsmustalsobe

observedfortheinstallationandoperationofthisunit(FRG:ZH1/119,DIN12880Part1)

Theapplicablenationalenvironmentalregulationsmustbeobservedfortheextractionofexhaust

gasesthatareproducedduringheattreatment.SuitablemeasuresmustbeImplementedto

ensurethatsuchgasesaresafelyledoutside(FRG:BlmSchG,UVPG,AbfG,WHG,ChemG,...).

Theunitmustnotbeusedtodryorheatsubstanceswhichmayreleasecombustiblegasesor

vapoursIntotheatmosphere,whichcouldbumorexplodewhenmixedwithair.Theunitis

equallyunsuitablefortheheattreatmentofcombustibledustsorfibrousmaterials.

Checkthemainsleadandconnectorfordamagebeforeusingtheunit.Ifthereareanysignsof

damage,donotconnecttheunituptothemains.

Thevoltagequotedontheratingplate(ratedvoltage)mustagreewiththemainssupplyvoltage.

Protectivegloves,gogglesetc.mustbemadeavailabletotheoperatorbecauseofthepotentially

highoperatingtemperatures.

ThesurfacesaroundtheopeningoftheInnercompartmentbecomehotathighoperating

temperatures• RISKOFBURNING- Avoidcontactwiththesesurfaces.

Ensurethattheovertemperatureprotectiondeviceworksproperlybyconductinga functional

checkatregularIntervals,every3 monthsatleast,andchecktheelectricalequipmentatleast

oncea year.

Anyworktobeconductedontheelectricalequipmentoftheunitmayonlybeperformedbya

qualifiedelectrician.Theunitmustbedisconnectedfromthemainssupplybeforecommencing

serviceorrepairwork.

Onlyuseapprovedaccessoriesandapprovedgenuinespareparts.Theuseofanyotherparts

mayresultInunforeseenproblemsandshouldbeavoidedunderallcircumstances.

Theserviceabilityandsafetyoftheunitcanonlybeguaranteedifthenecessarytests,

maintenance,servicingandrepairworkIscarriedoutbytheHeraeusservicepersonnelorother

agencieswhoareauthorizedtoactonourbehalf.

HeraeusInstrumentsGmbHcannotacceptanyliabilityforanydamagethatoccursasa resultor

improperuseorrepairwork,whichhasnotbeenperformedbyHeraeusservicecenters,orif

partsotherthantheapprovedgenuinespareparts/ accessoriesareused.

6/3450042750Issue:May,1994

SETUPANDINSTALLATION

Transport

Handletheunitwithcare.Avoidjarringandprotectagainstdamage.Donotliftbythedoor

handle,thedooritself,thecontrolunit,theblowerbox,thespacerorthepowerlead.

RefertotheTECHNICALDATAfordimensionsandweight.

•Unpackingtheunit:

Unpacktheunit,removethetransportsafetyfixturesfromtheinnercompartmentandremove

anydirtordustwhichmayhaveaccumulatedintransit.

Installation

Theunitmustbeinstalledina dryenvironment.

Therelativehumidityshouldbebetween60andZO% undernormalconditions.

Condensationshouldbeavoided.Ifcondensationhasformedontheunitfollowinga changeof

locationorduringtransporalion.forexample,waituntiltheunithasdriedoutcompletelybefore

puttingintooperation.

Theambientairshouldnotcontainexcessiveamountsofdust.

(ComplywiththeinstructionsintheMAINTENANCEsection).

Donotcoverorobstructtheventilationorexhaustventsintheunithousing,removeanydustor

dirtwitha vacuumcleaner.

Theambienttemperatureshouldnotexceed40*C.

Placetheunitona firm,fireproofsurface(e.g.laboratorytable,supportframe)ina stable,

perfectlyuprightposition.

Keeptheunitawayfromdirectsunlight(UVradiation).

Ifyouwishtostacktwounitsontopofoneanother,usethestackingframe(availableasan

option).Neverstackmorethantwounitsontopofoneanother.Whenstackingunitsofdifferent

types,makesurethate.g.anIncubatorisalwaysatthebottom,andpreventanymutual

influence.

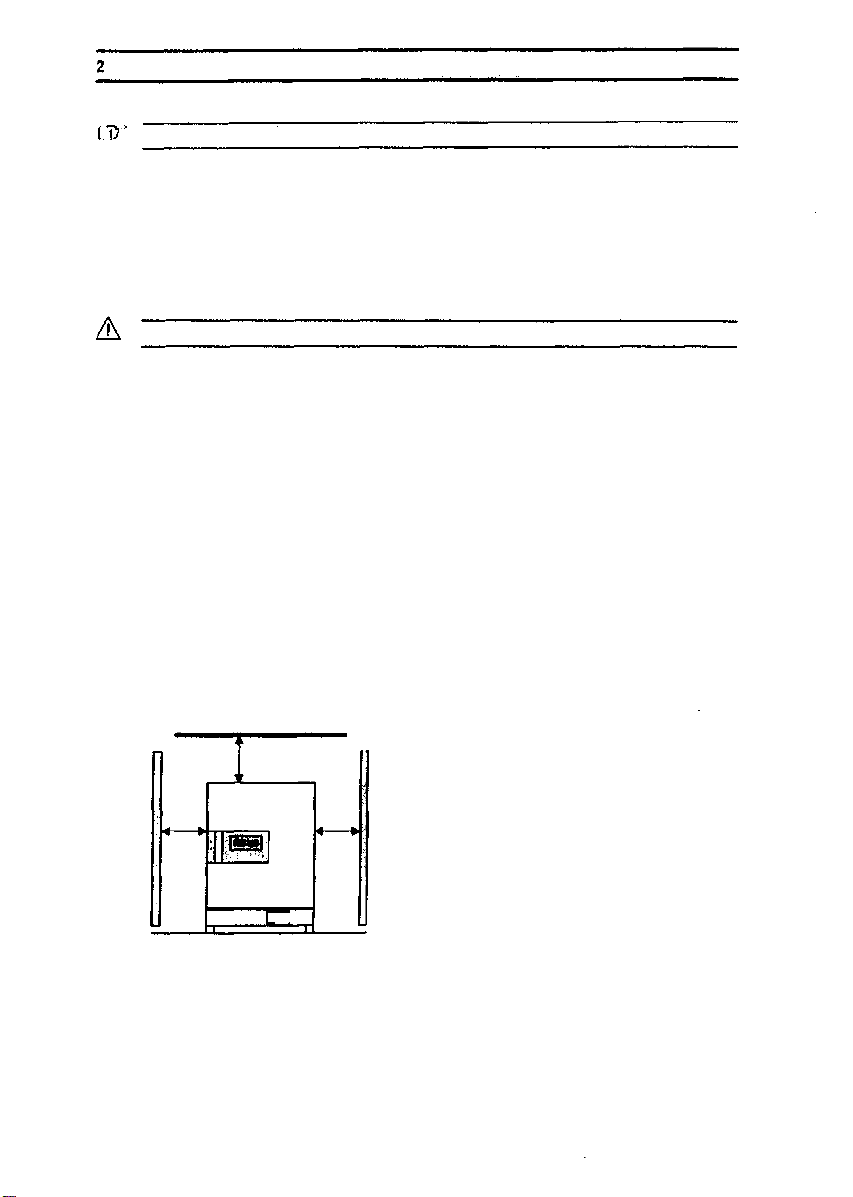

Fig.1/2:Clearancestoadjacentsurfaces/ objects:

:5cm

30cm

*m>JI

•

5cm>

Maintaina distancefromtheback:

UT6P:atleast12cm

UT12P:atleast8 cm

UT20P:atleast8 cm

Thewallspacermayonlyberemovedifthe

unitisconnecteduptoanextractionsystem.

Theexhaustgasesmustbeledthrough/ past

adjacentsurfaces/ objectslocatedaboveor

behindtheunitwithheatinsulationto avoid

thedangeroffire.

IftheunitUT6 P istobefittedundera tableorintoa laboratoryfixture,itmustbeconnected

toanexhaustairextractionsystem.Thetopclearancemayonlybereducedtomin.5 cmunder

suchcircumstances.Ensureadequateventilation.

TypesUT12P andUT20P arenotsuitabletobefittedundera table.

Issue:May,1994500427507/34

SETUPANDINSTALLATION

Roomventilation

Adequateventilationmustbeprovidedwherevertheunitisinstalled.

DonotoperatetheunitInnon-ventilatedenclosedspaces.

Specialventilationmeasures(e.g.ventilationofdesignatedworkareas,FRGalsorefertoVDI

1946Part7)whenseveralunitsareInstalledinoneroom.

Mainsconnection

Thelaboratoryunitissuppliedwitha permanentlyconnected,flexiblemainspowerleadwith

connector(grounded).

Theconnectorservestodisconnecttheunitfromthemainspowersupply.

Examinethepowerleadandconnectorfordamagebeforeusingtheunit.Ifthereareanysigns

ofdamage,donotconnecttheunittothemainssupply.

Thevoltagequotedontheratingplate(ratedvoltage)mustagreewiththenominalmains

voltage.

Theunitmayonlybeconnecteduptothemainsviaa properlyInstalledsocketoutletwithPE

conductor(protectionclassI)ora permanentterminalconnection.

Intheeventofa permanentterminalconnection,a masterswitch(lockableInthe"Off"

position)mustalsobeinstalledtodisconnecttheunitfromthemains.

Anearth-leakagecircuit-breakershouldalsobefittedinthesupplysystemtoprovide

additionalprotectionagainstelectricshocks.

Rubber-sheathedflexiblecableofatleast2.5mm3diameter(H07RN-F...)shouldbeusedfor

anyextensionsthatmayberequiredtoconnecttheunit.

RefertotheTECHNICALDATAsectionfortheratedpowerconsumption,circuitprotection

witha T16A fusiblelinkora 8 16circuit-breaker.

NoiseInsulation

Theunitdevelopsa constantnoiseload.

RefertotheTECHNICALDATAsectionforthenoiselevel.

TheunitmayproducehighernoiselevelsInunfavorableInstallationconditions.Supplementary

measuresmayhavetobeImplementedtoImprovethesoundinsulationintheroom.

8/3450042750Issue:May,1994

SETUPANDINSTALLATION

/j\ Connectingtoanextractionsystem

Complywiththeapplicablenationalenvironmentalregulationsfortheextractionof

exhaustgasesreleasedduringtheheattreatment.Suitablemeasuresmustbe

implementedtoensurethatsuchgasesaresafelyledoutside(FRG:BlmSchG).Such

measuresmayinvolvethermalorcatalytictreatmentoffluegases.

RefertotheTECHNICALDATAsectionforthevolumeflowandtemperatureoftheexhaust

gases.

Fig.2/2:Exampleofaninstallation

1Inletairflow

2Heatingcabinet

3Adjacentsurface/ object

4Exhaust-airblower

5Exhaustairflow

Draftbreaker

Implementationinstructions:

•A draftbreakermustbeusedtoconnecttheunittoanextractionsystem.

•Allflueductsmustbemadeoffireproofmaterials.

•Aperturesmustbeprovidedtoenabletheremovalofresidueandcondensate.Theflue

ductsmustbethermallyinsulated(recommendation:half-shellsleevesmadeoflaminated

mineralTiber).

•Theexhaustair/ gasesfromtheunitmustnevercomeintocontactwithcombustionex-

haustgases.

•Usethedraftbreakertoadjusttheairflowvolumeinsucha waythatexhaustgasescanbe

extractedreliablywithoutproducinganyeddyingattheunit'sexhaust-gasconnector.

•Technicalmeasuresshouldbeimplementedtomonitortheflowofairandfluegasesandto

preventoperationoftheheatingunitiftheventilationsystemIsswitchedoff/ defective

(electricalinterlock).

Issue:May,1994500427509/34

3.UNITSPECIFICATION

Fig.1/3:Overviewofthecontrolelements

I1 c

--~i—.

I4-

—B

A

ULJ

ASwitchgearunit

BAutomaticcontrolunit

CDoorhandle

ItemA:Swltchgearunit

Fig.

1-

4-

•1

2/3:Switchgearunitcontrolpanel

ON/ OFFswitch:

-21On/ Offswitch

2Overtemperatureprotection,

controlelement

3"Fault"signallamp

4Fresh-airflapadjustment

Toswitchtheunitonandoff:

"on"= Unitswitchedon,thetemperatureInsidetheunitappearsonthedisplaypanel

ofthecontrolunit,

"off'= Unitswitchedoff,temperaturedisplayoff.

•2 & 3 Overtemperatureprotectiondevice/ signallamp:

Theunitisequippedwithanelectronicupper-limitcut-outdevice(TWB)ofprotectionclass2

asdefinedbyDIN12880Part1.IIIselectricallyandfunctionallyindependentofthetemperature

controlsystem.Intheeventofa faultIntheunitheatingsystem,theoperationalTWBshuts

downtheunitheatingacrossallpolesassoonasthetemperatureexceedsthepresetvalue.

TheredsignallampIndicatesactivationoftheprotectionfunction(Fig.2/3:Item3).

Theunitmustberesetmanually,bypressingthecontrolelement.

*Allowtheunittocooldown(byapprox.30*C),pressthecontrolelement,theredsignallamp

willgoout.

TheoperatevalueIsadjustedwiththehelpofa tool(coin,screwdriver...).

Adjust(otherequiredprotectionlevel:

•touppertemperaturelimit»unitprotection(protectstheunitanditsenvironment).

*•toapprox.10*Chigherthantheoperating temperaturesetonthecontrolunit=

materialprotection(protectstheunit,Itsenvironmentandtheloadedmaterial).

Ensurethattheovertemperatureprotectiondeviceworksproperlybyconductinga

functionalcheckatregularIntervals,every3 monthsatleast,andchecktheelectrical

equipmentatleastoncea year.

10/3450042750Issue:May,1994

3.UNITSPECIFICATION

•2 & 3 Overtemperatureprotectiondevice/ signallamp:

FunctionaltestoftheTWB

(Prerequisite:requiredworkingtemperature(controlunit)hasbeenreached/remainsconstant)

SettheTWBtoapprox.10- 20'Cbelowthetemperaturedisplayedonthecontrolunit.The

TWBmustrespond,theredsignallampindicates"Fault".

TheTWBisworkingproperly.PressthecontrolelementtoreleasetheTWB.

NowsettheTWBtothetemperaturelimitfortherequiredtypeofprotection.

If"Fault"issignalledduringoperation:

CheckthesettingsoftheTWBandthecontrolunitandcorrectifnecessary.Ifsetfor"material

protection",thismayindicatea blowermalfunction.Iftheproblempersists,contacttheservice

center.

•4 Fresh-airflapcontrol

Forcontinuouscontrolofthefresh-airsupplytotheinnercompartment.

•*Settoleft-handstop= minimumfresh-airsupply

*•Settoright-handstop= maximumfresh-airsupply

Issue:May,19945004275011/34

3.UNITSPECIFICATION

ItemB:Automaticcontrolunit

Theautomaticcontrolunitcontainsthebasicfunctionsofa 2-posilioncontrollerwithPD/PID

controlresponse,timeswitchtoswitchtheheatingandventilationon/ offafterthesettime,the

addedfeaturesofpermanentlyprogrammedheatingprocessprogramsandtheprogrammed

controllerfunctionsofa freelyprogrammableprocesscontroller.

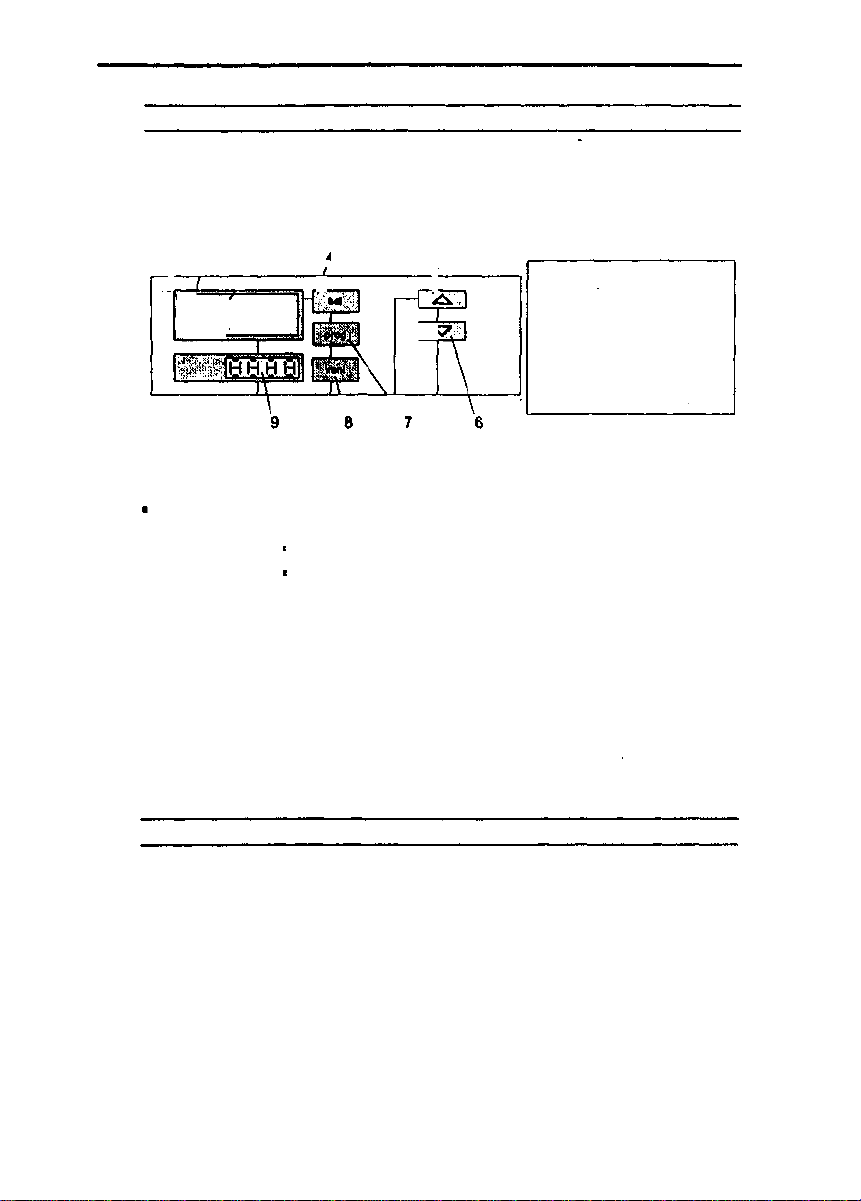

Fig.3/3:Controlunitcontrolpanel

1\\

"C

2

I

IB

*vl

3

/

/

DP

QQ

iA

5

//

M

\\

1

2

3

4

5

6

7

8

9

Signallamp- healing&talus

Signallamp- controlumlstatus

Displaypanel

Controlkey

"Increasedisplayedvalue"key

"Reducedisplayedvalue"key

"Programmingfunction"key

"Airspeedadjustment"key

Displaypanel

ThestatusofthecontrolunitisIndicatedbysignallampsinthedisplaypanel.

THEYELLOWSIGNALLAMP(Item1)indicatesthecurrentstatusoftheheatingcontrolsy-

stem:

unitheatingactivated

heatingoff

»•Lampswitchedon•

••Lampswitchedoff:

Rhythmicflashingofthissignallampindicatesthatthetemperaturecontrollerisregulating

theoperating temperature.

•THEGREENSIGNALLAMP(Item2)indicatesthestatusofthecontrolunit:

>Lampon» controlunitswitchedon:heatingandblowerenabled.

Theheatingandblowerareactivatedwhentheunitis switchedon (On/ Offswitch).

••Lampoff» controlunitswitchedoff:heatingandblowerdisabled.

Theheatingandblowerarenotactivatedwhentheunitisswitchedon

*•Lampflashes* time-switchfunctionactivated.

Basicfunctions

Thecontrolunitisequippedwiththe"temperaturecontrol","timeswitch"and"insideair

speedadjustment"basicfunctions.

Theunitcansetanoperatingtemperatureofupto250*C,switchingtimesofbetween

0:01and99:00hoursandandInsideairspeedinstagesofapprox.40%,approx.70% and

100%.

RefertoSTARTINGUPWITHBASICFUNCTIONSforinformationaboutthecommandsfor

thebasicfunctions.

12/3450042750Issue:May,1994

3.UNITSPECIFICATION

Added-featureprogrammingfunctions,fixedprograms

Thecontrolunitiscapableofrunningheatingprocessprogramswithfixed,preselected

parametersfroma database.

Theprogramsegmentandtheparametersarestoredinthedatabase.

Thefixedprogramcontainsa maximumoffourprogramsegmentsanda statuscommand.

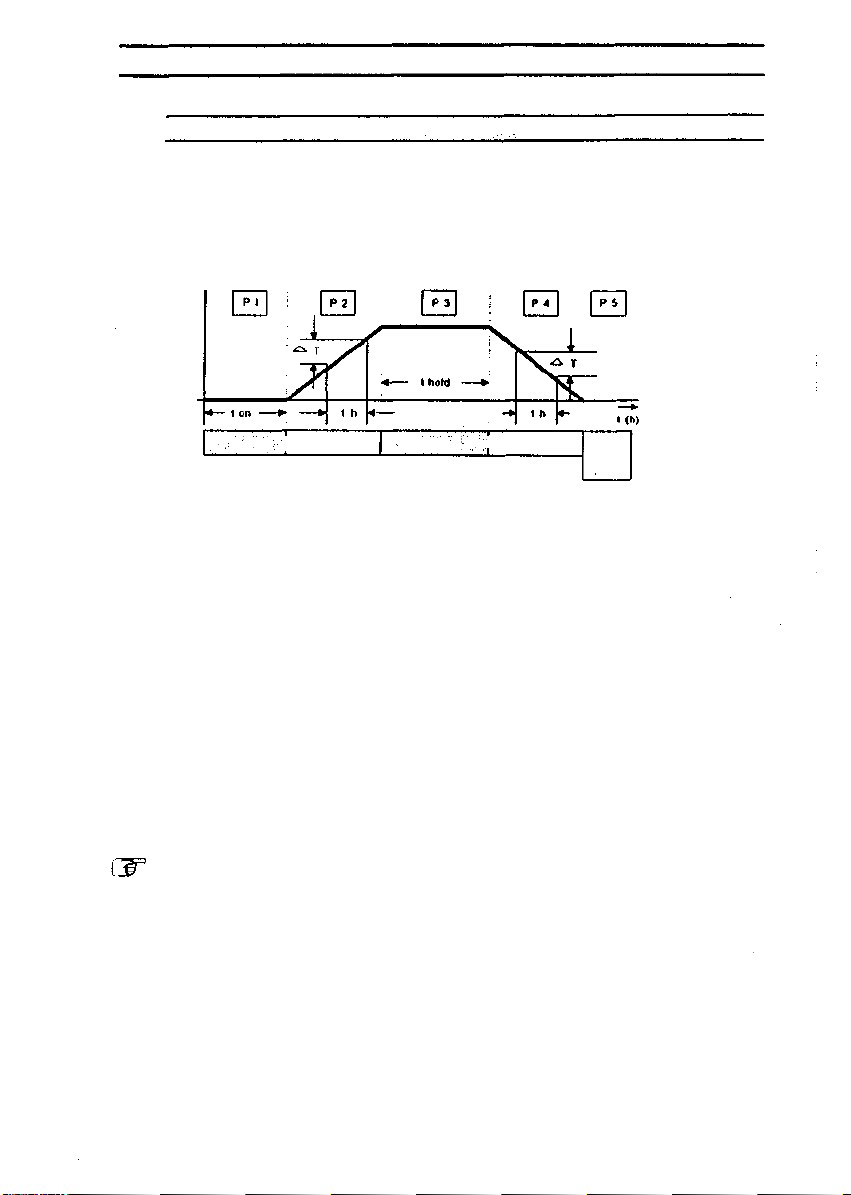

Fig.4/3:Exampleofa temperalure/timeprocess,controlledbythefixedprogram

t

TfC)

PI.0-PI.9:jP2.0-P2.9P3.0.P3.»j.lP4.0-P4.9P.OF

P.OFI

P.re

Eachprogramsegment,P I - P 4,isassignedtoa typicaltemperature/ timeresponse.10

selectablesetsofparametersarepermanentlystoredInthedatabaseforeachprogram

segment.Thesesetsofparameterscan.beassignedwithintheprogram.

Astatuscommandisprovidedasthefifthprogramsegment.Thisdeterminesthesubsequent

actionwiththeprogramselectedfromthefixedprogrammemory:

*Programonstandby,donotexecuteyet= Select"P.o F'

••Programonstandby,waitforprogramstart• Select"P.o n"

••Deleteprogramfrommemorycompletely• Select"P.r E "

Theprogrammemoryiserasedondelivery.IftheoperatorInterrogatestheprogramsegments,

"Parametersetoff'appearsinthedisplaypanel= e.g."P.I -".

Whencompilinga program,selecting"parametersetoff"withintheselectedprogramsegment

causesthecontrolunittobypassthissegmentforthefixedprogramfunction.

TheselectedprogramalwaysrunsfromprogramsegmentP I.n toprogramsegmentP 4.n.

IfprogramsegmentP 3.n iscombinedwithprogramsegmentP 4.n,theheatingandblowerare

onlyswitchedofffollowingterminationofsegmentP 4.n.

Ifa programisinterruptedandstartedagain,thesequencecommencesatsegmentP I.n.

Thepreviouslyselectedoperatingtemperaturecannotbechangedoncetheprogramhas

started.

Theheatingisswitchedoffintheeventofa powerfailure(>20ms)withsubsequentrestoration

ofthepowersupply,thetemperatureinsidetheunitIsdisplayedasa flashingvalueandthe

programmustbestartedagain.

Issue:May,19945004275013/34

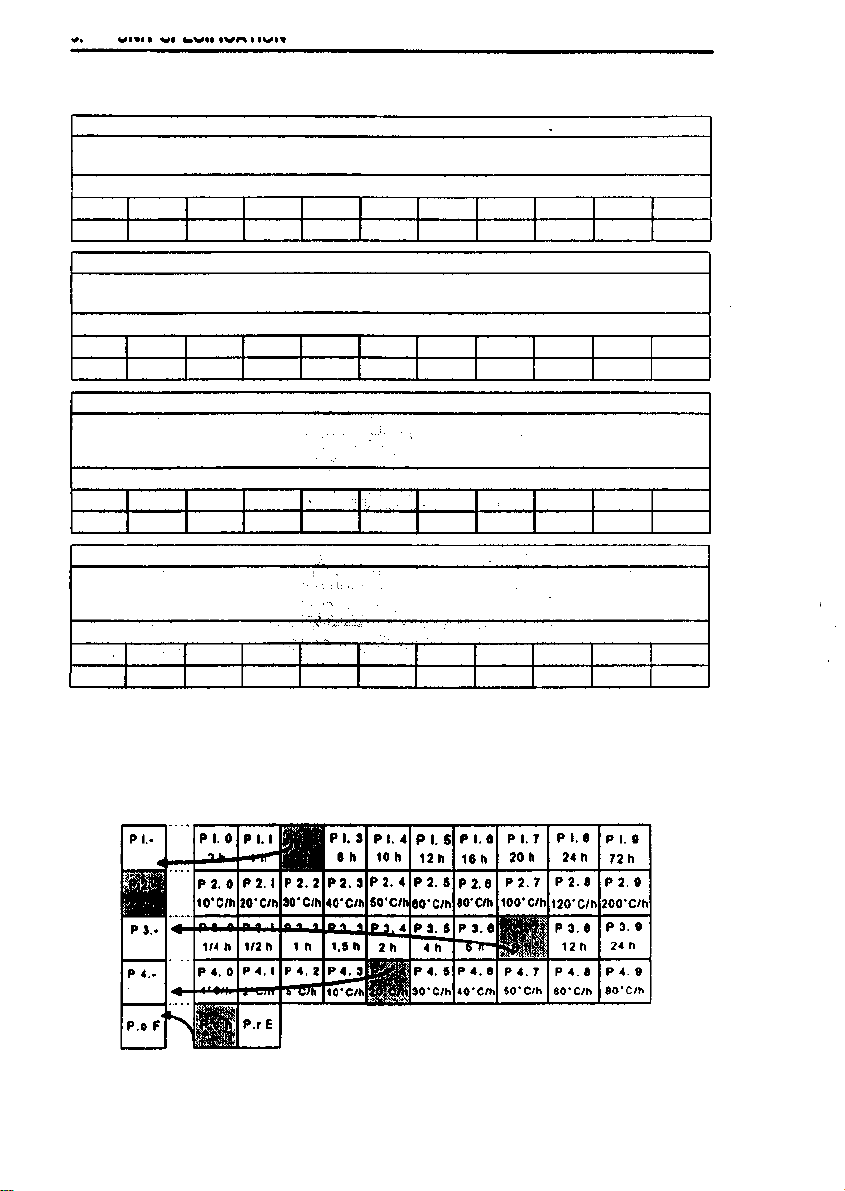

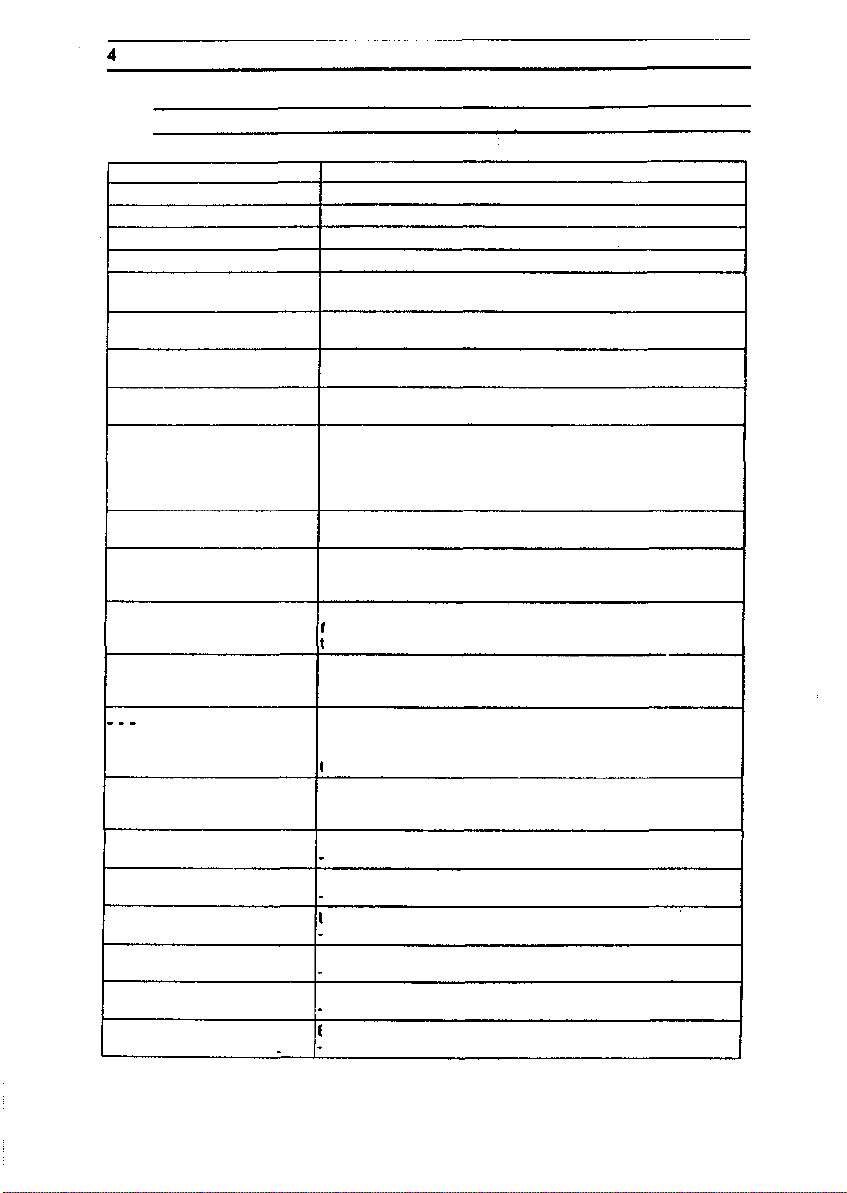

•Fixedprogramsegments:

Programsegment"P 1.n " (n= -,0...9):

Assigninga parameter(0...9)fromthedatabasecausestheunittoswitchonheatingandventilation

onexpiryofa presetperiod.

SelectableparametersInthisprogramsegment:

PI- PL 0 PI.I PI.2 PI.3

PI.4

PI.5 PI.6 PI.7 PI.8 PI.9

Off2h4h6h8h10h12h16h 20h 24h 72h

Programsegment"P 2.n " (n«-,0 ...9):

Assigninga parameter(0...9)causestheunittoheatuptothepresetoperatingtemperatureata

specificrateoftemperaturechangeperhour.'1

SelectableparametersInthisprogramsegment:

P2.-

P2.0 P2.1P2.2 P2.3P2.4 P2.5 P2.6P2.7 P2.8 P2.9

off

10*C/h20'C/h

30"C/h

40'C/h50'C/h

60*C/h

80'C/h

100'C/h120*C/h

200'C/h

Programsegment"P 3.n " (n• -,0...9):

Assigninga parameter(0...9)causestheunKtoheatuptothepresetoperatingtemperature,to

maintainthistemperatureforthepresetperiodandtosubsequentlyswitchoffheatingand

ventilation

SelectableparametersInthisprogramsegment:

P3.-

P3.0P3.1P3.2P3.3P3.4P3.5P3.8P3.7P3.8 P3.9

off15min.30mln.1h1.5h 2h4h6h8h12h 24h

Programsegment"P 4.n " (n«-,0 .*9):,.

Assigninga parameter(0...9)causestheunittocooldownfromthepreviouslyreachedInside

temperatureata specificrateoftemperatureChangeandtosubsequentlyswitchoffheatingand

ventilation.11•*:;

SelectableparametersInthisprogramsegment:

P4.-P4.0P4.1P4.2J»4!/3'P4.4P4.5P 4.6P 4.7P4.8P 4.9

off1'C/h

2*C/h

5'C/h

10*C/h20"C/h30"C/h40'C/h50'C/h60"C/h80'C/h

1)KOORDnglonvxM»ndload

•Compilationofa fixedprogram

Afteractivatingtheadded-featurefunction,thesequenceiscompiledbymarkingtherequired

programsegments.

Example:FixedprogramcomprisingP I.2;P 2.-;P 3.7;P 4.4andP.o n :

14/3450042750Issue:May,1994

3.UNITSPECIFICATION

•Exampleofa fixedprogram

*•ExampleE1:Hot-airsterilizationprocess

Theheatingshouldswitchonin8 hours,theunitshouldheatuptoanoperatingtemperature of

190*C(sterilizationtemperature)ata rateof200*C/h,maintainthistemperaturefor4 hours

(equalizationphaseandsterilizationperiod)andshouldsubsequentlycooldownata rateof20

•C/h.

Theprogramshouldstartfollowingprogramselection(statuscommand:P.on).

Fig.5/3:Programprofile- hot-airsterilizationprocessEl

190-Cc1S2S3S4' S1- S 4«Programmsegment

:/A

miP3.5

P.onl

SequenceE1:

Aftersketchingtheprocesscharacteristic,selectthesegmentswhichcorrespondtothe

requiredsequencefromthematrix.

Marktheprogramsegmentsandthe" P.o n"statuscommand.LeaveprogramInputmode.

Select190"Castherequiredoperatingtemperature.Startthefixedprogram.

Whiletheprogramisrunningthedisplayalternatesbetweenthetemperatureinsidethe

cabinetandthecurrentprogramsegment.

RefertoSTARTINGUPWITHADDED-FEATUREPROGRAMMINGFUNCTIONSforfurther

information.

Issue:May,19945004275015/34

OPERATION

Programmedcontrollerfunction

Theprogrammedcontrollerfunctionenablesthearbitrarydefinitionoftemperature/ time

processes.

Youmayselectupto9 programsegments.Operatingtemperature,periodandairspeedlevel

canbeselectedforeachsegment.

Terminationcommands

Aterminationcommandcanbeselectedasthelastprogramsegment.Theterminationcommand

determinesthefunctiontobeperformedbytheunitafterrunningthroughtheprogram

Therearethreeoptionalterminationcommands:

••" hold" = Oncetheprogramhasterminated,theoperatingtemperaturesetforthelast

programsegmentismalntaneduntila newoperatingtemperaturehasbeen

selected.

*••stOP" = Oncetheprogramhasterminated,Iheheatingandblowerareswitchedoff

untilthe"stop"commandIscancelled.

>•••CYCL"- Oncetheprogramhasterminated,Itreturnstothebeginningandisrepeated

continuouslyuntilthe"CYCL"commandiscancelled.

Aterminationcommandmustalwaysbeenteredattheendofeveryprogram.

Fig.6/3:Exampleofa temperature/ time/ ventilationprogramwith"CYCL"termination

command

40

r

%T1

1M

\7

\.\ST3

i

T4

4

100%

\

•»T5V

T7

/

n8

T8

\

V

>

T9

\

11t2t314t5re t7t8t9t

n10«CYCL

•Definitions

n1...n9

n10

T1 ...T9

11...t 9

Programsegments

Terminationcommands(hold,StOPorCYCL)

Specifiedoperatingtemperature(SO- 250*C)

Specifiedtime- programsegment(0:01- 99:0h)

U1 ...U 3 Specifiedventilationlevel(approx.40%.approx70% and100%)

•RefertoSTARTINGUPWITHPROGRAMMEDCONTROLLERFUNCTIONSfordetails.

16/3450042750Issue:May,1994

OPERATION

Whathappensif...?

Possibledisplay

888

OFF

Onedigitinthedisplayflashes

P1.3

P1.3alternatingwithinside

temperature

P.o n

P.OF

P.rE

Proalternatingwithinside

temperature

nI

hold

stop

CYCL

E-3

E-4

E-S

E-6

E-7

E-8

E-9

Explanation

Controlunittestphase

Statusofthecontrolunit,heatingandventilationdisabled

Theflashingvaluecanbechanged

Programsegmentwhenenteringanadded-featureprogramfunction

Programsegmentwhiletheadded-featureprogramisinprogress

Statuscommandforanadded-featureprogram:

Programonstandby,waitforprogramstart

Statuscommandforanadded-featureprogram:

Programonstandby,donotexecuteyet

Statuscommandforanadded-featureprogram:

Deleteprogramfrommemorycompletely

Enteredprogramonstandby

Powerfailure(>20ms)withsubsequentrestoration:theheating

switchesoff,"Pr o"alternateswiththetemperatureinsidetheunit

onthedisplay,ifa programisinprogressItisInterruptedandmust

bestartedagain.

Programsegmentwhenenteringandactivatingtheprogrammed

controllerfunction.

Terminationcommandwhenenteringtheprogrammedcontroller

function:thetemperaturesetforthelastprogramsegmentis

maintainedonterminationoftheprogram

Terminationcommandwhenenteringtheprogrammedcontroller

unction:theheatingandventilationisswitchedoffonterminationof

heprogram

Terminationcommandwhenenteringtheprogrammedcontroller

function:whentheprogramisterminated,itretumstothebeginning

andstartsagain

Aterminationcommandisenteredforthisprogramsegmentwhen

enteringtheprogrammedcontrollerfunction.Thetermination

commandmustbechangedtoa timevaluetoenabletheinputofa

emperaturevalue.

Storeddatadefective

Switchtheunitoffandonagain.Iftheproblempersists,contactthe

servicecenter

Errorofmeasurementinthereferencevalues

contact(heservicecenter-

Upper-limitviolationofactualtemperaturetolerance

contacttheservicecenter-

.ower-limitviolationofactualtemperaturetolerance

contacttheservicecenter-

Temperaturesensororinputdefective

contacttheservicecenter-

Storeddatadefective

contacttheservicecenter-

Erroneousreferencevalues

contacttheservicecenter-

Issue:May,19945004275017/34

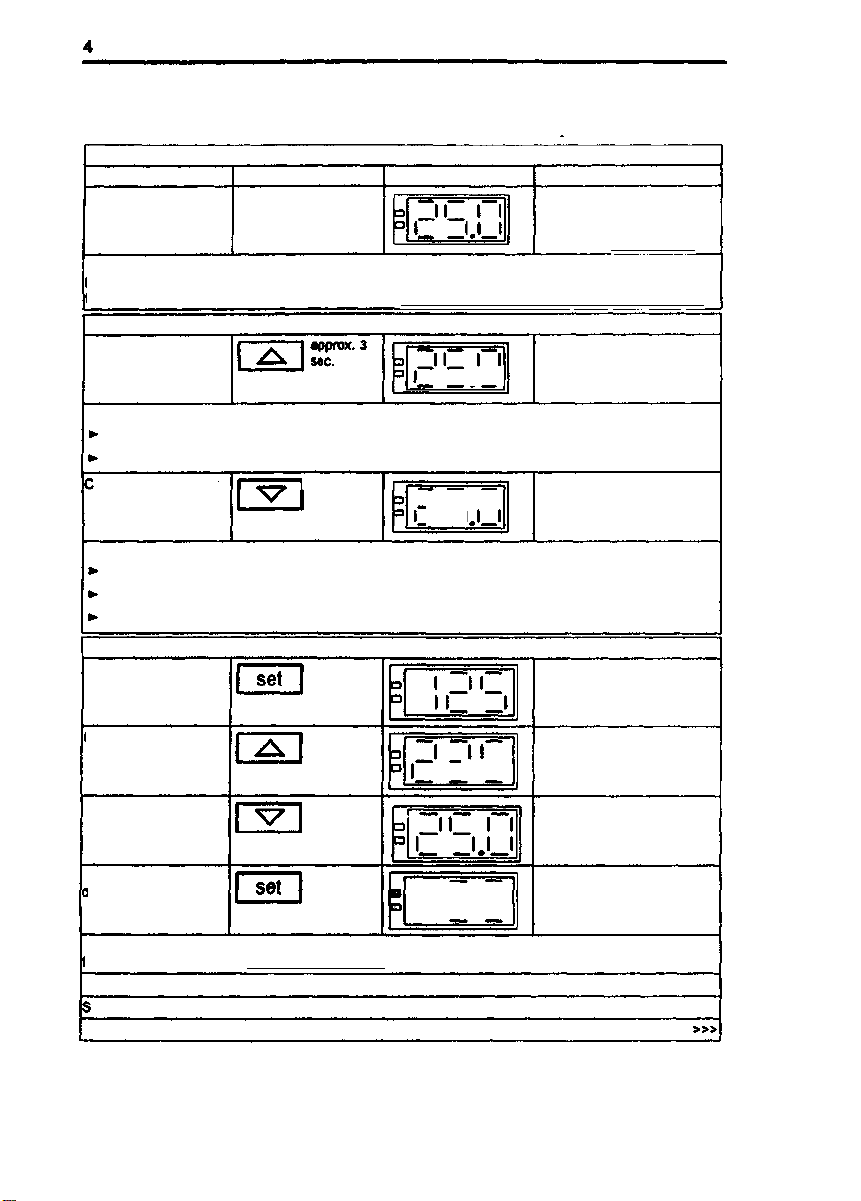

OPERATION

AflerletupandInstallation,proceedasfollowstostartup:

Startingupwithbasicfunctions,withoutprogramming

InstructionKey(s)

ExampleoldisplayRemarks

SwitchunitonOn/ Offswitch= "on"Thegreenstatusdisplay

indicatesthestatus.

Displaypanel:inside

temperature

Theunitrunsthrougha self-testphaseafterswitchingon,display:" 888".

Ifthe"off'statuswasselectedforthepreviousoperatingphase,thedisplayalternatesbetweenthe

lemperatureInsidethecabinetandthe"oFF"status.

Selectingthecontrolunitstatusfunction

Controlunit"on":

(heatingand

ventilationenabled)

1.1

li

Insidetemperature,green

signallamplightsup

continuously

Selectthisstatusfunction

tooperatetheunit,or

tousethetime-switchfunctiontoswitchtheheatingandventilationoffaftera presetperiod

ontrolunit"off":

(heatingand

ventilationdisabled)

Iapprox.3

sec.III I

:D

Insidetemperature,

greensignallampremains

dark

Selectthisstatusfunction

toswitch theheatingandventilationoff,or

IftheheatingandventilationIstoremainoffduringprogramming,or

tousethetime-switchfunctiontoswitchtheheatingandventilationonaftera presetperiod

Saltingtheoperating temperature

Displaythepreset

operatingtemperaturePresetoperatingtemperature

Displayflashes

Increasethepreset

operatingtemperature 'II

Valueincreases

Displayflashes

Reducethepreset

operatingtemperatureValuedecreases

Displayflashes

Storenewpreset

iperatlngtemperature IIII

I""III

Newoperatingtemperature

isstored,thenInside

temperature appearson

display

Unitregulatestheoperatingtemperaturewhenstatus"on",yellowsignallampindicatesthestatusof

Iheheatingcontrolsystem.

Adjustingtheovertemperatureprotectiondevice:refertoChapter3

ettlngthepositionofthefresh-airflap

18/3450042750Issue:May,1994

OPERATION

Settingtheswitchingtime

Instruction

Selecttime-switch

function,displaytime

remainingfortiming

period

Increasepresettime

Reducepresettime

Key(s)

Exampleofdisplay

II III

I.IIII

lI II

.lI l

Remarks

Displayflashes,lime-swilch

funcitionisdisplayed.Ifliming

periodinprogress,displays

timeremaining

Valuecanbeadjusted

between1 minuleand99

hoursAdjustableinfullhours

from10.0hourselling

Theheatingisswitchedonor

off.accordingtoselstatus.

oncetimingperiodhas

expired

Storenewpresettime

value

setII

.II

Thelimevalueistransferred

tothememory,theinside

temperaturethenappearson

thedisplay

TheflashingstatusdisplayIndicatesthatthetime-switchfunctionhasbeenactivated.

Ifyoudonotwishtousethetime-switchfunction,enter0.00 asthepresettime.

Selectingtheairspeedlevel

Displaythepresetair

speedlevel•"I

1

11

11

1

r

'—

1

-1

'-'1

in

•-•1

Presetairspeedlevel

Displayflashes,

speedsymbol

Increasepresetair

speedlevel

IIUU|

Valueincreases

(e.g.70%/100%)

Displayflashes,speed

symbol

Reducepresetair

speedlevellt ~^—**~^i Valuedecreases

(e.g.70% / 40%)

Displayflashes,speed

symbol

Storenewpresetair

speedlevelAirspeedlevelisstoredand

thedisplaythengoesdark

Issue:May,19945004275019/34

4OPERATION

Fig.1/4:Exampleofa hot-airsterilizationprocess

190*C

S1 - S 4 • Programmsegment

P3.5

P.onl

Theheatingistoswitchonin8 hours,theunitshouldheatupto190'Cat200'C/h,maintainthis

temperaturefor4 hours,thenswitchoff.

Theprogramshouldstartfollowingprogramselection(P.o n).

Startingupwithadded-featureprogrammingfunctions

|Key(s).

|Exampleofdisplay|Remarks

Instruction

Switchuniton,selectoperatingtemperature:refertostart-upwithbasicfunctions

Adjustingtheovertemperatureprotectiondevice:refertoChapter3

Controlunit"oir,unit

shouldnotheatup

duringthisinput

-==—Iapprox.3

>/sec.II

UI

Statusdisplay= "off",

controlunitisdisabled,Inside

temperatureIsdisplayed

Callfixedprogram

memory

——Iapprox.6

setsec.Displayflashes,program

segmentS1appearsafter6

SelectparameterPI.3 II I Programmabledigitflashes.

PI.Isdisplayedifno

parameterhasbeenmarked

UI _J

IL I

Programmabledigitflashes

MarkP I.3 asthe

requiredparameterin

programsegmentS1setII I _

I.I

PI.3 istransferredlothe

memory,programmabledigit

flashes

Selectprogram

segmenlS2Programmabledigitflashes

ContinueInthesamemannertoenter/ markprogramsegmentsP 2.9,P 3.5 undP 4.

20/34

50042750Issue:May,1994

This manual suits for next models

6

Table of contents

Other Heraeus Oven manuals

Popular Oven manuals by other brands

Fargas

Fargas CBF5S user manual

Creda

Creda S036E Instructions for installation and use

Groen

Groen CONVECTION COMBO CC-E series Operator's manual

Siemens

Siemens HB23.B..0 Series instruction manual

Salton

Salton Vitantonio VT6 owner's manual

Electrolux

Electrolux GourmeXpress Installation and operating manual