Heritage Glastonbury SGSIN05 User manual

Instaation

Guide

Models Covered:

Sequential and Concentric

Exposed Shower Valves

Please keep this booklet for future

reference.

Installer: When you have read these

instructions, please ensure you leave them

with the user.

2

INTRODUCTION

Thank you for buying a Heritage Product. When you buy a Heritage product, you can be condent

that it not only features a beautiful, distinctive, classic design, but that it has also been made to the

very highest quality standards.

To ensure that it works to its full potential, it needs to be tted correctly.

These tting instructions have been created to give you all of the information you need and, if you

need any further help, please do not hesitate to give us a call on: 0330 026 8503.

CONTENTS

SAFETY NOTES 3

SPECIFICATION 4

INSTALLATION REQUIREMENTS 5-7

PRIOR TO INSTALLATION 8-9

TOOLS REQUIRED 10

INSTALLATION 10-11

O P E R AT I ON 11

MAINTENANCE 12-17

TROUBLESHOOTING 18

CARING FOR YOUR PRODUCT 19

GUARANTEE 19

NEED HELP? 19

3

Please make sure you read these instructions and retain for future use.

All products manufactured by Heritage Bathrooms are safe, providing they are installed and used

correctly and also receive maintenance when needed.

These ttings, including the connecting water and waste system need to be installed in accordance

with and meet the requirements of the Water Supply Regulations 1999 (Water Fittings) and current

by-laws. If you are in doubt about your ability to install this product correctly or safely, you should

employ the services of an experienced qualied plumber.

This product must not be modied in any way otherwise this will invalidate the guarantee.

Remove all packaging and check the contents for damage before starting installation.

Warning: Before installing the new mixer valve it is essential that you thoroughly ush through the

pipework in order to remove any remaining swarf, solder, etc. Failure to carry out this

procedure could cause problems or damage to the workings of the mixer tap.

Fitting isolating valves to the inlet feeds is required for ease of maintenance.

Warning: Do not operate the mixer if you suspect it is frozen. Do not site the mixer valve

where it might be subjected to freezing conditions.

Consider the following whilst using power tools:

• Prior to drilling into walls, check there are no hidden electrical cables or wires and

there are also no water pipes. These can potentially be found using an electrical or

metal detector. You may also need to know some of the schematics of previous

installations to determine the suitability and accommodation of the installation.

• Wear the correct PPE, especially ear, eye and hand protection

when using power tools. Unplug any mains equipment after use.

• Keep electrical equipment away from sources of water.

• If a blow-lamp is used when plumbing, the ame must be kept well away from

the product otherwise damage may occur.

If in doubt, contact a registered plumber, your Local Water Authority or the Secretary of The Institute

of Plumbing, address as follows;-

The Institute of Plumbing,

64 Station Lane,

Hornchurch,

Essex, RM12 6NB

Tel:01708 472791

SAFETY NOTES

4

SPECIFICATION

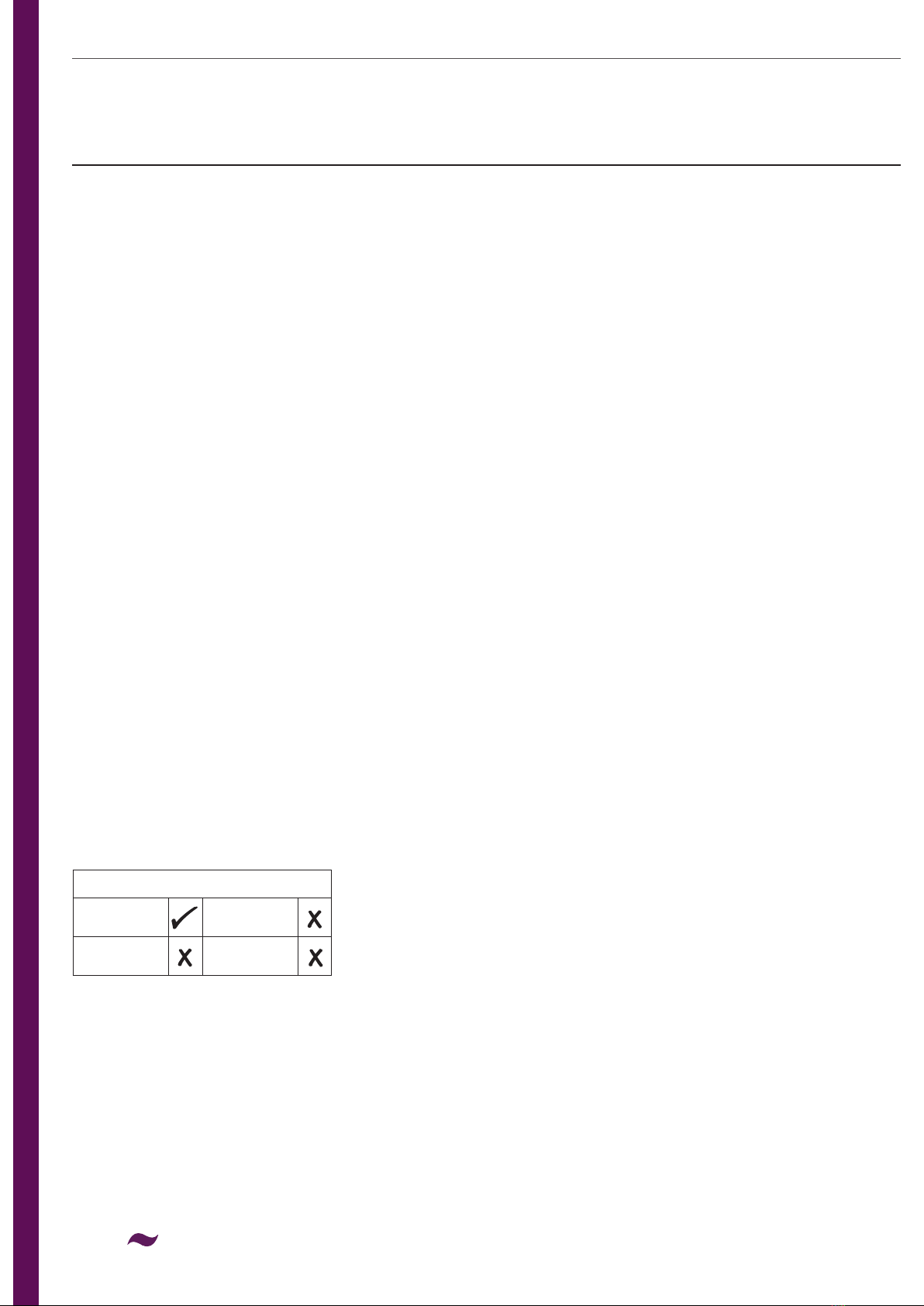

Recommended Usage

Domestic Heavy

Commercial

Light

Commercial Health Care

Shower Valve:

Inlet connection: 15mm compression with 135-158mm adjustable centres.

Outlet connection: G 1/2”

Operating pressure range: Min. 0.1 Bar - Max. 5.0 Bar

Maximum recommended imbalance between hot and cold supply should not exceed a ratio of 5:1.

Maximum Static Pressure: 10 Bar

System Requirements: Suitable for all plumbing systems

Note: Nominally equal (balanced) inlet supply pressures are recommended for optimum performance.

If the tting is installed at low pressure (tank fed), then the minimum distance from the outlet to the

underside of the cold tank should be at least 1 metre to ensure adequate performance

Supply Requirements:

Minimum cold water supply temperature: 5°C.

Maximum cold water supply temperature: 25°C.

Maximum hot water supply temperature: 80°C.

BS 8558 recommends hot water should be stored and distributed at a temperature of not less than

60°C which will help minimise the build-up of lime scale in hard water areas.A maximum hot water

supply temperature of 60 - 65°C is recommended for ablutionary purposes.

Note:The inlet hot water temperature must be at least 10°C above the required blend temperature

(eg. mixer temperature 41°C: minimum hot supply 51°C).

Maximum Outlet Temperature: Factory pre-set to 42°C

These showers are designed to be used in conjunction with Heritage shower kits.We cannot

guarantee compatability or adequate performance when used with other kits.This would also

invalidate your guarantee. Please refer to the installation manual supplied with your Heritage

shower kits for their specication information.

5

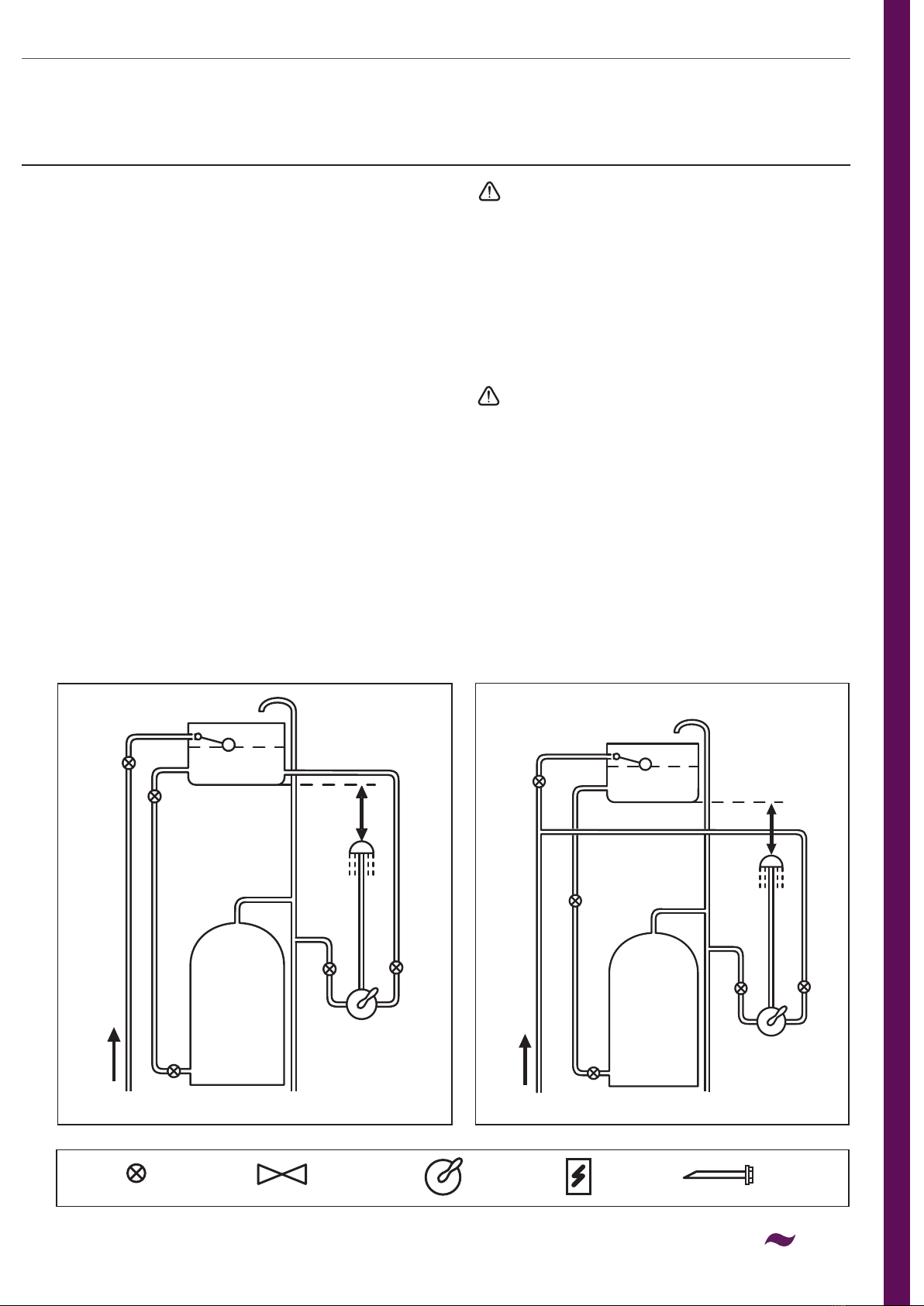

INSTALLATION REQUIREMENTS

This shower valve must be installed in compliance

with current water regulations. If you have any

doubts about the water regulation requirements

contact your local water services provider or use

the services of a professional plumber.

This shower valve is suitable for use with the

following water supply systems:

• Gravity Fed Hot and Cold

(pressure imbalance should not exceed

a ratio of 5:1 - see Specication section)

• Gravity Fed Hot and Mains Cold

(pressure imbalance should not exceed

a ratio of 5:1 - see Specication section)

• Instantaneous water heater

(combination boiler)

• Unvented System

• Pumped System

Gravity Fed Hot and Cold Gravity Fed Hot and Mains Cold

cold mains supply cold mains supply

Important: If you install this shower

valve with a gravity fed system, there must be

a minimum head (vertical distance) from the

underside of the cold water storage tank to the

outlet of at least 1 metre .

Note: Pumped system (with Essex ange)

If you install this shower valve to a pumped

gravity fed system where the minimum head

(vertical distance) from the underside of

the cold water storage tank to the top of

the hot water cylinder is less than 1 metre we

recommend an Essex ange is used as shown.

Flushing Pipe-work

Important: Before connecting the shower valve

(see ‘Installation’ on pages 11-12), the supply

pipe-work must be ushed to clear debris before

connecting the shower. Debris will reduce the

performance and life of the mixer.

1m min.

1m

min.

Key: Isolating

Valve

Reducing

Valve

Shower

Valve Pump Essex

Flange

6

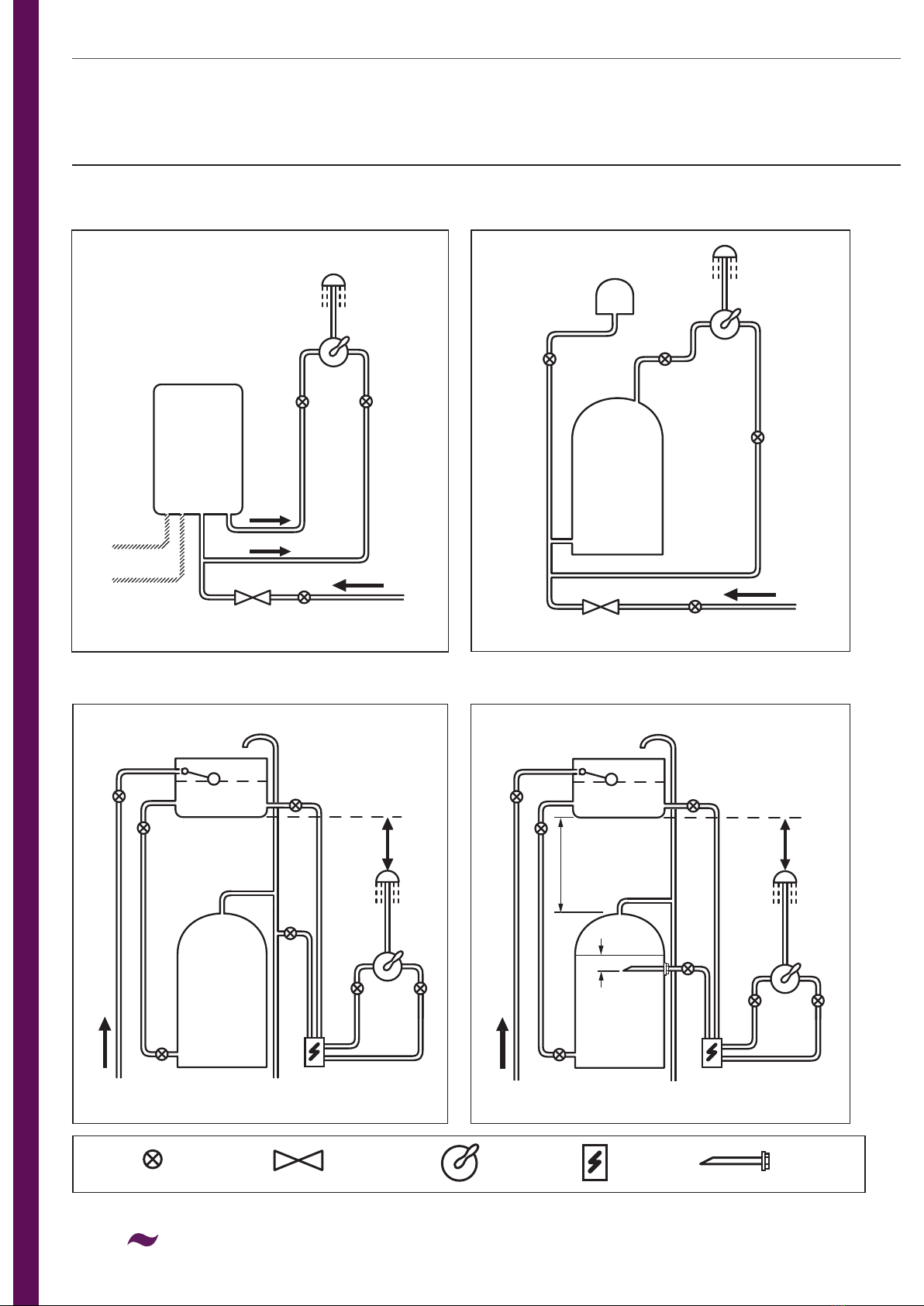

INSTALLATION REQUIREMENTS

Unvented System

Instantaneous Water Heater

Pumped System

cold mains supply

cold mains supply

cold mains supply

Pumped System (with Essex ange)

cold mains supply

1m min.1m min.

50mm

If less

than 1m

see note.

Key: Isolating

Valve

Reducing

Valve

Shower

Valve Pump Essex

Flange

7

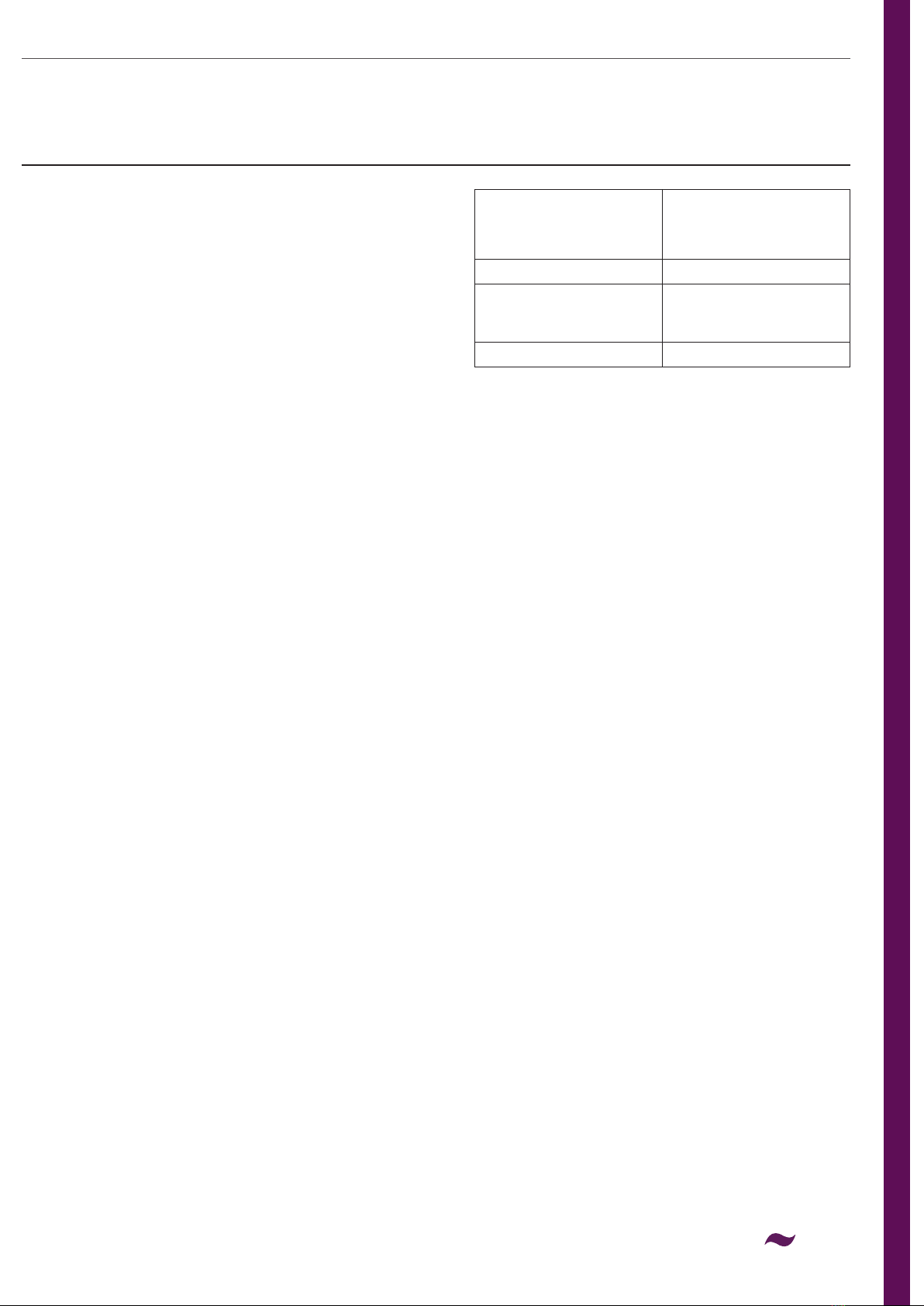

INSTALLATION REQUIREMENTS

This tting needs to be installed in accordance

with the following Installation Requirements

and Notes (IRN) to ensure they meet the

requirements of the Water Supply (Water Fittings)

Regulations 1999 and the Scottish Byelaws 2004.

IRN R001: See text of entry for Installation

Requirements or Notes.

IRN R040 - Schedule 2-15 (1): The tting shall be

installed so that its outlet discharges above the

spill-over level of any xed appliance as indicated

below:-

For backow protection in domestic or

installations up to, and including, Fluid Category 3.

If the tting cannot be installed as indicated in the

table opposite it shall be installed as either a or b

below:

a: with an approved double check valve assembly

or some other no less effective backow

prevention device immediately upstream of the

inlet.

b: so that it draws water by gravity only from a

cistern, or cylinder having a permanently open

vent pipe, and the distributing pipe supplies no

other ttings (other than a draining tap) at a

lower level.

For backow protection in premises or

installations up to, and including Fluid Category 5.

The vertical distance of the outlet above the spill-

over level shall be not less than 20mm or twice

the diameter of the inlet pipe to the tting, which

ever is the greater. If the tting cannot be installed

as indicated it shall be installed with a backow

prevention arrangement suitable for the Fluid

Category.

Size of tap or

combination tting

Vertical distance

of outlet above

spill-over level

1. Not exceeding ½” 20mm

2. Exceeding ½”

but not exceeding

¾”

25mm

3. Exceeding ¾” 70mm

8

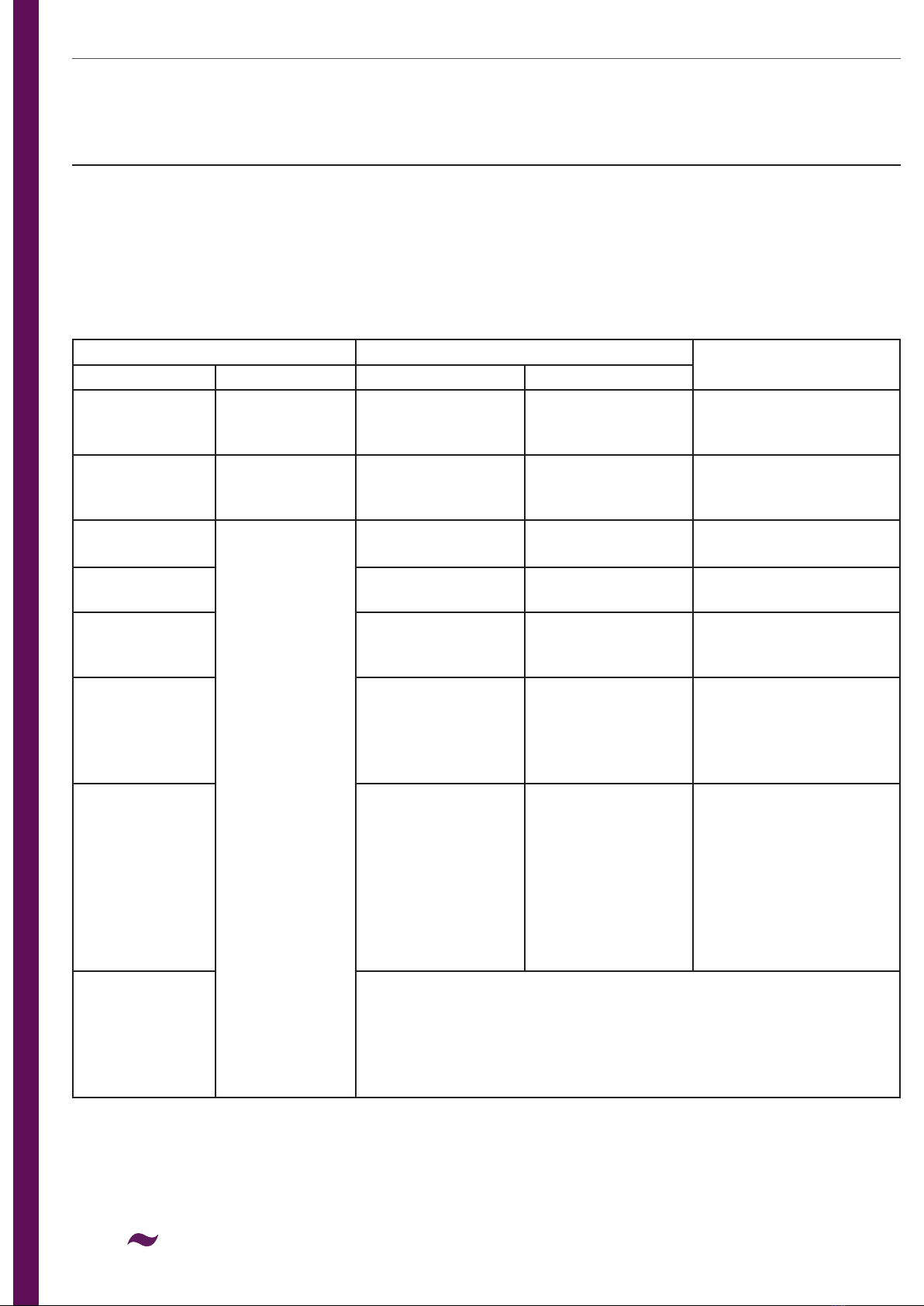

PRIOR TO INSTALLATION

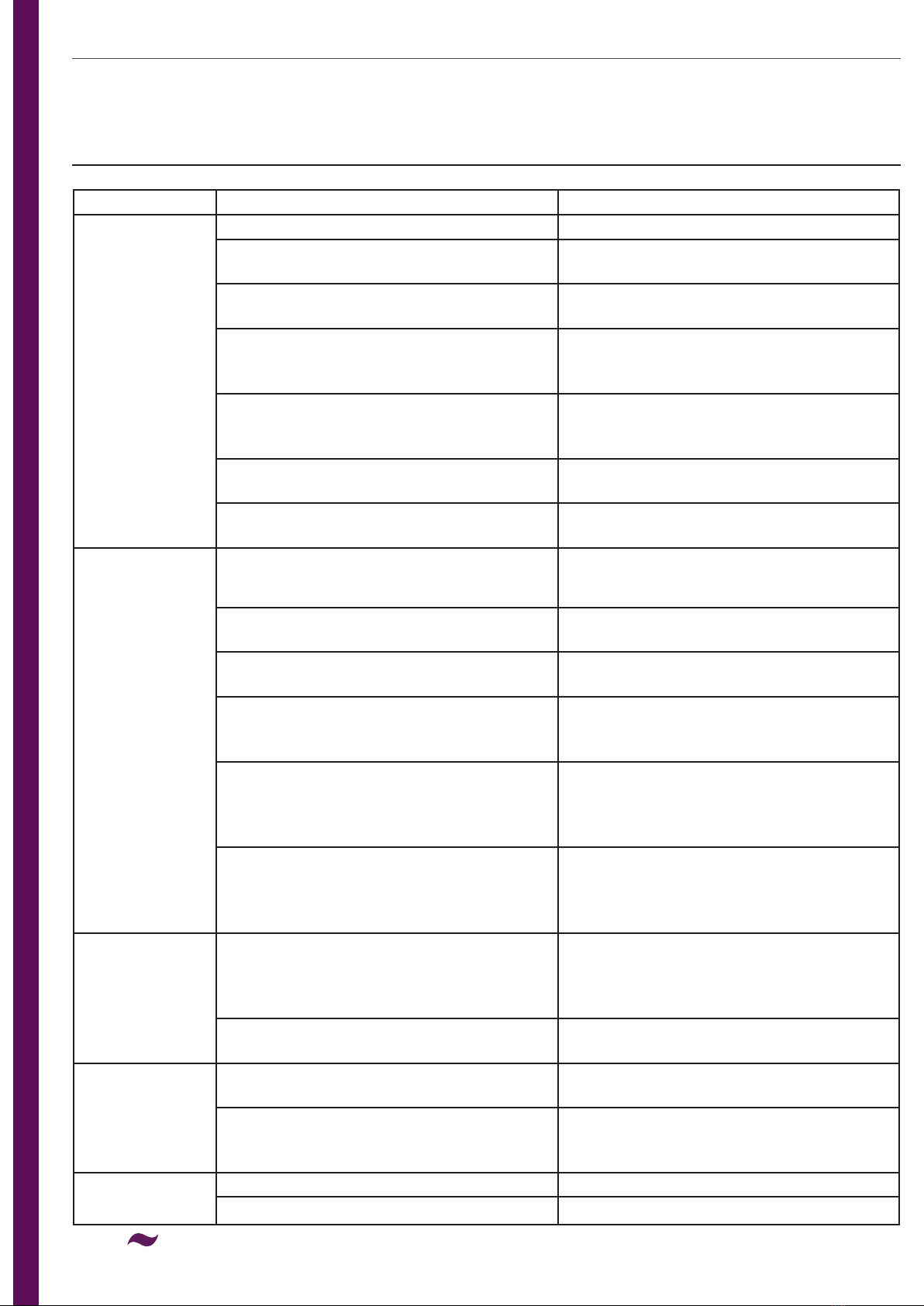

Supply System Flow Regulator Comments

Hot Supply Cold Supply Hot Supply Cold Supply

0.1 - 1.0 bar 0.1 - 1.0 bar Not Required Not Required

Maximum pressure

loss ratio 5:1 between

inlets

1.0 - 5.0 bar

or pumped

1.0 - 5.0 bar

or pumped White (8 litre) White (8 litre)

Optional, can be used

if water economy

is required

Gravity Fed

0.1 - 0.5 bar

Mains 1.0 - 10

bar

Not Required White (8 litre)

Gravity Fed

over 0.5 bar White (8 litre) White (8 litre)

Unvented

Mains/ Mains

Pressurised

White (8 litre) White (8 litre)

Instantaneous

Water Gas

Heater

White (8 litre) White (8 litre)

It may not be

necessary on some gas

water heaters to have a

ow regulator on the

hot water supply.

Instantaneous

Water Electric

Heater

Not Required White (8 litre)

It is a requirement that

a stable ow of water

passes through the

heater. This can be

achieved by tting a

ow stabiliser before

the heater. The heater

temperature should also

be adjusted to 45-50°C

Any vented

(open outlet)

Heater

Gas/Electric

e.g.

Electric Shower

Do not use mixer valves with this type of water system;

this would be extremely dangerous!

Two 8 litre per minute ow regulators have been pre-tted to this product for water efciency.

If you have low water pressure, or certain water supply systems these may need to be removed

in order to achieve adequate ow. Please see the table to check whether the ow regulators

need to be removed.

9

PRIOR TO INSTALLATION

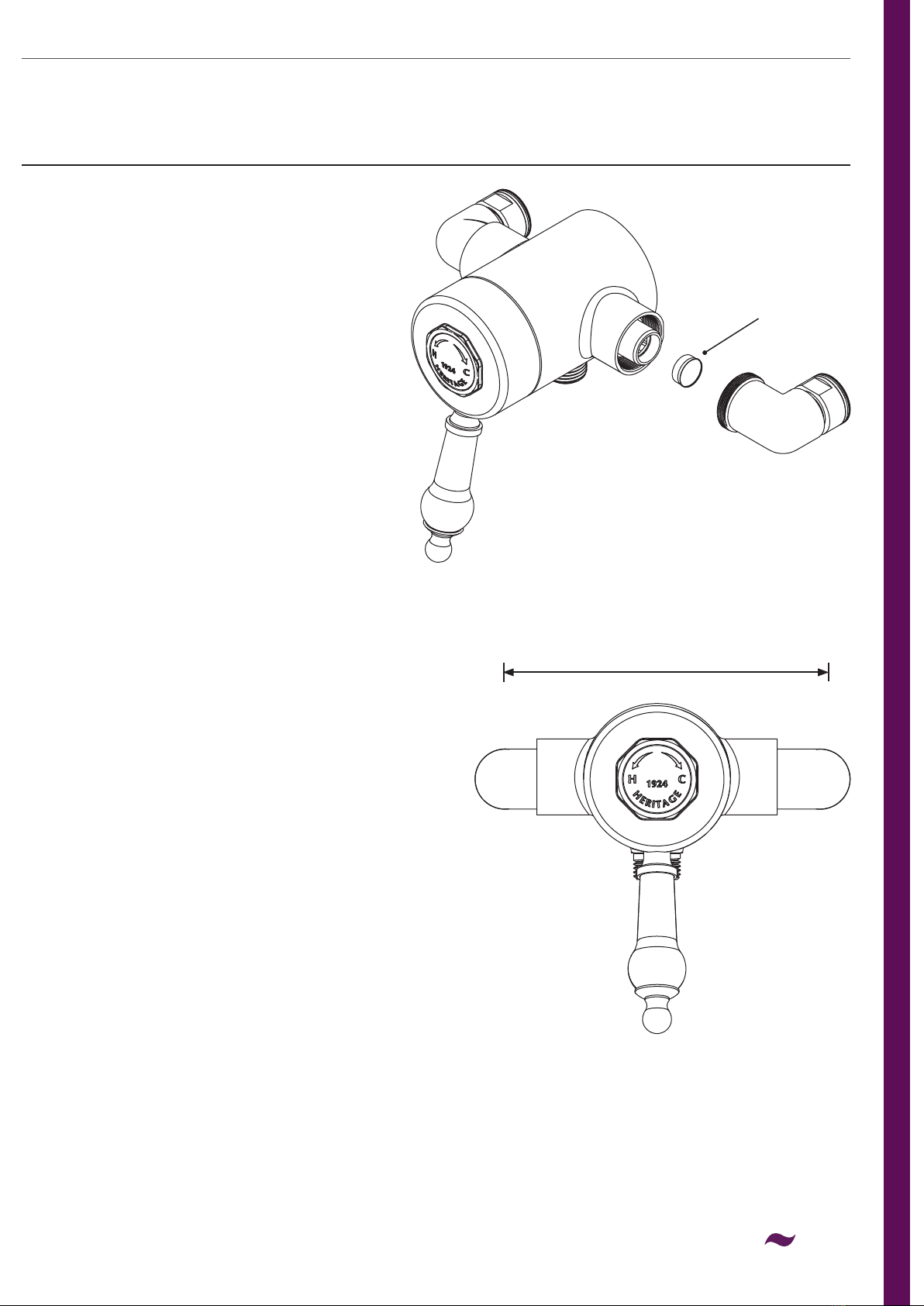

1. Unscrew both inlet elbows

anti-clockwise from the valve

body.

2. Remove the ow regulators using

long-nosed pliers.

3. Screw the inlet elbows

clockwise to t back into

the valve body.

To Remove/Replace:

Conguring the Inlet Elbows:

The shower valve is supplied with elbows (pre

-tted) that can adjust between 135-158mm.

The elbows can be pointed to feed from the top,

bottom or rear.

Two full turns are required to t the elbow into

the body properly.

1. Unscrew both inlet elbows anti-clockwise from

the valve body.

2. Screw in the desired elbows clockwise for

two complete turns to t. This will set to

largest possible centre measurement.

3. The elbows can be screwed a maximum

of 1.5 turns after tting for adjustment.

Screw further clockwise to reduce the centre

measurement; anti-clockwise to increase.

To Adjust Elbows:

135-158

Centres

Flow Regulator

10

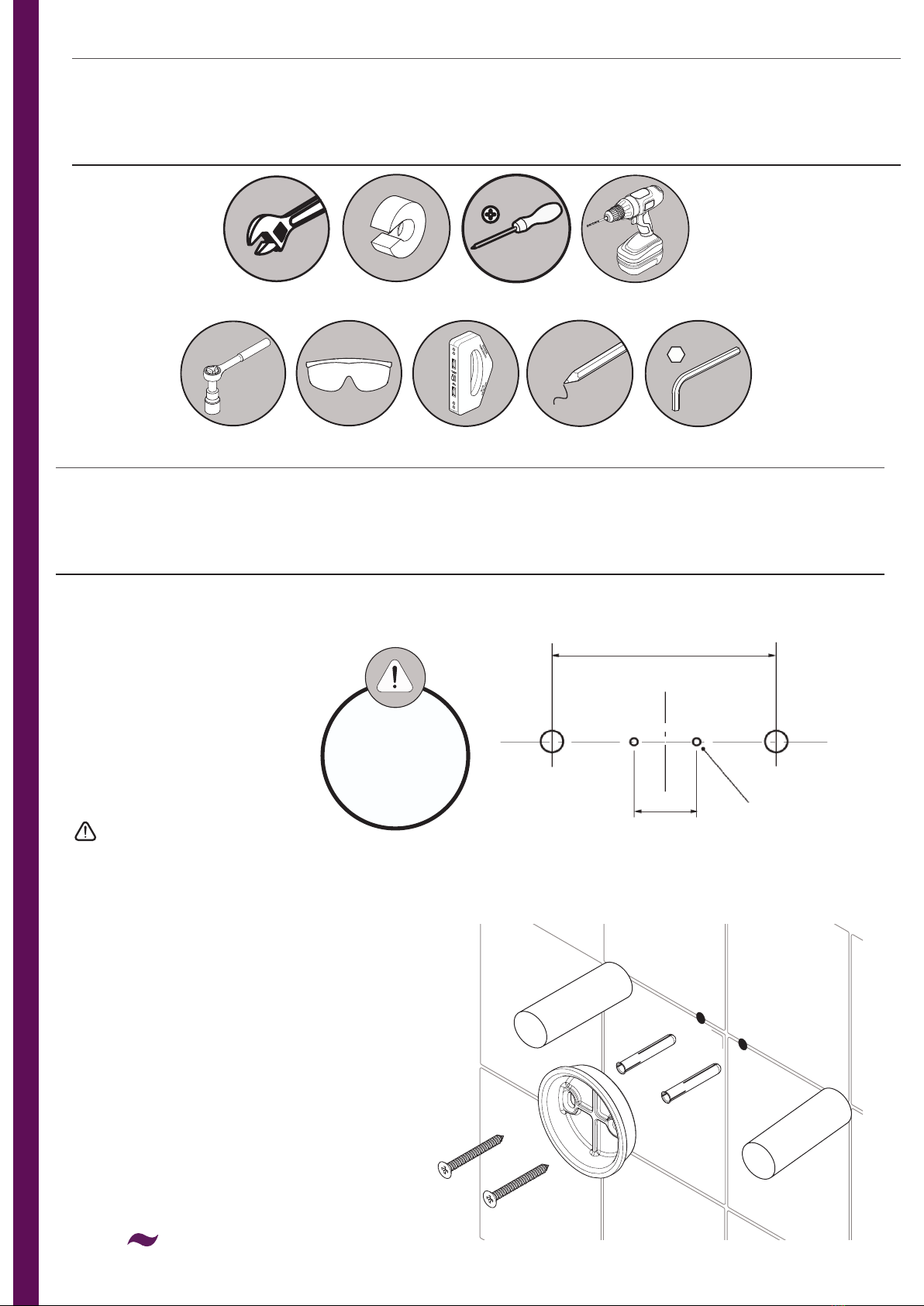

INSTALLATION

1. Prepare the 15mm water pipework, leaving

sufcient pipe protruding from the nished

wall to t into the elbows.

Flush through the pipework to

ensure removal of any debris.

Turn off the mains water

supply and close any

isolating valves.

Important: Water supplies to

the mixer must be with hot on

theleft and cold on the right

when viewed from the front.

2. Measure the centre distance. Measure the

half-way point between the centres and

mark on the wall.

3. Congure the inlet elbows

to meet the centre distance.

4. Undo the grub screws at the back of the

shower valve to remove the backplate.

Place the backplate on the marked half-way

point between the centres and mark the

xing holes.

TOOLS REQUIRED

REMEMBER

Fit isolation

valves for future

maintenance.

135-158mm

Hot Cold

Backplate

Fixing

Holes

30-35mm

Pipe Cutter

Adjustable

Spanner

Cross Head

Screwdriver Drill

30mm

Socket Spanner Safety Goggles Electronic

Detector Pencil 2.5mm & 10mm

Hexagonal Keys

11

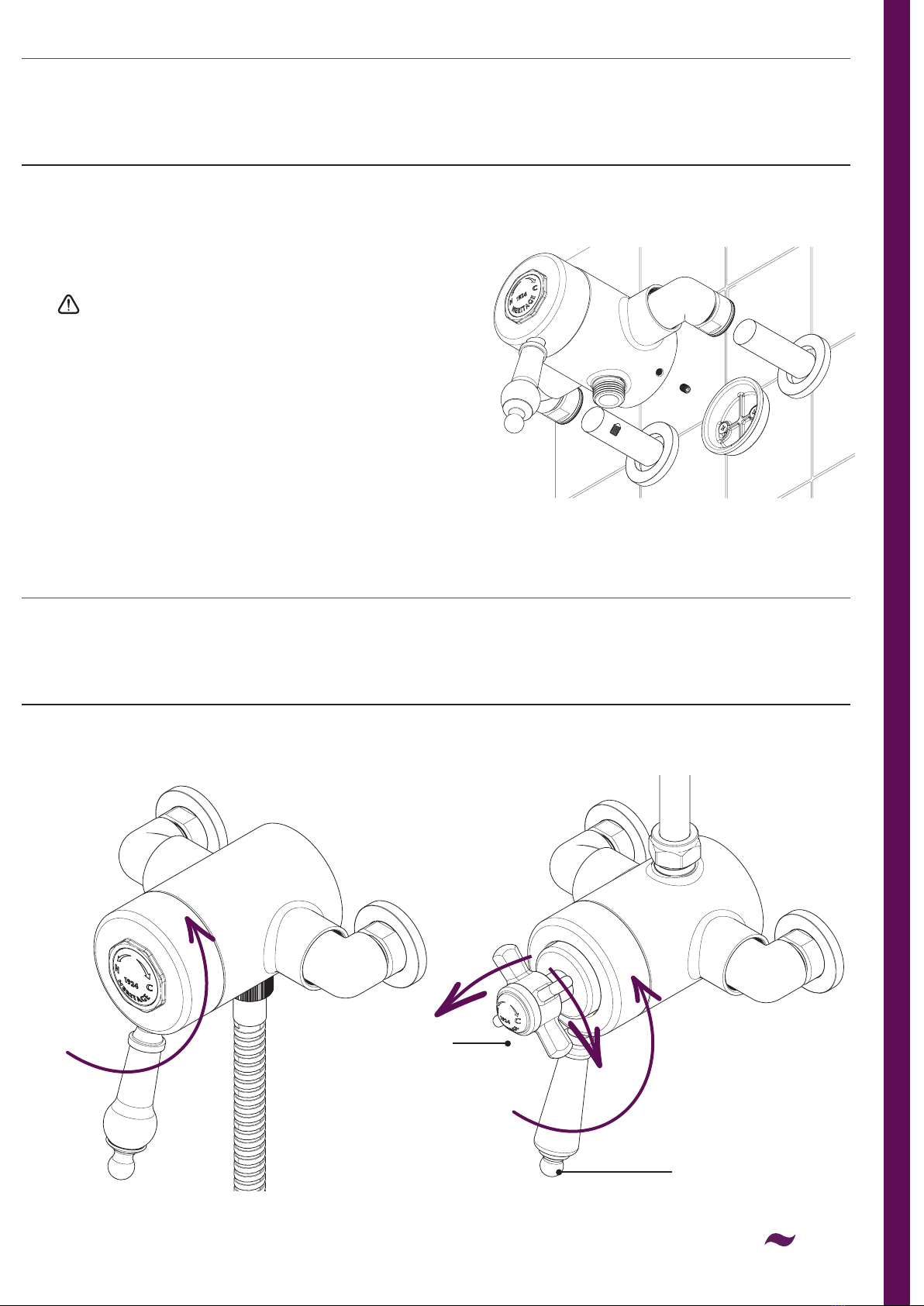

INSTALLATION

OPERATION

5. Drill the xing holes using a suitable drill bit.

A pilot drill will be required if drilling into tiles.

Insert the wall plugs and screw the backplate to

the wall.

Warning: Please check for any hidden

pipes and cables before

drilling holes into the wall.

6. Place the plinths over the water supply pipes.

Feed the shower valve on to the water supply

pipes and tighten with the nut and olives.

Secure the valve to the back plate using the

grub screws.

Please refer to your shower kit instruction

manual to install the shower kit.

Flow Handle

Increase Flow

Increase

Temperature

and Flow

Hot

Off Off

Cold

Temperature

Handle

Sequential Shower Valves: Concentric Shower Valves:

12

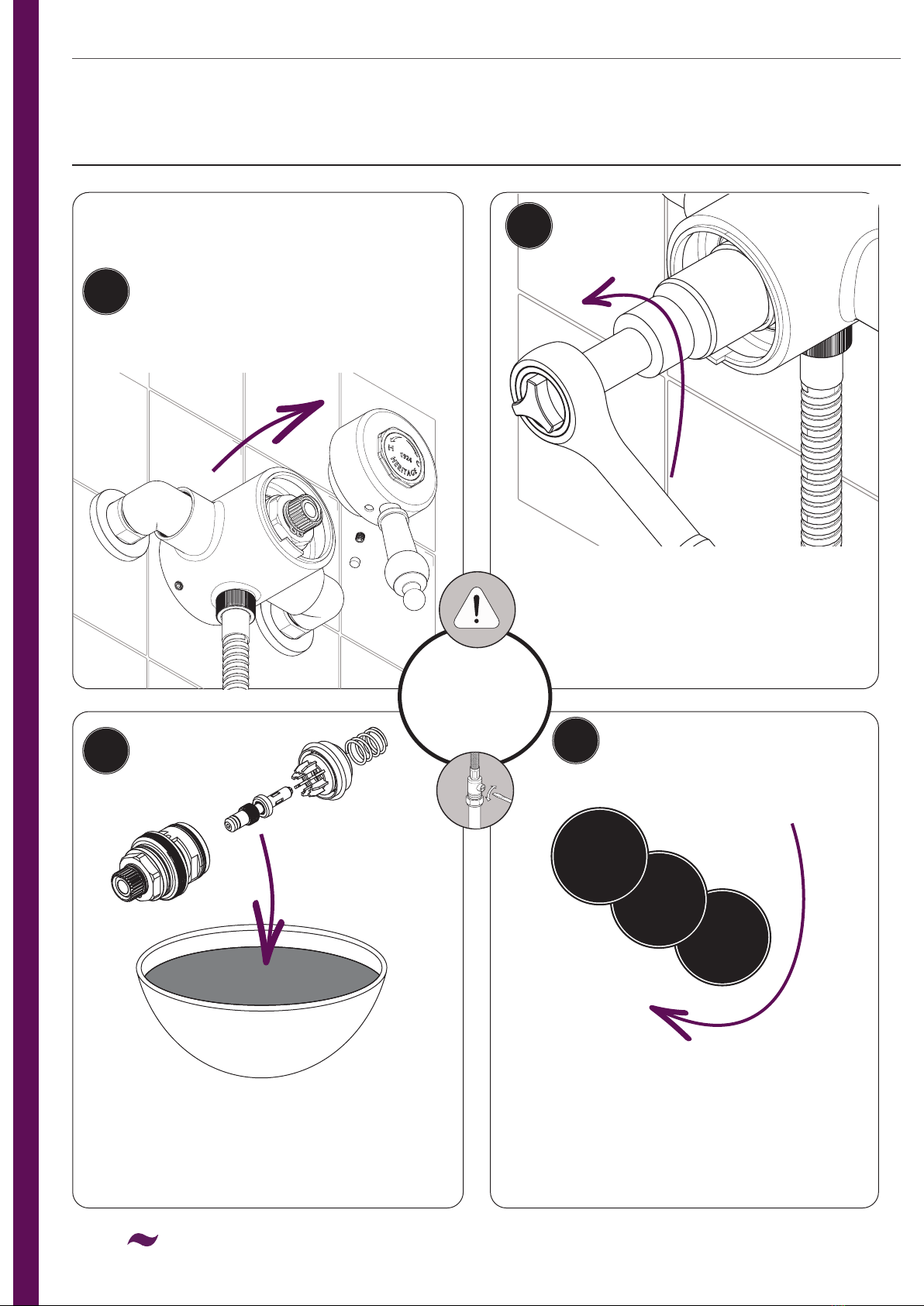

MAINTENANCE

Use a 30mm socket spanner to unscrew

the cartridge from the valve body.

Carefully remove the cartridge and spring.

Reverse the steps to re-t the cartridge and

handle. Reset the maximum temperature.

Remove all seals and check for any damage.

Place the cartridge in a suitable solution and

soak until fully de-scaled. Rinse thoroughly.

Replace all seals and grease with a

WRAS approved sealant.

Undo the grub screw to

remove the handle.

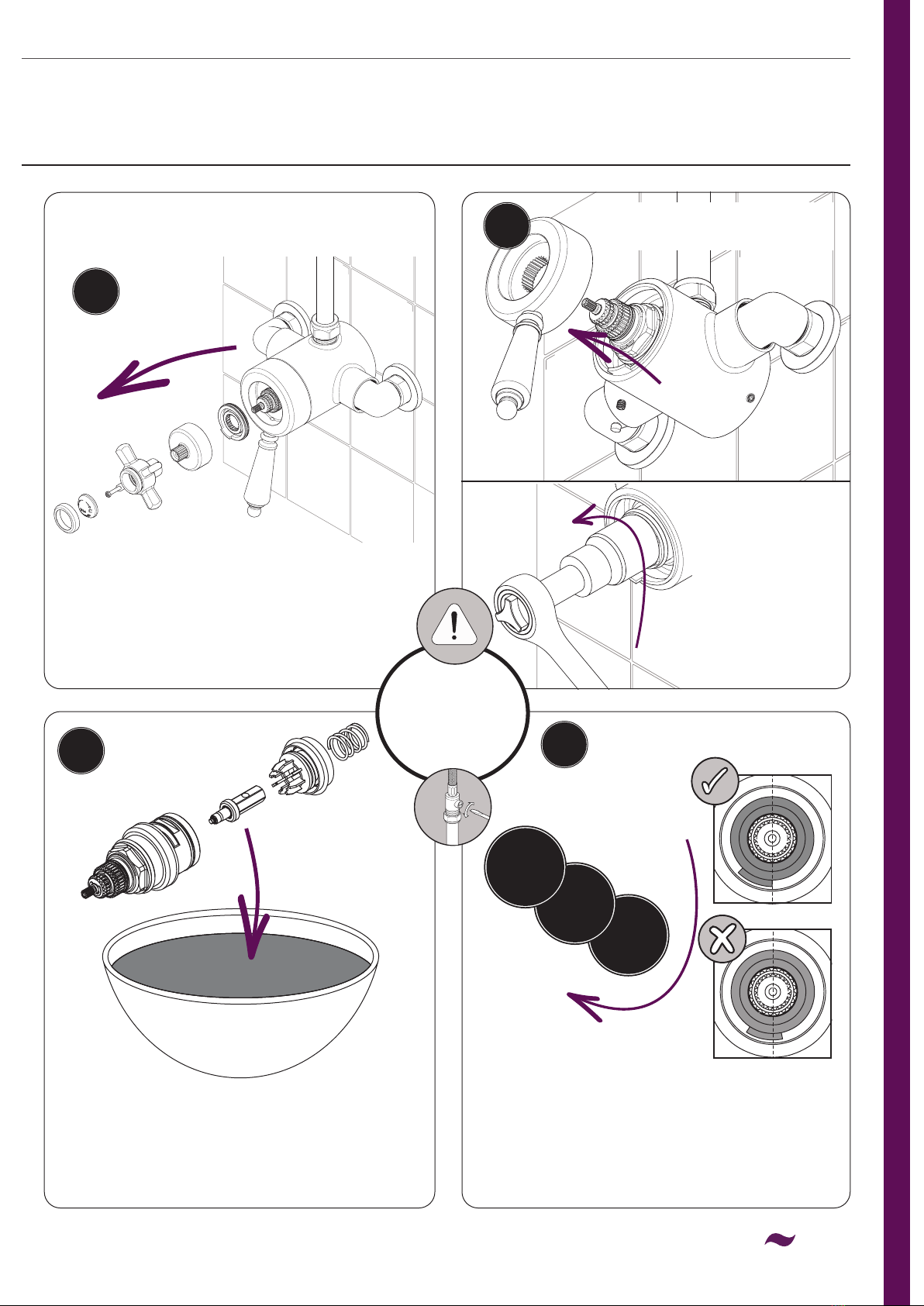

Replace/Clean Cartridge:

Sequential Shower Valves:

1

2

34

3

2

1

IMPORTANT

Isolate the

water supply

before starting!

13

MAINTENANCE

Reverse the steps to re-t the cartridge and

handle. Ensure the temperature stop is tted

correctly. The stop should sit at the bottom

left, aligned centrally to the cartridge.

Reset the maximum temperature.

Remove all seals and check for any damage.

Place the cartridge in a suitable solution and

soak until fully de-scaled. Rinse thoroughly.

Replace all seals and grease with a

WRAS approved sealant.

Undo the indice housng and

unscrew the screw to remove the

temperature handle. Unscrew the

shroud and remove the

temperature stop.

Undo the grub screw to

remove the ow handle.

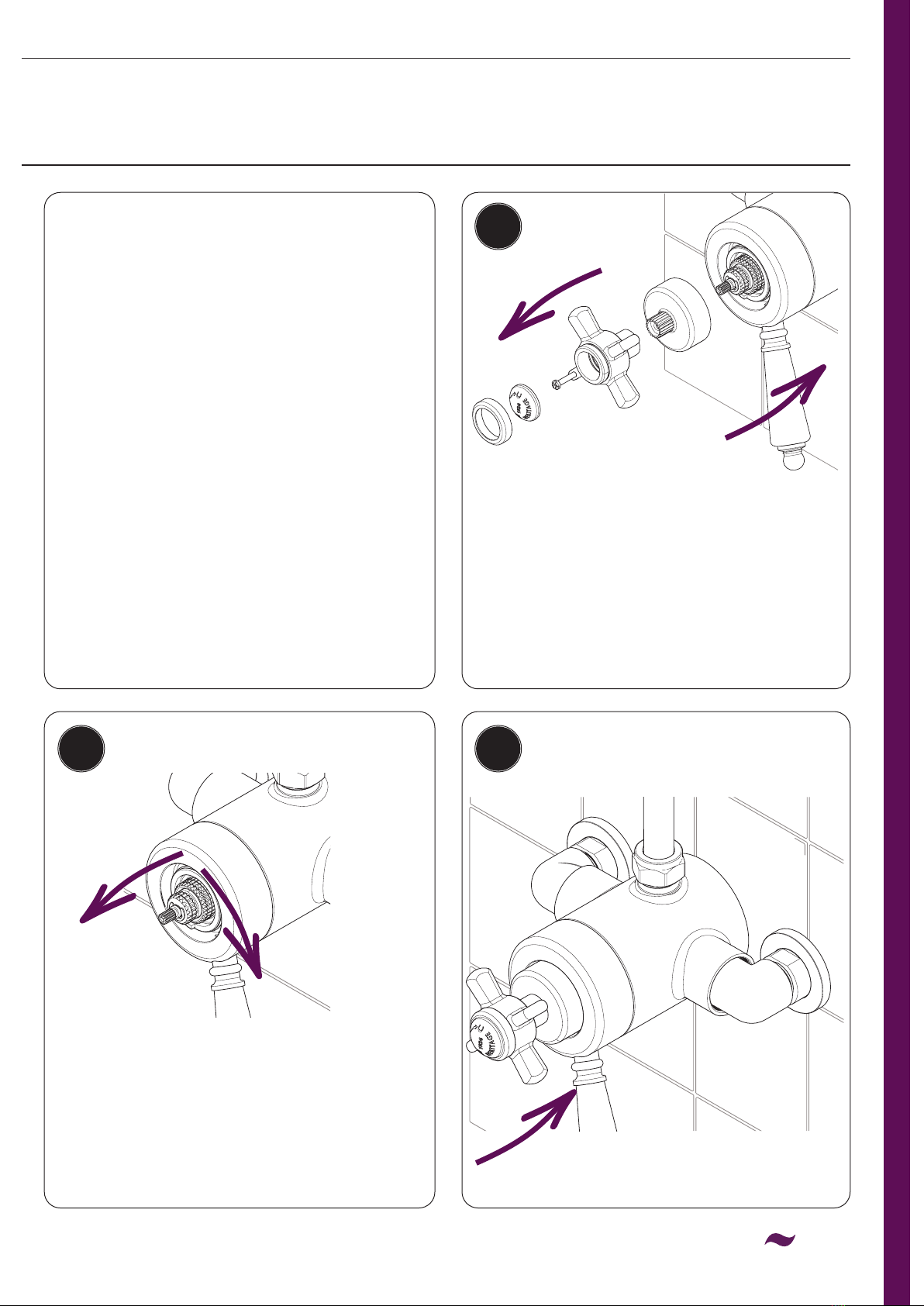

Replace/Clean Cartridge:

Concentric Shower Valves:

1

2

34

3

2

1

IMPORTANT

Isolate the

water supply

before starting!

Use a 30mm

socket spanner

to unscrew the

cartridge from

the valve body.

Carefully remove

the cartridge

and spring.

14

MAINTENANCE

The shower has been pre-set to 41°C.

This is based on being tted with nominally

balanced pressures with the hot water inlet

supply at 65°C. If your operating conditions

are different to the above your maximum

outlet temperature may differ.

We recommend setting the maximum

outlet temperature no higher than 43°C.

Using the 2.5mm hex key supplied,

adjust the temperature:

Turn the temperature handle to the

maximum temperature. Undo the grub

screw to remove the handle.

Re-t the temperature handle back in the

maximum temperature position.

Sequential Shower Valves:

Maximum Temperature Setting:

2 3

1

Wait for a couple of minutes for the

temperature to stabilise after adjusting.

Measure the water outlet temperature

using a thermometer. Adjust until the

desired temperature is reached.

Decrease

Temperature

Increase

Temperature

15

MAINTENANCE

Adjust the maximum temperature by

turning the spindle:

Turn the temperature handle to the

maximum temperature. Remove the

temperature handle and unscrew the

shroud. Turn on the shower.

Re-t the temperature handle back in

the maximum temperature position.

The shower has been pre-set to 41°C.

This is based on being tted with nominally

balanced pressures with the hot water inlet

supply at 65°C. If your operating conditions

are different to the above your maximum

outlet temperature may differ.

We recommend setting the maximum

outlet temperature no higher than 43°C.

Maximum Temperature Setting:

Concentric Shower Valves: 1

2 3

Wait for a couple of minutes for the

temperature to stabilise after adjusting.

Measure the water outlet temperature

using a thermometer. Adjust until the

desired temperature is reached.

Decrease

Temperature

Increase

Temperature

16

MAINTENANCE

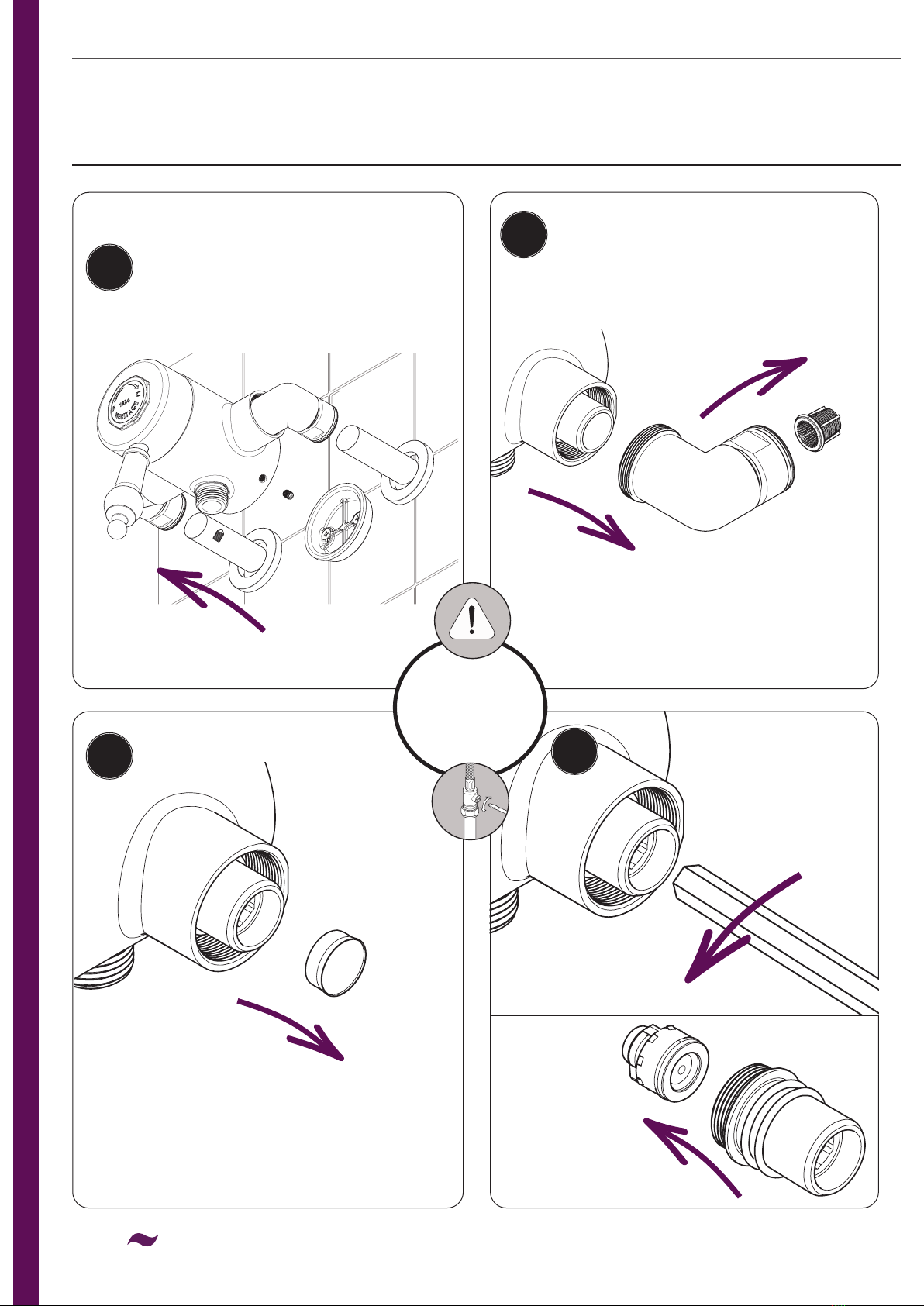

Servicing the Elbows:

IMPORTANT

Isolate the

water supply

before starting!

2

1

34

Disconnect your shower kit.

Undo the compression nuts and grub

screws at the bottom of the shower

valve to remove from the wall.

Remove the lters from both elbows

and set aside. Unscrew the elbows

completely from the shower valve.

If installed, use a pair of long-nosed

pliers to remove any ow regulators

tted. Set aside.

Remove the

check valves

from the

back of each

housing.

Use a 10mm hex key

to remove the check

valve housing from

each inlet.

17

MAINTENANCE

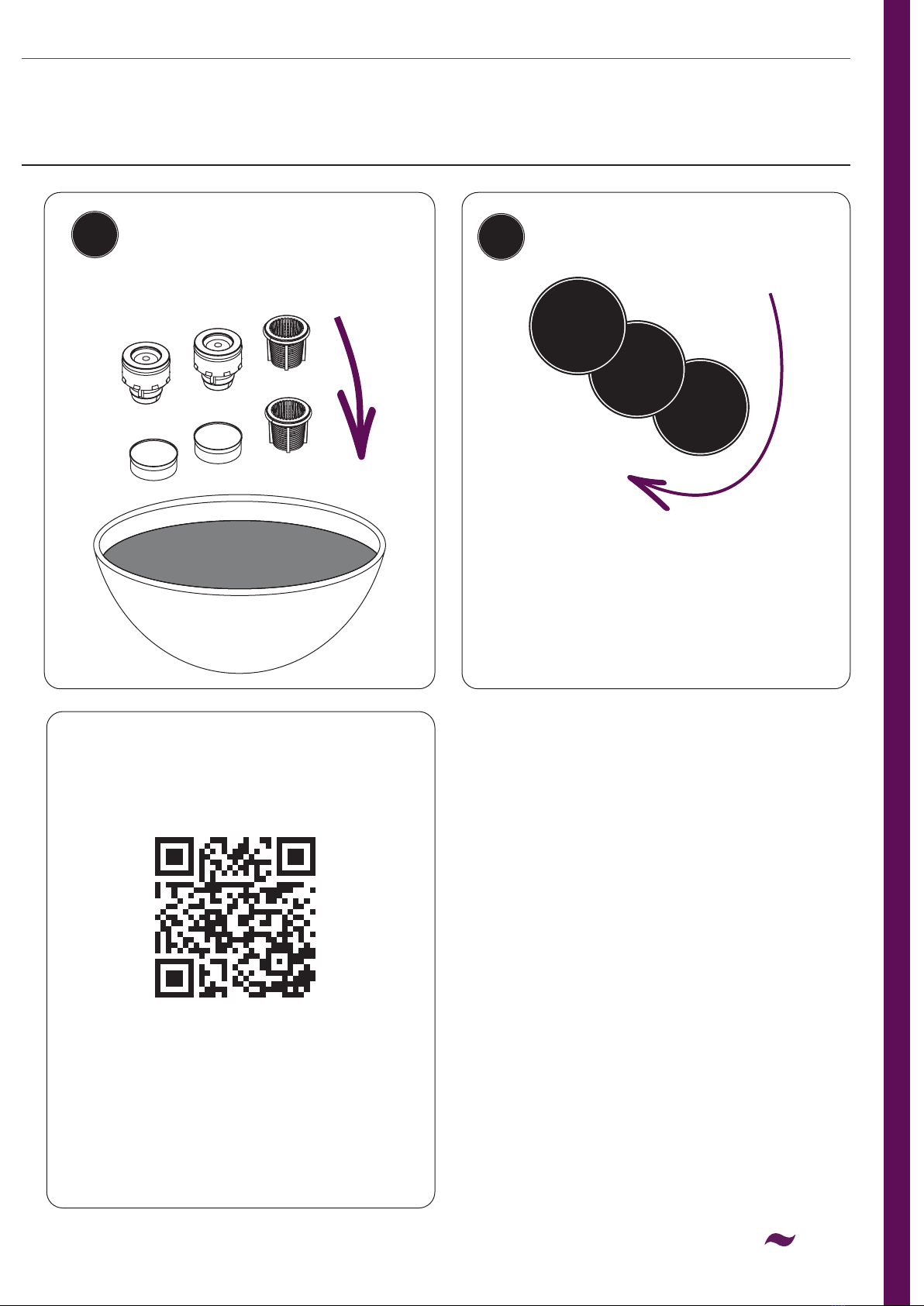

56

Check all components for

damage and replace if necessary.

Rinse thoroughly in clean water

to remove any debris.

Reverse the steps to re-t the

elbows and secure the shower

to the wall. Test all joints and

connections for any leaks.

3

2

1

Spare Parts

Please visit

www.heritagebathrooms.com

or scan the QR Code and search

for your product code to replace any

available spare parts for your tap.

18

TROUBLESHOOTING

Symptom Cause Remedy

No ow or low

ow rate

Partially closed isolation valve. Open isolation valve.

Instantaneous water heater cycles on and off

as ow rate or pressure is too low.

Increase water ow rate or

pressure through system.

Head of water is below the

minimum distance required.

Refer to the specication for the

minimum distance required.

Are the water supply pressures balanced?

If pressures are unbalanced, a pressure

reducing valve should be used for

optimum performance.

Hot or cold water being drawn off elsewhere

causing pressure changes or instantaneous

boiler temperature changes.

Do not use other water outlets when

using the shower.

Airlock or partial blockage in the

supply pipework.

Flush through pipework and lters to ensure

removal of debris and any airlocks.

Hot/Cold water supply has failed Check the hot and cold feeds. The shower

will not work if either fails.

Outlet Water

Temperature

too Hot/Cold

Maximum Water Temperature

needs adjusting.

Refer to the Temperature Setting section to

set your desired maximum temperature.

Filter/pipe blockage Flush through pipework and lters to ensure

removal of debris and any airlocks.

Installation conditions outside

operating parameters.

Refer to the specication for the

minimum distance required.

Hot water temperature is less than 10°C

above the required blend temperature

Adjust hot water temperature or wait

for water to reheat if a stored water

system is used.

Instantaneous water not igniting because

the water ow rate is too low.

Increase water ow rate through the system.

Refer to the Maintenance section to clean/

check the cartridge and lters for any damage.

Contact your boiler manufacturer.

Instantaneous water not igniting because the

water pressure is too low.

Refer to the specication for system

requirements. Increase water pressure

through the system.

Contact your boiler manufacturer.

Only hot/cold

water from

Shower Valve

Inlet water supplies are reversed.

Check the water inlet connections are the

correct way around: Hot on the left, Cold on

the right when viewed from the front. Rework

pipework as necessary.

Filter/pipe blockage Flush through pipework and lters to ensure

removal of debris and any airlocks.

Water

dripping from

shower

This is normal for a short time after

using the shower.

This is caused by residual water tension,

the build up of water in the shower.

If water continues to drip,

possibly due to the cartridge

Remove cartridge and clean, refer to

'Maintenance' section before starting

any maintenance.

Shower does

not turn on

Closed isolation valve. Open isolation valve.

Mains water supply turned off. Turn on mains water supply.

19

Heritage products are made from premium materials, with hand polishing, PVD, EPD and

electroplated nishes.

Your product should be regularly cleaned with warm water, a mild pH-neutral liquid soap, and

polished with a soft cloth. Any residues from soap, toiletries etc. should be rinsed off straight

after use.

Household bleaches and cleaners contain harsh chemicals and may damage the surface nish.

Avoid using abrasive cloths, scouring pads, scrub sponges, steel wool or anything similar.

Some surfaces such as nickel and pewter may be affected by the dye found in some cloths, so it is

also important to avoid leaving cloths on surfaces.

The condence we have in the quality of our products and services enables us to offer a free

peace-of-mind product guarantee from 2 years up to a lifetime guarantee against any manufacturing

faults, with proof of purchase. In addition, our attentive customer service team are available to

help solve any problems which may arise quickly and effectively so you can enjoy your bathroom.

To see the specic guarantee for this product, scan the QR Code

or visit the following URL:

https://www.heritagebathrooms.com/service-centre/guarantee

In the unlikely event that you encounter a problem with your Heritage product, you must, in the

rst instance, contact the retailer you purchased it from. They will advise as to whether it is due

to a manufacturing fault or an installation fault. If the problem is due to a manufacturing fault, they

will contact us to arrange a supply of a replacement product as soon as possible. To speak to a

Heritage customer service advisor, please contact our technical helpline on 0330 026 8503.

NEED HELP?

GUARANTEE

CARING FOR YOUR PRODUCT

We love to see how Heritage products are used so please keep in

touch and share pictures of your new bathroom with us.

If you have any queries, our dedicated customer service teams and products experts are available

to help.

Email us enquire@heritagebathrooms.com Call us 0330 026 8503 Website www.heritagebathrooms.com

@heritagebathrooms

UK: Heritage Bathrooms, Pooley Hall Drive, Birch Coppice Business Park, Dordon, Tamworth B78 1SG

EU: Masco Europe S.à.r.l., 14 Rue Strachen, 6933 Mensdorf, Luxembourg.

D4

This manual suits for next models

2

Table of contents

Other Heritage Bathroom Fixture manuals

Popular Bathroom Fixture manuals by other brands

Kohler

Kohler Mira Sport Max J03G Installation and user guide

Moen

Moen 186117 Series installation guide

Hans Grohe

Hans Grohe Raindance Showerpipe 27235000 Instructions for use/assembly instructions

Signature Hardware

Signature Hardware ROUND SWIVEL BODY SPRAY 948942 Install

fine fixtures

fine fixtures AC3TH installation manual

LIXIL

LIXIL HP50 Series quick start guide