HERMOS LFM 4x Reference guide

Customer manual

LFM 4x Reader

RFID

WE GENERATE SOLUTIONS

LFM 4x Reader Rev1.4

2

www.hermos.com

0. Table of contents

0. Table of contents ..................................................................................................................................2

1 . I n t r o d u c t i o n ...............................................................................................................................6

1.1 Using the device 7

2. Version history......................................................................................................................................8

3. Used abbreviations and designations...................................................................................................8

4. General instructions..............................................................................................................................9

4.1 Objective of the product manual 9

4.2 Warranty and liability 9

5. Safety instructions and warnings........................................................................................................10

5.1 Scope and symbols 10

5.2 Safety symbols - according to DIN 4844-2 10

5.2.1 Mandatory signs 11

5.2.2 Warning signs 11

5.2.3 Prohibition signs 11

5.2.4 Other signs 12

5.3 Obligations 12

5.3.1 Operator’s obligations 12

5.3.2 Responsibilities of operating personnel 13

5.3.3 ESD Instructions 13

5.4 Residual risks 14

5.5 Supplemental instructions 15

5.5.1 Regulations and certifications 15

6. Functional description.........................................................................................................................16

6.1 General information 16

6.2 Basic functions - operating modes 16

6.2.1 Normal operation 16

6.2.2 Polling mode 16

6.2.4 Test module 16

6.3.1 Top view 17

6.3.2 Front view 18

6.3.3 Back view 19

6.4 Technical Specification 20

6.4.1 Power supply and current input 20

6.4.2 Device labels 21

6.4.3 Device Label FCC ID 2AP5OLFM-4x 21

Feh

Customer manual

LFM 4x Reader

RFID

WE GENERATE SOLUTIONS

LFM 4x Reader Rev1.4

3

www.hermos.com

ler! Textmarke nicht definiert.

6.4.4 Test mode sticker 22

7. Installation...........................................................................................................................................23

7.1 Safety instructions 23

7.2 Qualified installation personnel 24

7.3 Unpacking 24

7.4 Mounting the device 25

7.5 Installing the antenna 26

7.5.1 Positioning the antenna 26

7.5.2 Rod Antenna M dimensions 27

7.5.3 Connecting the antenna 27

7.6 Power Supply 27

7.7 DIP-switch 28

7.8 RS232 connection 29

8.Commissioning ....................................................................................................................................30

8.1 Operating conditions 30

8.2 The serial interface parameters 30

8.3 Parameter of the ethernet interface 31

8.3.1 Change networksettings with DeviceDiscoverer 31

8.3.2 Firmware update with DeviceDiscoverer 33

8.3.3 Test Device with DeviceDiscoverer 34

9. Operating ............................................................................................................................................37

9.1 Operating personnel 37

9.2 Protocol change 37

9.2.1 General 37

9.2.2 Automatic protocol detection 37

9.3 Addressing the antenna port 38

9.4 Customer Factoryparametersets 39

10. ASCI-I1 Communication protocol .....................................................................................................40

10.1 Structure of the communication protocol 40

10.2 Packet content 40

Packet header 40

Message data 41

Packet end 41

10.3 Data elements 42

10.4 Protocol Commands 45

10.4.1 X - Read data 47

10.4.2 R –Automatic read 48

10.4.3 W - Write data 49

Customer manual

LFM 4x Reader

RFID

WE GENERATE SOLUTIONS

LFM 4x Reader Rev1.4

4

www.hermos.com

10.4.4 G –Query parameter 50

10.4.5 F –Query parameter 51

10.4.6 P –Set parameter 52

10.4.7 N –Reset 53

10.4.8 e –Error message 54

10.4.9 E –Error message 54

10.4.10 H –Heartbeat 55

10.4.11 V –Query software version 56

10.4.12 L - Lock data area 57

10.4.13 I –Adjust RF module 58

10.4.14 J –RF module Queries the vote 59

10.4.15 A –Sensor event object removed 60

10.4.16 B –Sensor event object detected 61

10.4.17 O –Set output 62

10.4.18 Q –Querying the status of the inputs and outputs 63

10.5 Parameter 64

10.6 Message examples 67

10.7 Error Codes 69

10.8 Wiring of the outputs 71

10.8.1 ASC-W1 Mode: Reader in operation mode and sensor triggered reading 71

10.8.2 ASC-W1-Mode: Reader in operation mode and external triggeredreading 73

10.9 ASCII –table 75

11.SECS / HSMS Communications protocol..........................................................................................78

11.1 Structure of a message 78

11.2 Directory Data Elements 81

11.3 Protocol commands 87

11.3.1 Stream 1 (system state) 88

11.3.2 Stream 2 (system control) 89

11.3.3 Stream 3 (Material-state) 91

11.3.4 Stream 5 (Exception handling) 93

11.3.5 Stream 9 (system error) 93

11.3.6 Stream 18 (control and data transfer) 95

11.4 Parameter 101

11.5 Examples of a SECS / HSMS message 109

11.6 Error codes 110

12. Service and Troubleshooting...................................................................................................111

12.1 General information 111

12.2 Troubleshooting personnel 111

Customer manual

LFM 4x Reader

RFID

WE GENERATE SOLUTIONS

LFM 4x Reader Rev1.4

5

www.hermos.com

12.3 Safety instructions 112

12.4 Error indications on the device 113

12.5 No communication with the reading device 113

12.6 Software releases 114

12.7 Customer service 115

13. Disassembly and storage ........................................................................................................116

13.1 Disassembly 116

13.2 Storage 116

14. Transport and disposal ........................................................................................................116

14.1 Transport 116

14.2 Disposal 116

Customer manual

LFM 4x Reader

RFID

WE GENERATE SOLUTIONS

LFM 4x Reader Rev1.4

6

www.hermos.com

1. Introduction

These operating instructions correspond with the "Radio and Telecommunications

Terminal.Equipment Act and Directive 2014/53/EU (RED) "

These operating instructions are intended for the operator who must pass these on to the personnel

responsible for installation, connection, use, and repairs of the machine.

The operator must ensure that the information contained in these operating instructions and in the

accompanying documents has been read and understood.

The operating instructions must be kept at a known place that is easy to reach, and they must be

consulted if there is the slightest doubt.

The manufacturer assumes no responsibility for damage to persons, animals, or objects or to the

unit itself arising from the improper use or the disregard or insufficient consideration to the safety

criteria contained in these operating instructions or based on modifications of the unit or the use of

unsuitable replacement parts.

The copyright for the operating instructions lies solely with

HERMOS AG

Track & Trace - RFID Division Gartenstr. 19

95490 Mistelgau

or its legal successor.

Reproduction or circulation of this document to third parties only by express written permission of

copyright holder. This also applies if only excerpts of the document are copied or circulated.

These same conditions apply to the disclosure of the document in digital format.

As of: July - 2018

Customer manual

LFM 4x Reader

RFID

WE GENERATE SOLUTIONS

LFM 4x Reader Rev1.4

7

www.hermos.com

1.1 Using the device

The device is exclusively used to read and write passive LF transponders.

Any other use of the machine or any use beyond its intended purpose is considered non-intended

and thus improper.

In this case, the device safety and the device protection provided may be compromised. HERMOS

AG is not liable for damages resulting from such use.

The device was developed for the use in an industrial environment as a built-in device in other

systems. It was not developed as a stand-alone or mobile device in a non-industrial environment,

such as dome- stic, vehicle or open air use.

Intended use also includes the following:

•Following all the operating instructions

•Following all the safety instructions

Improper use, which can endanger the unit, the user and third parties, include:

•The use of the device contrary to its intended use

•Changes to the device as well as attachments and conversions

•Operating the unit when there are obvious problems

WARNING

Danger of injury due to unauthorised modifications

There are risks from unauthorised modifications on the device.

Only original spare parts from the manufacturer must be used. No

modification, attachment or conversion may be performed on the device

without the permission of HERMOS AG.

WARNING Danger of injury and interruption of operation due to improper use

There are risks through the improper use of the device.

The device must only be used according to its intended use.

Customer manual

LFM 4x Reader

RFID

WE GENERATE SOLUTIONS

LFM 4x Reader Rev1.4

8

www.hermos.com

2. Version history

Version

Date

Author

Amendments

1.0

12.05.2017

HERMOS AG, MZ

Initial version of customer documentation

1.1

10.07.2017

HERMOS AG, RK

Document revised and added parameters

1.2

19.01.2018

HERMOS AG, RK

ASC-W1 mode documented

1.3

09.07.2018

HERMOS AG, RK

Factoryparametersets 4 and 5

documented

1.4

26.02.2019

HERMOS AG, RK

Chapter 9.3 and Reader-ID revised

Chapter 9.4 Factoryparametersets revised

Chapter 10.5 und 11.4 Changes of

parameters

Chapter 12.6 added softwarerevision V1.5

Chapter 8.3 revised

3. Used abbreviations and designations

RFID

Radio Frequency Identification

LF

Low Frequency 134,2 kHz

SEMI

Semiconductor Equipment and Materials

SECS

SEMI Equipment Communications Standard

HSMS

High-Speed SECS Message Service

PoE

Power over Ethernet

DHCP

Dynamic Host Configuration Protocol

Customer manual

LFM 4x Reader

RFID

WE GENERATE SOLUTIONS

LFM 4x Reader Rev1.4

9

www.hermos.com

4. General instructions

All previous versions of this document lose their validity with the issue of this version.

We compiled the information in this document according to the best of our ability.

HERMOS AG does not guarantee the accuracy and completeness of the information

provided in this document and is also not liable for consequential damages based on

faulty or incomplete information.

4.1 Objective of the product manual

The product manual serves as support and contains all the necessary information

that must be followed for general safety, transport, installation and operation.

The product manual with all safety instructions (as well as all additional documents) must be:

•Followed, read and understood by all persons working with the unit (especially

knowledge of the safety instructions)

•Easily available at all times to all persons

•Consulted if even the slightest doubt arises (safety)

Objectives:

•Prevent accidents

•Increase the service life and reliability of the unit

•Reduce the costs of production downtime

4.2 Warranty and liability

The „General Terms and Conditions of Sale and Delivery“ of HERMOS AG shall apply.

The warranty period is 24 months beginning with the delivery of the device, which is

verified by the invoice or other documents.

The warranty includes repairs of all damages to the unit that occur during the warranty

period, and were clearly caused by material or manufacturing defects.

Warranty and liability claims in the event of personal injury or property damage are

excluded if they arise from one or more of the following causes:

•Improper use of the unit

•Disregarding the information in the operating instructions

•Unauthorised structural modifications of the unit

•Insufficient maintenance and repairs

•Disaster events due to impact with foreign objects or force majeure

Customer manual

LFM 4x Reader

RFID

WE GENERATE SOLUTIONS

LFM 4x Reader Rev1.4

10

www.hermos.com

5. Safety instructions and warnings

5.1 Scope and symbols

Follow the general safety instructions as well as special safety instructions included

in the chapters.

The unit was built according to state-of-the-art technology and recognised safety regulations. In

order to prevent danger to life and limb of the user, third parties, or the unit, only use the unit for its

intended purpose and in perfect condition with regard to safety.

Bodily injuries and/or property damages resulting from non-compliance with the

instructions pro- vided in the operating instructions are the responsibility of the

company operating the unit or the assigned personnel.

Faults that may compromise safety must be eliminated immediately.

DANGER Risk of death, injury and property damage.

There is a risk of danger due to disregard of the product manual and

the safety information contained therein.

Read the product manual carefully before putting the unit into

operation for the first time. Fulfil all required safety conditions.

5.2 Safety symbols - according to DIN 4844-2

The following special safety symbols in accordance with DIN 4844-2 are used at the

corresponding passages in the text of this product manual and require special attention

depending on the combi- nation of the signal word and symbol.

DANGER Risk of injury due to disregarding the safety symbols.

Risks exist when disregarding warnings in the

operating instructions. Follow all warnings.

Customer manual

LFM 4x Reader

RFID

WE GENERATE SOLUTIONS

LFM 4x Reader Rev1.4

11

www.hermos.com

5.2.1 Mandatory signs

Observe additional

information

Use safety goggles

Wear ear protection

Wear safety shoes

Important note

5.2.2 Warning signs

Warning of a hazardous

area

Warning of hazardous

electrical voltage

Warning of electromagnetic

radiation

Warning of flammable

substances

Warning of explosive

substances

Warning of electrostatically

sensitive components

5.2.3 Prohibition signs

Unauthorised access is

prohibited

Fire, open flame and

smoking prohibited

Switching prohibited

Prohibited

Customer manual

LFM 4x Reader

RFID

WE GENERATE SOLUTIONS

LFM 4x Reader Rev1.4

12

www.hermos.com

5.2.4 Other signs

Verpackungsmaterial vor-

schriftsgemäß entsorgen

Recycling

5.3 Obligations

5.3.1 Operator’s obligations

A safe condition and use of the unit is a requirement for a safe operation of the unit. For that rea-

son, the operator has the obligation to ensure that the following points are adhered to:

The unit may only be operated by trained and authorised personnel.

Prohibitunsafeordangerousworkingmethods!Ifnecessary,checktheconduct

and actions of its personnel!

Have personnel who must be trained, instructed or within the scope of general

training work only on the unit under the supervision of an experiencedperson!

Havethepersonnelconfirmbytheirsignaturethattheoperatinginstructionshave

been understood!

Preciselyestablishresponsibilitiesaccordingtothevarioustask

areas (operation, installation)!

Operatingpersonnelmustberequiredtoimmediatelyreportanyoccurringand

identifiable safety deficiencies to theirsuperior!

Customer manual

LFM 4x Reader

RFID

WE GENERATE SOLUTIONS

LFM 4x Reader Rev1.4

13

www.hermos.com

5.3.2 Responsibilities of operating personnel

The operating personnel are obligated to contribute to the prevention of work accidents and their

consequences by their personal conduct.

Risk of injury due to insufficient personnel qualifications

WARNING

There are dangers to personnel and the proper operation due to

inadequately qua- lified personnel.

Only trained personnel may operate the unit.

New operating personnel must be instructed by the existing operating

personnel. The operator must precisely regulate the personnel’s areas

of responsibility, com- petence, and monitoring precisely.

The personnel for the areas of responsibility mentioned above must

have the corresponding qualification for this work (training, instruction).

If necessary, this can be done by the manufacturer on behalf of the

operator. In case of disregard, all warranty claims are void.

5.3.3 ESD Instructions

CAUTION Static electricity can damage electronic components in the unit. All

persons who install or maintain the unit must be trained in ESD

protection.

ESD protective measures must be applied when opening the unit.

Disconnect the power supply prior to removing or adding components!

Observe the basic principles of ESD protection

Take the appropriate ESD precautionary measures

Customer manual

LFM 4x Reader

RFID

WE GENERATE SOLUTIONS

LFM 4x Reader Rev1.4

14

www.hermos.com

5.4 Residual risks

Despite all precautionary measures taken, there may still be residual risks that are not apparent.

Adhering to the safety instructions, the intended use, and the product manual as a whole can re- duce

residual risks.

DANGER

ATTENTION

DANGER

WARNING

Danger caused by electrical current

Electrical residual energy remains in lines, equipment and devices after

shutting down the device.

Only qualified electricians may perform work on the electrical supply system.

Disconnect the unit from the power supply system if active parts of the unit

can be accessed using tools. Access is only permitted by authorised

personnel.

Regularly check the electrical equipment of the unit. Regularly check all

moving cables for damage within the scope of maintenance and repair work.

Dangers of fire and explosion

There is a risk of fire and explosions in the vicinity of the device.

Smoking, exposed flames and fire are strictly prohibited in the vicinity of the unit.

Do not store any flammable liquids within the hazardous area of the device.

A fire extinguisher must be kept in the vicinity of the device.

Warning of electromagnetic radiation

Electromagnetic radiation develops when transmitting and receiving data. Arrange

the antenna in such a position that it is not in the vicinity or make

contact with the human body while transmitting.

The device satisfies the standard EN50364:2010 (Human Exposure).

Customer manual

LFM 4x Reader

RFID

WE GENERATE SOLUTIONS

LFM 4x Reader Rev1.4

15

www.hermos.com

5.5 Supplemental instructions

Readandunderstandallsafetyandoperatinginstructionspriortoinstallingandoperating

the device.

This documentation was written for specifically trained personnel. The installation,

operationanderrorhandlingmayonlybecarriedoutbyspecificallytrainedpersonnel.

Keep these instructions. Keep this documentation in a location that is accessible to all

personnel involved with the installation, use, and error handling of thedevice.

Follow all warnings. Follow all warnings onand in the device and inthe documentation.

Install the unit only in accordance with the manufacturer‘s instructions.

Use only the accessories and cables from the manufacturer.

Troubleshootingthatisnotdescribedinthechapter

a

serviceandtroubleshootingmay

only be performed by themanufacturer.

When connecting cable connections, only pull on the plug and not on the cable.

Only use spare parts specified by themanufacturer.

The provisions of the accident-prevention regulations of the government safety organisations

always apply to all work on the unit.

Applicable, legally binding accident prevention regulations.

Applicable binding regulations at the place ofuse

Technical standards for safety and professional work

Existing environmental protectionregulations

Other applicable regulations

5.5.1 Regulations and certifications

The electrical design and documentation satisfy the DIN / VDE, EN / IEC regulations.

Customer manual

LFM 4x Reader

RFID

WE GENERATE SOLUTIONS

LFM 4x Reader Rev1.4

16

www.hermos.com

6. Functional description

6.1 General information

LF reading devices are radio frequency identification systems that use radio transmission to read

or write data of LF transponders (134,2 kHz), which operate as tamper-proof electronic tags. The

LF reading devices communicate with common transponders (134,2kHz) according to ISO 18000-2

and ISO 11785 that are available on the market.

The data is transmitted via the existing interface with the preset transmission parameters. If seve-

ral interfaces are available and connected to the host, the transmission is always carried out on the

most recently used interface. The data is embedded in a defined communication protocol and

exchanged between the reader and host.

6.2 Basic functions - operating modes

During normal operation, the LF reading device supports various basic functions:

•Heartbeat function, software version query

•Scanning of transponders in the antenna area (UID)

•Reading data

•Writing data

•Locking data

•Setting and reading out parameters

•Setting and querying inputs and outputs

The LF devices can be set in 3 other operating modes by setting the parameters: Polling operation

(optional), sensor-triggered automatic reading and test mode.

6.2.1 Normal operation

During normal operation, the LF reading device is immediately ready for operation after a reset. It

does not perform any automatic actions in this mode (standby). During normal operation, actions are

triggered by protocol commands from the host.

A scanning procedure or reading in the data area is initiated by a command of the host system

using the communication protocol.¬

In addition to the actions triggered by the host, a corresponding message can be automatically sent

to the host and an automatic reading operation can be started by activating or releasing a sensor.

When the reading operation is successful, the read data is immediately transmitted to the host. If

several antenna ports are occupied simultaneously, the reading operations are processed sequen-

tially.

Writing actions (data saved to a transponder) are generally only possible via commands from the

host.

6.2.2 Polling mode

LF reading devices can be set into a continuous reading state, which is referred to as

polling mode. The device then performs reading operations at regular intervals and

outputs the corresponding data of the read LF transponder.

The reading device also continues carrying out protocol messages in polling mode. This

may, however, result in delays in the poll rhythm. The polling functionality is optional

customer-specific available!

6.2.4 Test module

Customer manual

LFM 4x Reader

RFID

WE GENERATE SOLUTIONS

LFM 4x Reader Rev1.4

17

www.hermos.com

The HERMOS LF reading devices support a test mode that facilitates setting up the antenna and

checking the reading ranges during commissioning. HF reading devices feature several DIP swit-

ches on the housing. These switches can be used to activate test mode.

The functions in test mode are described on a sticker located on the reading device housing. The

evaluation of the DIP switch depends on parameters

If the device is in test mode, the red status LED flashes at about 1 Hz. The yellow status LED then

indicates the status of the test mode. If the read or write process was unsuccessful, the yellow LED

flashes at the read or write frequency. If the read or write process is successful, the yellow LED

remains permanently lit.

With the existing I / O module, HERMOS LF readers with ASC-W1 protocol also show the success-

ful or incorrect reading of the transponder at the respective first output port. See also behavior of

the output ports in test mode.

see also chapter „DIP-switch“

6.3 Illustration

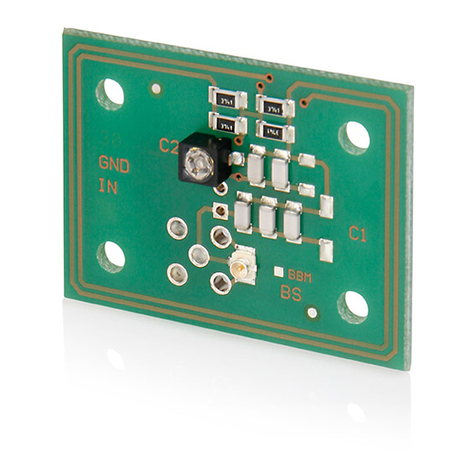

6.3.1 Top view

1. Black and white anodised aluminium

housing

2. Reading device type imprint

3. Data Matrix Code

www.hermos.com

Customer manual

LFM 4x Reader

RFID

WE GENERATE SOLUTIONS

LFM 4x Reader Rev1.4

18

www.hermos.com

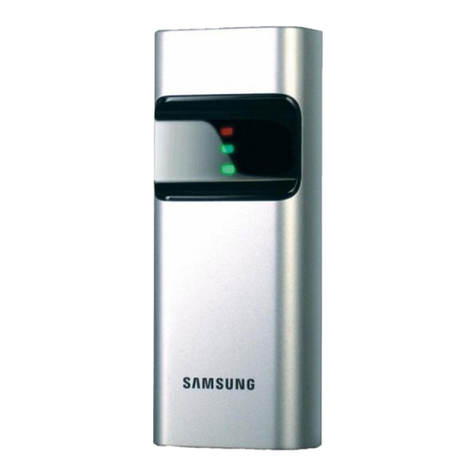

6.3.2 Front view

1. Power supply connection

2. Status- and power LEDs

3. DIP-switch

4. Ethernet interface

5. RS232 interface

Component

Description

Power supply

connection

Three-pin socket for the connection of the 24V DC power supply.

Power-LED

The power LED indicates that the operating voltage is present and

the rea- ding device is ready for operation.

Status-LEDs

The two status LEDs are used for the reading and writing feedback in

test and polling mode. If the device is in test mode, the red status

LED flashes at about 1 Hz. The yellow status LED then indicates the

status of the test mode. If the read or write process was

unsuccessful, the yellow LED flas- hes at the read or write frequency.

If the read or write process issuccessful, the yellow LED remains

permanently lit.

In normal operation, if an error occurs, the display of this

occurs via the red LED:

Red LED constantly on: read error (no tag)

red LED flashing rapidly: antenna error (tuning, cable

break). This display will reset automatically with the next

valid reading.

After a restart, a short self-test of the LEDs, then display of the

protocol: SECS: The red LED goes on briefly

ASCII: The yellow LED goes on briefly

DIP-switch

DIP-switch 4 starts an automatic antenna

tuning. DIP-switch 3 activates a test

mode.

DIP-switch 1 and 2 serve the antenna selection.

Ethernet interface

The reading device features an Ethernet interface depending on the

de- vice model. The communication with the device can be carried

out via the 10/100 BaseT interface.

RS232 interface

Depending on the device model, the reading device features a RS232

in- terface. The communication with the device can be carried out via

the serial interface (9-pin Sub D)

Customer manual

LFM 4x Reader

RFID

WE GENERATE SOLUTIONS

LFM 4x Reader Rev1.4

20

www.hermos.com

6.4 Technical Specification

Technical data

Voltage (protected against reverse

polarity)

20 –28 V DC,

Power consumption

(passive, reading, pulse-by-pulse)

75mA@24V, 200mA, max.400mA

Fuse type Nano2

375 mA

Operating temperature

-0 to 50 °C

Storage temperature

-20 °C to 70 °C

Permissible humidity at 50°C

25 –80 %

Transmission frequency

134,2 kHz

Ethernet interface

10/100 BaseT,

Protocol

ASCII, SECS / HSMS

Housing material

Aluminium, black and white anodised

Protection

IP40

Reader dimensions

130 x 124 x 45 mm

Weight

approx. 500 g

6.4.1 Power supply and current input

Description

Min.

Typ

Max.

Unit

Voltage (reverse polarity protected)

20

24

28

V (DC)

Current consumption (Read/Write

Pulse manner (50ms)

110

330

mA

Current (passive)

80

mA

Table of contents