hestan KRT365 User manual

EN

©2018 Hestan Commercial Corporation

1

EN

GAS CONVERSION KIT

Installation Instructions

Range/Rangetop

FOR SERVICE PERSONNEL ONLY

IMPORTANT - READ ALL INSTRUCTIONS BEFORE YOU BEGIN

THE INSTRUCTIONS HEREIN MUST ONLY BE PERFORMED BY A QUALIFIED SERVICE

TECHNICIAN. THE RANGE MUST BE COMPLETELY COOL AND THE GAS SOURCE MUST

BE SHUT OFF OR REMOVED BEFORE ATTEMPTING GAS CONVERSION.

Some parts inside your range have sharp edges. Care must be taken when handling the various

components to avoid personal injury. Wear gloves when handling.

TOOLS REQUIRED:

Work gloves

Safety glasses

Phillips screwdriver

Flat-blade screwdriver

Plastic or non-marring pry tool

Pipe wrench or large slip-joint pliers

Socket wrench with 8mm socket

Open end or combination wrenches (8, 10, 12, 14mm)

IF THE INFORMATION IN THIS MANUAL IS NOT FOLLOWED

EXACTLY, A FIRE OR EXPLOSION MAY RESULT CAUSING

PROPERTY DAMAGE, PERSONAL INJURY, OR DEATH.

Flammable Gas - disconnect all propane or natural gas supplies to this

unit before servicing.

Electrical Parts & Components – disconnect all power supplies before

servicing.

DANGER

If you smell gas:

1. Shut off gas to the appliance.

2. Extinguish any open flame.

3. Open windows and doors in the room.

4. If odor continues, keep away from the

appliance and immediately call your gas

supplier or your fire department.

DANGER

1. Do not store or use gasoline or

other flammable liquids or vapors

in the vicinity of this or any other

appliance.

2. An LP cylinder not connected for

use shall not be stored in the vicinity

of this or any other appliance.

READ THIS MANUAL CAREFULLY AND COMPLETELY BEFORE USING YOUR

RANGE TO REDUCE THE RISK OF FIRE, BURN HAZARD, OR OTHER INJURY.

KEEP THIS MANUAL FOR FUTURE REFERENCE.

©2018 Hestan Commercial Corporation

2

EN

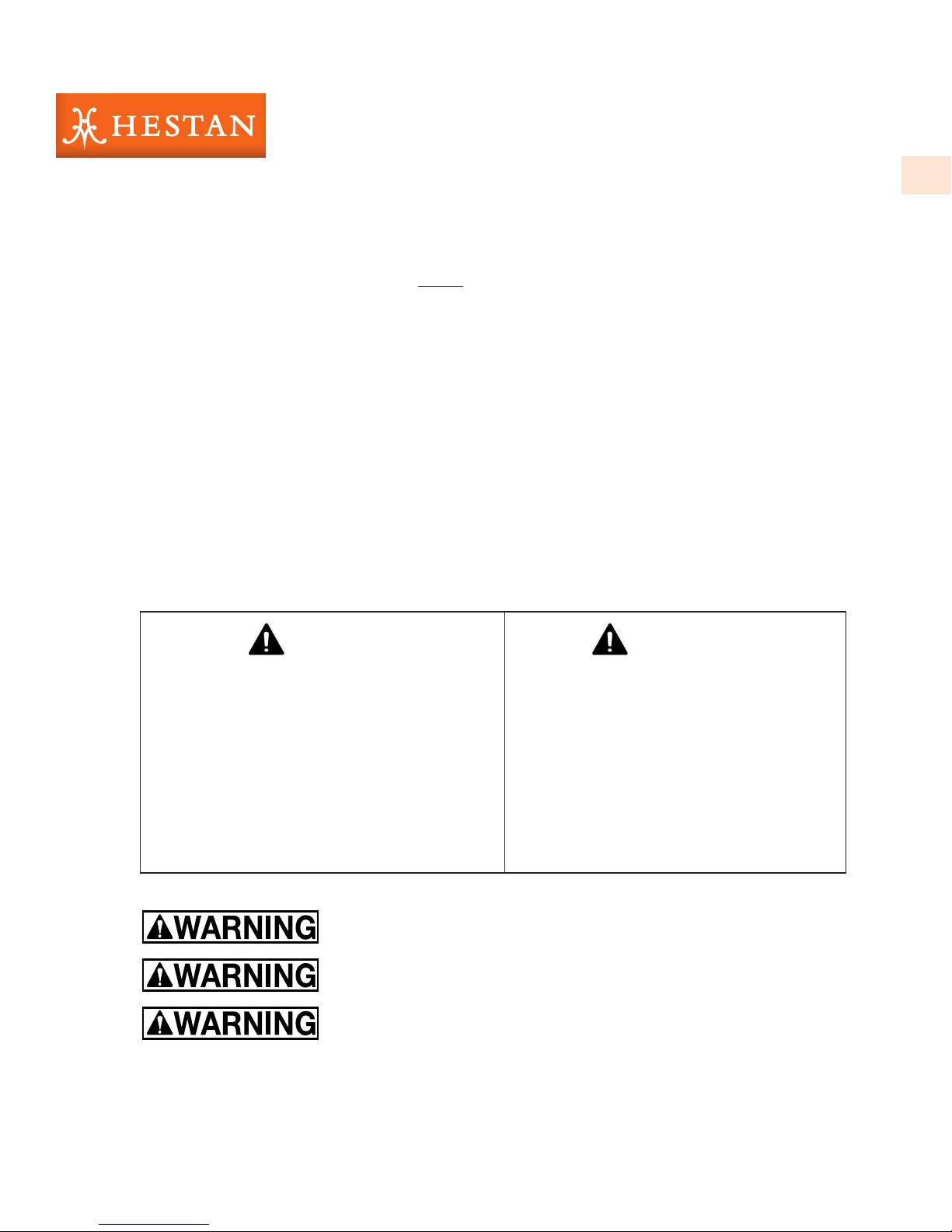

DISASSEMBLY (KRT365 shown)

2. Insert a plastic or other non-marring tool to pry into the seam between the control panel and the

body in the approximate location shown. Apply light pressure to release the bottom edge of the

control panel from the ball retaining studs hidden inside. Repeat for other side. Swing out the

bottom edge to remove the panel, and set aside.

1. Remove the knobs, grates, burner caps and burner rings as shown below.

INSERT TOOL HERE

©2018 Hestan Commercial Corporation

3

EN

DISASSEMBLY

(continued)

4. Slide the bullnose trim assembly forward as shown and set aside.

3. Remove the screws shown below to detach the bullnose trim assembly.

REMOVE

2 SCREWS

LEFT SIDE RIGHT SIDE

REMOVE

2 SCREWS

SLIDE FORWARD

5. Remove all screws around each burner

base which hold the burner bowl in

place.

REMOVE ALL SCREWS

©2018 Hestan Commercial Corporation

4

EN

7. Remove each LED board from unit as shown below. You do not have to disconnect each wire

connector - they can be left hanging in place.

DISASSEMBLY

(continued)

6. Remove the burner bowl as shown below.

NOTE: CENTER BURNER IGNITER

WILL REMAIN ATTACHED TO BURNER

BOWL WHEN RAISED. DISCONNECT

THIS WIRE.

TILT UP BURNER BOWLABOUT

30 DEG. TO DETACH FROM REAR

ISLAND TRIM / RISER.

REMOVE LED BOARDS TO EXPOSE

VALVE ORIFICE ACCESS HOLES

©2018 Hestan Commercial Corporation

5

EN

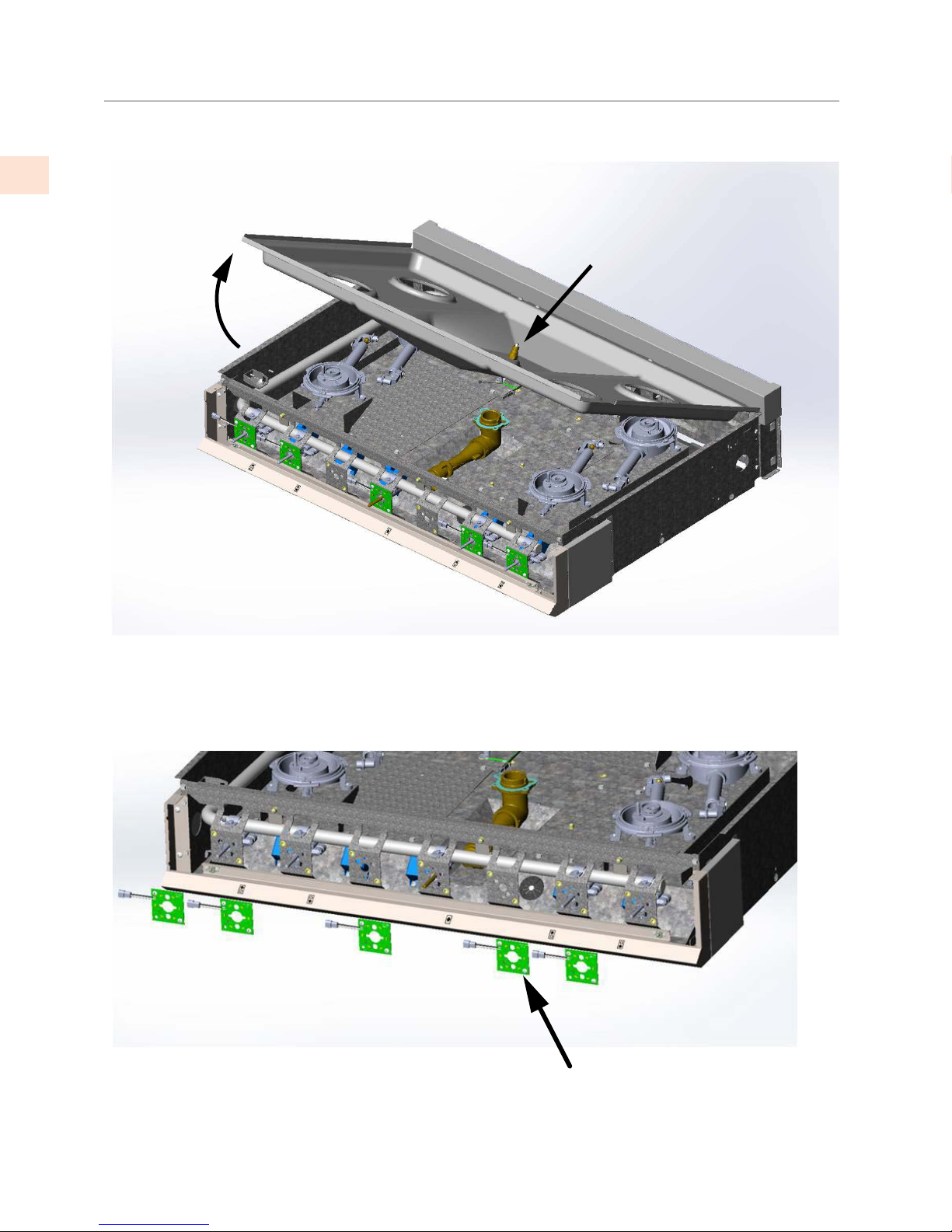

ORIFICE LOCATIONS

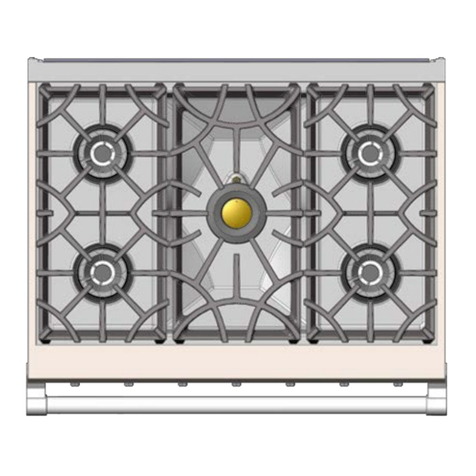

8. Shown below is a typical burner layout. The dual-flow rear burners have 15500 BTU output, while

the dual-flow front burners are 23000 BTUs. The center single-flow burner (if equipped) has a 30000

BTU output (or 23000 on LP gas).

TYPICAL BURNER LAYOUT

(KRT365 SHOWN)

15.5k 15.5k

23k 23k

30k

The following pages describe how to replace the orifices in each burner type and each valve type. Do

one item at a time so as not to mix up orifices. All orifices must be fully seated and hand-tight to

reduce the chances of a gas leak. DO NOT USE any sealant, pipe dope, teflon tape, or anything else

on the orifice threads.

ABOUT HOSES: If you need to disconnect any hoses during this process, use caution to avoid

unnecessarily bending, twisting, or kinking any hoses. Hoses are stainless steel flex type which can

become brittle with age and can crack if handled roughly. Disconnect the fitting carefully where

necessary. You will perform a complete gas leakage test at the end of this procedure.

©2018 Hestan Commercial Corporation

6

EN

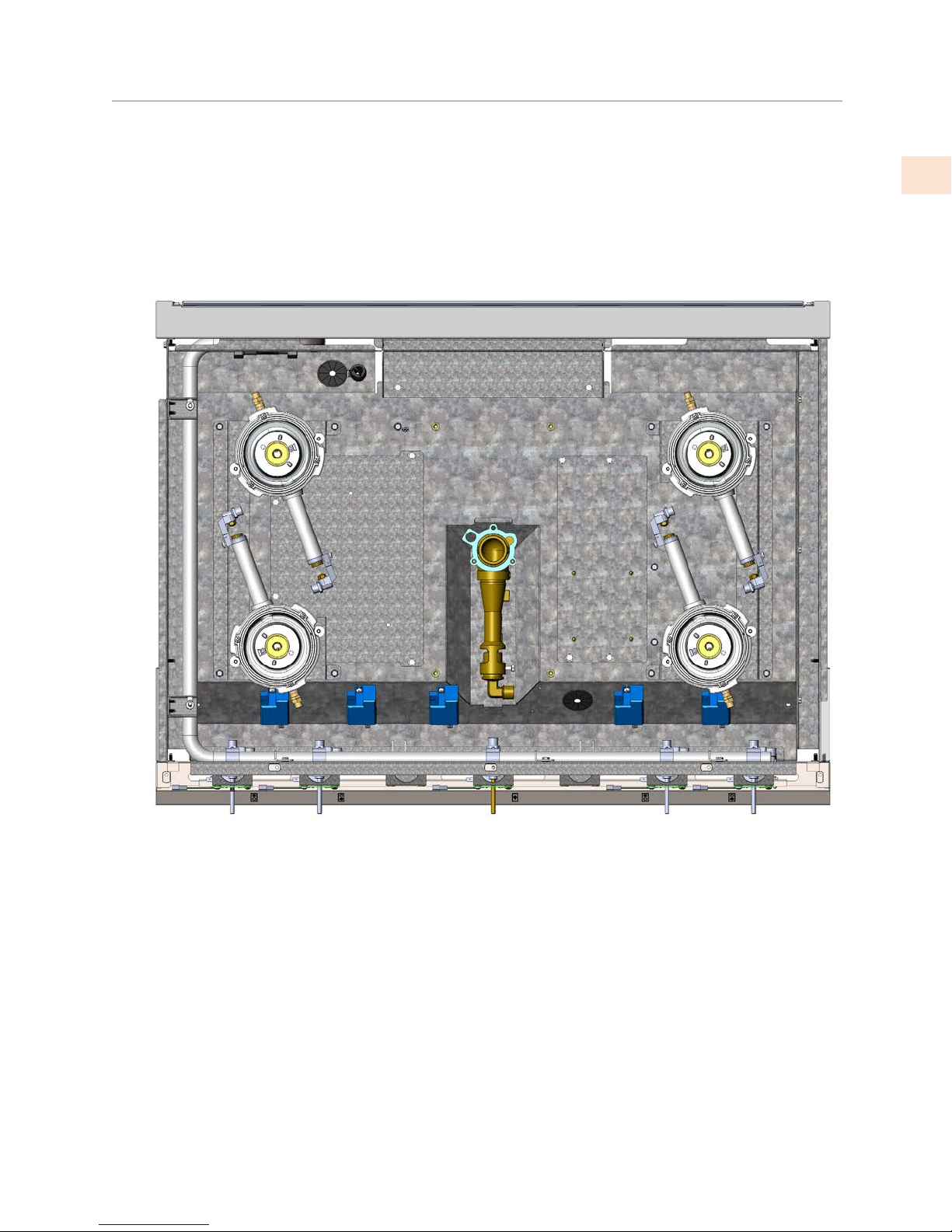

ORIFICE CHARTS

9. USE THIS CHART AS A GUIDE FOR REPLACING THE ORIFICES. SEE FOLLOWING PAGES FOR

REPLACEMENT INSTRUCTIONS FOR BURNERS AND VALVES.

NG LP NG LP NG LP NG LP NG LP

Front 23000 23000 046 055 073 078 065 073 080 087

Rear 15500 15500 052 058 073 078 065 073 080 087

Front 23000 23000 047 055 073 078 065 073 080 087

Rear 15500 15500 053 060 073 078 065 073 080 087

Front 23000 23000 049 056 074 079 065 073 080 087

Rear 15500 15500 054 062 074 079 065 073 080 087

H1

2000 - 5999 ft (600 - 1800m)

H2

6000 - 10000 ft (1800 - 3050m)

Sea Level - 1999 ft (600m)

BURNER

LOCATION

ALTITUDE

Dual Flow Burner

Main Orifice

023690-xxx

Dual Flow VALVE

Simmer Orifice

023701-xxx

Dual Flow Burner

Simmer Orifice

023698-xxx

Dual Flow VALVE

Low Orifice

023701-xxx

BURNER OUTPUT

(BTU/hr)

©2018 Hestan Commercial Corporation

7

EN

CHANGING BURNER ORIFICES

SIMMER ORIFICE

023698-XXX

MAIN ORIFICE

023690-XXX

.177 inch [4.5mm]

VENTURI /

AIR SHUTTER

THIS PORT TO

BE FULLY OPEN

DUAL-FLOW

BURNER BASE

ASSEMBLY NOTE: ALIGN VENTURI / SHUTTER WITH 2nd GROOVE.

DIMENSION SHOWN FOR REFERENCE ONLY.

LOCK

SCREW

10. The main BURNER orifice can be replaced without disconnecting the hose. The simmer orifice hose

must be disconnected to access the orifice inside. See the chart on pg. 6 to select the appropriate orifice

for your gas type / altitude. The part numbers and identification (color / stamp) for the orifice are given

in the tables above.

The detail view shows the appropriate venturi / air-shutter dimension. The dimension is shown for

reference only in case the lock screw was loosened, or the flame characteristics are not correct and need

adjustment. If adjustment is needed, loosen the lock screw and adjust the air shutter in or out in very

tiny increments, lock down the screw, replace all the components and check the flame again.

©2018 Hestan Commercial Corporation

8

EN

MAIN ORIFICE

(SEE P/N ABOVE)

AIR SHUTTER

SINGLE-FLOW

BURNER BASE

ASSEMBLY

X

LOCK

SCREW

ORIFICE

HOLDER

CHANGING BURNER ORIFICES

(continued)

11. The main BURNER orifice can be replaced without disconnecting the hose, however care must be

taken when handling to avoid bending or kinking the hose. Loosen the lock screw to extract the

orifice holder from the main body. See the chart on pg. 6 to select the appropriate orifice size for

your gas type / altitude. The part number and identification for the orifice is given in the table above.

When reinstalling the orifice holder in the body, be sure to set the correct air shutter distance

(Dimension X), then tighten the lock screw. If later on, the flame characteristics require adjustment,

loosen the lock screw and adjust the air shutter in or out in very tiny increments, lock down the

screw, replace all the components and check the flame again.

©2018 Hestan Commercial Corporation

9

EN

12. Remove the valve orifices via the access holes in the bracket as shown below.

ACCESSING VALVE ORIFICES

SINGLE-FLOW

VALVE DUAL-FLOW

VALVE

VALVE LOW

ORIFICE

VALVE

SIMMER

ORIFICE

VALVE LOW

ORIFICE

©2018 Hestan Commercial Corporation

10

EN

DUAL-FLOW

VALVE

NOTE: REMOVE AND REPLACE ONE ORIFICE

AT ATIME. MAKE SURE ORIFICE IS FULLY

TIGHTENED ON INSTALLATION.

VALVE LOW

ORIFICE

023701-XXX

VALVE SIMMER

ORIFICE

023701-XXX

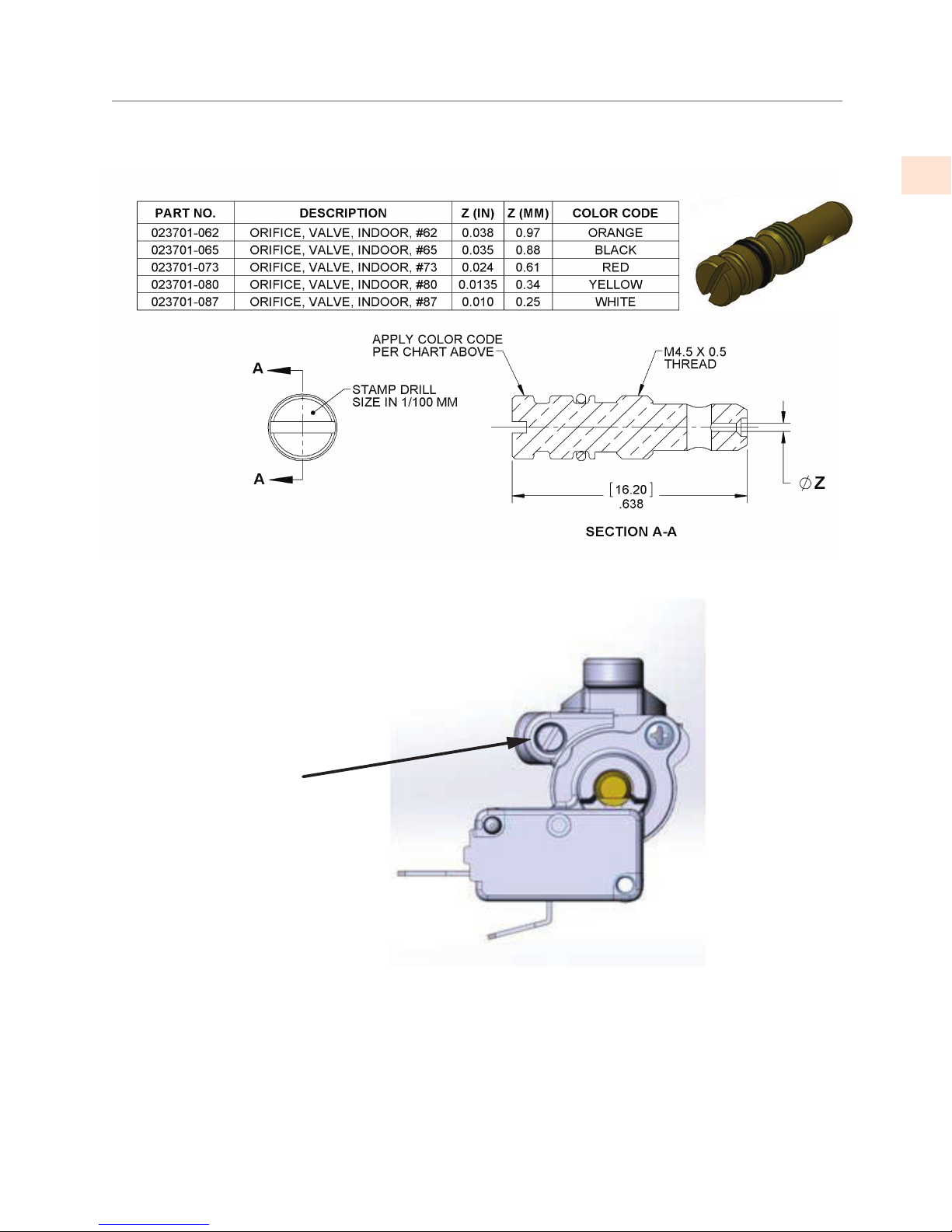

CHANGING VALVE ORIFICES

13. Replace the VALVE orifices as shown below. See the chart on pg. 6 to select the appropriate orifice

size for your gas type / altitude. The part number and identification (color code) for the orifice is

given in the table below.

©2018 Hestan Commercial Corporation

11

EN

SINGLE-FLOW

VALVE

NOTE: REMOVE AND REPLACE ONE ORIFICE

AT ATIME. MAKE SURE ORIFICE IS FULLY

TIGHTENED ON INSTALLATION.

VALVE LOW

ORIFICE

023701-XXX

CHANGING VALVE ORIFICES

(continued)

14. Replace the VALVE orifice as shown below. See the chart on pg. 6 to select the appropriate orifice

size for your gas type / altitude. The part number and identification (color code) for the orifice is

given in the table below.

©2018 Hestan Commercial Corporation

12

EN

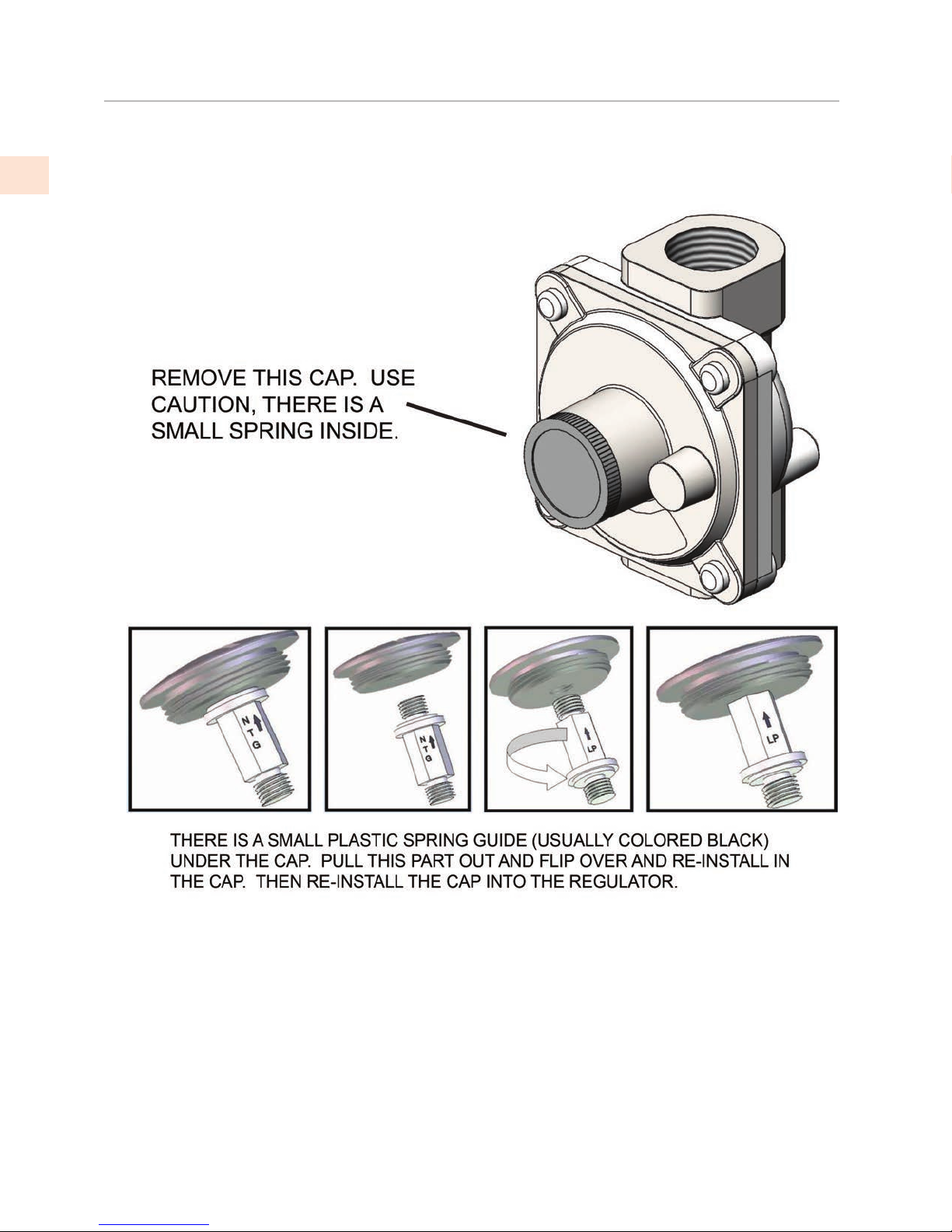

CONVERTING THE REGULATOR

15. With access to the rear of the appliance, you can convert the gas type of the regulator by

following the instructions below (conversion from NG to LP gas is shown). This can be done

without removing the regulator.

©2018 Hestan Commercial Corporation

13

EN

LEAK TESTING & ADJUSTMENT

16. At this point, all conversion components should be installed and any hoses removed previously

have been returned and tightened. Before replacing the various sheetmetal parts, a complete leak

check must be performed on all gas-carrying components. Begin by temporarily supporting the

center burner (if equipped) with a small block of wood as shown below.

Also return all the burner rings and caps to the other burners (see image on next page).

GAS SUPPLY

The local gas authority or supplier should be consulted at the installation planning stage in order to

establish the availability of an adequate supply of gas (NG or LP). If it is a new installation, have the

gas authorities or supplier check the meter size and piping to assure that the unit is supplied with the

necessary amount of gas supply and pressure to operate the unit(s).

Gas connections should be made by a qualified plumber, or your professional appliance service

technician.

All fixed (non-mobile) appliances must be fitted with an accessible upstream gas shutoff valve as a means

of isolating the appliance for emergency shut off and for servicing. This valve was described in the

appliance Installation Manual.

Make certain new piping and connections have been made in a clean manner and have been purged so

that piping compound, chips, etc. will not clog regulators, valves, orifices, or burners.

IF THE INFORMATION BELOW IS NOT FOLLOWED EXACTLY, A FIRE OR EXPLOSION MAY RESULT

CAUSING PROPERTY DAMAGE, PERSONAL INJURY, OR DEATH.

LEAK TESTING

GENERAL

A complete gas tightness check must be performed of all gas-carrying components due to possible

movement during installation, or excessive pressure unknowingly being applied to parts of the unit.

BEFORE TESTING

• DO NOT SMOKE while leak testing.

• Never leak test with an open flame.

• Make a soap solution of one part liquid detergent and one part water for leak testing purposes.

• Apply the solution to the gas fittings by using a spray bottle, a brush or small sponge.

©2018 Hestan Commercial Corporation

14

EN

LEAK TESTING & ADJUSTMENT

(continued)

• For LP units, always check with a full LP cylinder.

• Check for adequate inlet gas pressure - 7” w.c. for Natural gas, 11” w.c. for LP gas.

Gas pressure from the regulator must be 5” w.c. for Natural gas and 10” w.c. for LP gas.

TO TEST

• Make sure all control valves are in the “OFF” position.

• Apply the soap solution described above to all fittings, flex hoses, etc.

• Turn the gas supply on.

• CHECK ALL CONNECTIONS! Check from the supply line, up to and including the manifold pipe

assembly, regulator, etc. Check ALL the hoses from end to end. Bending of the hoses may have

resulted in small cracks in the hoses which must be found. Apply the soapy solution liberally to

detect any leaks. If hoses are cracked, you will need to replace them.

• Soap bubbles will appear where a leak is present. If a leak is present, immediately turn off gas

supply, tighten any leaking fittings, turn the gas supply back on, and recheck.

• If you cannot stop a gas leak, turn off the gas supply and call the dealer where you purchased your

appliance.

• DO NOT USE THE APPLIANCE UNTIL ALL CONNECTIONS HAVE BEEN CHECKED AND DO

NOT LEAK!

Once the leak check is done and there are no leaks, proceed to re-install all the sheetmetal parts, LED

boards, etc. that were previously removed. Don’t forget to re-connect the ignition wire for the center

burner (if equipped). Restore the electrical power to the unit. Turn the gas shut-off valve to the open

position.

NOTICE

All the control knobs must be in the OFF position to prevent unintended operation at power up.

©2018 Hestan Commercial Corporation

15

EN

LEAK TESTING & ADJUSTMENT

(continued)

Return all the burner rings and caps as shown below. Ensure the sealed burner heads are properly

installed and seated on the burner base as shown below. There are notches on the burner base and

cross ring to help with alignment. The outer burner head features a long slot on the top of the head

which aligns with the spark igniter. Assembly of the single-flow burner head is similar.

Verify ignition at each burner. Igniter will make a clicking sound until the flame lights within 4

seconds, then the clicking will stop. Check flame characteristics at each burner per the descriptions

below. Flames should be stable and not dance or lift off the burner ports. Flame may need to burn

for a few minutes to purge the gas lines of impurities. These appear as intermittent orange tips or

even tiny sparks in the flame. This is normal and the flame will eventually stabilize like those shown

in the image below.

If after a few minutes the flames continue to burn mostly yellow, verify that the burner head is

properly installed on the base, then retest. Use caution when handling the burner heads. They can

be very hot.

Turn down the control knob to the simmer setting to check function.

Check each burner individually, then check they operate satisfactorily with other burners on.

Light blue flame - Natural gas normal flame

Light blue flame with yellow tips - LP gas normal flame

Yellow flame - Needs adjustment

LABEL

After conversion, the label provided in the kit must

be attached to the unit. For the range, affix in the

upper right corner as shown. For the rangetop, affix

underneath the unit next to the existing rating label.

The qualified service technician will fill in the Gas Type,

Manifold Pressure, and BTU Rates for each burner type

(per the chart on pg. 6). The technician should sign and

date the label as well.

BURNER

RING

BURNER

HEAD

BURNER

BASE

IGNITER

INNER

BURNER

HEAD

OUTER

BURNER

HEAD

BEAUTY

RING

CROSS

RING

BURNER

BASE

DUAL FLOW

BURNER

SINGLE FLOW

BURNER

Hestan Commercial Corporation

3375 E. La Palma Ave.

Anaheim, CA 92806

(888) 905-7463

RETAIN THIS MANUAL FOR FUTURE REFERENCE

©2018 Hestan Commercial Corporation P/N 023730 REV A

Table of contents

Other hestan Range manuals

hestan

hestan HFT Series User manual

hestan

hestan KRG Series User manual

hestan

hestan KRD365LPYW User manual

hestan

hestan KRG365NGYW User manual

hestan

hestan KRD485GD-NG User manual

hestan

hestan KRD485GDNGYW User manual

hestan

hestan KRI30 User manual

hestan

hestan KRG User manual

hestan

hestan KRDS Series User manual

hestan

hestan KRD485GDNGWH User manual