©2015 Hestan Commercial Corporation

Riser Installation

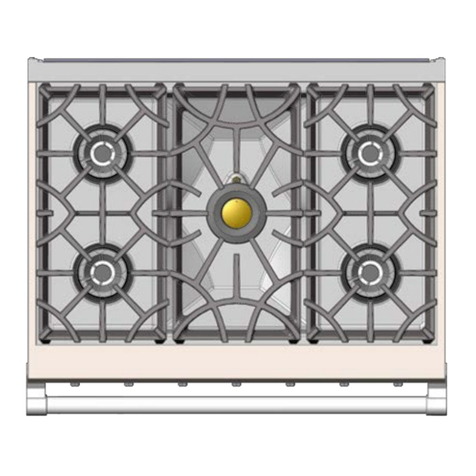

1) Remove back panel from riser assembly by removing mounting screws

2) Remove the four bolts at the rear of the appliance holding on the side panels (two on each side, see

diagram below)

3) Place riser on support brackets on back of the appliance.

4) Re-install the four bolts into the back of the appliance through the riser channels, do not tighten

5) Attach the bottom supports with supplied bolts, two on each side

6) Tighten the four bolts that attach riser to appliance.

7) Tighten the four bolts that attach riser to bottom supports

8) Re-install back cover

Range Top Bolts

NOTE: Failure to re-install back cover could cause improper venting of exhaust gases/heat from the appliance,

creating soot that clogs the burner(s) and flue and/or creates a temperature risk to cabinet and

components.

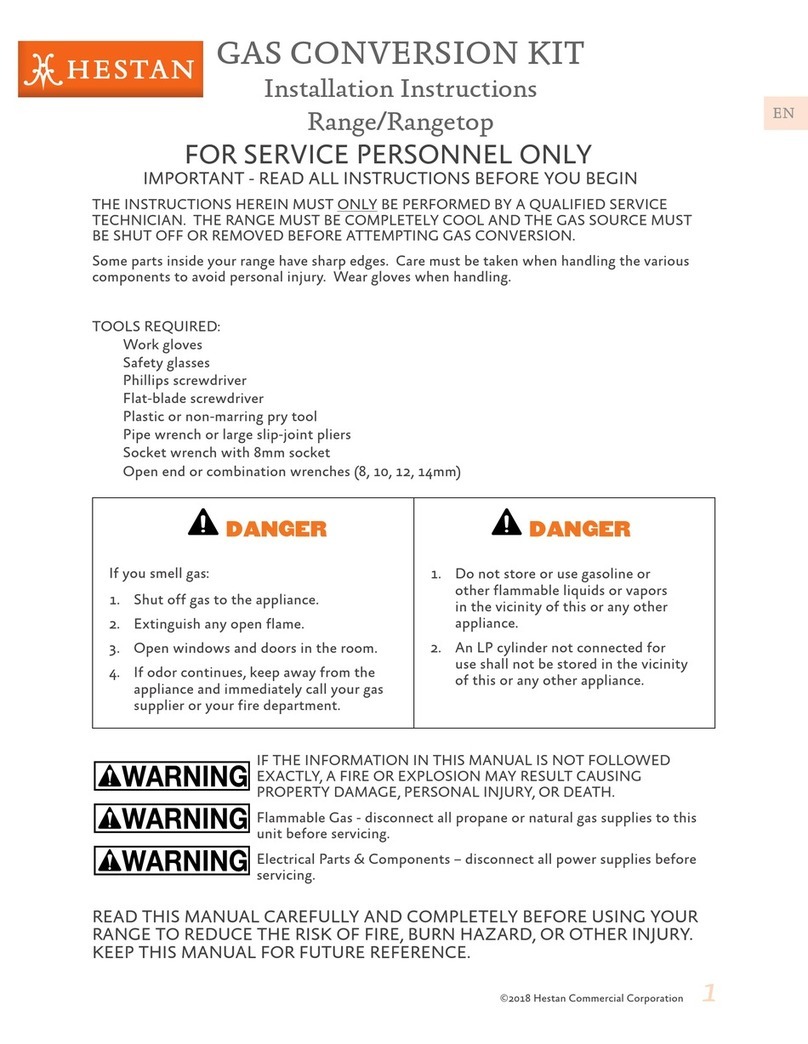

Statutory Regulations (Install Codes)

The installation of this appliance must be carried out by a properly trained and qualified installer and in

accordance with the relevant regulations, codes of practice and the related publications of the Country, State,

County and City of destination.

United States of America

1) Local Codes

2) In the absence of local codes, installation must conform to the National Fuel Gas Code, ANSI

Z223.1/NFPA 54, or the Natural Gas and Propane Installation Code, CSA B149.1, as applicable.

Copies may be obtained from the American Gas Association, Inc., on their web site:

http://www.aga.org/

3) National Electrical Code, ANSI/NFPA-70, or latest edition. Copies may be obtained from the

National Fire Protection Association, on their web site: http://www.nfpa.org/

4) Vapor Removal From Cooking Equipment, NFPA-96, or latest edition. Copies may be obtained from

the National Fire Protection Association, on their web site: http://www.nfpa.org/

Canada

1) Local Codes

2) CSA B149.1 Natural Gas and Propane Installation Code.

3) CSA C22.1 Canadian Electrical Code

4) CSA C22.2 Canadian Electrical Code

Canadian codes can be found on the CSA website: http://www.csa.ca