Hewalex EKONTROL OPTI-ENER 2.0 User manual

Scan this code to download the latest technical documentation

KONTROL

B Y H E W A L E X

B Y H E W A L E X

09.03.2022

OPTI-ENER 2.0

Installation and Operating Manual

Your assistant for managing your home energy analysis

HEWALEX Sp. z o.o. Sp. k.

+48 32 214 17 10

www.hewalex.pl

EN

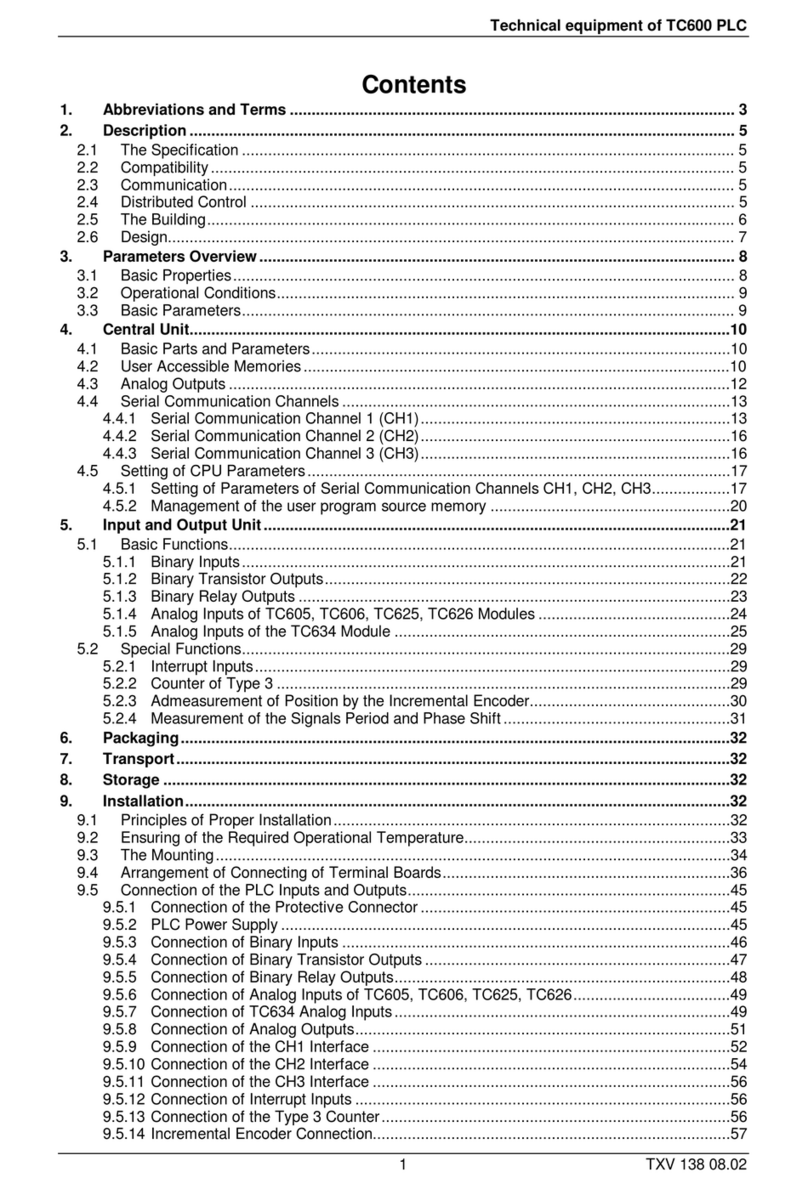

SPIS TREŚCI

1. Safety requirements ........................................................................................................................................................................... 2

2. Device description.............................................................................................................................................................................. 3

2.1. PCB overview and assignment of inputs......................................................................................................................................................................4

3. Installation........................................................................................................................................................................................ 4

3.1. Installation location......................................................................................................................................................................................................4

3.2. Connecting the current and voltage measurement lines.............................................................................................................................................5

3.3. Internet connection ......................................................................................................................................................................................................6

3.4. Connecting the OPTI-TEMP module.............................................................................................................................................................................7

3.5. Connecting the inverter................................................................................................................................................................................................7

3.6. OPTI-ENER operating keys...........................................................................................................................................................................................8

4. Electrical load power control ................................................................................................................................................................ 8

4.1. Dry NO contacts ...........................................................................................................................................................................................................8

4.2. SG Ready ......................................................................................................................................................................................................................9

5. Account conguration......................................................................................................................................................................... 9

5.1. Settings– Conguration ...............................................................................................................................................................................................9

5.2. Settings – Setup.........................................................................................................................................................................................................10

6. Troubleshooting............................................................................................................................................................................... 10

7. Notice on the labelling and collection of waste electronic equipment........................................................................................................ 11

NOTE

Read carefully and follow the specied safety conditions.

WARNING

During operation of the device, do not insert metal objects into its housing or place them on surface of the control PCB – risk of

electric shock.

Read the following instructions carefully before operating this device. The instructions specify important safety information which must be

understood and strictly followed. The manufacturer will not accept any liability in the event of non-compliance with the safety rules, improper

use of the device or incorrect settings of the controls.

This equipment is not intended to be serviced by individuals (including children) with reduced physical, sensory or mental capabilities or lack of

experience and knowledge of the equipment, unless they have been given supervision of an authorised professional electrician or instruction

concerning the use of the equipment by individuals responsible for their safety.

The device is used through a website or a mobile application and only with appropriate instructions for its safe use and provided that the user

understands the risks of device operation.

Due to its protection class/level (IP 40), the device is intended for domestic use only. Outdoor installation is possible provided that the unit is

installed in an enclosure with a higher protection class, e.g. inside of an electrical switchgear (rated at IP65-IP68). Do not store explosive or

ammable materials, including aerosol cans, and do not store or use gasoline or other ammable materials near the device. Keep a sufcient

distance between any gas installation and the device in accordance with applicable standards. Make sure that the device is not left near a

source of water or exposed to dust. The device is designed to operate in locations with temperatures between -20° and +60° C and a relative

humidity between 5% and 85%. The device may not function properly or can be permanently damaged if it is left for an extended period of time

in a room with the ambient air parameters outside of these limits.

Never use steam cleaners. Wear protective gloves when cleaning and maintaining the device. Disconnect the device from the electrical power

supply before attempting any maintenance on the device. Do not clean plastic parts with harsh or abrasive cleaning agents, such as window

cleaners, scouring agents, ammable liquids, cleaning waxes, concentrated detergents, bleach, or cleaners based on petroleum products. Do

not use paper towels, sponges or other rough or sharp instruments for cleaning.

2

1. SAFETY REQUIREMENTS

a

b

c

d

e

Safety requirements:

Safety warning:

Permitted use:

Installation location:

Cleaning and maintenance:

NOTE

The OPTI-ENER controller requires Internet

connectivity for full performance and access to logged data.

The OPTI-ENER system is designed and produced to manage electrical power consumption. The principle of operation is based on the

measurement of the voltage and current of different power supply phases of the building service line connected to the grid and power source

(e.g. photovoltaic systems). This way the user has control over the amount of generated energy, fed back into the grid, taken from the grid, and

consumed by household appliances. The OPTI-ENER facilitates automatic operation and control (to turn on and off) of electrical equipment and

loads according to the preset priorities and the power surplus generated by the power source and returned to the grid.

The LED indicators are explained in Table 1.

OPTI-ENER controller specications:

• Power supply: 230V AC, 50 Hz

• Dimensions (width x height x depth): 210x140x42 mm

• Working conditions:

-Ambient temperature: from -20° to 60°

-RH: from 5% to 85% (no condensation and/or icing)

• Power consumption: <3W

• Degree of protection: IP 40

Included:

• OPTI-ENER Controller

• Operating Manual

• Opti-Ener LiYY wiring harness

• Mounting bracket

Icon Description Indication

Power supply continuous light - device on

no signaling - device switched off

Device status

The menu mode opened with the conguration key:

Single ash – no menu option selected;

Double ash – optional module pairing mode;

Triple ash – subnetwork device removal mode;

Quadruple ash – device reset to default settings;

Menu mode off: - Steady light – no active errors;

- Single ash – heater detection error;

- Double ash – storage tank temperature sensor error.

Optional module

communication

Steady on – device paired;

Off – no communication with optional modules

Connection status Flashing – connection established

Updating Fast ashing (9 Hz) – update in progress

3

Fig. 1. Opti-Ener - front view

Table 1. LED indicator overview

2. DEVICE DESCRIPTION

The OPTI-ENER features two measurement inputs for current and voltage, and RS485 bus communication ports which include a Modbus RTU

output. The device has an SD memory card slot and an Wi-Fi module for wireless connectivity to your home Internet network and SG Ready

socket.

The connection terminal locations are shown in Fig. 2. The detailed wiring connection diagrams are provided in Section 3, Installation.

Fig. 3 shows the location of keys B1, B2, and B3 for operation and 8P8C port.

The OPTI-ENER 2.0 controller is intended for surface mounting. Use the dedicated mounting bracket shown in Fig. 4 to install the OPTI-ENER.

Install OPTI-ENER near the main distribution panel of the building. For indoor installation, the recommended installation location should be at

least 10 cm away from xed partitions. The controller is IP40 rated and outdoor installation is only permitted in a weather-proof enclosure rated

IP65 or higher.

Internet connectivity is essential for correct operation of the controller – provide a Wi-Fi network (2.4 GHz) or a LAN UTP Cat. 5 or higher

Ethernet cable with a 8P8C plug.

4

Relay 2

Relay 4

ModBus

Master

Relay 3

Relay 1

SG Ready

Wiring relief Configuration

keys

8P8C

12V

SD card

Wi-Fi module

GND

A+

B+

ModBus

RTU

12V

GND

A+

B+

RS485

2

12V

GND

A+

B+

B3 B2 B1

CH2

CH1

B3 B2 B1 8P8C

Fig. 2.

Fig. 3. Fig. 4.

Control PCB layout

Location of conguration keys B1 B2 B3, 8P8C

port, and POWER receptacle

Mounting bracket for easy wallmounted installation of

the controller

2.1. PCB overview and assignment of inputs

3. INSTALLATION

3.1. Installation location

NOTE

An isolation switch or overcurrent circuit breaker is not included in the OPTI-ENER kit!

NOTE

The parameter values measured by the OPTI-ENER system do not include the unmonitored period of operation of the

PV system. The controller’s measurement tolerance is ± 2.5%.

NOTE

The output connection to the home electrical wiring system must be downstream of the CTs on L1, L2,

and L3 so that the CTs monitor the total power input/output from/to the grid.

The OPTI-ENER includes a factory-provided, 12-wire harness approximately 1 m long. Split the harness into two bundles, one for voltage

measurement with the wires coded N, L1, L2, and L3, and one for current measurement with the wires coded CT1, CT2, CT3, and CT4.

OPTI-ENER, with the help of current transformers, measures the value of the current and determines the direction of its ow. Each CT must

be properly oriented when installed on the live conductor to be monitored. Incorrect installation will cause operating errors of the OPTI-ENER.

Put each CT over the phase (live) conductor between the power meter and the point of power distribution to the loads in the electrical system

at home. This allows to monitor the total power input from or output to the grid. Fig. 5 to 6 show the correct installation method and orientation

of the CTs.

If the transformer wiring needs to be extended, connect the extension leads by soldering or use quick connectors. Wire the connections

according to good electrical wiring practice and ensure the splices/connections are isolated from any risk of reduced electrical contact. Due to

possible interference, do not lay data output wires of the CTs along high-voltage cables.

The voltage measurement requires connecting each supply phase/live conductor to the respective input terminals on the controller with a 0.5

mm2 interconnection wire.

Each power phase voltage and current measurement includes the phase angle and both measured values are strictly interrelated. Wiring a

voltage measurement line (for phase L1) with a current measurement (for phase L2) to the same measurement channel will produce wrong

power and energy readings, resulting in incorrect performance of the OPTI-ENER. Fig. 7 shows the correct wiring connections with the controller.

5

Fig. 5. Fig. 6.

Installation of a CT on a phase/live conductor of the

home electrical wiring system

Power grid end (on the

CT side with markings)

Power grid end (on the

CT side with markings)

Home wiring system (on the

CT side w/o markings)

Inverter end (on the CT

side w/o markings)

Installation of a CT on a phase/live conductor of an

inverter

3.2. Connecting the current and voltage measurement lines

NOTE

When connecting Wi-Fi, be sure to turn off Packet Data (in order not to interfere with the local connection).

The OPTI-ENER controller can be connected to the Internet via an 8P8C Ethernet cable or a local Wi-Fi network. For Internet connectivity over

local Wi-Fi, the Hewalex Wi-Fi mobile app from Hewalex is required. The app is available for Android (+9.1) and iOS (+11.0).

Once the above steps have been correctly completed, the controller will be assigned to a user account and its operation can be monitored from

the Ekontrol platform in both browser and mobile versions.

See the essential steps below:

1) Download and install the application.

2) Create a user account - an option available in the application menu.

3) Turn on the power of the Opti-Ener controller (after turning on the power, the device will emit its own Wi-Fi network for 5 minutes).

4) Go to Phone Settings, search for the Opti-Ener controller’s Wi-Fi network and connect to it by entering the standard password „12345678”.

5) Go to the Hewalex Wi-Fi app. A new Opti-Ener device will show up in the device list. Click the + next to the device name.

6) In the next step, selecting the Wi-Fi Network option, assign the target network with Internet access by entering the network name, entering

the password and approving the selection.

7) Opti-Ener will establish a connection to the home Wi-Fi network while breaking the local connection.

8) Next, return to the Phone Settings and connect to the network assigned to the Opti-Ener controller.

9) Return to the Hewalex Wi-Fi app, click on the Opti-Ener controller name again, select Remote Access, approve the required approval and

complete the device conguration process.

Using a wired connection, skip steps 3,4,5,6.

6

OPTI - ENER 2.0

See the installation

details in Fig. 4

See the

installation

details in Fig. 5

Power grid

Power meter

Main breaker

N L1 L2 L3

N

L1

L2

L3

Disconnect

PV panels

Inverter

RCD

Home power load

distribution

CT1

N L1i L2i L3i

N

L1i

L2

L3

L1

CT1

CT2

CT3

CT4

*CAUTION: It is recommended to use the power disconnect for the OPTI-ENER controller.

Fig. 7. Wiring connection diagram

iOS

Mobile

application

3.3. Internet connection

CAUTION

The OPTI-ENER supports the SOLIS (Ginlong) inverters only. The connection requires purchasing a separate data communication

adapter plug.

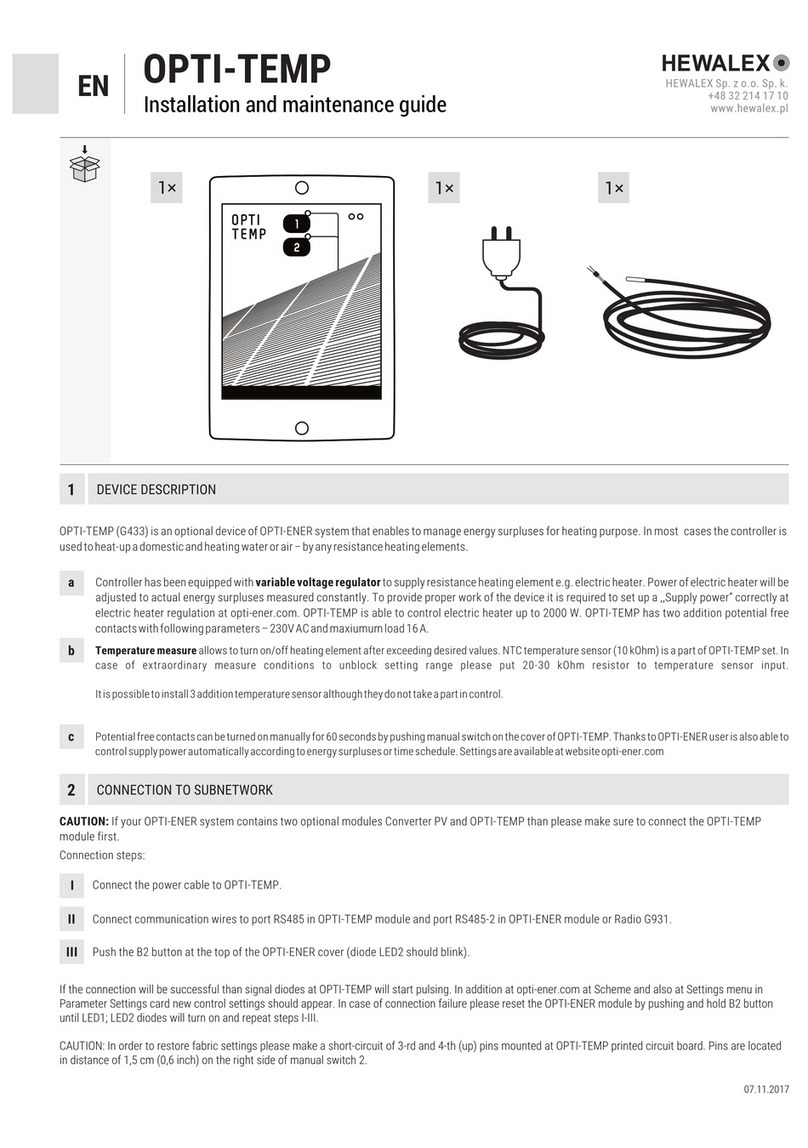

The OPTI-TEMP provides stepless power control for an electric immersion heater rated up to 2 kW. The control logic is based on utilising

transient power surplus generated by the PV system, above the running power input consumption. This allows reducing the power surplus

output to the grid and keeps the power input to output balance zero. The OPTI-TEMP module wiring connection diagram is shown in Fig. 8. See

the manual included with the OPTI-TEMP module for details.

The OPTI-ENER controller can remotely read the parameters monitored by an inverter. If stepless limiting of the PV power output is required, the

OPTI-ENER can maintain a preset limit threshold for the power output to the grid. Example: with a 20 kW PV system, the OPTI-ENER will keep the

maximum power output to the grid at or below the preset 10 kW limit threshold. This feature can be especially useful in locations which cannot

output surplus electrical power to the grid. The wiring diagram is shown in Fig. 9.

If the data communication with the inverter is correct, the LED indicator is steadily on.

7

Relay 1

Relay 2

Relay 3

Relay 4

CT

DC input RS 485 AC output

Relay 4

Relay 3

Relay 2

Relay 1

Fig. 8.

Fig. 9.

Wiring connection diagram of the OPTI-TEMP module

Wiring connection diagram for a Solis inverter

3.4. Connecting the OPTI-TEMP module

3.5. Connecting the inverter

CAUTION*

Directly connecting the power supply to the

device with a maximum current exceeding 5A

for relay 1,2 and 8A for relay 3,4 from the relay’s

short-circuit contact is prohibited and risks

damaging the board.

CAUTION

The gure shows the power supply wired to all relays,

whereas the contactor coil power is output to relay 1;

other relays are wired in the same way.

The following power limiter operating modes are available:

A - Off, power limiter disabled;

B - Inverter power output limited to the lowest-load phase of the 1-phase inverter;

C - Inverter power output limited to the level dependent on the power balance between phase L1, L2, and L3;

D - Inverter power output limited to the lowest-load phase of the 3-phase inverter;

E - PV system power output limited from the current voltage

The power limiter governs only the power surplus which can be generated with all lines of the OPTI-ENER and OPTI-TEMP in operation. PV power

output limiting is only supported if a Solis inverter is connected.

The OPTI-ENER controller features three operating keys designated B1, B2, and B3, and located at the bottom of the enclosure. When the OPTI-

ENER controller is in operation, the LED indicator „ ” ashes once. The LED indicator „ ” stays on if the data connection is established

with the OPTI-TEMP module. Table 2 lists the conguration of the functions which can be called with keys B1, B2, and B3, and the special

outputs of the LED indicators.

Options : Restart controller, remove devices from subnet, restore factory settings and remove Wi-Fi from memory available up to 3 minutes after

powering on the Opti-Ener controller.

Key Key Description Indication

B2 ashes twice Adding the optional OPTI-TEMP module or a Solis

inverter to the OPTI-ENER subnetwork.

The green ( ) LED indicator comes on for 1 second,

followed by ashing. The red ( ) LED indicator ashes 3

times.

B2 ashes three

times

Controller reset

Removes all peripheral devices from the OPTI-ENER

subnetwork. The controller settings remain unaffected.

The green ( ) and red ( ) LED indicators come on for

1 second and go off.

B2 ashes four

times

Reset to default settings and removal of all peripheral

devices from the OPTI-ENER subnetwork.

After 5 seconds, the red ( ) LED indicator comes and

stays on. Releasing the keys makes the green ( ) LED

indicator come on for 1 second.

B2 hold the key for 5

seconds

ReErasing connected Wi-Fi network from memory

OPTI-ENER Controller. After 5 seconds, the green LED ( ) will be interrupted.

Opti-Ener has the possibility of connecting a radio

transmitter allowing wireless control of four groups

of devices by means of G1 remote sockets which

are included in the set/available from Hewalex.

Details on commissioning and operation are included

in the manual delivered with the OPTI-HOME system.

An alternative method of controlling the electrical loads is

to wire the 12V DC power output of the controller’s dry NO

contact to the contactor coil to make/break the circuit.

8

Table 2. Key overview

OPTI - ENER 2.0

Relay 2

: Imax =

5A

Relay 4 : Imax = 8A

Relay 3 : Imax = 8A

Relay 1 : Imax = 5A

Contactor

Fig. 10. NO contact wiring connection Fig. 12 diagram for loads

3.6. OPTI-ENER operating keys

4. ELECTRICAL LOAD POWER CONTROL

4.1. Dry NO contacts

NOTE

Circuits with priority 0 (disabled) do not participate in SG Ready control.

The Opti-Ener controller is equipped with a special connector that allows integration with the Smart Grid (SG).

SG Ready functionality refers to the operation of the Opti-Ener controller’s circuit control algorithm.

The device’s cooperation with the smart grid can take place according to four modes of operation, the description of which is presented below.

1) Lockout mode 1:0

No authorization of Opti-Ener + Opti-Temp circuits.

2) Normal mode 0:0

Idle state. Does not affect changes in the control of Opti-Ener circuits.

3) Elevated mode 0:1

Forces two circuits with the highest priority to be switched on.

4) Elevated mode and forcing 1:1 on

Forces switching on circuits 1E,2E,3E,4E + 1T,2T and the heater (where the heater operates 0/1 until max temp is reached).

From the moment the switch-off signal is received, the circuit remains switched on according to the setting of the „Minimum switch-on time”

parameter.

Having successfully installed the OPTI-ENER controller, perform the procedure below:

1) Download and install the Hewalex Wi-Fi conguration mobile app.

2) Congure the Wi-Fi network per the app’s instructions or connect the device to the LAN 8P8C Ethernet cable.

3) Create and activate the user account on ekontrol.pl or in the mobile app from Hewalex.

4) Go to the Settings tab and open the Conguration panel.

5) Expand and complete the General ribbon - selection of energy balancing method, mode of operation, power returned to the grid, power

source, type of transformer, nominal power of the power source.

6) Expand and complete the ribbon Opti-Ener circuit control and Opti-Temp circuit control (optional). For correct control settings of each circuit,

the following elds must be completed:

• Phase selection - declare the order in which the circuits are switched on (option available for operation mode B).

9

OPTI - ENER 2.0

Relay 2

Relay 4

12V

GND

A+

B-

Relay 3

Relay 1

1

CH2

CH1

CH2

SG Ready

SMART METER

CH1

0

1

0

1 0 1 0

12V

GND

A+

B-

8P8C

Fig. 11. Wiring connection diagram for a Smart Meter

5. ACCOUNT CONFIGURATION

5.1. Settings– Conguration

4.2. Sg Ready

• Priority - declare the order in which the circuits will be switched on

• Power surplus threshold - declare the value of power surplus that will turn on the circuit (device)

• Switch on delay time - declare the period of time for which the power surplus must persist in order to switch on the circuit (device)

• Switch-on time - declare the minimum time for which the circuit (device) is to remain on.

7) Expand and ll out the Mobile App ribbon to specify the app’s resettable counters.

8) Expand and ll out the Energy Costs ribbon to specify the power billing method and the power purchase rate.

9) Expand and ll out the Investment ribbon to specify the installation cost required for the ROI determination.

A detailed explanation of each of these parameters is displayed by tapping the Info „ ” button. The priority of the parameter settings for

correct performance of the system is colour-coded:

• Red – a setting relevant to the control algorithm selection; editable by the installer only;

• Yellow – a setting relevant to the control algorithm selection; editable primarily by the installer;

• Green – a setting editable by the user.

The Settings window is used for user changes, where we will nd the time program and manual control. This is the place where we will nd up

to two ribbons - Opti-Ener circuit control and, for owners of the add-on module, the Opti-Temp control ribbon, whose description can be found

in the device manual.

1) Manual control - switching on/off the circuit (devices).

2) Timer program - setting a program that will turn on the circuit (device) regardless of other settings.

A detailed description of each parameter is available for calling after clicking the information button „ ”.

# Problem Remedy

1The device does not turn on

– the LED indicators are off.

1. Verify that terminals N and 25 are wired as shown in the diagram in Fig. 7.

2. Verify that the wiring is live.

3. Verify that the wiring is correctly connected to the terminals.

2The device is not shown in the app or on the

ekontrol.pl website. 1. Verify that the device is powered on – the LED indicator should stay on.

2. Verify that the Ethernet cable of the LAN is connected properly.

3. Verify that the Wi-Fi network has been congured successfully in the mobile

app. Repeat the process if necessary.

4. Verify that the controller has been assigned to the user account in the mobile

app.

3The RCD tripped when the device was wired

to power.

1. Verify that the wiring connections are correct.

2. Test the RCD for malfunctions.

4The power readings are always zero. 1. Check the power supply voltage on the phases.

2. Verify that the measurement system is connected correctly with reference to

Fig. 7.

5The OPTI-ENER reads a power value 3 times

below the power reading of the inverter.

1. Change the power sources to 3-phase in the menu Settings-Conguration-

General- Power Source.

6The power readings have an incorrect sense.

The power input from the grid reads negative.

The power output to the grid reads positive.

1. Verify that the readings on phase L1, L2, and L3 are positive (for the power

output to the grid); if yes, reverse the orientation of the CT on the phase lead or

swap the CT lead connections wired to the OPTI-ENER.

2. Verify that the inverter reading is negative (for the power input from the grid);

if yes, reverse the orientation of the CT on the L1 phase lead coming from the

inverter or swap the CT lead connections wired to the OPTI-ENER.

7The system reads incorrect power input and/or

output values.

1. Check that the CT type selected is correct in Settings > Conguration > General

> Instrument Transformer Type.

2. The voltage and current measurement on the same measurement channel are

wired to different phases (see Section 3.2).

10

6. TROUBLESHOOTING

6.1. Settings – Setup

This symbol on the product or its packaging requires separate collection of waste electrical and electronic equipment

(WEEE). It means that this product should not be disposed of with other household waste. Proper disposal of WEEE helps

to avoid potential harm to the environment and human health.

The mandatory selective collection of waste equipment is the liability of the user, who should hand over WEEE to a waste

equipment collection plant.

• This equipment is not intended to be operated by individuals (including children) with reduced physical, sensory or

mental capabilities or lack of experience and knowledge of the equipment, unless they have been given supervision or

instruction concerning the use of the equipment by individuals responsible for their safety. Children should be supervised

to ensure that they do not play with the equipment.

• If the integrated power cord is damaged, have it replaced by the manufacturer, a professional repair service, or a qualied

professional to avoid hazards.

CAUTION!

# Problem Remedy

8The generated power output is added to the

power input consumed.

1. Verify that powering on/off the inverter during the same day results in an

increase/reduction of the power meter reading at home:

• No – the performance is correct and no further actions are required..

• Yes – verify that the wiring connections are made as shown in Fig. 7.

2. Verify that the PV systems’ output connection to the home electrical wiring

system is downstream of the CTs on L1, L2, and L3 so that the CTs monitor the

total power input output from/to the grid.

9The OPTI-ENER fails to power on/off a circuit

(load) despite the specied power surplus.

1. Update the OPTI-ENER rmware.

2. Verify that the dry NO contacts are wired correctly with reference to Fig. 10.

3. Verify that the Manual Priority is not enabled in Settings > Setup > Circuit

Control > Priority.

4. Verify that the power surplus limit threshold is achieved to power on the circuit

(load).

5. Verify that the minimum power-on duration was achieved for the circuit (load).

6. Verify that the circuit (load) delay time has expired.

10 The OPTI-ENER fails to connect to the

OPTITEMP or the SOLIS inverter.

1. Check the LED indicator readings on the OPTI-TEMP by following the module’s

manual.

2. Check the LED indicator reading.

3. Verify that the communication ports are connected correctly with reference to

Fig. 8-9.

4. Reset the controller and repeat the pairing process.

11

7. NOTICE ON THE LABELLING AND COLLECTION OF WASTE ELECTRONIC

EQUIPMENT

Table of contents

Other Hewalex Controllers manuals