Heyer AGS 80 D User manual

Instructions for Use

Switch Unit

AGS 80 D

Variant A

Instruction for use • Switch unit AGS 80 D

Seite 2 von 29

Please note !!!

The notes and technical details mentioned in this documentation /

these instructions for installation reflect the status at the time of printing.

Due to permanent development efforts for our products,

we reserve the right to constructional modifications

at any time.

For this reason and depending on the state of construction and development,

the illustrations of this documentation

may deviate from the actual appearance of the product.

But this fact does not have any influence on the functional correctness

of the notes and operational sequences.

Heyer Aerotech GmbH

Nieverner Straße 30

D-56132 Nievern

Phone: +49 (0)2603 / 2004

Fax: +49 (0)2603 / 4020

E-Mail: office@heyer-aerotech.de

Instruction for use • Switch unit AGS 80 D

Seite 3 von 29

Table of Contents Page

1. Manufacturer’s Data .......................................................................................4

2. Introduction .....................................................................................................5

3. Putting into Operation.....................................................................................6

4. Settings .............................................................................................................6

5. Functional and Operational Principles ..........................................................7

5.1. Pneumatic components ................................................................................................ 7

5.1.1 Illustration ................................................................................................................ 8

5.2. AGS D Monitor ........................................................................................................... 9

5.2.1 Functionality............................................................................................................. 9

5.2.1.1 General information ............................................................................................... 9

5.2.1.2 Emergency power supply ..................................................................................... 10

5.2.1.3 Pressure monitoring ............................................................................................. 10

5.2.1.4 Switching............................................................................................................. 11

5.2.1.5 Issuing alarms ...................................................................................................... 11

5.2.1.6 Logging ............................................................................................................... 11

5.3 Electrical connections ..................................................................................................12

5.4 Service Menu...............................................................................................................14

7. Technical Details............................................................................................19

8 Design Variants...............................................................................................20

10. Warranty......................................................................................................23

11. Technical Documentation............................................................................ 24

Instruction for use • Switch unit AGS 80 D

Seite 4 von 29

1. Manufacturer’s Data

Product:

AGS 80 D

Manufacturer and Sales Office

Heyer Aerotech GmbH

Nieverner Straße 30

D-56132 Nievern

Tel.: +49 (0) 26 03 / 20 04

Fax.: +49 (0) 26 03 / 40 20

E-Mail: office@heyer-aerotech.de

Instruction for use • Switch unit AGS 80 D

Seite 5 von 29

2. Introduction

Dear customer!

Thank you for choosing a HEYER Aerotech product.

HEYER Aerotech appliances are state-of-the-art technology and manufactured according to

extremely strict quality standards.

You have purchased a highly professional and long-lasting product which is easy to maintain. It

is based on the experience of decades and the know-how of powerful medical technology.

The switch unit AGS 80 D complies with all the standards and guidelines currently applicable for

the production and operation of the equipment.

If, nonetheless, you should find a reason for complaint please do not hesitate to contact our

customer service department at any time.

Before putting the equipment into operation for the first time, please carefully

read these instructions for use and pay special attention to the notes which

have been marked additionally.

Instruction for use • Switch unit AGS 80 D

Seite 6 von 29

3. Putting into Operation

Use the patented screw joints of the curved tube on both sides of the cylinder rack to connect the

gas cylinders. Tighten the screws with your hands. Please do not use any pliers, because the

tightness will be achieved by the cylinder pressure.

Close all the high-pressure cut-off intervalves and ventilation valves of the high-pressure

manifold.

Now you can open the cylinder valves to test if all the connections are tight.

After that you can open the high-pressure intervalves. The pressure of the cylinder on the right

and on the left is displayed on the corresponding pressure gauges.

Please note !!

Cylinder valves and high-pressure intervalves always have to be opened very slowly.

BE CAREFUL – DANGER OF EXPLOSION!

When connecting oxygen please observe the applicable accident prevention

regulations for oxygen. Free from oil and grease.

No open light or fire.

4. Settings

The reduction valves installed in the switch unit have been set at the factory.

The high-pressure reduction valves (⇒Illustr. 2 →8) have been set to appr. 12 bar. This setting

is displayed on the corresponding pressure gauge.

The high-pressure reduction valves (⇒Illustr. 2 →8) are equipped with safety valves which

have been set to appr. 16 bar.

The constant pressure reducer (⇒Illustr. 2 →2) has been set to 5 bar. This setting is also

displayed at the corresponding pressure gauge.

For the operation of the switch unit only 1 mains pressure reducer is necessary.

The second redundant mains pressure reducer has to be kept closed and is only used during

service works at the first mains pressure reducer.

When you open the mains cut-off valves (⇒Illustr. 2 →5) the pressure developing in the piping

system will be displayed on the instruments (⇒Illustr. 2 →6).

When you open one side of the mains cut-off valves (⇒Illustr. 2 →5) the corresponding

pressure in the piping system will be displayed on the instruments (⇒Illustr. 2 →6).

appr. 12 bar

appr. 12 bar

5 bar

appr. 5 bar

Liquid gas vaporizer min. 15 bar

Instruction for use • Switch unit AGS 80 D

Seite 7 von 29

5. Functional and Operational Principles

5.1. Pneumatic components

The HEYER AEROTECH switch unit AGS 80 D is a device which is capable of switching

between a liquid gas vaporizer or two cylinder racks by means of adjustable pressure limits.

The functions „Reserve 1“ or „Reserve 2“ can be assigned individually to these two cylinder

racks.

The device can also be operated without a liquid gas vaporizer.

All the pressures displayed are monitored on the basis of their individual alarm thresholds.

This is why the HEYER AEROTECH switch unit AGS 80 D is able to ensure a permanent

supply of medical gas with the types of gas at its disposal.

Instruction for use • Switch unit AGS 80 D

Seite 8 von 29

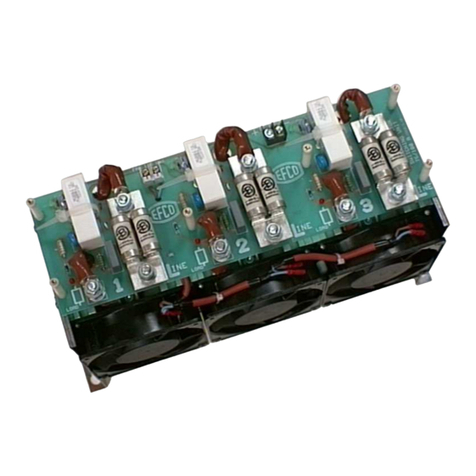

5.1.1 Illustration

Illustr. 2 Switch unit AGS 80 D

Model O2Article No.: 538-3100

Legend:

1

Magnetic valve

8

High pressure reducer

2

Constant pressure reducer, mains

pressure ¾“

9

Sensor high pressure

3

Connection 3rd source of supply

10

Emergency supply

4

One-way valves

11

Mains connection

5

Cut-off valve ¾“

12

Relief line

6

Sensor mains pressure

13

Sensor medium pressure / system

pressure

7

Safety valve 6 bar

1

12

8

2

5

6

3

4

7

9

10

11

13

Instruction for use • Switch unit AGS 80 D

Seite 9 von 29

5.2. AGS D Monitor

5.2.1 Functionality

5.2.1.1 General information

The control unit AGS-D is used for automatic switching in a gas switching unit for medical gas

supply. The mains pressure is kept by automatic switching between a main source and two

auxiliary sources. The control unit makes sure that the corresponding gas is permanently

supplied. Pressures of the main source and of the auxiliary sources as well as system and mains

pressures are constantly monitored. Channel control is carried out by pressure transmitters (4-

20mA).

Each pressure has been assigned to a (multi-coloured) LED. These LEDs either show the normal

condition (green) or a state of alarm (yellow or red for mains pressure). The QUIT key allows the

user to suppress the acoustic alarm. With an alarm of the mains pressure, the acoustic signal is

repeated after 12 minutes.

The LCD displays the sources, the alarm thresholds and the current pressure. In addition, the

sequence of sources, which is relevant for switching, is displayed in Roman numerals. The

currently active source is shown by inverting the source designation. In the lower area, the state

of the corresponding pressure is displayed in text form (i.e. OK, HIGH, LOW).

Instruction for use • Switch unit AGS 80 D

Seite 10 von 29

The following 5 keys are on the user interface:

a) ON/OFF key

b) QUIT key

c) UP and DOWN keys

d) ENTER key

Pressing the ON/OFF key for some time will turn the unit on or off. The QUIT key can be used

to suppress the acoustic signal. For navigating in the service menu use the UP and DOWN keys

and the ENTER key.

On the user interface there are 3 additional LEDs (Battery, Controller, Info).

The LED for Battery is green when the state of the batteries is ok. The Battery LED is red when

the battery is faulty or when it has not been connected. The LED for Controller is green when the

micro-controller system has not found any failures during its regular self-test, otherwise it is red.

The LED for Info flashes green when the cache contains messages.

5.2.1.2 Emergency power supply

When the main power supply via transformer unit fails one battery will backup the power

supply of the control unit. The electronic elements will stay in operation for appr. 2 more hours.

During this time the backlights of the LCDs will be turned off. At the push of a button, the

backlights will be activated for 15 seconds. The switching valves and the signal relays will be

turned off as well.

5.2.1.3 Pressure monitoring

The channels in use are monitored on the basis of an upper and a lower alarm threshold. In case of

an error, the corresponding LED will shine red or yellow and the status in the LCD will flash. In

addition, an acoustic alarm will be activated. When pressing the QUIT key, the acoustic alarm

will be suppressed and both the source and the LED will flash. With an alarm of the mains

pressure, the suppression will be overridden after 12 minutes.

Pressure monitoring of the sources left and right has a hysteresis of 2bar at the lower alarm

threshold. That means, pressure must exceed the lower alarm threshold by 2bar upwards before

pressure for the control unit is accepted as OK by the system.

Instruction for use • Switch unit AGS 80 D

Seite 11 von 29

5.2.1.4 Switching

When the pressure of the liquid gas vaporizer falls below a preset threshold value, the system

will switch to the cylinder rack defined as ”Source II“. When the corresponding switching

pressure falls below the acceptable value the system will also switch. When the pressure of

“Source II” lies below its also adjustable threshold value, the system will immediately change to

the cylinder rack ”Source III“.

In case that the cylinder rack “Source II“ falls below its threshold value, the control unit will also

switch to “Source III”.

As soon as the pressure of the liquid gas vaporizer has reached a level above its threshold value,

the cylinder racks will be deactivated again.

5.2.1.5 Issuing alarms

Issuing alarms for failure states is carried out by means of potential-free signal contacts. For that

purpose, 5 alarm contacts and a common contact are available.

5.2.1.6 Logging

The control unit has been equipped with a cache for a maximum of 250 entries and a history

memory for a maximum of 1,000 entries. Any important failures or messages will be recorded in

the cache. After acknowledging them in the service menu, they will be transferred to the history

memory.

Instruction for use • Switch unit AGS 80 D

Seite 12 von 29

5.3 Electrical connections

On the rear side of the control unit you will find the following connections:

Identifier

Description

Trafoeinheit/

Transformer unit

Connection to the transformer unit

Ventil 1 / Valve 1

Magnetic valve for cylinder rack left

Ventil 2 / Valve 2

Magnetic valve for cylinder rack right

Floweinheit / Flow

unit

Connection to flow unit

USB

Connection to PC

CAN-Bus

Connection to net

S1

Pressure sensor mains pressure

S2

Pressure sensor medium pressure

S3

Pressure sensor liquid gas vaporizer

S4

Pressure sensor cylinder rack right

S5

Pressure sensor cylinder rack left

Alarm contacts

D-Sub 25-pole socket signal contacts

Vorw.-relais /Pre-

heating relay

Connection for pre-heating unit

Table 1: Connections of control unit

Colour

Description

Brown

1: +UB

Blue

2: -UBOut 4-20mA

Table 2: Terminal assignment sensor cable

Instruction for use • Switch unit AGS 80 D

Seite 13 von 29

Contact

Description

1

G: Common contact

2

A: Common contact

3

R: Alarm contact 1

4

G: Alarm contact 2

5

A: Alarm contact 2

6

R: Alarm contact 3

7

G: Alarm contact 4

8

A: Alarm contact 4

9

R: Alarm contact 5

10

11

12

13

14

R: Common contact

15

G: Alarm contact 1

16

A: Alarm contact 1

17

R: Alarm contact 2

18

G: Alarm contact 3

19

A: Alarm contact 3

20

R: Alarm contact 4

21

G: Alarm contact 5

22

A: Alarm contact 5

23

24

25

Table 3:Contact assignment D-Sub 25-pole socket

Instruction for use • Switch unit AGS 80 D

Seite 14 von 29

Explanation:

For each alarm contact there is a relay with an operating and a rest contact.

−G: common contact

−A: operating contact

−R: rest contact

When G is connected through to R, this means that an error has come up or that the equipment

has been switched off.

When G is connected through to A, this means that there is no error, i.e. the channel is OK.

5.4 Service Menu

The service menu is started by pressing the ENTER key. When no key has been activated in the

service menu for 1 minute it will be closed automatically.

The service menu is set up as follows:

1 Current messages

2 Old messages

3 I: Cyl. left II: Cyl. right

4 Info

5 Alarm thresholds

6 Service

7 EXIT

By using the UP and DOWN keys, the entry required can be selected (inverse presentation). By

pressing the ENTER key you can change to the corresponding sub-menu. You can leave the main

menu by selecting „7 EXIT“ and pressing the ENTER key. You can also leave the main menu by

pressing the QUIT key.

Instruction for use • Switch unit AGS 80 D

Seite 15 von 29

To 1) The sub-menu „aktuelle Meldungen/current messages“ allows you to view the cache.

Use the UP and DOWN keys to browse the cache which includes up to 250 messages. The first

message will be at the top of the memory.

In order to delete the current messages the arrow has to be placed on the first message. Then use

the ENTER key to select the entry (inverse). By pressing the QUIT key, the entry will be

transferred from the cache to the history memory.

To 2) The sub-menu „alte Meldungen/old messages“ allows you to view the history memory.

The history memory is made up of a maximum of 1,000 messages.

When exceeding this limit, the oldest message will be deleted.

The last entry, chronologically seen, is at the top of the list. Use the UP and DOWN keys to view

the history memory.

To 3) In „II: Fl. Links III: Fl. Rechts/II: Cyl. left III: Cyl. right“ you can change the order of

sources by pressing the ENTER key.

Instruction for use • Switch unit AGS 80 D

Seite 16 von 29

To 4) The sub-menu „Info“ allows you to view the following system information:

−System time

−Next service month

−Serial number

−Software versions

To 5) The upper and lower alarm thresholds for ”Flasche Links/cylinder left“, ”Flasche

Rechts/cylinder right“, “Kaltvergaser/liquid gas vaporizer“, ”Mitteldruck/medium pressure“ and

”Netzdruck/mains pressure“ can be changed in this sub-menu.

Use the UP and DOWN keys to select the value to be changed. The entry is displayed in inverse

form when you use the ENTER key and can then be changed by means of the UP and DOWN

keys. Pressing the ENTER key again will inactivate the inversion and save the value. Use EXIT

to leave the sub-menu.

Pressure sensor

Lower threshold

Upper threshold

Steps

0 – 250 bar

10 – 250 bar

10 – 250 bar

5 bar

0 – 20 bar

5 – 20 bar

5 – 20 bar

1 bar

0 – 12,5 bar

3 – 6 bar

3 – 6 bar

0,1 bar

Table 4: Ranges for setting thresholds

To 6) Sub-menu ”Service“

This menu item is used to determine and carry out the basic settings and customer-specific

parameters of the control system.

In order to guarantee trouble-free operation only expert service personnel has access to this menu

item.

Instruction for use • Switch unit AGS 80 D

Seite 17 von 29

The following values are set at the factory:

Designation

Standard value

Upper alarm threshold source left

220 bar (250 bar sensor)

Lower alarm threshold source left

50 bar (250 bar sensor)

Upper alarm threshold source right

220 bar (250 bar sensor)

Lower alarm threshold source right

50 bar (250 bar sensor)

Upper threshold liquid gas vaporizer

18 bar (20 bar sensor)

Lower alarm threshold liquid gas vaporizer

9 bar (20 bar sensor)

Upper alarm threshold medium pressure

18 bar (20 bar sensor)

Lower alarm threshold medium pressure

9 bar (20 bar sensor)

Upper alarm threshold mains pressure

5,5 bar (12,5 bar sensor)

Lower alarm threshold mains pressure

4,5 bar (12,5 bar sensor)

Order of sources “Source II”

Cylinder rack left

Liquid gas vaporizer available

Yes

Pre-heater available

No

Number of short events within 1 hour

5

Switch pressure liquid gas vaporizer pressure Cold →R1

9 bar

Switch pressure medium pressure Cold →R1

9 bar

Switch pressure medium pressure R1 →R2

9 bar

Switch delay Cold →R1

0.5 sec

Switch delay R1 →R2

0.5 sec

Alarm delay cylinder rack left

2 sec

Alarm delay cylinder rack right

2 sec

Alarm delay liquid gas vaporizer

2 sec

Alarm delay medium pressure

2 sec

Alarm delay mains pressure

2 sec

Alarm delay liquid gas vaporizer – medium pressure

2 sec

Service interval

6 months

Service month

01 2009

Service phone number

02603-2004

Rest cache

50

Common contact – message with service

Yes

Common contact – message with overflowing cache

Yes

Common contact – message with too many temporary events

Yes

LCD contrast

32

Table 5: Factory settings

Instruction for use • Switch unit AGS 80 D

Seite 18 von 29

Purpose and characteristics

Monitoring pressures of supply source (negative pressure) for medical gas supplies and

monitoring mains pressure (excess and negative pressure), displaying cylinder rack ready for

operation and signalling status

•Monitoring 5 pressures simultaneously. Red, orange (state of alarm) and green

(pressure OK) LEDs

•Display of cylinder rack ready for operation

•Acoustic alarm with buzzer

•Suppressing acoustic alarm by means of button

•Signalling state by potential-free changeover contact per channel

Electrical connections

2 contacts for connection of 24V supply, DC voltage or AC voltage (50Hz).

Connections for Channel 1 / 2 / 4 (for designation of channels see Illustr. 3):

•2 contacts for press key ’Pressure alarm low’ (opens in a state of alarm)

•3 contacts for remote control

Connections for Channel 3 (for designation of channels see Illustr. 3):

•3 contacts for switch „Operating status display“

Connections for Channel 5 (for designation of channels see Illustr. 3):

•2 contacts for press key ’Pressure alarm low’ (opens in a state of alarm)

•2 contacts for press key ’Pressure alarm high’ (opens in a state of alarm)

•3 contacts for remote control

For press keys, please only use potential-free switches.

When a press key is not used its connections have to be short-circuited.

Instruction for use • Switch unit AGS 80 D

Seite 19 von 29

7. Technical Details

Electrical Details

Operating voltage: 230 V, 50 Hz

Connecting power: 50 VA

Pneumatic Details

Max. cylinder pressure: 250 bar

Operating pressure: 9 to 12 bar

Input pressure

liquid gas vaporizer min. 15 bar

Max. flow rate: 80 to 120 Nm3/h, depending on design

Potential-free contacts: 5 pcs.

Components

Cut-off valve Constant pressure reducer

Pressure sensors Magnetic valves

Safety valve High-pressure reducer

One-way valve

Instruction for use • Switch unit AGS 80 D

Seite 20 von 29

8 Design Variants

AGS 80 D

- with two constant pressure reducers incl. connection of 3rd source of supply

Gas type Article no.:

O2 538-3100

Air 538-3105

N2O 538-3110

CO2 538-3120

Please indicate flow rate

Table of contents

Popular Switch manuals by other brands

Allied Telesis

Allied Telesis AT-SBx908 Gen2 installation guide

I/O Interconnect

I/O Interconnect SV142P1 user manual

Interlogix

Interlogix NS3503-16P-4C Quick installation guide

steute

steute RF 96 SW868-NET Mounting and wiring instructions

Siemens

Siemens RUGGEDCOM RX1501 installation manual

Hubbell

Hubbell M3 Instructions for installation, operation and maintenance

TechLogix Network

TechLogix Network TL-4X1-HD user manual

Heitronic

Heitronic 36404 Installation and operating instructions

HP

HP ProCurve 2610 Series Read me first

Lindy

Lindy 32810 user manual

Powtier Controls

Powtier Controls MAXIWAT TC230E Series instruction manual

Lenovo

Lenovo RackSwitch G8264CS Product guide